Professional Documents

Culture Documents

Adfsgkhjlhgfdsa

Uploaded by

abhishek0 ratings0% found this document useful (0 votes)

4 views1 pagesadhadssdfg

Original Title

adfsgkhjlhgfdsa

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentsadhadssdfg

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views1 pageAdfsgkhjlhgfdsa

Uploaded by

abhisheksadhadssdfg

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 1

The surfaces of two components to be

joined are cleaned, placed close together

and heated while being protected from

oxidation. A pool of molten metal forms

Fusion processes and connects the components, a filler rod

may be used to add metal to the joint.

This category covers a very wide range of

processes, some of which are considered

in more detail later

The metals to be joined do not melt, they are

heated, usually by friction heating generated

by sliding the parts together under a normal

load, this softens the metals and removes

surface contamination. The sliding is then

stopped, the normal load is increased and the

two surfaces join together.

Solid phase processes Friction welding is the main process in

this class and is widely used to join

axisymmetric components in two

different types of steels. Examples

include engine valves where a heat

resistant alloy head is required, but a

steel that will slide well in the guide is

needed for the stem.

You might also like

- Why Do Metals Rust? An Easy Read Chemistry Book for Kids | Children's Chemistry BooksFrom EverandWhy Do Metals Rust? An Easy Read Chemistry Book for Kids | Children's Chemistry BooksNo ratings yet

- Cleaning & heating components to join through fusionDocument1 pageCleaning & heating components to join through fusionabhishekNo ratings yet

- Welding: Dharma Maheswara E 1 / 2 1 0 5 1 4 6 1 9 2 1 3Document6 pagesWelding: Dharma Maheswara E 1 / 2 1 0 5 1 4 6 1 9 2 1 3TM Dharma maheswaraNo ratings yet

- PressedDocument30 pagesPressedShantanu SinghNo ratings yet

- Heat Treatment (Annealing)Document6 pagesHeat Treatment (Annealing)arhummajeed751No ratings yet

- Solid State WeldingDocument61 pagesSolid State Weldingakramakram123No ratings yet

- Soldering, Brazing and WeldingDocument18 pagesSoldering, Brazing and WeldingJaydeep Nayak100% (1)

- Heat Treating: Training ObjectiveDocument7 pagesHeat Treating: Training ObjectiveDaniel GiraldoNo ratings yet

- BrazingDocument5 pagesBrazingmeghrajkadamNo ratings yet

- Elements of Mechanical Engineering-CompliedDocument10 pagesElements of Mechanical Engineering-CompliedzingadayNo ratings yet

- 5 Joining of Metals ReducedDocument20 pages5 Joining of Metals Reducedhb8btk4s8cNo ratings yet

- Non Mechanical Joints 1 & 2Document31 pagesNon Mechanical Joints 1 & 2Muhammad IkhwanNo ratings yet

- Heat Treatment of MetalsDocument3 pagesHeat Treatment of MetalsIhuhwa Marta TauNo ratings yet

- Soldering, Brazing and Welding BasicsDocument7 pagesSoldering, Brazing and Welding BasicsJerin CyriacNo ratings yet

- PT Unit 2Document5 pagesPT Unit 2C MohanNo ratings yet

- Laboratory Experiment 2: Mohd Ashraf Mohd IsmailDocument16 pagesLaboratory Experiment 2: Mohd Ashraf Mohd IsmailMohd Ashraf Mohd Ismail100% (1)

- Basic Mechanical - Engineering-Soldering Brazing and WeldingDocument10 pagesBasic Mechanical - Engineering-Soldering Brazing and WeldingRavichandran GNo ratings yet

- Mechanical Engineering Joining ProcessesDocument11 pagesMechanical Engineering Joining ProcessesalysonmicheaalaNo ratings yet

- Part-1, Basic Metallurgy of Fusion WeldsDocument29 pagesPart-1, Basic Metallurgy of Fusion WeldsTEJENDRA SINGH SINGHALNo ratings yet

- Welding: Ideal Conditions For WeldingDocument8 pagesWelding: Ideal Conditions For WeldingSviveka VivekaNo ratings yet

- The 4 Types of Heat Treatment Steel Undergoes - Kloeckner MetalsDocument5 pagesThe 4 Types of Heat Treatment Steel Undergoes - Kloeckner MetalsSrivishnu vemulaNo ratings yet

- Fig 1.1 Fig 1.2Document6 pagesFig 1.1 Fig 1.2Parveen SwamiNo ratings yet

- Welding MetallurgyDocument17 pagesWelding Metallurgydanish moinNo ratings yet

- Solid State Welding Processes ExplainedDocument21 pagesSolid State Welding Processes ExplainedAshutosh PandeyNo ratings yet

- Metal Casting & Welding 15Me35ADocument39 pagesMetal Casting & Welding 15Me35ASHEKHARAPPA MALLURNo ratings yet

- Heat Treatment Online Notes PDFDocument10 pagesHeat Treatment Online Notes PDFSandeep KadamNo ratings yet

- Chap8 Fundamental Joining ProcessDocument20 pagesChap8 Fundamental Joining ProcessjojoNo ratings yet

- Heat Treating - WikipediaDocument12 pagesHeat Treating - WikipediaAlainNo ratings yet

- Heat Treatment of MetalsDocument7 pagesHeat Treatment of MetalsGian BanaresNo ratings yet

- Formation of Zones in WeldingDocument39 pagesFormation of Zones in Welding01061975No ratings yet

- Joint TypesDocument1 pageJoint Typessrsethu00No ratings yet

- Heat Treatment Processes and Metal Plating Methods ExplainedDocument5 pagesHeat Treatment Processes and Metal Plating Methods Explainedanon_294705394No ratings yet

- Welded ConnectionsDocument11 pagesWelded Connections051Bipradeep ChandaNo ratings yet

- 7691IV - 4th Semester - Metallurgical and Materials EngineeringDocument18 pages7691IV - 4th Semester - Metallurgical and Materials EngineeringankNo ratings yet

- Microstructure Crystals CrystallitesDocument2 pagesMicrostructure Crystals CrystallitesmanandpatelNo ratings yet

- Heat Treatment ProcessesDocument13 pagesHeat Treatment ProcessesRajesh BishnoiNo ratings yet

- Noble Metal AlloysDocument77 pagesNoble Metal AlloysVivek Choukse50% (2)

- SET-2 Brazing - SolderingDocument8 pagesSET-2 Brazing - SolderingSyed TanveerNo ratings yet

- WWW NDT Ed OrgDocument2 pagesWWW NDT Ed OrgGuru SamyNo ratings yet

- Annealing (Metallurgy)Document3 pagesAnnealing (Metallurgy)shofira zuhrahNo ratings yet

- Delafuente CP2 EMAT MENM4-2BDocument2 pagesDelafuente CP2 EMAT MENM4-2BJio Aizen dela FuenteNo ratings yet

- Metals and AlloysDocument13 pagesMetals and Alloyswoi mariaNo ratings yet

- Glossary - Heat TreatmentDocument4 pagesGlossary - Heat TreatmentmaadNo ratings yet

- How To Determine The Best Heat Treatment For Your PartsDocument10 pagesHow To Determine The Best Heat Treatment For Your Partswilderness_666No ratings yet

- Mechanical Joining Methods GuideDocument10 pagesMechanical Joining Methods GuideAbrahamNo ratings yet

- Question 3Document4 pagesQuestion 3Fazerin ShahNo ratings yet

- Brazing, Soldering, AdhesivesDocument31 pagesBrazing, Soldering, AdhesivesAchinthya PereraNo ratings yet

- Biomaterials Cat 2 1st PptDocument28 pagesBiomaterials Cat 2 1st Pptgomathy.2023No ratings yet

- MS Module 2 PDFDocument24 pagesMS Module 2 PDFChidu KNo ratings yet

- Segregation and Banding in Carbon and Alloy Steel - 2013-10-07 - Industrial HeatingDocument3 pagesSegregation and Banding in Carbon and Alloy Steel - 2013-10-07 - Industrial HeatingharieduidNo ratings yet

- Aircraft Materials and Production Lecture NotesDocument98 pagesAircraft Materials and Production Lecture NotesRadhika AmmuluNo ratings yet

- Types of WeldingsDocument5 pagesTypes of WeldingsUPENDAR REDDY PULLAGURLANo ratings yet

- Common Metal Surface Coating Methods ExplainedDocument10 pagesCommon Metal Surface Coating Methods ExplainedShristi Singh100% (1)

- Heat Treating Is A Group ofDocument11 pagesHeat Treating Is A Group ofshrikant mishraNo ratings yet

- Heat Treatment Explained: What It Is and Why It's ImportantDocument12 pagesHeat Treatment Explained: What It Is and Why It's ImportantGanesh JadhavNo ratings yet

- Fundmentals of ManufacturingDocument4 pagesFundmentals of ManufacturingBivas PanigrahiNo ratings yet

- Difference Between Brazing and WeldingDocument3 pagesDifference Between Brazing and WeldingThanh HuaNo ratings yet

- Solidification Process ExplainedDocument3 pagesSolidification Process ExplainedA K SinghNo ratings yet

- Metallurgy II - Annealing Normalizing and TemperingDocument3 pagesMetallurgy II - Annealing Normalizing and TemperingTamás HalasiNo ratings yet

- PDF To WordDocument4 pagesPDF To WordabhishekNo ratings yet

- Introduction To Automation& Control: Definition: Automation Is A Set of Technologies ThatDocument1 pageIntroduction To Automation& Control: Definition: Automation Is A Set of Technologies ThatabhishekNo ratings yet

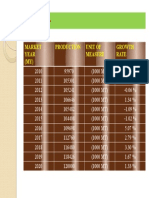

- Market Year (MY) Production Unit of Measure Growth Rate: Annual Rice Production in IndiaDocument1 pageMarket Year (MY) Production Unit of Measure Growth Rate: Annual Rice Production in IndiaabhishekNo ratings yet

- Wfteryiu Lkjhrgefdw AFSGDHFJKHL KDocument1 pageWfteryiu Lkjhrgefdw AFSGDHFJKHL KabhishekNo ratings yet

- Syllabi GATE2017 PDFDocument73 pagesSyllabi GATE2017 PDFAnkit Kumar AJNo ratings yet

- DA3Document1 pageDA3abhishekNo ratings yet

- Mahabharat Family TreeDocument2 pagesMahabharat Family TreeabhishekNo ratings yet

- The Meaning and History of Child Labour ExplainedDocument1 pageThe Meaning and History of Child Labour ExplainedabhishekNo ratings yet

- AmanDocument3 pagesAmanabhishekNo ratings yet

- STEVE JOBS: THE EARLY LIFE AND CAREER OF THE APPLE CO-FOUNDERDocument3 pagesSTEVE JOBS: THE EARLY LIFE AND CAREER OF THE APPLE CO-FOUNDERabhishekNo ratings yet

- AmanDocument3 pagesAmanabhishekNo ratings yet

- AmanDocument3 pagesAmanabhishekNo ratings yet

- AmanDocument3 pagesAmanabhishekNo ratings yet

- Joukowsky TransformDocument3 pagesJoukowsky TransformabhishekNo ratings yet