Professional Documents

Culture Documents

The Conversion Cycle (For Online Classes Part 2)

Uploaded by

Aaron Ng0 ratings0% found this document useful (0 votes)

17 views9 pagesThis document discusses internal controls for manufacturing processes. It outlines several key controls including:

1. Transaction authorizations like work orders and move tickets that authorize movement of batches through production.

2. Segregation of duties between production planning, inventory control, and cost accounting to separate responsibilities.

3. Supervision of production processes by work center supervisors to ensure proper material usage and minimize waste.

4. Access controls over assets like storerooms and warehouses, and controls over documents like requisitions and time cards.

5. Independent verification processes where cost accounting reconciles materials and labor to standards, and auditing of inventory counts.

Original Description:

cycle

Original Title

conversion

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses internal controls for manufacturing processes. It outlines several key controls including:

1. Transaction authorizations like work orders and move tickets that authorize movement of batches through production.

2. Segregation of duties between production planning, inventory control, and cost accounting to separate responsibilities.

3. Supervision of production processes by work center supervisors to ensure proper material usage and minimize waste.

4. Access controls over assets like storerooms and warehouses, and controls over documents like requisitions and time cards.

5. Independent verification processes where cost accounting reconciles materials and labor to standards, and auditing of inventory counts.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views9 pagesThe Conversion Cycle (For Online Classes Part 2)

Uploaded by

Aaron NgThis document discusses internal controls for manufacturing processes. It outlines several key controls including:

1. Transaction authorizations like work orders and move tickets that authorize movement of batches through production.

2. Segregation of duties between production planning, inventory control, and cost accounting to separate responsibilities.

3. Supervision of production processes by work center supervisors to ensure proper material usage and minimize waste.

4. Access controls over assets like storerooms and warehouses, and controls over documents like requisitions and time cards.

5. Independent verification processes where cost accounting reconciles materials and labor to standards, and auditing of inventory counts.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 9

Chapter 7

The Conversion Cycle

(for online classes Part 2)

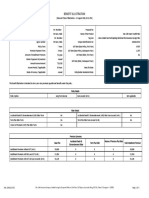

Summary of Internal Controls

Internal Controls

Transaction authorizations

work orders – reflect a legitimate need

based on sales forecast and the finished

goods on hand

move tickets – signatures from each

work station authorize the movement of

the batch through the work centers

materials requisitions – authorize the

warehouse to release materials to the work

centers

Internal Controls

Segregation of duties

production planning and control

department is separate from the work

centers

inventory control is separate from

materials storeroom and finished goods

warehouse

cost accounting function accounts for

WIP and should be separate from the

work centers in the production process

Internal Controls

Supervision

work center supervisors oversee the

usage of raw materials to ensure that

all released materials are used in

production and waste is minimized

employee time cards and job tickets

are checked for accuracy (work center

supervisors have the primary responsibility to ensure that

whatever is reflected on both documents are correct to avoid any

possibility of fraud by the employees)

Internal Controls

In my experience, theft by production employees were rampant. This

was however at a time that technological controls like CCTVs were not

Access control yet adopted in factories. There are cases of:

1. Employees taping or tying products, e.g., ham slices, to their body

particularly parts that will not be frisked by security personnel at

the

direct access to assets

gates. There was one time that while frisking an employee, the

products, which were scotch taped to the inner thighs, fell out of

controlled access

the employees pants. to storerooms,

Employee production

was immediately terminated. For

work centers,they

female employees, and

tapefinished

it under theirgoods

breasts orwarehouses

inside their

underwear. They would usually do this for 250 gram packages and

quantities

if done regularly in

can excess

amount toof standard

a substantial amounts

quantity of products

stolen.

require

2. To approval

avoid the frisking of guards at the gates, employees would throw

products over the walls (around 15 feet high). Accomplices would

indirect access to assets

be waiting at the other side of the wall.

3. Employees would eat products inside the factory. Sometimes

controlled use of materials requisitions, excess

bringing with them bread in which the product can be placed in.

materialsInstant requisitions, andforemployee

sandwich. No need “baon”. time

cards. (unused documents must be safeguarded to prevent

misuse by unauthorized personnel)

Internal Controls

Accounting records (proper use of the following is

a good control):

pre-numbered documents

work orders

cost sheets

move tickets

job tickets

material requisitions

WIP and finished goods files

Internal Controls

Independent verification

cost accounting reconciles material usage (material

requisitions) and labor usage (job tickets) with standards

variances are investigated (Mam Bel already taught you this,

right?)

GL dept. verifies movement from WIP to FG by reconciling

journal vouchers from cost accounting and inventory

subsidiary ledgers from inventory control

internal and external auditors periodically verify the raw

materials and FGs inventories through a physical count ( for

BSAs, participation in physical counts would be among the first things you

will experience as new CPAs. Usually done at year end – either last week

of December or the first week of January. For BSMs, if you are in the

Accounting Department of a company, even if you are not in Cost

Accounting, you are tasked to perform inventory counts as well.)

9

You might also like

- Statement 05312019Document6 pagesStatement 05312019Marcus GreenNo ratings yet

- Chapter 1: Inrtoduction 1.1 Introduction of Inventory ManagementDocument61 pagesChapter 1: Inrtoduction 1.1 Introduction of Inventory ManagementSuma Ooha100% (1)

- Inventory RCM - Version 1Document16 pagesInventory RCM - Version 1talktopuneet100% (5)

- Your Vi Bill: Mr. Venkatachalapathi SivaprakasaDocument3 pagesYour Vi Bill: Mr. Venkatachalapathi Sivaprakasadekans000No ratings yet

- A Short History of Financial EuphoriaDocument61 pagesA Short History of Financial EuphoriaJatinder Singh Sodhi100% (3)

- Job Order & Process Cost SystemDocument46 pagesJob Order & Process Cost SystemTIANTIAN HAONo ratings yet

- Practical Guide To Production Planning & Control [Revised Edition]From EverandPractical Guide To Production Planning & Control [Revised Edition]Rating: 1 out of 5 stars1/5 (1)

- Inventory PDFDocument7 pagesInventory PDFJose De CuentasNo ratings yet

- Inventory ManagementDocument37 pagesInventory ManagementPrincess Darlyn AlimagnoNo ratings yet

- (Store Operation and Supply Chain Management: Tybms 1Document46 pages(Store Operation and Supply Chain Management: Tybms 1deffjamwezzstarNo ratings yet

- Stores ManagementDocument7 pagesStores ManagementVinay SinghNo ratings yet

- Inventory ManagementDocument23 pagesInventory ManagementvmktptNo ratings yet

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1From EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Rating: 4.5 out of 5 stars4.5/5 (2)

- Warehouse Management Final Project ReportDocument22 pagesWarehouse Management Final Project ReportNainesh KNo ratings yet

- Types of InventoryDocument16 pagesTypes of Inventorydanie chasesa100% (1)

- CHL Unit 2 Task 9 ResponseDocument3 pagesCHL Unit 2 Task 9 Responsekenneth chaunoda100% (2)

- Accounting For Materials: How Costs Get Attached To Products? Cost Control SystemDocument8 pagesAccounting For Materials: How Costs Get Attached To Products? Cost Control SystemcesiareenaNo ratings yet

- Chapter 5Document24 pagesChapter 5Genanew AbebeNo ratings yet

- SC4&5Document3 pagesSC4&5Angela 18 PhotosNo ratings yet

- Chapter 9 - Manufacturing BusinessDocument3 pagesChapter 9 - Manufacturing BusinessNyah MallariNo ratings yet

- Group2 Managerial AccountinggDocument15 pagesGroup2 Managerial AccountinggVerano Michelle M.No ratings yet

- Om ReviewerDocument14 pagesOm ReviewerPippsie MalganaNo ratings yet

- Topic 2 - Accounting For Material, Labour and Overheads - PDF To StudentsDocument101 pagesTopic 2 - Accounting For Material, Labour and Overheads - PDF To StudentsSAIYIDAH AFIQAH BINTI MUHAMAD YUSOFNo ratings yet

- Storeman DetailsDocument2 pagesStoreman DetailsPaul SimonNo ratings yet

- Audit of The Inventory and Warehousing CycleDocument24 pagesAudit of The Inventory and Warehousing CycleTilahun TesemaNo ratings yet

- Week 6Document33 pagesWeek 6BISMA RAFIQNo ratings yet

- Ia PlanningDocument39 pagesIa PlanningQryne MonarmyNo ratings yet

- Costing and Pricing PrelimDocument6 pagesCosting and Pricing PrelimJV EstanislaoNo ratings yet

- Week 11Document30 pagesWeek 11ak8ballpool111No ratings yet

- Acc 116 - Chap 2Document19 pagesAcc 116 - Chap 2Azlie ArzimiNo ratings yet

- SPS-Assignmen02 Ellen Elisabeth Marsinar 2327000010Document4 pagesSPS-Assignmen02 Ellen Elisabeth Marsinar 2327000010Ellen DoloksaribuNo ratings yet

- Youthlink Magazine - April 1-7, 2014: ContributedDocument12 pagesYouthlink Magazine - April 1-7, 2014: ContributedAngel LawsonNo ratings yet

- Cost Acc Chapter 7Document14 pagesCost Acc Chapter 7ElleNo ratings yet

- LMGT 211 Material Management With NOTESDocument4 pagesLMGT 211 Material Management With NOTESNeil RodriguezNo ratings yet

- Lesson 09Document45 pagesLesson 09Reney RajuNo ratings yet

- Chap 2Document9 pagesChap 2worknehNo ratings yet

- Top 10 WHDocument12 pagesTop 10 WHvamseedeepakNo ratings yet

- Cost Accaunting 2Document12 pagesCost Accaunting 2ዝምታ ተሻለNo ratings yet

- Inventory ManamementDocument30 pagesInventory ManamementBELAL AHAMADNo ratings yet

- How Does Inventory Management WorkDocument12 pagesHow Does Inventory Management Workpatrick muolaNo ratings yet

- Inventory Audit-Importance and ProceduresDocument17 pagesInventory Audit-Importance and Procedurescriselda salazarNo ratings yet

- Internal Control Sample PapersDocument21 pagesInternal Control Sample PapersKamper DanNo ratings yet

- Inventory Managemnt, Inventory Control, and Benfits of Inventory CotrolDocument6 pagesInventory Managemnt, Inventory Control, and Benfits of Inventory CotroltomNo ratings yet

- Job Order Costing ModuleDocument9 pagesJob Order Costing ModuleClaire BarbaNo ratings yet

- Seminar On Inventory ManagementDocument45 pagesSeminar On Inventory Managementrishu dNo ratings yet

- Fase 3 Base de Datos BodegaDocument8 pagesFase 3 Base de Datos BodegaCadir CastilloNo ratings yet

- Unit - 1 PART - 1Document5 pagesUnit - 1 PART - 1Manjunath ReddyNo ratings yet

- Prefinals ReviewerDocument20 pagesPrefinals ReviewerAbbie PolesticoNo ratings yet

- Inventory ManagementDocument6 pagesInventory ManagementZafar IqbalNo ratings yet

- Cbmec FinalsDocument7 pagesCbmec FinalsApple DacaldacalNo ratings yet

- Inventory ManagementDocument41 pagesInventory ManagementRishbha patelNo ratings yet

- Introduction To Basic Cost FlowsDocument2 pagesIntroduction To Basic Cost FlowsClariz Angelika EscocioNo ratings yet

- Inventory Accuracy Through Warehouse Control - ProQuest Central - ProQuest PDFDocument4 pagesInventory Accuracy Through Warehouse Control - ProQuest Central - ProQuest PDFphamanh1803No ratings yet

- Course Name Course Code Assignment OnDocument11 pagesCourse Name Course Code Assignment OnMd.Amir hossain khanNo ratings yet

- CH 6 Audit of Conversion CycleDocument24 pagesCH 6 Audit of Conversion CyclerogealynNo ratings yet

- Stores Magt.Document5 pagesStores Magt.Vinay SinghNo ratings yet

- Cost Accounting Module - 3Document4 pagesCost Accounting Module - 3Ken Ivan HervasNo ratings yet

- It Is The Process of Inspecting All Incoming and Outgoing Materials and Products, As Well As Manufacturing ProceduresDocument3 pagesIt Is The Process of Inspecting All Incoming and Outgoing Materials and Products, As Well As Manufacturing ProceduresApple Jean100% (1)

- Inventory ManagementDocument17 pagesInventory Managementacostaaugusto24No ratings yet

- Operations Research 2Document132 pagesOperations Research 2Cesar Amante TingNo ratings yet

- 32 - Nguyễn Thị Thảo TrangDocument4 pages32 - Nguyễn Thị Thảo Trangtrangnguyen.31221021691No ratings yet

- KANBAN: Streamlining Workflow for Effortless Efficiency (2023 Guide for Beginners)From EverandKANBAN: Streamlining Workflow for Effortless Efficiency (2023 Guide for Beginners)No ratings yet

- CC01 - A3 - Lê Nguyễn Minh Trang - 1852801Document2 pagesCC01 - A3 - Lê Nguyễn Minh Trang - 1852801Minh TrangNo ratings yet

- TransNum - May 29 - 141139 PDFDocument8 pagesTransNum - May 29 - 141139 PDFAziz KhanNo ratings yet

- Unit 1Document8 pagesUnit 1kubastepien55No ratings yet

- Etsu Board of Trustees Agenda 11-19-21Document116 pagesEtsu Board of Trustees Agenda 11-19-21Van JonesNo ratings yet

- Company Profile Askari TechDocument21 pagesCompany Profile Askari TechRakhshan ZulfiqarNo ratings yet

- 64bf055a20eabc7f1d348ee9 - Cold Emailing PlaybookDocument75 pages64bf055a20eabc7f1d348ee9 - Cold Emailing Playbookemre.email.5No ratings yet

- Great Zimbabwe University: Faculty of CommerceDocument4 pagesGreat Zimbabwe University: Faculty of CommercendmudhosiNo ratings yet

- Simulation and Optimization of Gyratory Crusher Performance Based On The Discrete Element MethodDocument30 pagesSimulation and Optimization of Gyratory Crusher Performance Based On The Discrete Element Methodthe requiem LastNo ratings yet

- United Construction P.L.C - Ethiopian ConstructionDocument2 pagesUnited Construction P.L.C - Ethiopian Constructionermias asalifNo ratings yet

- Palva Application FormDocument6 pagesPalva Application Formbigdealsin14No ratings yet

- North South University: ID# 161 2389 025 DegreeDocument2 pagesNorth South University: ID# 161 2389 025 DegreePartho BasakNo ratings yet

- Digital Marketing RemovedDocument11 pagesDigital Marketing RemovedManoj DewanNo ratings yet

- Benefit Illustration: UIN: 104N116V02 Page 1 of 3Document3 pagesBenefit Illustration: UIN: 104N116V02 Page 1 of 3Ravindar aNo ratings yet

- SFM Marking Scheme 2019Document10 pagesSFM Marking Scheme 2019Dilu - SNo ratings yet

- TRM Consulting Services Currently Has The Following Capital Structure New DebtDocument1 pageTRM Consulting Services Currently Has The Following Capital Structure New DebtHassan JanNo ratings yet

- Assignment DeedDocument5 pagesAssignment Deedmail2allamaprabhuNo ratings yet

- 2021 - Enrolment Pending StatusDocument423 pages2021 - Enrolment Pending StatusIlampariNo ratings yet

- Rodriguez Jescente Robin E. ACT 4 The Critical Path Method and Earned Value AnalysisDocument14 pagesRodriguez Jescente Robin E. ACT 4 The Critical Path Method and Earned Value AnalysisPaul A. JimenezNo ratings yet

- Public Health Budget (2012-2022)Document3 pagesPublic Health Budget (2012-2022)Fahim HasnatNo ratings yet

- Govbusman Module 6 - Chapter 7Document5 pagesGovbusman Module 6 - Chapter 7Rohanne Garcia AbrigoNo ratings yet

- ReceiptDocument1 pageReceiptRahul MakhijaNo ratings yet

- TNEB Online PaymentDocument1 pageTNEB Online PaymentveerNo ratings yet

- Siemens TXR 320 Installation ManualDocument16 pagesSiemens TXR 320 Installation ManualRomel HufalarNo ratings yet

- Strategies For Product Structure Management at MFGDocument11 pagesStrategies For Product Structure Management at MFGErdal TekinNo ratings yet

- Apostila Preparatória - Workshop de Psicologia Perinatal - 14wppDocument25 pagesApostila Preparatória - Workshop de Psicologia Perinatal - 14wppRose FalcãoNo ratings yet

- Intellectual Property Rights: Unit-IDocument93 pagesIntellectual Property Rights: Unit-ILalita snigdhaNo ratings yet

- Governor Stitt Veto MessageDocument1 pageGovernor Stitt Veto MessageDavid MarkNo ratings yet

![Practical Guide To Production Planning & Control [Revised Edition]](https://imgv2-2-f.scribdassets.com/img/word_document/235162742/149x198/2a816df8c8/1709920378?v=1)