Professional Documents

Culture Documents

10-11. Chicken Meat and Egg

Uploaded by

alladzi aufa saif0 ratings0% found this document useful (0 votes)

21 views7 pagesOriginal Title

10-11. chicken meat and egg

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views7 pages10-11. Chicken Meat and Egg

Uploaded by

alladzi aufa saifCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 7

CHICKEN SLAUGHTERING AND PROCESSING

• By : Edy Susanto, S.Pt MP (Fapet UNISLA)

• Refference : FAO, 2010. Poultry Meat and Egg.

Viale delle Terme di Caracalla, 00153 Rome,

Italy.

Poultry processing operations

• Preprocessing

The birds are usually transported by truck to the poultry slaughterhouse.

Upon arrival, the birds are held in the reception area in the transport crates,

pending veterinarian inspection. In most countries, the official veterinarian

then inspects each transport crate of live birds to approve them for human

consumption. Sick birds are killed and disposed of. After inspection, the

birds are removed from the crates in the reception area and put on the

killing line. The birds are hung upside down by their feet by shackles on

a conveyor, which moves them to the stunning area. Once the birds are

shackled, stunning is carried out using one of three possible methods that

include (i) an electrically-charged water bath, (ii) gas inhalation or (iii) a

blow to the head using a blunt object.

• Slaughtering, bleeding and scalding

Slaughtering can be performed manually or by using an automatic

circularknife

system. The birds should bleed for at least two minutes to ensure a

total bleed-out. The blood is collected in a tank and handled as an

animal

by-product for further processing.

After bleeding, the birds are exposed to either steam or hot water as

part

of the scalding procedure. Scalding loosens the feathers and facilitates

plucking.

• Further processing and evisceration

Feathers are removed in a specially designed plucking machine or by hand.

Feathers are collected and treated as an animal by-product. The birds are

showered with water during the automated plucking operation and the

feathers are collected in a trough under the plucking machine. Following

scalding and plucking activities, the head and feet are removed. Inedible

organs, including the intestinal tract and lungs, are removed and treated

as animal by-products. The eviscerated carcass should be rinsed internally

and externally with potable water before further processing. Depending on

country-specific regulations, companies may use disinfectants (chlorine or

tri-sodium phosphate solutions) to reduce the bacteriological contamination

on meat surfaces.

• Storing and packaging

After rinsing, the carcass should be cooled as quickly as possible to or below

4 °C. Several methods are used for chilling, including: air chilling, which

takes place in either a chill room or by continuous air blast; spray chilling

whereby water aerosols are added to the air; and immersion chilling, which

involves moving carcasses through a counter-flow current in a water bath.

Birds are weighed individually and sorted according to their weight. After

weighing, the birds are inspected visually and categorized. Whole birds

are typically packed in plastic bags or in containers wrapped in film. Birds are

stored before sale at or below 4 °C. Birds intended to be sold as

quickfrozen poultry are frozen in a blast freezer or similar equipment that

enables rapid freezing.

• Cleaning of the processing plant

Cleaning of the plant is one of the most important tasks in a poultry

processing plant. Some rinsing and cleaning should occur during working

hours. After working hours, a total cleaning and disinfection of the plant

is carried out, normally on a daily basis. Cleaning involves the following

major steps, including disassembling of machinery and equipment, as

necessary; physical removal of solid material; cycles of rinsing and

washing;

disinfection; drying; and application of lubricants.

• Rendering

Rendering is the heat treatment of animal by-

products to eliminate the risk of

spreading disease to animals and humans and to

produce usable products

such as proteins and fat. Rendering involves

evaporative processes that

may generate a foul odour.

You might also like

- The Jerky Bible: How to Dry, Cure, and Preserve Beef, Venison, Fish, and FowlFrom EverandThe Jerky Bible: How to Dry, Cure, and Preserve Beef, Venison, Fish, and FowlNo ratings yet

- Butterfly Brochure pf5Document2 pagesButterfly Brochure pf5api-297693705100% (1)

- Specimen Paper Cpea Social StudiesDocument51 pagesSpecimen Paper Cpea Social StudiesAquilia Franklin100% (1)

- Poultry ProcessingDocument19 pagesPoultry ProcessingElianaNo ratings yet

- Sanitation of Animal HousesDocument18 pagesSanitation of Animal HousesRashiNo ratings yet

- Bio SecurityDocument5 pagesBio SecurityAhmed FathiNo ratings yet

- Muscovy DucksDocument27 pagesMuscovy DucksStephenNo ratings yet

- A Guide To The Pathology and Inspection of Poultry: H Thompson R Irvine D J Taylor W SteeleDocument92 pagesA Guide To The Pathology and Inspection of Poultry: H Thompson R Irvine D J Taylor W SteeleorigatNo ratings yet

- Biosecurity For Poultry FarmsDocument9 pagesBiosecurity For Poultry FarmsDr.Kedar Karki ,M.V.Sc.Preventive Vet.Medicine CLSU PhilippinesNo ratings yet

- Diseases of Poultry - How to Know Them, Their Causes, Prevention and Cure - Containing Extracts from Livestock for the Farmer and Stock OwnerFrom EverandDiseases of Poultry - How to Know Them, Their Causes, Prevention and Cure - Containing Extracts from Livestock for the Farmer and Stock OwnerRating: 4.5 out of 5 stars4.5/5 (4)

- GHP Milk ProductionDocument22 pagesGHP Milk ProductionGuleRia ShiVani100% (2)

- ANTE MORTEM Presentation 1Document23 pagesANTE MORTEM Presentation 1Mr. QARAAMI88% (8)

- Poultry MeatDocument26 pagesPoultry Meatjoebelle senadorNo ratings yet

- Ensuring Food Safety Through Proper Slaughter and Processing PracticesDocument30 pagesEnsuring Food Safety Through Proper Slaughter and Processing PracticesSivaasankar Cg80% (5)

- Cocoa ProductionDocument57 pagesCocoa ProductionumeshNo ratings yet

- Sanitation in Slaughter HouseDocument6 pagesSanitation in Slaughter Houseडा. सत्यदेव त्यागी आर्यNo ratings yet

- Poultry Processing: Ensuring Food Safety Through Proper Sanitation and Contamination ControlDocument76 pagesPoultry Processing: Ensuring Food Safety Through Proper Sanitation and Contamination ControlsunnyooiNo ratings yet

- Sanitation Standard Operating Procedure of Slaughter Houses - Abhishek KadyanDocument35 pagesSanitation Standard Operating Procedure of Slaughter Houses - Abhishek KadyanNaresh Kadyan100% (2)

- Name Wedzerai K Chigara Student Number N01312870T Faculty Industrial Technology Department Chemical Engineering Course TCE 5104 Lecturer Dr. J Tshuma Assignment 2Document21 pagesName Wedzerai K Chigara Student Number N01312870T Faculty Industrial Technology Department Chemical Engineering Course TCE 5104 Lecturer Dr. J Tshuma Assignment 2Sithandiwe Sindiso MlalaziNo ratings yet

- Foodscience Poultry 171101185821Document44 pagesFoodscience Poultry 171101185821Md. Harun-Ar RashidNo ratings yet

- Killing Dressing and Drawing PoultryDocument13 pagesKilling Dressing and Drawing PoultryMitch Vallo ParasoNo ratings yet

- Poultry ProcessingDocument10 pagesPoultry ProcessingAkhila MpNo ratings yet

- Poultry ProcessingDocument47 pagesPoultry ProcessingGenNo ratings yet

- Poutlry AssignmentDocument15 pagesPoutlry AssignmentFadzai FunguraNo ratings yet

- Poultry Meat ProcessingDocument3 pagesPoultry Meat ProcessingAKILAN MNo ratings yet

- How chickens are slaughtered and processed in 10 stepsDocument9 pagesHow chickens are slaughtered and processed in 10 stepsamirq4No ratings yet

- Lecture #3&4Document11 pagesLecture #3&4muzzamilkaziNo ratings yet

- Poultry Processing: Lesson # 9Document12 pagesPoultry Processing: Lesson # 9Maymay AuauNo ratings yet

- How Chicken Nuggets Are Made From Farm to PlateDocument9 pagesHow Chicken Nuggets Are Made From Farm to PlatepototoygangbangNo ratings yet

- Sample Research Proposal (Chapter 1-3)Document31 pagesSample Research Proposal (Chapter 1-3)Celisty Faith Go-opioNo ratings yet

- Technical General Standard 117Document47 pagesTechnical General Standard 117Fernando CruzNo ratings yet

- Broilers Management and Production: Dr. Sherzad M. Hussein Dr. Shawkat M'SadeqDocument30 pagesBroilers Management and Production: Dr. Sherzad M. Hussein Dr. Shawkat M'SadeqTahir A AhmadNo ratings yet

- Presented By, Gowri Balah.G Iswarya.V Presented By, Gowri Balah G Iswarya VDocument35 pagesPresented By, Gowri Balah.G Iswarya.V Presented By, Gowri Balah G Iswarya VgowriNo ratings yet

- Hand Out Food Micro Lec. Poultry and Poultry ProductsDocument6 pagesHand Out Food Micro Lec. Poultry and Poultry ProductsJem QuintoNo ratings yet

- Unit 4 Poultry Word DocumentDocument7 pagesUnit 4 Poultry Word DocumentFood Science and Technology RMC CollegeNo ratings yet

- Step 1: Arrival at The Processing Plant: Electrical Stunning Controlled Atmosphere StunningDocument31 pagesStep 1: Arrival at The Processing Plant: Electrical Stunning Controlled Atmosphere StunningKarl CastilloNo ratings yet

- Learn MoreDocument553 pagesLearn MoreTudor NicoaraNo ratings yet

- Frozen BeefDocument15 pagesFrozen BeefFiza Meleveettil - 26No ratings yet

- SadsadsadsadsaDocument3 pagesSadsadsadsadsajuliaperezcayNo ratings yet

- Small-Scale Poultry ProcessingDocument3 pagesSmall-Scale Poultry ProcessingJoy NapierNo ratings yet

- UntitledDocument5 pagesUntitledrogerNo ratings yet

- .Trashed-4 - Abattoir Management Emergency Slaughter Rigor MortisDocument24 pages.Trashed-4 - Abattoir Management Emergency Slaughter Rigor MortisManish GhimireNo ratings yet

- Standard Operating ProceduresDocument3 pagesStandard Operating ProceduresPrasanna BabuNo ratings yet

- Teagasc Biosecurity Precautions For Pig Farms 050115Document3 pagesTeagasc Biosecurity Precautions For Pig Farms 050115Muni SwamyNo ratings yet

- Bioseurity Guid CommercialDocument22 pagesBioseurity Guid Commercialanwar kadiNo ratings yet

- 3. Scallops Processing in Fish PlantDocument1 page3. Scallops Processing in Fish PlantRastha RomaNo ratings yet

- Design and Fabrication of Chicken Defeathering Machine 08107788058, 08158648531 Chapter One 1.1 Background of The StudyDocument11 pagesDesign and Fabrication of Chicken Defeathering Machine 08107788058, 08158648531 Chapter One 1.1 Background of The StudyUmar FarouqNo ratings yet

- Good Hygiene PracticesDocument30 pagesGood Hygiene PracticesIonut MuscaNo ratings yet

- NYC Food Safety Rules ReviewDocument8 pagesNYC Food Safety Rules ReviewMandibahauddin 70No ratings yet

- Animal Welfare, Ritual Slaughter and Slaughter Floor OperationsDocument16 pagesAnimal Welfare, Ritual Slaughter and Slaughter Floor Operationsد.عدنان بيرخدريNo ratings yet

- 9.5.1 Meat Packing PlantsDocument7 pages9.5.1 Meat Packing PlantsdkaringamNo ratings yet

- Cariño, Franz Tchelen L. Bsmt-2B: 1.) The Five Freedom of AnimalsDocument3 pagesCariño, Franz Tchelen L. Bsmt-2B: 1.) The Five Freedom of AnimalsFranz Thelen Lozano CariñoNo ratings yet

- 100 - FSM - Sindu - A1Document23 pages100 - FSM - Sindu - A1shubham vatsNo ratings yet

- Module 9.2Document42 pagesModule 9.2robelyn veranoNo ratings yet

- Best in Quality Practices at M-Artal Poultry International (PVT) LimitedDocument11 pagesBest in Quality Practices at M-Artal Poultry International (PVT) Limitedkoib789No ratings yet

- Meat and Poultry Processing GuideDocument77 pagesMeat and Poultry Processing Guiderobel kassawNo ratings yet

- CAPE - Agricultural Science - UNIT 1 - Animal ProductionDocument28 pagesCAPE - Agricultural Science - UNIT 1 - Animal Productionkeith Da SilvaNo ratings yet

- GMP & GHP StandardsDocument30 pagesGMP & GHP StandardsKhalid GulNo ratings yet

- Code of Slaughtering Practices for GoatsDocument13 pagesCode of Slaughtering Practices for GoatsJRSA SAALNo ratings yet

- Classification of Low Risk and High Risk Materials Generated in An Abattoir and Its Hygenic DisposalDocument6 pagesClassification of Low Risk and High Risk Materials Generated in An Abattoir and Its Hygenic DisposalAbhinav GuptaNo ratings yet

- Waste Management: The What and How of Spreading DiseaseDocument8 pagesWaste Management: The What and How of Spreading Diseaseaike_amoraNo ratings yet

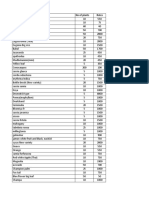

- Plant inventory table with prices under 40 charactersDocument2 pagesPlant inventory table with prices under 40 charactersPraveen Kumar MNo ratings yet

- 3082 9237 1 PBDocument10 pages3082 9237 1 PBainal mardiah rahmahNo ratings yet

- Bio ProjectDocument18 pagesBio ProjectVivek Prasad90% (10)

- Glaia - Nanotechnology Optimizing Plant Performance - Pitch Deck 2021DECDocument13 pagesGlaia - Nanotechnology Optimizing Plant Performance - Pitch Deck 2021DECJelly NiNo ratings yet

- Syb 2019 PDFDocument662 pagesSyb 2019 PDFJohn SmithNo ratings yet

- THPT Quốc gia 2017 môn Tiếng Anh đề số 12Document5 pagesTHPT Quốc gia 2017 môn Tiếng Anh đề số 12kimlamtranNo ratings yet

- Krishna Mkondiwa 2023 Economics of Crop Residue ManagementDocument24 pagesKrishna Mkondiwa 2023 Economics of Crop Residue ManagementJorge GarzaNo ratings yet

- Title Proposal NewDocument10 pagesTitle Proposal Newsteven idanoNo ratings yet

- 10 Reasons Why Farmers Are in Distress - Times of IndiaDocument10 pages10 Reasons Why Farmers Are in Distress - Times of IndiaPulkeshi JaniNo ratings yet

- District Profile Report SwatDocument31 pagesDistrict Profile Report SwatXshan NnxNo ratings yet

- B2B Expat Presentation 22 May 2018 PDFDocument19 pagesB2B Expat Presentation 22 May 2018 PDFJaved Abdul JaleelNo ratings yet

- Rule: Plant-Related Quarantine, Domestic: Golden NematodeDocument1 pageRule: Plant-Related Quarantine, Domestic: Golden NematodeJustia.comNo ratings yet

- Coffee Brand PreferencesDocument43 pagesCoffee Brand PreferencesJong LuyNo ratings yet

- Livelihood Pattern Study of Communities Residing in Kanha-Pench CorridorDocument50 pagesLivelihood Pattern Study of Communities Residing in Kanha-Pench CorridorV VishalNo ratings yet

- Sahara Forest ProjectDocument1 pageSahara Forest Projectddb01No ratings yet

- iMET Preparatory Advice Sample Question Paper Answer Key - 2020 21 PDFDocument22 pagesiMET Preparatory Advice Sample Question Paper Answer Key - 2020 21 PDFKarthik AgarwalNo ratings yet

- Agro-Ecologicalzones of Ethiopia - PdfabbyyyDocument136 pagesAgro-Ecologicalzones of Ethiopia - PdfabbyyyHenok HenokNo ratings yet

- ADWR Low Water Use Plant Lists PDFDocument28 pagesADWR Low Water Use Plant Lists PDFBen HeydonNo ratings yet

- Real Good Juice Co. MenuDocument1 pageReal Good Juice Co. MenuAlisa HNo ratings yet

- CV1 Gerry PDFDocument3 pagesCV1 Gerry PDFRosana MerisNo ratings yet

- Smart GreenHouseDocument6 pagesSmart GreenHouseOussama EL ABBOUDYNo ratings yet

- Health Risks GMOsDocument12 pagesHealth Risks GMOsDavid Velázquez SeiferheldNo ratings yet

- Biodiversity of Cacao in Ghana PDFDocument83 pagesBiodiversity of Cacao in Ghana PDFShreeRajShresthaNo ratings yet

- AdlaiDocument2 pagesAdlaiJoresel Coronado100% (5)

- LBP vs. Franco, GR 203242, March 12, 2019Document24 pagesLBP vs. Franco, GR 203242, March 12, 2019pennelope lausanNo ratings yet

- INDUSTRIAL REV TRANSFORMS ENGLANDDocument4 pagesINDUSTRIAL REV TRANSFORMS ENGLANDLoreinNo ratings yet

- DIABETES EXCHANGE LISTSDocument10 pagesDIABETES EXCHANGE LISTSironNo ratings yet

- Ind Potential SurveyDocument19 pagesInd Potential SurveyNimish PilankarNo ratings yet