100% found this document useful (2 votes)

1K views34 pagesTypes of Propellers

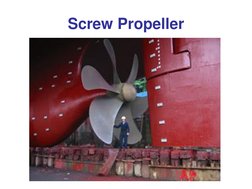

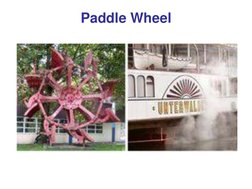

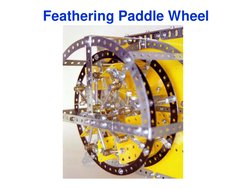

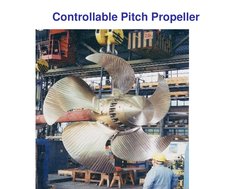

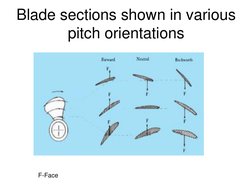

Ship propellers come in several types including screw, paddle wheel, controllable pitch, and nozzle propellers. Controllable pitch propellers allow the pitch of the propeller blades to be adjusted to control ship speed and provide thrust without changing engine rpm or direction. Nozzle propellers surround a screw propeller with a duct to increase efficiency at low speeds through reduced tip vortex and increased thrust. Other propeller arrangements include contra-rotating, tandem, and podded propellers. Waterjet propulsion uses an impeller inside the ship to draw in and accelerate water out through a nozzle for propulsion, providing excellent maneuverability.

Uploaded by

jagan k jCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

100% found this document useful (2 votes)

1K views34 pagesTypes of Propellers

Ship propellers come in several types including screw, paddle wheel, controllable pitch, and nozzle propellers. Controllable pitch propellers allow the pitch of the propeller blades to be adjusted to control ship speed and provide thrust without changing engine rpm or direction. Nozzle propellers surround a screw propeller with a duct to increase efficiency at low speeds through reduced tip vortex and increased thrust. Other propeller arrangements include contra-rotating, tandem, and podded propellers. Waterjet propulsion uses an impeller inside the ship to draw in and accelerate water out through a nozzle for propulsion, providing excellent maneuverability.

Uploaded by

jagan k jCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd