0% found this document useful (0 votes)

703 views30 pagesDirect Gold Filling Techniques Guide

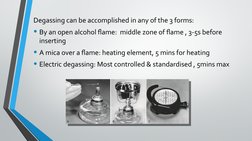

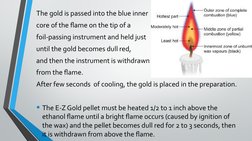

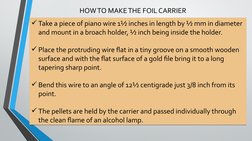

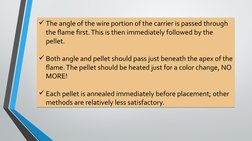

The document discusses the process of direct gold fillings, including preparation of the tooth cavity, heating and condensing gold pellets or foil to fill the cavity, and finishing and polishing the restoration. Different types of condensers and techniques for compacting gold foil or powder are described. The document emphasizes that direct gold restorations can provide the highest quality restoration when placed correctly.

Uploaded by

ShaliniCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

703 views30 pagesDirect Gold Filling Techniques Guide

The document discusses the process of direct gold fillings, including preparation of the tooth cavity, heating and condensing gold pellets or foil to fill the cavity, and finishing and polishing the restoration. Different types of condensers and techniques for compacting gold foil or powder are described. The document emphasizes that direct gold restorations can provide the highest quality restoration when placed correctly.

Uploaded by

ShaliniCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd