100% found this document useful (1 vote)

537 views25 pagesDFMA: Principles and Practices Explained

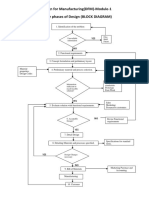

The document discusses design for manufacturing and assembly (DFMA), which aims to design products to be easy and cost-effective to manufacture and assemble. It outlines the DFMA process, which includes conceptualization, analysis of components and processes, redesign to improve manufacturability and reduce costs, and concluding evaluation. The key principles of DFMA are described as minimizing parts, standardizing designs, creating modular assemblies, efficient joining, and simplifying manufacturing operations.

Uploaded by

Kartika putriCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

537 views25 pagesDFMA: Principles and Practices Explained

The document discusses design for manufacturing and assembly (DFMA), which aims to design products to be easy and cost-effective to manufacture and assemble. It outlines the DFMA process, which includes conceptualization, analysis of components and processes, redesign to improve manufacturability and reduce costs, and concluding evaluation. The key principles of DFMA are described as minimizing parts, standardizing designs, creating modular assemblies, efficient joining, and simplifying manufacturing operations.

Uploaded by

Kartika putriCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd