Professional Documents

Culture Documents

Binary Operations: Simatic S7

Uploaded by

mhaioocOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Binary Operations: Simatic S7

Uploaded by

mhaioocCopyright:

Available Formats

Binary Operations

I0.0 I0.1 Q 8.0

Q 8.1 (MCRA)

I 0.0

( MCR< )

I 1.0 I 1.1 Q 8.0

( )

M0.0

I1.2 Q 9.3

SR

S Q

I1.3

R

SIMATIC S7 Date: 27.12.20 Information and Training Center

Knowledge for Automation

Siemens AG 1999. All rights reserved. File: SYH_08E.1

Cyclical Program Execution

Start-up block (OB 100)

Execution once after e.g. power on

Input

Start of the cycle monitoring time

Module

Reading the signal states from the modules

and saving the data in the process image (PII)

CPU Cycle

Execution of the program in OB1 Block

(cyclical execution) A I 0.1

OB 1 A I 0.2

Events (time-of-day interrupt, hardware interrupts etc.)

= Q8.0

call other OBs, FBs, FCs, etc.

Writing the process-image output table Output

(PIQ) to the output modules Module

SIMATIC S7 Date: 27.12.20 Information and Training Center

Knowledge for Automation

Siemens AG 1999. All rights reserved. File: SYH_08E.2

Process Images

PII PIQ

User

Byte 0 Program Byte 0

Byte 1 Byte 1

Byte 2 1 Byte 2

: : :

: : : 1

: A I 2.0 :

= Q 4.3

:

:

:

:

CPU Memory Area CPU Memory Area

SIMATIC S7 Date: 27.12.20 Information and Training Center

Knowledge for Automation

Siemens AG 1999. All rights reserved. File: SYH_08E.3

Program Structure

Linear Program Program Partitioned into Areas Structured Program

Recipe A

Pump

OB 1 OB 1 Recipe B OB 1

Mixer

Outlet

Outlet

All instructions are The instructions for the indi- Reuseable functions are loaded

found in one block vidual functions are found in into individual blocks.

(normally in the individual blocks. OB 1 calls the OB 1 (or other blocks) call

organization block OB 1) individual blocks one after the these blocks and pass on the

other. pertinent data.

SIMATIC S7 Date: 27.12.20 Information and Training Center

Knowledge for Automation

Siemens AG 1999. All rights reserved. File: SYH_08E.4

Types of Program Blocks

Operating System

Cycle

Time OB

FB FC SFB

Organization

Process Blocks

FB FB SFC

Error

OB = Organization Block

Legend:

FB = Function Block

FC = Function

SFB = System Function Block

SFC = System Function FB with instance

data block

SIMATIC S7 Date: 27.12.20 Information and Training Center

Knowledge for Automation

Siemens AG 1999. All rights reserved. File: SYH_08E.5

Normally Open and Normally Closed Contacts, Sensors and Symbols

Process Interpretation in PLC program

The The sensor Voltage Signal Check for Check for

sensor is ... present state signal state “1” signal state “0”

is a ... at at

input? input Symbol / Result of Symbol / Result of

Instruction check Instruction check

NO activated

contact LAD: LAD:

Yes 1 “Yes“ “No”

1 0

“NO contact” “NC contact”

not No

activated 0 “No” “Yes”

0 1

FBD: FBD:

& &

NC activated

No 0 “No” “Yes”

contact

0 1

not

STL: STL:

activated Yes 1 “Yes” “No”

A I x.y 1 AN I x.y 0

SIMATIC S7 Date: 27.12.20 Information and Training Center

Knowledge for Automation

Siemens AG 1999. All rights reserved. File: SYH_08E.6

Exercise

Task: In all three examples the light should be on when S1 is activated and S2 is not activated!

Hardware

S1 S2 S1 S2 S1 S2

II1.0

1.0 II1.1

1.1 II1.0

1.0 II1.1

1.1 II1.0

1.0 II1.1

1.1

Programmable controller Programmable controller Programmable controller

Q 4.0 Q 4.0 Q 4.0

Light Light Light

Software

I 1.0 I 1.1 Q 4.0 I1.0 I1.1 Q 4.0 I1.0 I1.1 Q 4.0

LAD

I 1.0 & I1.0 & I1.0 &

FDB

I1.1 Q 4.0 I1.1 Q 4.0 I1.1 Q 4.0

....... I1.0 ....... I1.0 ....... I1.0

STL ....... I1.1 ....... I1.1 ....... I1.1

....... Q 4.0 ....... Q 4.0 ....... Q 4.0

SIMATIC S7 Date: 27.12.20 Information and Training Center

Knowledge for Automation

Siemens AG 1999. All rights reserved. File: SYH_08E.7

Addressing of S7-300 Modules

Slot No. 1 2 4 5 6 7 8 9 10

Modules PS CPU SM SM SM SM SM SM SM

Address 0.0

Address 0.7

Address 1.0

Address 1.7

SIMATIC S7 Date: 27.12.20 Information and Training Center

Knowledge for Automation

Siemens AG 1999. All rights reserved. File: SYH_08E.8

DI/DO Addressing in Multi-Tier Configurations

PS IM 96.0 100.0 104.0 108.0 112.0 116.0 120.0 124.0

Rack

3 (Receive) to to to to to to to to

99.7 103.7 107.7 111.7 115.7 119.7 123.7 127.7

PS IM 64.0 68.0 72.0 76.0 80.0 84.0 88.0 92.0

Rack (Receive) to to to to to to to to

2 67.7 70.7 75.7 79.7 83.7 87.7 91.7 95.7

PS

IM 32.0 36.0 40.0 44.0 48.0 52.0 56.0 60.0

Rack to to to to to to to to

1 (Receive)

35.7 39.7 43.7 47.7 51.7 55.7 59.7 63.7

PS 0.0 4.0 8.0 12.0 16.0 20.0 24.0 28.0

CPU IM

Rack (Send) to to to to to to to to

0 3.7 7.7 11.7 15.7 19.7 23.7 27.7 31.7

Slot 1 2 3 4 5 6 7 8 9 10 11

SIMATIC S7 Date: 27.12.20 Information and Training Center

Knowledge for Automation

Siemens AG 1999. All rights reserved. File: SYH_08E.9

Binary Logic Operations: AND, OR

Circuit Diag. LAD FBD STL

S1 (I 0.0)

I0.0 I0.1 Q 8.0 I 0.0 & Q 8.0 A I0.0

= A I0.1

AND S2 (I 0.1) I 0.1

= Q 8.0

Q 8.1 Q 8.1 = Q 8.1

=

L1 L2

(Q 8.0) (Q 8.1)

S3

(I 0.2) I0.2 Q 8.2

Q 8.2 O I0.2

S4 I 0.2 >=1

OR = O I0.3

(I 0.3) I 0.3 = Q 8.2

I0.3

L3 (Q 8.2)

SIMATIC S7 Date: 27.12.20 Information and Training Center

Knowledge for Automation

Siemens AG 1999. All rights reserved. File: SYH_08E.10

Binary Logic Operations: Exclusive OR (XOR)

LAD FBD STL

I 0.4 & A I0.4

I0.4 I0.5 Q 8.0 Q 8.0 AN I0.5

I 0.5 >=1

= O

AN I0.4

I 0.4 & A I0.5

I0.4 I0.5 I 0.5 = Q8.0

Q 8.0 X I0.4

I 0.4 XOR X I0.5

=

I 0.5 = Q8.0

SIMATIC S7 Date: 27.12.20 Information and Training Center

Knowledge for Automation

Siemens AG 1999. All rights reserved. File: SYH_08E.11

Result of Logic Operation, First Check. Examples

Example 1 Example 2 Example 3

Result of Check

Result of Check

Result of Check

Result of Logic

Result of Logic

Result of Logic

Signal State

Signal State

Signal State

First Check

First Check

First Check

Operation

Operation

Operation

A I 1.0 0 1 1

AN I 1.1 0 1 0

A M 4.0 0 1 1

= Q 8.0

= Q 8.1

A I 2.0 0 1 0

SIMATIC S7 Date: 27.12.20 Information and Training Center

Knowledge for Automation

Siemens AG 1999. All rights reserved. File: SYH_08E.12

Assignment, Setting, Resetting

LAD FBD STL

I 1.0 I 1.1

Q 8.0 A I 1.0

I 1.0 & A I 1.1

Assignment ( ) Q 8.0

= Q 8.0

I 1.1 =

I 1.2 I 1.3

Q 8.1 I 1.2 A I 1.2

& Q 8.1

Set (S ) A I 1.3

I 1.3 S S Q 8.1

I 1.4 Q 8.1

(R) I 1.4 O I 1.4

>=1 Q 8.1 O I 1.5

Reset I 1.5 R R Q 8.1

I 1.5

SIMATIC S7 Date: 27.12.20 Information and Training Center

Knowledge for Automation

Siemens AG 1999. All rights reserved. File: SYH_08E.13

Setting / Resetting a Flip Flop

LAD FBD STL

M0.0 M0.0

I1.2 Q 9.3 A I 1.2

SR SR S M 0.0

Dominant S Q I1.2 S

Reset A I 1.3

Q9.3 R M 0.0

I1.3

R = A M 0.0

R I1.3 Q

= Q 9.3

M0.0 M0.0

I1.3 Q 9.3 A I 1.3

Dominant RS RS R M 0.0

R Q I1.3 R

Set A I 1.2

Q9.3 S M 0.0

I1.2

= A M 0.0

S I1.2 S Q

= Q 9.3

SIMATIC S7 Date: 27.12.20 Information and Training Center

Knowledge for Automation

Siemens AG 1999. All rights reserved. File: SYH_08E.14

Connector

LAD STL

I 1.0 I 1.1 M0.0 I 2.0 I 2.1 M 1.1 Q 4.0

( ) NOT ( ) ( ) A I 1.0

A I 1.1

= M 0.0

A M 0.0

FBD A I 2.0

A I 2.1

NOT

I 1.0 & = M 1.1

M0.0

A M 1.1

I 1.1 &

= Q 4.0

I 2.0 M1.1 Q 4.0

I 2.1 =

SIMATIC S7 Date: 27.12.20 Information and Training Center

Knowledge for Automation

Siemens AG 1999. All rights reserved. File: SYH_08E.15

Instructions, that Affect the RLO

LAD FBD STL

A I0.0

I0.0 I0.1

Q8.0 I0.0 & A I0.1

NOT Q8.0

NOT ( ) I0.1 = NOT

= Q8.0

CLR not available not available CLR

SET not available not available SET

I1.6 A I1.6

SAVE ( SAVE ) I1.6 & SAVE SAVE

BR Q8.1 Q8.1 A BR

BR ( ) BR = = Q 8.1

15 8 1

Status word

BR RLO

SIMATIC S7 Date: 27.12.20 Information and Training Center

Knowledge for Automation

Siemens AG 1999. All rights reserved. File: SYH_08E.16

Master Control Relay Function

LAD FBD STL

( MCRA ) MCRA MCRA // Activated

I0.0

A I0.0 // Enable MCR

( MCR< ) A0.0 & MCR<

MCR( // Open MCR

I0.7 Q8.5 Q8.5

( ) A I0.7 // NO Contact

A0.7 & =

= Q8.5 // Output Coil

M0.6 M0.6

= M0.6 // Output Coil

( ) =

Q16.0 Q16.0 A I0.4 // NO Contact

I0.4

(S) A0.4 & S S Q16.0 // Set Output

( MCR> ) MCR> )MCR // Close MCR

M69.0 AN M5.5 // Emerg.Contact

M5.5 I4.7 M5.5 M69.0

( ) & AN I4.7 // Emerg.Contact

I4.7 =

= M69.0 // Output Coil

( MCRD ) MCRD

MCRD // Deactivate

SIMATIC S7 Date: 27.12.20 Information and Training Center

Knowledge for Automation

Siemens AG 1999. All rights reserved. File: SYH_08E.17

Unconditional Jump (Independent of RLO)

LAD FBD STL

Network 1 Network 1 Network 1

NEW1 NEW1

( JMP ) .... JMP JU NEW1

Network 2 Network 2 Network 2

: : :

: : :

: : :

: : :

Network x Network x Network x

NEW1 NEW1

M69.0 NEW1: AN M5.5

M5.5 I4.7 M5.5 & M69.0 AN I4.7

( ) =

I 4.7 = M69.0

SIMATIC S7 Date: 27.12.20 Information and Training Center

Knowledge for Automation

Siemens AG 1999. All rights reserved. File: SYH_08E.18

Conditional Jump (Dependent on RLO)

LAD FBD STL

I 0.0 I 0.1 NEW1 I0.0 & A I0.0

Jump if NEW1 A I0.1

RLO=1 (JMP) I0.1 JMP JC NEW1

Jump if I 0.2 I 0.3 I0.2 & A I0.2

NEW2 NEW2

RLO=0 A I0.3

(JMPN) I0.3 JMPN JCN NEW2

SIMATIC S7 Date: 27.12.20 Information and Training Center

Knowledge for Automation

Siemens AG 1999. All rights reserved. File: SYH_08E.19

RLO - Edge Detection

LAD FBD STL

A I1.0

I1.0 I1.1 M1.0 M8.0 I1.0 &

M1.0 M8.0 A I1.1

P FP M1.0

I1.1 P = = M8.0

I1.0 I1.1 M1.1 M8.1 I1.0 A I 1.0

& M8.1 A I 1.1

M1.1

N FN M1.1

I1.1 N = = M8.1

OB1-Cycle

I1.0

I1.1

RLO

Example

M1.0

M1.1

M8.0

M8.1

SIMATIC S7 Date: 27.12.20 Information and Training Center

Knowledge for Automation

Siemens AG 1999. All rights reserved. File: SYH_08E.20

Signal - Edge Detection

LAD FBD STL

I1.1 I1.0 & A I1.0

I1.0 M8.0 I1.1 A (

POS POS M8.0 A I1.1

Q

M1.0 M_BIT = FP

M1.0 M_BIT M1.0

)

I1.1 =

I1.0 I1.0 &

M8.1 I1.1 M8.0

NEG A I1.0

Q NEG M8.1

A (

M1.1 M_BIT M1.1 M_BIT = A I1.1

FN

M1.1

I1.0 )

=

I1.1 M8.1

Example M1.0

M1.1

OB1-Cycle

M8.0

M8.1

SIMATIC S7 Date: 27.12.20 Information and Training Center

Knowledge for Automation

Siemens AG 1999. All rights reserved. File: SYH_08E.21

Exercise: Program for a Bottling Plant (Mode Selection)

Plant ON/OFF: Manual/Automatic mode:

I 0.0 = Start (Mom.-cont. switch with NO function) I 0.4 = Manual/Automatic (Switch)

I 0.1 = Stop (Mom.-cont. switch with NC function) I 0.5 = Adopt mode (Momentary-

contact switch, NO function)

I 0.2 = Jog forward (M-C sw., NO funct.)

I 0.3 = Jog backward (M-C sw., NO func.)

Bottle

sensor

I 16.6 (I 8.6)

M

Q 20.5 (Q 8.5) Conveyor forwards

Q 20.6 (Q 8.6) Conveyor backwards

SIMATIC S7 Date: 27.12.20 Information and Training Center

Knowledge for Automation

Siemens AG 1999. All rights reserved. File: SYH_08E.22

You might also like

- PLC Programming from Novice to Professional: Learn PLC Programming with Training VideosFrom EverandPLC Programming from Novice to Professional: Learn PLC Programming with Training VideosRating: 5 out of 5 stars5/5 (1)

- 26 Rules To Becoming A Successful SpeakerDocument46 pages26 Rules To Becoming A Successful SpeakerSpeakerMatch100% (23)

- Adobe Premiere Pro Help - Keyboard Shortcuts in Premiere Pro CC PDFDocument11 pagesAdobe Premiere Pro Help - Keyboard Shortcuts in Premiere Pro CC PDFMunna TeronNo ratings yet

- r121 Auto Cash App ErdDocument2 pagesr121 Auto Cash App ErdLam TranNo ratings yet

- Parts of The Microscope Quiz PDFDocument2 pagesParts of The Microscope Quiz PDFEnriele De GuzmanNo ratings yet

- Using Electronic Signatures PDFDocument58 pagesUsing Electronic Signatures PDFmhaioocNo ratings yet

- Typical ScheduleDocument14 pagesTypical Schedulereghouache100% (1)

- On The Potential and Limits of (Global) Justice Through Law. A Frame of Research. Gianluigi PalombellaDocument12 pagesOn The Potential and Limits of (Global) Justice Through Law. A Frame of Research. Gianluigi Palombellaben zilethNo ratings yet

- Data Analysis Using Lichtman's 3 C'sDocument2 pagesData Analysis Using Lichtman's 3 C'sLyka Yusay60% (5)

- 8259 Programmable ControllerDocument44 pages8259 Programmable ControllerShilpa ShettyNo ratings yet

- SCE en 030-020 R1209 Timers and CountersDocument41 pagesSCE en 030-020 R1209 Timers and CountersYoga AdiNo ratings yet

- MotoSimEG-VRC Us PDFDocument816 pagesMotoSimEG-VRC Us PDFRafael SchroerNo ratings yet

- Semi-Detailed Lesson Plan in TLE VIDocument3 pagesSemi-Detailed Lesson Plan in TLE VIPepper Santiago100% (5)

- Training Devices and Addressing ......................................................................... 1-2Document9 pagesTraining Devices and Addressing ......................................................................... 1-2Haddou50% (2)

- Zhong-Lin Lu, Barbara Dosher-Visual Psychophysics - From Laboratory To Theory-The MIT Press (2013)Document465 pagesZhong-Lin Lu, Barbara Dosher-Visual Psychophysics - From Laboratory To Theory-The MIT Press (2013)IrinaNo ratings yet

- Using SQL PDFDocument70 pagesUsing SQL PDFmhaioocNo ratings yet

- Digital Operations: CMP IDocument34 pagesDigital Operations: CMP INeagoe CristianNo ratings yet

- PRO1 08E Digital OperationsDocument29 pagesPRO1 08E Digital OperationsLộc QuangNo ratings yet

- MTRX Unit4 PLCDocument51 pagesMTRX Unit4 PLCprasadpalkarNo ratings yet

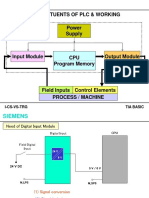

- Constituents of PLC & Working PLC: I-Cs-Vs-Trg Tia BasicDocument31 pagesConstituents of PLC & Working PLC: I-Cs-Vs-Trg Tia BasicSoma ChakravortyNo ratings yet

- SERV1 09e BinaryOpDocument21 pagesSERV1 09e BinaryOpNeagoe CristianNo ratings yet

- 7 Binary OperationsDocument23 pages7 Binary Operationshaftu gideyNo ratings yet

- HW 8 Abdullateef JoqaDocument3 pagesHW 8 Abdullateef JoqadennisNo ratings yet

- Binder 1Document4 pagesBinder 1iieeianNo ratings yet

- Twincat eDocument26 pagesTwincat ecristiNo ratings yet

- Training Devices and Addressing ......................................................................... 1-2Document12 pagesTraining Devices and Addressing ......................................................................... 1-2Julian David Arevalo GarciaNo ratings yet

- Bai Tap 1-12Document16 pagesBai Tap 1-12hoiphiho2No ratings yet

- 15 - Function Block and Organisation BlockDocument14 pages15 - Function Block and Organisation Blockmohamed.these2023No ratings yet

- Shorting WeightDocument6 pagesShorting WeightUgur AkgünNo ratings yet

- ESE R&A Lab Group-IDocument6 pagesESE R&A Lab Group-IAbdul Haseeb KhanNo ratings yet

- PRO1 07E Binary OperationsDocument20 pagesPRO1 07E Binary OperationshwhhadiNo ratings yet

- Nov Dec 2018Document2 pagesNov Dec 2018pecoxor808No ratings yet

- P115Document9 pagesP115ridho kusumaNo ratings yet

- Department of Electrical EngineeringDocument12 pagesDepartment of Electrical EngineeringMohd Shahrul EffendiNo ratings yet

- ASIC Alvarez Valverde ReportDocument17 pagesASIC Alvarez Valverde ReportJuan VALVERDENo ratings yet

- OB1 - : Name Data Type Address CommentDocument3 pagesOB1 - : Name Data Type Address CommentCaleb Sant AnnaNo ratings yet

- Een23 (Exp 1) - Rojas, Emmanuel A - Bsee IV GiDocument12 pagesEen23 (Exp 1) - Rojas, Emmanuel A - Bsee IV GiRojas EmmanNo ratings yet

- 11 Organization Blocks - R01Document15 pages11 Organization Blocks - R01thaibkproNo ratings yet

- System Overview: Simatic HmiDocument16 pagesSystem Overview: Simatic HmiNTNo ratings yet

- 04 Editing Blocks - R01Document27 pages04 Editing Blocks - R01thaibkproNo ratings yet

- PLC Programming and ApplicationsDocument8 pagesPLC Programming and ApplicationsLarva cartoon tvNo ratings yet

- PLC Basic 3Document11 pagesPLC Basic 3Rajdeep SikdarNo ratings yet

- IE LAB 8 HamzaDocument7 pagesIE LAB 8 HamzaHamza BilgramiNo ratings yet

- Project Objective: User Module Project - OneshotDocument6 pagesProject Objective: User Module Project - OneshotJorge Rodríguez EsquivelNo ratings yet

- MultiControl Supplement en V3.1Document152 pagesMultiControl Supplement en V3.1LeonetteNo ratings yet

- Applications Examples: Transistor AnalysisDocument5 pagesApplications Examples: Transistor Analysisمحمد الساعديNo ratings yet

- Zigbee Based Speed ControlDocument68 pagesZigbee Based Speed Controlbvkarthik2711No ratings yet

- EN MultiControl Supplement OnlineDocument136 pagesEN MultiControl Supplement OnlineDavid TorresNo ratings yet

- Micom P741: Numerical Busbar ProtectionDocument36 pagesMicom P741: Numerical Busbar ProtectionDũng Đinh TiếnNo ratings yet

- Shorting StationDocument6 pagesShorting StationUgur AkgünNo ratings yet

- Program Blocks and Program Editor ................................................................... 6-2Document31 pagesProgram Blocks and Program Editor ................................................................... 6-2MiguelGonzalezNo ratings yet

- 6-TIA MICRO1 06E ProgBlockEditorDocument35 pages6-TIA MICRO1 06E ProgBlockEditorFernando LeonNo ratings yet

- Chapter-1 Introduction To PLC: Types of PLC Avialable in MarketDocument50 pagesChapter-1 Introduction To PLC: Types of PLC Avialable in MarketSarikaNo ratings yet

- Presentation IrfanDocument32 pagesPresentation IrfanirfanmaoNo ratings yet

- Microprocessors and Microcontrollers: Instructor Name: Prof. Santanu Chattopadhyay Institute: IIT KharagpurDocument1 pageMicroprocessors and Microcontrollers: Instructor Name: Prof. Santanu Chattopadhyay Institute: IIT KharagpurAnkur Agarwal100% (1)

- Micro-Control 8 0: Advance Microprocessor - 8051 Prof. Utkal MehtaDocument85 pagesMicro-Control 8 0: Advance Microprocessor - 8051 Prof. Utkal Mehtashashank_shankNo ratings yet

- Micom P741: Numerical Busbar ProtectionDocument32 pagesMicom P741: Numerical Busbar ProtectionDũng Đinh TiếnNo ratings yet

- Sepk Lab7Document14 pagesSepk Lab7ritikgbmrcNo ratings yet

- TIA MICRO1 10E Connecting HMI KTP600Document23 pagesTIA MICRO1 10E Connecting HMI KTP600gsrNo ratings yet

- Microcontroller Lab - RB - For CirculationDocument36 pagesMicrocontroller Lab - RB - For Circulationpanave3104No ratings yet

- Ew 2008 2Document10 pagesEw 2008 2Recep IvedikNo ratings yet

- s7 200 WiringDocument8 pagess7 200 WiringAndrewNo ratings yet

- OB1 - : Name: Family: Author: Block Version: Time Stamp Code: Interface: Lengths (Block/logic/data)Document2 pagesOB1 - : Name: Family: Author: Block Version: Time Stamp Code: Interface: Lengths (Block/logic/data)akita 25No ratings yet

- Microcontroller Lab - RB - For CirculationDocument36 pagesMicrocontroller Lab - RB - For Circulationpanave3104No ratings yet

- Mohamed 2016Document38 pagesMohamed 2016Usha KrishnaNo ratings yet

- Nov - Decdd - 2022 AaaaaaaaaaaaaaaDocument2 pagesNov - Decdd - 2022 Aaaaaaaaaaaaaaapecoxor808No ratings yet

- Input Capture Mode PIC32Document24 pagesInput Capture Mode PIC32Oscar Mauricio Gomez JaimesNo ratings yet

- Location: Station - 07 / 3 Feeder Name 2. Name Plate DetailsDocument2 pagesLocation: Station - 07 / 3 Feeder Name 2. Name Plate DetailsSubramaniam NPNo ratings yet

- gb1 MergedDocument7 pagesgb1 MergedNyx Phoebe WPNo ratings yet

- Series D61: Directional Control ValvesDocument16 pagesSeries D61: Directional Control ValvesmhaioocNo ratings yet

- Masterlogic Programmable Logic Controller: Key FeaturesDocument4 pagesMasterlogic Programmable Logic Controller: Key FeaturesmhaioocNo ratings yet

- 2/2-Way Solenoid Valve Servo Operated For High PressureDocument3 pages2/2-Way Solenoid Valve Servo Operated For High PressuremhaioocNo ratings yet

- اصطلاحات دکل حفاري PDFDocument23 pagesاصطلاحات دکل حفاري PDFmhaioocNo ratings yet

- Easytrak: Technical SpecificationDocument7 pagesEasytrak: Technical SpecificationmhaioocNo ratings yet

- Manual: Functional SafetyDocument24 pagesManual: Functional SafetymhaioocNo ratings yet

- Deltav Virtualization: Course# 7029 (Ceus: 3.2)Document1 pageDeltav Virtualization: Course# 7029 (Ceus: 3.2)mhaioocNo ratings yet

- Implementing Security 3.0Document113 pagesImplementing Security 3.0mhaioocNo ratings yet

- Using VisiconXDocument172 pagesUsing VisiconXmhaioocNo ratings yet

- Development Modification Phase(s) : Unit/Train: Discipline: INSTRUMENTATION System No.: Subsystem No.Document4 pagesDevelopment Modification Phase(s) : Unit/Train: Discipline: INSTRUMENTATION System No.: Subsystem No.mhaioocNo ratings yet

- Instruction Manual: 1. MarkingDocument4 pagesInstruction Manual: 1. MarkingmhaioocNo ratings yet

- Trending Historical DataDocument134 pagesTrending Historical DatamhaioocNo ratings yet

- Driver Server HelpDocument16 pagesDriver Server HelpmhaioocNo ratings yet

- Proficy HMI/SCADA - iFIX: U I Fix P PDocument24 pagesProficy HMI/SCADA - iFIX: U I Fix P PmhaioocNo ratings yet

- Implementing SecurityDocument126 pagesImplementing SecuritymhaioocNo ratings yet

- OPC Client DriverDocument166 pagesOPC Client DrivermhaioocNo ratings yet

- Upgrading To Ifix 5.0: Installing The Hardware KeyDocument9 pagesUpgrading To Ifix 5.0: Installing The Hardware KeymhaioocNo ratings yet

- Proficy HMI/SCADA - iFIX: M F FIX32 IfixDocument54 pagesProficy HMI/SCADA - iFIX: M F FIX32 IfixmhaioocNo ratings yet

- iFIX GlossaryDocument104 pagesiFIX GlossarymhaioocNo ratings yet

- The SIMATIC ManagerDocument19 pagesThe SIMATIC ManagermhaioocNo ratings yet

- Digital Operations: CMP IDocument28 pagesDigital Operations: CMP ImhaioocNo ratings yet

- Symbols: Simatic S7Document14 pagesSymbols: Simatic S7mhaioocNo ratings yet

- Entrepreneurship 1 Burt S BeesDocument5 pagesEntrepreneurship 1 Burt S BeesAly BhamaniNo ratings yet

- Reviewer in Math 8Document13 pagesReviewer in Math 8Cañeda AlejanioNo ratings yet

- Sketched Symbol Recognition Using Zernike MomentsDocument11 pagesSketched Symbol Recognition Using Zernike MomentsmailforspamNo ratings yet

- Sun Safety PresentationDocument14 pagesSun Safety Presentationrichard_mikealNo ratings yet

- Junior High School University of Santo Tomas: G7 EnglishDocument1 pageJunior High School University of Santo Tomas: G7 EnglishRAINIER AMIR ABELANo ratings yet

- Lecture 1 EntrepreneurshipDocument35 pagesLecture 1 EntrepreneurshipNipul BafnaNo ratings yet

- Loquendo TTS User GuideDocument73 pagesLoquendo TTS User GuideNakedCityNo ratings yet

- Crüe, Chatting Done CorrectlyDocument7 pagesCrüe, Chatting Done Correctlyctjw.financeNo ratings yet

- Bhabha Atomic Research Centre BARC, MysuruDocument2 pagesBhabha Atomic Research Centre BARC, Mysururajesh kumarNo ratings yet

- Patterns of Economic Continuity and Change in Early Hafsid Ifriqiya - Kabra Patricia - 2Document366 pagesPatterns of Economic Continuity and Change in Early Hafsid Ifriqiya - Kabra Patricia - 2Mohammed sabeelNo ratings yet

- Course Outline BA301-2Document4 pagesCourse Outline BA301-2drugs_182No ratings yet

- MOP QuizDocument2 pagesMOP QuizJude MagbanuaNo ratings yet

- PLC & HMI Interfacing For AC Servo Drive: Naveen Kumar E T.V.Snehaprabha Senthil KumarDocument5 pagesPLC & HMI Interfacing For AC Servo Drive: Naveen Kumar E T.V.Snehaprabha Senthil KumarNay Ba LaNo ratings yet

- Unit N°1: Institucion Educativa Politécnico de Soledad English 10ThDocument3 pagesUnit N°1: Institucion Educativa Politécnico de Soledad English 10ThMaria EscolarNo ratings yet

- 03 Task Performance 1 - ARG - MMW - RelevoDocument4 pages03 Task Performance 1 - ARG - MMW - Relevocessarine relevoNo ratings yet

- Bcpp6e TB Ch01Document32 pagesBcpp6e TB Ch01tnguyen194No ratings yet

- Significance Testing (T-Tests)Document3 pagesSignificance Testing (T-Tests)Madison HartfieldNo ratings yet

- Revolutionize Your Business With The Industrial Internet of Things (IIoT)Document16 pagesRevolutionize Your Business With The Industrial Internet of Things (IIoT)Sarah Walker100% (1)

- Medical AssistantDocument2 pagesMedical Assistantapi-78670766No ratings yet

- Toefl PBTDocument3 pagesToefl PBTLuis Fernando Morales100% (1)