0% found this document useful (0 votes)

121 views45 pagesDC Motors

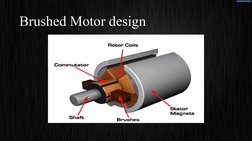

The document discusses different types of DC motors, including their design and operation. It describes brushed DC motors, brushless DC motors, and stepper motors. For brushed DC motors, it explains the rotor, brushes, and stator components and different winding types like permanent magnet, shunt wound, and series wound. For brushless DC motors, it outlines the rotor, stator, and hall sensor components as well as inner and outer rotor designs. Stepper motors are described as converting electrical pulses into precise rotational steps through their stator windings.

Uploaded by

tristan jeff bautistaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

121 views45 pagesDC Motors

The document discusses different types of DC motors, including their design and operation. It describes brushed DC motors, brushless DC motors, and stepper motors. For brushed DC motors, it explains the rotor, brushes, and stator components and different winding types like permanent magnet, shunt wound, and series wound. For brushless DC motors, it outlines the rotor, stator, and hall sensor components as well as inner and outer rotor designs. Stepper motors are described as converting electrical pulses into precise rotational steps through their stator windings.

Uploaded by

tristan jeff bautistaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

- DC Motors Design: An introduction to DC motor design principles and foundational concepts.

- Types of DC Motors: Overview of different DC motor types, including brushed and brushless variations.

- Operations: Explains the operational principles and functions of DC motors, with practical examples.

- Detailed Motor Types: In-depth exploration of DC motor types, including brushed, brushless, and stepper variants.

- Uses and Applications: Discusses various applications of different types of DC motors in industry and daily life.

- References: Lists references and sources for further reading and exploration of DC motor topics.