Professional Documents

Culture Documents

CSF - Defects - TQMC

Uploaded by

SIDDHARTH GAUTAMOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CSF - Defects - TQMC

Uploaded by

SIDDHARTH GAUTAMCopyright:

Available Formats

CSF- Defects

Consequences of Defects

DEFECTS

1. Market complaints- DEFECTS

• Implies customer is not satisfied

• Indicates dissatisfaction regarding the clinical indication, quality BEFORE AFTER

or packaging which is lodged verbally or in written forma BEFORE

LAUNCH AFTER

LAUNCH

LAUNCH LAUNCH

2. Drug Recall-

• Due to lack of integrity in quality and safety of manufactured drug

Drug Recall Classification

Methods used to minimize defects- Product may cause serious

Class -1

• Check Sheets health problem or death

• Cause-effect Diagram

Product may cause a

• Pareto Chart Class-2

• Process-Flow Chart

temporary health problem

Class-3

Product violates labelling or

manufacturing laws

CSF-Supplier Relation Management

Supplier relationship management (SRM) is the systematic approach of assessing suppliers’ contributions and

influence on success, determining tactics to maximize suppliers’ performance. The typical goal of SRM is to

streamline and improve processes between a buyer and its suppliers

Supplier relationship management is important because, over time, a long-term relationship between your

company and its suppliers allows for the free-flow of feedback and ideas. Over time, this will create a more

streamlined, effective supply chain that will have a positive impact on costs and customer service.

Benefits of SRM-

SRM allows for making quick and informed

decisions

SRM leads to ongoing process improvement

SRM leads to reduced costs.

SRM boosts supplier-led innovation

Technological Advancements Supporting TQM

Diffuse Reluctance Measurement-

• It is an excellent sampling tool for powdered or crystalline materials in the mid-IR and NIR (near-infra red)

spectral ranges

• It is used for monitor an ongoing process or ongoing reaction

CIP & WIP-

• CIP is also called clean in place. It involves cleaning of equipment with minimum involvement of the

operator. WIP is also known as wash in place

• Benefits of CIP & WIP:

-Reduction of cleaning time

-Improved health and safety

Sensors Technology in Packaging-

• Sensors based technology in packaging of pharmaceuticals has opened a new vista in online and in-process

monitoring of packaging process.

• Some of the recently used sensors are

-Ultrasonic sensor for filling level measurement

-Holographic Technique

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Dhanservices - Assignment - FinalDocument6 pagesDhanservices - Assignment - FinalSIDDHARTH GAUTAMNo ratings yet

- Dhan SErvices - Assignment03Document14 pagesDhan SErvices - Assignment03SIDDHARTH GAUTAMNo ratings yet

- Dhan Services - Assignment04Document10 pagesDhan Services - Assignment04SIDDHARTH GAUTAMNo ratings yet

- Shampoo Min Price (100ml) Max Price (100ml) Average Price Price For 250mlDocument4 pagesShampoo Min Price (100ml) Max Price (100ml) Average Price Price For 250mlSIDDHARTH GAUTAMNo ratings yet

- KPI's For Sales ManagerDocument2 pagesKPI's For Sales ManagerSIDDHARTH GAUTAM100% (2)

- PM Project - Group11Document32 pagesPM Project - Group11SIDDHARTH GAUTAMNo ratings yet

- Yogita Gautam: Email IDDocument2 pagesYogita Gautam: Email IDSIDDHARTH GAUTAMNo ratings yet

- Detailedanalysisofbigbasket 150228084411 Conversion Gate01 PDFDocument18 pagesDetailedanalysisofbigbasket 150228084411 Conversion Gate01 PDFSIDDHARTH GAUTAMNo ratings yet

- Wbs FinalDocument1 pageWbs FinalSIDDHARTH GAUTAMNo ratings yet

- Instructions and Assumptions:: Bottles 1 Tranche (Rev) 2 Tranche (Rev) 3 Tranche (Rev) Total RevDocument2 pagesInstructions and Assumptions:: Bottles 1 Tranche (Rev) 2 Tranche (Rev) 3 Tranche (Rev) Total RevSIDDHARTH GAUTAMNo ratings yet

- TATADocument1 pageTATASIDDHARTH GAUTAMNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 547874EN - Group 80 (Electricity) - 200215Document266 pages547874EN - Group 80 (Electricity) - 200215Were WolfNo ratings yet

- Information Assurance PlanDocument5 pagesInformation Assurance PlanEddyOmburahNo ratings yet

- CMP A2 FI436 Issue 5Document2 pagesCMP A2 FI436 Issue 5Gokul MuraliNo ratings yet

- Microcare Single Phase Grid Tied LimiterDocument5 pagesMicrocare Single Phase Grid Tied Limiterfopoku2k2No ratings yet

- CT2 Motor Controller Installation - ComNavDocument11 pagesCT2 Motor Controller Installation - ComNavDare DoreNo ratings yet

- Wei, J., Et Al. (2022) - Emergent Abilities of Large Language Models. ArxivDocument16 pagesWei, J., Et Al. (2022) - Emergent Abilities of Large Language Models. ArxivAhmed IsmailNo ratings yet

- Job Card: Process Inspection ReportDocument10 pagesJob Card: Process Inspection ReportAbhi YadavNo ratings yet

- BirthCertificate 8044114Document1 pageBirthCertificate 8044114raju ansari50% (2)

- Barrier Interface Unit (For Use With Intrinsically Safe Detectors)Document2 pagesBarrier Interface Unit (For Use With Intrinsically Safe Detectors)bluesierNo ratings yet

- Chapter 4 - Memory Part 2Document28 pagesChapter 4 - Memory Part 2Yaseen AshrafNo ratings yet

- Chapter 4 - Test ScenarioDocument7 pagesChapter 4 - Test ScenarioAamir AfzalNo ratings yet

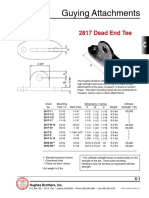

- HB PolelineDocument99 pagesHB PolelineCharlee100% (1)

- OLTP To OLAP COnversionDocument39 pagesOLTP To OLAP COnversionAmit SharmaNo ratings yet

- Ab Ipbox 55Hd: HDTV Linux ReceiverDocument8 pagesAb Ipbox 55Hd: HDTV Linux ReceiverAlexander WieseNo ratings yet

- Iso 17635 2016 en PDFDocument8 pagesIso 17635 2016 en PDFUfuk ÇimenNo ratings yet

- Practical 5 - Text Processing PDFDocument2 pagesPractical 5 - Text Processing PDFDarian ChettyNo ratings yet

- Design Journeys Through Complex Systems Tools PostersDocument41 pagesDesign Journeys Through Complex Systems Tools PostersAmerika SanchezNo ratings yet

- Vacuum Oil Filling On Site: Power Transformers and ReactorsDocument11 pagesVacuum Oil Filling On Site: Power Transformers and Reactorsmanaf100% (1)

- Excel 2010 Shortcuts PDFDocument1 pageExcel 2010 Shortcuts PDFRosa Martin HuelvesNo ratings yet

- TeSys Giga Contactors - LAG8N203Document3 pagesTeSys Giga Contactors - LAG8N203muez zabenNo ratings yet

- مختبر ابلايد 1Document6 pagesمختبر ابلايد 1عبد الرحمن أبوخاطر, أبو رزقNo ratings yet

- Using Apple's Standard EULA For Your Mobile AppDocument21 pagesUsing Apple's Standard EULA For Your Mobile AppTermsFeedNo ratings yet

- Assignment Brief BTEC Level 4-5 HNC/HND Diploma (QCF) : To Be Filled by The StudentDocument101 pagesAssignment Brief BTEC Level 4-5 HNC/HND Diploma (QCF) : To Be Filled by The StudentronicaNo ratings yet

- (I) No. Name Stipend Stream Avgmark Grade Class: Create The Table Givem Below With Name and StiudentDocument1 page(I) No. Name Stipend Stream Avgmark Grade Class: Create The Table Givem Below With Name and StiudentUdit JunejaNo ratings yet

- Appx Brochure NewDocument5 pagesAppx Brochure NewBarbarian KingNo ratings yet

- BestGrid EA 2.1 - (Cost $560) - For FREE - ForexCrackedDocument9 pagesBestGrid EA 2.1 - (Cost $560) - For FREE - ForexCrackedVilayNo ratings yet

- Led DMX Decoder User Manual PDFDocument4 pagesLed DMX Decoder User Manual PDFjaziel daitNo ratings yet

- Cutting Master 2 User ManualDocument29 pagesCutting Master 2 User ManualLéo SouzaNo ratings yet

- Lesson 5 Managing Text Flow 742780943 (Yeah Good Day)Document37 pagesLesson 5 Managing Text Flow 742780943 (Yeah Good Day)Ahmed El IssawiNo ratings yet

- Volumes by Sections Using Prismoidal FormulasDocument4 pagesVolumes by Sections Using Prismoidal FormulasfaizalprbwNo ratings yet