Professional Documents

Culture Documents

Mechanical Properties of Solids Explained

Uploaded by

Rahul Pugazhendi0 ratings0% found this document useful (0 votes)

123 views37 pages1. The document discusses various mechanical properties of solids including elasticity, plasticity, stress, strain, Hooke's law, elastic limit, types of stresses and strains, stress-strain curves, elastic potential energy, Poisson's ratio, and numerical examples.

2. Key concepts covered include how materials respond elastically or plastically to deforming forces, definitions of stress as internal restoring force and strain as ratio of dimensional change, Hooke's law of proportionality between stress and strain, and modulus of elasticity.

3. Different types of stresses, strains, and moduli are defined including Young's modulus, bulk modulus, and shear modulus. Stress-strain curves are analyzed to describe elastic and

Original Description:

Original Title

Mechanical Properties of Solids

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1. The document discusses various mechanical properties of solids including elasticity, plasticity, stress, strain, Hooke's law, elastic limit, types of stresses and strains, stress-strain curves, elastic potential energy, Poisson's ratio, and numerical examples.

2. Key concepts covered include how materials respond elastically or plastically to deforming forces, definitions of stress as internal restoring force and strain as ratio of dimensional change, Hooke's law of proportionality between stress and strain, and modulus of elasticity.

3. Different types of stresses, strains, and moduli are defined including Young's modulus, bulk modulus, and shear modulus. Stress-strain curves are analyzed to describe elastic and

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

123 views37 pagesMechanical Properties of Solids Explained

Uploaded by

Rahul Pugazhendi1. The document discusses various mechanical properties of solids including elasticity, plasticity, stress, strain, Hooke's law, elastic limit, types of stresses and strains, stress-strain curves, elastic potential energy, Poisson's ratio, and numerical examples.

2. Key concepts covered include how materials respond elastically or plastically to deforming forces, definitions of stress as internal restoring force and strain as ratio of dimensional change, Hooke's law of proportionality between stress and strain, and modulus of elasticity.

3. Different types of stresses, strains, and moduli are defined including Young's modulus, bulk modulus, and shear modulus. Stress-strain curves are analyzed to describe elastic and

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 37

Mechanical Properties of Solids

Deforming force : A force which changes the size or

shape of a body is called a deforming force.

Elasticity. If a body regains its original size and shape

after the removal of deforming force , it is said to be

elastic body and this property is called elasticity.

Perfectly elastic body. If a body regains its original size

and shape completely and immediately after the

removal of deforming force , it is said to be

perfectly elastic body.

Plasticity. If a body does not regain its original

size and shape even after the removal of

deforming force it is said to be plastic body and

this property is called plasticity.

Stress . The internal restoring force set up per

unit area of cross-section of the deformed

body is called stress. The restoring force is

equal and opposite to the external deforming

force.

Stress = Applied Force/Area = F/A

SI unit N/m2 CGS Unit dyne/cm2

Dimensional Formula [ML-1T-2]

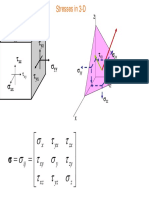

Types of stress

1.Tensile Stress. It is the restoring force set up per

unit cross-sectional area of a body when the

length of the body increases in the direction of

deforming force. It is also known as longitudinal

stress.

2. Compressional stress. It is the restoring force

set up per unit cross-sectional area of a body

when its length decreases under a deforming

force.

3. Hydrostatic stress. If a body is subjected to a

uniform force from all sides , then the

corresponding stress is called hydrostatic

stress.

4. Tangential stress or shearing stress.

When a deforming force acts tangentially to the

surface of a body, it produces a change in the

shape of the body. The tangential force

applied per unit area is equal to the tangential

stress.

Strain: The ratio of the change in any dimension

produced in the body to the original

dimension is called strain.

Strain = Change in dimension/ Original

dimension

Since it is the ratio of two like quantities, it has

no units and dimensions.

Strain is of three types.

1. Longitudinal strain. It is defined as the ratio of change

in length to the original length.

Longitudinal strain = ∆l/l

2. Volumetric strain =Change in Volume/original volume

= ∆V/V

3. Shear Strain . It is defined as the angle ϴ (in radians),

through which a face originally perpendicular to the

fixed face gets turned on applying tangential

deforming force

Shear strain =ϴ= tanϴ= ∆l/l

Elastic limit. The maximum stress within which

the body regains its original size and shape

after the removal of deforming force is called

elastic limit.

Hooke’s Law

It states that within the elastic limit, the stress is

directly proportional to strain

Stress/strain = Constant

The constant of proportionality is called

modulus of elasticity or coefficient of elasticity

of the material. Its value depends on the

nature of the material of the body and the

manner in which it is deformed.

Modulus of elasticity , E = Stress/strain

SI unit N/m2

Dimensional Formula [ML-1T-2]

Different types of elasticity

(i) Young’s modulus (Y) –the modulus of

elasticity of length

(ii) Bulk modulus (K) – the modulus of elasticity

of volume

(iii) Modulus of rigidity or shear modulus (ƞ) –

modulus of elasticity of shape.

Young’s modulus of elasticity (Y)

Within the elastic limit, the ratio of longitudinal

stress to the longitudinal strain is called

Young’s modulus of the material of the wire.

Y = (F/A)/ (∆l/l)

Y = F.l/A.∆l

If the wire has a circular cross-section of radius

r , then Area = πr2

Bulk modulus of elasticity.

K = Normal stress/Volumetric strain

= -(F/A)/ (∆V/V) = -PV/∆V

Where P is the normal pressure

Negative sign shows that the volume decreases

with the increase in stress.

SI unit N/m2 Dimensional formula [ML-1T-2]

Compressibility . The reciprocal of the bulk

modulus of a material is called its

compressibility

Compressibility = 1/K

SI unit N-1m2

Dimensional formula [M-1LT2]

Modulus of rigidity or shear modulus

ƞ=Tangential stress/Shear strain

=(F/A)/ϴ = F/Aϴ = Fl/A∆l

Stress- Strain

Important features of the graph

(i) The initial part OA of the graph is a straight line

indicating that stress is proportional to strain. Up to

the point A Hooke’s law is obeyed. The point A is

called the proportional limit. In this region the wire

is perfectly elastic.

(ii) After the point A , the stress is not proportional to

strain. A curved portion AB is obtained. But if the

load is removed at any point between O and B the

wire attains its original length.

The portion OB of the graph is called elastic region. The

point B is called elastic limit or yield point. The

corresponding stress is called yield strength.

(iii) Beyond the point B the strain increases more rapidly

than stress. If the force is removed at any point C, the

wire does not come back to its original length. It traces

the dotted line CE. Even on reducing the stress to zero , a

residual strain equals OE is left in the wire. The material is

said to have acquired a permanent set. The stress-strain

curve is not retraced. The strain is called elastic hysteresis.

• (iv) Further increase in force beyond C produces a

large increase in strain or length of the wire. In the

region B and D the length of the wire goes on

increasing even without addition of force. D is called

fracture point. The region BD is called plastic region.

The material is said to have plastic deformation.

• If large deformation takes place between the elastic

limit and the fracture point , the material is called

ductile. If it breaks soon after the elastic limit is

crossed, it is called brittle.

Elastic Potential Energy:

When a wire is stretched, the inter atomic forces

oppose the change. Work has to done against these

restoring forces. The work done in stretching the

wire is stored in it as its elastic potential energy.

Expression for elastic Potential Energy.

Let a force F applied on a wire of length l increases its

length by ∆l. Initially, the internal restoring force in

the wire is zero.

When the length is increased by ∆l, the internal

force increases from zero to F(= applied force)

Average internal force for an increase in length

∆l of wire = (0+F)/2 = F/2

Work done on the wire W = average force x ∆l

= ( F/2)x ∆l

This work done is stored as elastic potential

energy U in the wire.

U = ½ F x ∆l = ½ stretching force x increase in length

= ½ (F/A)x (∆l/l)x Al.

(multiplying and dividing by Al Where A is the area of

cross –section of the wire.)

U = ½ Stress x Strain x Volume of the wire.

Elastic potential energy per unit volume of wire or

elastic energy density = u = U/Volume

= ½ Stress x strain

= ½ Young’s modulus x ( strain)2

Poisson’s ratio:

When a wire is loaded, its length increases but its

diameter decreases. The strain produced in the

direction of applied force is called longitudinal

strain.

The strain produced in the perpendicular direction

is called lateral strain.

Within elastic limit, the ratio of lateral strain to the

longitudinal strain is called Poisson’s ratio.

Longitudinal strain =∆l/l

Lateral strain = -∆D/D ( The negative shows that

as length increases diameter decreases.)

Poisson’s ratio

= Lateral Strain/Longitudinal Strain

-(l/D). ∆D/∆l.

As Poisson’s ratio is the ratio of two strains, it

has no unit and dimension.

Numerical problems

1. One end of a wire 2m long and 0.2 cm2 is fixed in

a ceiling and a load of 4.8kg is attached to the

free end. Find the extension of the wire . Young’s

modulus of steel

= 2 x 10 11 N/m2. Take g= 10m/s2

Y = stress/strain

stress= F/A = T/A strain = ∆l/l

Y = (T/A)x l/∆l ∆l = Tl/AY

= 48 x2/0.2 x10-4 x 2x 10 11 =2.4 x10-5m

2. The length of a suspended wire increases by

10-4 of its original length when a stress of 107

N/m2 is applied on it. Calculate the Young’s

modulus of the material of the wire.

Stress = 107N/m2

Strain = ∆l/l = 10-4

Y = stress/strain = 107/10-4 = 1011 N/m2

3. A steel rod has a radius of 10mm and a length of

1m. A 100kN force stretches along its length .

Calculate (a) the stress (b) elongation

(c ) strain on the rod. Y of steel = 2 x1011 N/m2.

Data r= 10mm = 0.01m , l= 1m ,F = 100kN

=105 N , Y = 2 x1011N/m2

Stress = F/A = F/πr2= 3.18 x108 N/m2

Y = (F/A)(l/∆l) Elongation ∆l= 1.59mm

Strain = ∆l/l = 1.59 x10-3

4.A steel wire of length 2m is stretched through 2mm. The

cross sectional area of the wire is 4mm 2. Calculate the

elastic potential energy stored in the stretched condition.

Y of steel is 2x1011 N/m2

The strain in the wire = ∆l/l = 2mm/2m = 10 -3

The stress in the wire = Y x strain = 2x10 11x10-3

= 2 x108 N/m2

Volume of the wire = Ax l = 4 x10-6 x 2 = 8x10-6m3

The elastic potential energy = ½ Stress x Strain x Volume

=1/2 x2x108 x 10-3 x 8 x10-6 = 0.8J

5.One end of a metal wire is fixed to a ceiling

and a load of 2kg hangs from the other end. A

similar wire is attached to the bottom of the

load and another load of 1kg hangs from this

lower wire. Find the longitudinal strain in

both the wires. Area of cross section of each

wire is 0.005cm2 and Y of the metal is

2 x 10-11 N/m2. Take g= 10m/s2

T1 = 10N Stress = 10/5 x10-7 = 2 x 107N/m2

Longitudinal strain = stress/Y = 2 x107/2x 1011

= 10-4

Considering the equilibrium of the upper block,

T2 = 20 +T1 T2 = 20+10 =30N

Stress =30/5 x10-7 = 6 x107 N/m2

Longitudinal Strain = Stress/ Y = 6 x107/2 x1011

= 3 x10-4

6. Find the decrease in the volume of a sample

of water from the following data. Initial

volume =1000cm3, initial pressure = 105N/m2

Final pressure = 106N/m2

Compressibility of water = 50 x10-11m2/N

The change in pressure = ∆p = 106-105

= 9 x105 N/m2

Bulk modulus = 1/compressibility = 2 x109 N/m2

Bulk modulus B = -∆p/ (∆V/V)

∆V = - ∆P x V/ B

= - 9 x105 x 103/2 x109

=-4.5 x 10-1 cm3 = -0.45 cm3

Decrease in Volume = 0.45cm3

You might also like

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- Engineering PhysicsDocument31 pagesEngineering PhysicsJoan VincentNo ratings yet

- REGENT EDUCATION & RESEARCH FOUNDATIONDocument14 pagesREGENT EDUCATION & RESEARCH FOUNDATIONArghya ModakNo ratings yet

- Elasticity: These States Differ From Each Other Due To The Following Two FactorsDocument7 pagesElasticity: These States Differ From Each Other Due To The Following Two Factorspuput123No ratings yet

- Elasticity notes on stress, strain, Hooke's law and Young's modulusDocument5 pagesElasticity notes on stress, strain, Hooke's law and Young's modulusdjarwooNo ratings yet

- Simple Stresses & Strains ExplainedDocument24 pagesSimple Stresses & Strains Explainednithesh kumar jNo ratings yet

- Physics 2part 1 E.V PDFDocument5 pagesPhysics 2part 1 E.V PDFShira YukiNo ratings yet

- Mechanical Properties of SolidsDocument7 pagesMechanical Properties of SolidsStudent RequestNo ratings yet

- Mechanical Properties of SolidsDocument7 pagesMechanical Properties of SolidsSahil baggaNo ratings yet

- Elasticity PDFDocument8 pagesElasticity PDFrachna chhabraNo ratings yet

- Ywmx 3 Tksnli B7 Gamxn JNDocument12 pagesYwmx 3 Tksnli B7 Gamxn JNdhanukrishnagNo ratings yet

- Physics Notes Class 11 CHAPTER 9 MECHANICAL PROPERTIES OF SOLIDS PDFDocument7 pagesPhysics Notes Class 11 CHAPTER 9 MECHANICAL PROPERTIES OF SOLIDS PDFKaleelur RahmanNo ratings yet

- Physics Notes Class 11 Chapter 9 Mechanical Properties of SolidsDocument7 pagesPhysics Notes Class 11 Chapter 9 Mechanical Properties of SolidsBasharat Ali100% (7)

- Elasticity, Calorimetry & Thermal Expansion (Teaching Notes)Document21 pagesElasticity, Calorimetry & Thermal Expansion (Teaching Notes)Sankar KumarasamyNo ratings yet

- Instrumentation Training Tutorial Part1Document6 pagesInstrumentation Training Tutorial Part1Gary8100% (1)

- Tutorial 1 - Basic Engineering Science: Instrumentation and ControlDocument6 pagesTutorial 1 - Basic Engineering Science: Instrumentation and Controls_waqarNo ratings yet

- Basic engineering tutorial for instrumentation and control systemsDocument6 pagesBasic engineering tutorial for instrumentation and control systems@@ngNo ratings yet

- Tutorial 1 - Basic Engineering Science: Instrumentation and ControlDocument6 pagesTutorial 1 - Basic Engineering Science: Instrumentation and ControlMohd A IshakNo ratings yet

- 10.mechanical Properties of SolidsDocument21 pages10.mechanical Properties of SolidsSri DNo ratings yet

- Strength of Materials - PUPDocument60 pagesStrength of Materials - PUPshirelyna100% (1)

- Instrumentation BasicsTrainingDocument59 pagesInstrumentation BasicsTrainingSurya SenthilnathanNo ratings yet

- Instrumentation Tutorial 1Document6 pagesInstrumentation Tutorial 1Abhishek PrakashNo ratings yet

- Instrumentation Training Tutorial1 PDFDocument6 pagesInstrumentation Training Tutorial1 PDFchdiNo ratings yet

- MECHANICS OF SOLIDS: DHANALAKSHMI COLLEGE OF ENGINEERING QUESTIONSDocument10 pagesMECHANICS OF SOLIDS: DHANALAKSHMI COLLEGE OF ENGINEERING QUESTIONSRajeswariSathishNo ratings yet

- Engineering Physics Properties of MatterDocument26 pagesEngineering Physics Properties of MatterFede PerezNo ratings yet

- 09Document6 pages09RUDRA PATELNo ratings yet

- Measure Young's Modulus and Determine Material PropertiesDocument13 pagesMeasure Young's Modulus and Determine Material PropertiesKerry-Ann WilliamsNo ratings yet

- Mechanical PropertiesDocument16 pagesMechanical PropertiesPrathmeshNo ratings yet

- 4th Chap 2Document8 pages4th Chap 2سيف مهندNo ratings yet

- Young's Modulus, Shear Modulus, and Bulk Modulus Mechanical PropertiesDocument9 pagesYoung's Modulus, Shear Modulus, and Bulk Modulus Mechanical PropertiesBVoc AutomobileNo ratings yet

- Mechanical Properties of Solids ExplainedDocument4 pagesMechanical Properties of Solids ExplainedbgmiytNo ratings yet

- ElasticityDocument38 pagesElasticityIndra Dewa PutraNo ratings yet

- Gec224 - Lecture Note on Strength of MaterialsDocument54 pagesGec224 - Lecture Note on Strength of MaterialseltonmudzamiriNo ratings yet

- Chapter - 1 - Basic Engineering ScienceDocument8 pagesChapter - 1 - Basic Engineering ScienceMathavaraja Jeyaraman100% (3)

- Ce6306 Strength of MaterialsDocument21 pagesCe6306 Strength of Materialsmithunarjun10108No ratings yet

- Mechanical Properties of Solids NewDocument32 pagesMechanical Properties of Solids NewVijyata DhankharNo ratings yet

- Report 4 on Engineering Materials TestingDocument15 pagesReport 4 on Engineering Materials TestingsofiaNo ratings yet

- Topic 8 - Deformation of SolidsDocument8 pagesTopic 8 - Deformation of Solidsargh67% (3)

- STRENGTH OF MATERIALS NOTESDocument7 pagesSTRENGTH OF MATERIALS NOTESSurjith Bharathi SelvakumarNo ratings yet

- STRENGTH OF MATERIALS DOCUMENT ANALYSISDocument24 pagesSTRENGTH OF MATERIALS DOCUMENT ANALYSISsarul_murugan2483No ratings yet

- Dental Materials Mechanical PropertiesDocument136 pagesDental Materials Mechanical PropertiesDiksha SolankiNo ratings yet

- CEG 221 - LecturesDocument18 pagesCEG 221 - LecturesMoshood Mubarak AyindeNo ratings yet

- Chapter 13Document38 pagesChapter 13Chris SmithNo ratings yet

- Interatomic Forces and Stress-Strain RelationshipDocument19 pagesInteratomic Forces and Stress-Strain RelationshipSasidaran SasiNo ratings yet

- Deformation of Solid & Elasticity of Materials - Module 2: Michael Adeleye, PH.D, P.G. Dip - EdDocument27 pagesDeformation of Solid & Elasticity of Materials - Module 2: Michael Adeleye, PH.D, P.G. Dip - Edlar dinchiNo ratings yet

- Module-1 Stresses and StrainsDocument33 pagesModule-1 Stresses and StrainsC.E.M JEFFREYSNo ratings yet

- Mechanical Properties of Solids: ElasticityDocument12 pagesMechanical Properties of Solids: ElasticityParakram Singh ShekhawatNo ratings yet

- FALLSEM2018-19 MEE1006 ETH TT201 VL2018191005146 Reference Material I Deformation of SoildsDocument21 pagesFALLSEM2018-19 MEE1006 ETH TT201 VL2018191005146 Reference Material I Deformation of SoildsSHUBHAM KUMARNo ratings yet

- Simple - Stress-Strain and TrussDocument131 pagesSimple - Stress-Strain and Trussdarshan100% (3)

- Tensile Test Study of Mild SteelDocument7 pagesTensile Test Study of Mild SteelMir Md. Mofachel HossainNo ratings yet

- TOS 1 Unit 2 Simple Stresses and StrainsDocument12 pagesTOS 1 Unit 2 Simple Stresses and Strainsflower lilyNo ratings yet

- Instrumentation 1Document10 pagesInstrumentation 1Haytham Ben BrahimNo ratings yet

- Elasticity With Lecture 2020Document5 pagesElasticity With Lecture 2020mean comiaNo ratings yet

- Week 4Document6 pagesWeek 4Ѕєди Диԁяєш Вцвди ҨяцтдѕNo ratings yet

- Mechanical Properties of Solids NotesDocument24 pagesMechanical Properties of Solids Notespavithra.knpvNo ratings yet

- Chapter 17 Notes 2Document11 pagesChapter 17 Notes 2Rizwan MalikNo ratings yet

- Simple Stresses and StrainsDocument6 pagesSimple Stresses and StrainsNwankwo EmmanuelNo ratings yet

- Elasticity and Stress-Strain RelationshipDocument84 pagesElasticity and Stress-Strain RelationshipService ProviderNo ratings yet

- Met 2aDocument70 pagesMet 2aharshaNo ratings yet

- Stress-Strain Curve For 100 MM WallDocument61 pagesStress-Strain Curve For 100 MM WallPraYush RajbhandariNo ratings yet

- Hooke's Law ExperimentDocument7 pagesHooke's Law ExperimentRoda Gayle RañadaNo ratings yet

- SimAcademy-Nastran N Is For NonlinearDocument34 pagesSimAcademy-Nastran N Is For NonlinearMGAVIONNo ratings yet

- 7 Stress Transformations Gerilme Donusumleri 23022021Document50 pages7 Stress Transformations Gerilme Donusumleri 23022021Muhammet AkifNo ratings yet

- Buckling Analysis of Buildings Braced by Frameworks, Shear Walls and CoresDocument23 pagesBuckling Analysis of Buildings Braced by Frameworks, Shear Walls and Coressabareesan09No ratings yet

- Thesis Amin Abrishambaf 2015Document347 pagesThesis Amin Abrishambaf 2015Marcelo CarvalhoNo ratings yet

- Solution Methods For Nonlinear Finite Element Analysis (NFEA)Document39 pagesSolution Methods For Nonlinear Finite Element Analysis (NFEA)janaaidaas1996No ratings yet

- Crack WiseDocument210 pagesCrack Wisetgrclarke100% (1)

- Analysis of The Behaviour of Stainless Steel Bolted ConnectionsDocument11 pagesAnalysis of The Behaviour of Stainless Steel Bolted ConnectionsSam SamouraNo ratings yet

- Bridge Mechanics 5Document40 pagesBridge Mechanics 5cipele12No ratings yet

- Flexure FormulaDocument5 pagesFlexure FormulaAbdul RehmanNo ratings yet

- Ballistic Missile Structural AnalysisDocument86 pagesBallistic Missile Structural AnalysisrakeshsakoteNo ratings yet

- Gurson Model For Ductile FractureDocument27 pagesGurson Model For Ductile Fracturesaded05No ratings yet

- Solid Mechanics-8 PDFDocument8 pagesSolid Mechanics-8 PDFchetanNo ratings yet

- Analysis of Truck Chasis Frame Using FEMDocument6 pagesAnalysis of Truck Chasis Frame Using FEMRobert SimmonsNo ratings yet

- Vietnam Oil and Gas Corporation (Petrovietnam) Dung Quat Refinery (DQR) ProjectDocument8 pagesVietnam Oil and Gas Corporation (Petrovietnam) Dung Quat Refinery (DQR) ProjectSudip ShresthaNo ratings yet

- Isotropichardening UMATDocument16 pagesIsotropichardening UMATMAIKEL ANDRES VINCES MENDOZANo ratings yet

- 4 MaterialsDocument72 pages4 MaterialsCt Kamariah Md SaatNo ratings yet

- plant pressure vessel training manual 6 of 6 권-2007 div.2-pd번역-1 (강도계산포함) -4-2-간력sampleDocument36 pagesplant pressure vessel training manual 6 of 6 권-2007 div.2-pd번역-1 (강도계산포함) -4-2-간력samplekangrimNo ratings yet

- CM LC1Document28 pagesCM LC1Eng W EaNo ratings yet

- Strength of Casing and Tubing - PetroWiki PDFDocument15 pagesStrength of Casing and Tubing - PetroWiki PDFLuis David Concha CastilloNo ratings yet

- From Internet: Pipe Burst Working Pressure Calculator Barlow's FormulaDocument5 pagesFrom Internet: Pipe Burst Working Pressure Calculator Barlow's FormulaDipakNo ratings yet

- Lab 1 Compresive Test PDFDocument10 pagesLab 1 Compresive Test PDFDhania BaharuddinNo ratings yet

- Expt 5b.strain MeasurementsDocument7 pagesExpt 5b.strain Measurementsnikhil jaiswalNo ratings yet

- Finite Element Formulation For Vector Field Problems - Linear ElasticityDocument33 pagesFinite Element Formulation For Vector Field Problems - Linear Elasticity22ebook22No ratings yet

- ANSYS NeoHook UsermatDocument15 pagesANSYS NeoHook UsermatRohan Nair100% (2)

- Combined Effect of Damage and Plastic Anisotropy On The Ductility Limit of Thin Metal SheetsDocument8 pagesCombined Effect of Damage and Plastic Anisotropy On The Ductility Limit of Thin Metal SheetsKrunal MoreyNo ratings yet

- Torayca Carbon Fiber Summary DataSheet PDFDocument1 pageTorayca Carbon Fiber Summary DataSheet PDFaleatoryoNo ratings yet

- Dynamic Response of Concrete Subjected To High Rate of Loading: A Parametric StudyDocument17 pagesDynamic Response of Concrete Subjected To High Rate of Loading: A Parametric StudyJhuma DebnathNo ratings yet