Professional Documents

Culture Documents

Mineral Reserves

Uploaded by

Prince sey0 ratings0% found this document useful (0 votes)

19 views6 pagesmineral reserves lecture notes

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentmineral reserves lecture notes

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

19 views6 pagesMineral Reserves

Uploaded by

Prince seymineral reserves lecture notes

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 6

MINERAL RESERVES

The Rosemont Deposit is a large tonnage, copper-molybdenum deposit

located in close proximity to the surface and amenable to open pit

mining methods. The proposed pit operations will be conducted from 50-

foot high benches using large-scale mining equipment.

The mine has a 21-year life, with sulfide ore to be delivered to the

processing plant at an initial rate of 75,000 tpd. Provisions are included to

increase production to 90,000 tons of ore per day (tpd) in year 12 of

operations.

MINERAL RESERVES CNTD

Rosemont mineral reserves have been estimated from only measured and

indicated mineral resources; all inferred resources have been treated as

waste.

The reserves reflects an optimum pit at metal price of $1.88 /lb, Cu $11.07

/lb Mo, and $14.87 /oz Ag. Proven and probable sulfide mineral reserves

within the designed final pit total nearly 667 million tons grading 0.44% Cu,

0.015% Mo and 0.12 oz Ag/ton. There are 1.24 billion tons of waste

materials, resulting in a stripping ratio of 1.9:1 (tons waste per ton of ore).

Total material in the pit is 1.9 billion tons. Contained metal in the sulfide

(proven and probable) mineral reserves is estimated at 5.88 billion pounds

of copper, 194 million pounds of molybdenum and 80 million ounces of

silver.

Nearly 46% of the sulfide mineral reserves in the Rosemont ultimate

pit are classified as proven and the remainder (54%) is considered

probable. The classifications are based on the exploration drilling in

the Rosemont Deposit.

All of the mineral reserve estimates presented in this presentation are

dependent on market prices for the contained metals, metallurgical

recoveries and ore processing, mining and general/administration

cost estimates. Mineral reserve estimates in subsequent evaluations

of the Rosemont Deposit may vary according to changes in these

factors.

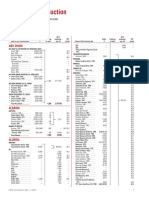

Effects of changing metal price on the reserve

A 20% increase in metal prices boosts the ore-grade measured and

indicated mineral resources by only 3%, while a 20% decrease in

prices reduces them by about 6%. Figure in the previous slide is a

graphical presentation of the sensitivity to metal prices. Similarly, a

20% mine operating cost increase lowers ore-grade mineral resources

by 1% and a 20% cost decrease adds to these resources also by about

1% in tonnage.

Effects of operation costs on the mine reserve

If mine operating costs increase as much as 50%, there is only a 4%

decrease in the contained resource. The graph below shows how

operation costs affects the reserves

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Iraq Petroleum Opportunities in Muthanna ProvinceDocument1 pageIraq Petroleum Opportunities in Muthanna ProvinceTaufik MananNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Tree Felling: Best Practice Guidelines ForDocument66 pagesTree Felling: Best Practice Guidelines ForAnteNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Overall Plot Plan: Annexure-IDocument30 pagesOverall Plot Plan: Annexure-IAnonymous 7I5qQ0eAxgNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Petroleum wholesaler sales recordsDocument9 pagesPetroleum wholesaler sales recordsabdulazizNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Map of Concession AreasDocument1 pageMap of Concession Areascjeski100% (1)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- BHN Akoh PDFDocument12 pagesBHN Akoh PDFmuhammad ripai pardosiNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Regional Coal Reserves Summary Philippines 2013Document1 pageRegional Coal Reserves Summary Philippines 2013Anonymous ilWXWxgNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The ElonDocument12 pagesThe ElonanishNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Unit 201 Prefractionation UnitDocument1 pageUnit 201 Prefractionation Unit16 Andaka Oktora PrasetyoNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Chapter IDocument10 pagesChapter IKRISHNA RANJANNo ratings yet

- Daftar Alamat An Migas Di IndonesiaDocument11 pagesDaftar Alamat An Migas Di Indonesiaandry_yogapratama100% (1)

- Kuliah 7 - Surface Mining Terrace PDFDocument11 pagesKuliah 7 - Surface Mining Terrace PDFAzman Azman0% (1)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Crude Oil Classification PropertiesDocument25 pagesCrude Oil Classification PropertiesAbdurabu AL-MontaserNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- 2014 Coal FactsDocument26 pages2014 Coal FactsKyle LangsleyNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- City Gas Distribution List - 2021Document8 pagesCity Gas Distribution List - 2021Divay PranavNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Jenis Dan Fungsi Offshore PlatformDocument23 pagesJenis Dan Fungsi Offshore PlatformsalssNo ratings yet

- Coal Mining in India: 2013Document4 pagesCoal Mining in India: 2013Anil RastogiNo ratings yet

- Internship CPCLDocument26 pagesInternship CPCLRaj Kumar Madhavaraj67% (3)

- Organization Chart of Kiocl Limited: Director (Production & Projects)Document8 pagesOrganization Chart of Kiocl Limited: Director (Production & Projects)KudremukhNo ratings yet

- Turning Wheat Straw in A Sustainable Raw Material For Paper Industry (2017)Document6 pagesTurning Wheat Straw in A Sustainable Raw Material For Paper Industry (2017)bogdan marian100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Maps - GoaDocument2 pagesMaps - Goaskp19533120No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Top paper and board producers in 2010Document1 pageTop paper and board producers in 2010Alejandro LeoneNo ratings yet

- Oil Gas Page12Document1 pageOil Gas Page12rk.shukla.idNo ratings yet

- List of Oil CompaniesDocument6 pagesList of Oil CompaniesSarfraz S A Saadia83% (12)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Ogj 2013Document44 pagesOgj 2013Vinaya NaralasettyNo ratings yet

- Upstream vs. DownstreamDocument4 pagesUpstream vs. DownstreamRiansyahNo ratings yet

- Screenshot 2023-12-07 at 16.29.22Document2 pagesScreenshot 2023-12-07 at 16.29.22Fithriani FithryNo ratings yet

- Jaydeep - Jesur@eil - Co.i N PK - Dwivedi@eil - Co.i N Jaydip@eil - Co.i NDocument3 pagesJaydeep - Jesur@eil - Co.i N PK - Dwivedi@eil - Co.i N Jaydip@eil - Co.i NMuthu Kumar RNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Summary of Immiscible WAG at Tapis FieldDocument2 pagesSummary of Immiscible WAG at Tapis FieldUmmu Mus'abNo ratings yet

- Jet Fuel A1 Fob HoustonDocument2 pagesJet Fuel A1 Fob HoustonLTPN (Jet Fuel A1)No ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)