Professional Documents

Culture Documents

Process of Streptomycin

Uploaded by

rad0 ratings0% found this document useful (0 votes)

25 views6 pagesThe fermentation process for producing Streptomycin involves inoculating spores into a growth medium to establish a culture. The culture is then introduced into a production vessel under conditions of high aeration and agitation at a temperature of 25-30°C and pH of 7-8. The process involves 3 phases - an initial growth phase with little antibiotic production, a production phase where glucose is added and consumed, and a final phase where production ceases as nutrients are depleted. The mycelium is separated and Streptomycin is recovered through filtration, acidification, neutralization, and purification using cation exchange resin and precipitation.

Original Description:

Original Title

PROCESS OF STREPTOMYCIN

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe fermentation process for producing Streptomycin involves inoculating spores into a growth medium to establish a culture. The culture is then introduced into a production vessel under conditions of high aeration and agitation at a temperature of 25-30°C and pH of 7-8. The process involves 3 phases - an initial growth phase with little antibiotic production, a production phase where glucose is added and consumed, and a final phase where production ceases as nutrients are depleted. The mycelium is separated and Streptomycin is recovered through filtration, acidification, neutralization, and purification using cation exchange resin and precipitation.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

25 views6 pagesProcess of Streptomycin

Uploaded by

radThe fermentation process for producing Streptomycin involves inoculating spores into a growth medium to establish a culture. The culture is then introduced into a production vessel under conditions of high aeration and agitation at a temperature of 25-30°C and pH of 7-8. The process involves 3 phases - an initial growth phase with little antibiotic production, a production phase where glucose is added and consumed, and a final phase where production ceases as nutrients are depleted. The mycelium is separated and Streptomycin is recovered through filtration, acidification, neutralization, and purification using cation exchange resin and precipitation.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 6

FERMENTATION

PROCESS

• Spores of S.griseus are inoculated into a medium to establish a culture

with high mycelial biomass for introduction into inoculum tank using,

using inoculum to initiate the fermentation process.

• Yield in production vessel responds to high aeration and agitation

conditions. Other condition involve:

Temperature range 25°C – 30°C

pH range 7-8

Time: 5-7 days

• The fermentation process for production of Streptomycin involves 3

phases

PHASE 1

• Initial fermentation phase and there is little production of streptomycin.

• Rapid growth with production of mycelial biomass.

• Proteolytic enzymatic activity of S.griseus releases NH 3 from soya meal, raising the pH to

7.5.

• Characterised by release of ammonia.

• Carbon nutrients of soya meal are utilized by growth.

• Glucose is slowly utilized with slight production of Streptomycin.

PHASE 2

• Little production of mycelia.

• Glucose added to the medium & the NH3

Released from soya meal are consumed

• pH remains fairly constant ranging

• Between 7.6 to 8.

PHASE 3

• Final phase of fermentation.

• Depletion of carbohydrates from medium.

• Streptomycin production ceases & bacterial cells begin to lose.

• Ammonia from laser cells increase the pH.

RECOVERY & PURIFICATION

• Mycelium is separated from broth by filtration & streptomycin is

recovered.

• Recover process – broth is acidified, filtered & neutralised. Then its

subjected to column containing cation exchange resin to adsorb

Streptomycin from the broth & column is washed with water &

Streptomycin eluted with HCl before concentration in vacuo almost to

dryness.

RECOVERY & PURIFICATION

• The Streptomycin is dissolved in methanol % filtered.

• Acetone is used in filterate to precipitate the antibiotic.

• Percipitate is washed with acetone & dried in vacuo.

• Purification is done by dissolving in methanol to form S.chloride

complex. Further by, adsorbing it onto activated charcoal & eluding

with acid alcohol.

You might also like

- Soy Sauce ProductionDocument25 pagesSoy Sauce ProductionIndah Riwayati100% (1)

- Plant and Animal Bio-Chemistry - Including Information on Amino Acids, Proteins, Pigments and Other Chemical Constituents of Organic MatterFrom EverandPlant and Animal Bio-Chemistry - Including Information on Amino Acids, Proteins, Pigments and Other Chemical Constituents of Organic MatterNo ratings yet

- 2.2 FED BATCH & Continuous Fermentation IIDocument36 pages2.2 FED BATCH & Continuous Fermentation IINixon Da Piedade CoutinhoNo ratings yet

- Production of AntibioticsDocument30 pagesProduction of AntibioticsRajesh Sharma100% (3)

- New Mic254 Lab Report Exp 1 PDFDocument13 pagesNew Mic254 Lab Report Exp 1 PDFNUR SABRINA MOHD SHAH100% (1)

- Biochemical Tests For Identification of Bacteria PDFDocument30 pagesBiochemical Tests For Identification of Bacteria PDFEmber BahianNo ratings yet

- Streptomycin ProductionDocument10 pagesStreptomycin ProductionVishnu Sai MokshagnaNo ratings yet

- Production of Antibiotics by FermentationDocument32 pagesProduction of Antibiotics by FermentationAneeqa OumarNo ratings yet

- Marin Maged 187Document12 pagesMarin Maged 187Marin MagedNo ratings yet

- Streptomycin Productionstreptomycin and VariousDocument2 pagesStreptomycin Productionstreptomycin and VariousHarsha VaniNo ratings yet

- Vitamin B12,: Denitrificans and Propionibacterium Shermanii Are More Commonly Used TodayDocument6 pagesVitamin B12,: Denitrificans and Propionibacterium Shermanii Are More Commonly Used TodayShehan TharukaNo ratings yet

- Contamination, Preservation and Spoilage of Milk andDocument16 pagesContamination, Preservation and Spoilage of Milk andAbu Al FarabiNo ratings yet

- ReportDocument17 pagesReportHafiniHambaliNo ratings yet

- 17-Chapter Manuscript-477-1-10-20200501Document14 pages17-Chapter Manuscript-477-1-10-20200501nikhilkapoor1999No ratings yet

- Fermentation TechnologyDocument14 pagesFermentation TechnologyUmarNo ratings yet

- Fermenting Rice and WineDocument5 pagesFermenting Rice and WineThanh VânNo ratings yet

- Enzyme Final ExamDocument16 pagesEnzyme Final ExamThuy AnhNo ratings yet

- Antigen Preparation Form BacteriaDocument17 pagesAntigen Preparation Form BacteriaProvince Public Health Laboratory JanakpurNo ratings yet

- AntibioticsDocument20 pagesAntibioticsFazal AminNo ratings yet

- Lab 1 Mic254 PDFDocument12 pagesLab 1 Mic254 PDFNADIA YASMIN MOHD ZAKINo ratings yet

- Diya Patidar Bio Process PresentationDocument7 pagesDiya Patidar Bio Process PresentationDiya PatidarNo ratings yet

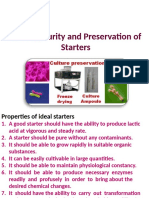

- Activity and Purity of StarterDocument22 pagesActivity and Purity of StarterRohit PandeyNo ratings yet

- Isolation, Preservation & Maintenance of Pure CultureDocument37 pagesIsolation, Preservation & Maintenance of Pure CultureShardul DalviNo ratings yet

- Microbiology and Parasitology PremidDocument7 pagesMicrobiology and Parasitology PremidRasheena Alaja JainalNo ratings yet

- Laboratory 1: Media, Culture & StainingDocument26 pagesLaboratory 1: Media, Culture & StainingSirine AjourNo ratings yet

- Biochemical Reactions MicroDocument24 pagesBiochemical Reactions MicropraneethasruthiNo ratings yet

- Detection of E - 3BOaRnPSfLDocument20 pagesDetection of E - 3BOaRnPSfLabdolu531No ratings yet

- Experiment - 1Document35 pagesExperiment - 1Sumanta KarNo ratings yet

- Secondary MetabolitesDocument22 pagesSecondary MetabolitesStephen MooreNo ratings yet

- ANTIBIOTICS PenicillinDocument17 pagesANTIBIOTICS PenicillinDitto V DavisNo ratings yet

- Phytase EnzymeDocument5 pagesPhytase EnzymeHussain TaqiNo ratings yet

- Isolationandpreservation of MoDocument31 pagesIsolationandpreservation of MopraneethasruthiNo ratings yet

- Pure Culture TechniquesDocument33 pagesPure Culture TechniquesRamachari K VNo ratings yet

- Bacterial Examination of CurdDocument2 pagesBacterial Examination of CurdSampoorna DeyNo ratings yet

- BCH4323 Industrial BiochemistryDocument35 pagesBCH4323 Industrial BiochemistryMusa AbubakarNo ratings yet

- Lect6 (Inoculum Preparation and Development) PDFDocument86 pagesLect6 (Inoculum Preparation and Development) PDFmmoradi55100% (5)

- Isolation Screening PDFDocument23 pagesIsolation Screening PDFMass ManiNo ratings yet

- Pembacaan Hasil Media Cair (1) - DikonversiDocument35 pagesPembacaan Hasil Media Cair (1) - Dikonversitutu totoNo ratings yet

- LJ MediaDocument3 pagesLJ MediaJerry ThompsonNo ratings yet

- Production of Cheese by Eric BioDocument15 pagesProduction of Cheese by Eric BioNkosinathiNo ratings yet

- Fundamental Principles of MicrobiologyDocument50 pagesFundamental Principles of MicrobiologySONAL SHARMANo ratings yet

- Chemistry ProjectDocument20 pagesChemistry ProjectVigneshNo ratings yet

- Inoculum BestDocument6 pagesInoculum BestSabarishNo ratings yet

- Singlecellprotein 120507100927 Phpapp01Document31 pagesSinglecellprotein 120507100927 Phpapp01GSNo ratings yet

- Experiment No 1Document3 pagesExperiment No 1Kristin Denis CorveraNo ratings yet

- Siwes Report SlideDocument12 pagesSiwes Report SlideAkintade TimothyNo ratings yet

- Ethanol Production by Wine FermentationDocument6 pagesEthanol Production by Wine FermentationSabyasachi DasguptaNo ratings yet

- 5.2 Bacterial ClassificationDocument11 pages5.2 Bacterial ClassificationSaleh AzizNo ratings yet

- Week 14 Industrial MicrobiologyDocument44 pagesWeek 14 Industrial MicrobiologyHerwanto ChrisTopel ManullangNo ratings yet

- Acetone-Butanol Fermentation Introduction, Chemical Structure, Process and UsesDocument1 pageAcetone-Butanol Fermentation Introduction, Chemical Structure, Process and Usessiti suzanaNo ratings yet

- Plant Tissue CultureDocument40 pagesPlant Tissue CultureSathish SizzyNo ratings yet

- Enzymes: M.Sc. Biotechnology Part II (Sem III) Paper III - Unit III Mumbai University By: Mayur D. ChauhanDocument61 pagesEnzymes: M.Sc. Biotechnology Part II (Sem III) Paper III - Unit III Mumbai University By: Mayur D. ChauhanAkshitaNo ratings yet

- Isolate Storag Packaging and TransportationDocument31 pagesIsolate Storag Packaging and TransportationkomalqadriNo ratings yet

- Alcohol ProductionDocument11 pagesAlcohol ProductionRabwa RazakNo ratings yet

- Tech SeminarDocument11 pagesTech SeminarNandhini SaranathanNo ratings yet

- MaltingDocument20 pagesMaltingSagar ShahNo ratings yet

- Mushroom CompostDocument17 pagesMushroom CompostAlirazaNo ratings yet

- L Lysine Production 1Document10 pagesL Lysine Production 1Löwänshï ÄtülNo ratings yet

- Conserver ses Aliments grâce à la LactofermentationFrom EverandConserver ses Aliments grâce à la LactofermentationNo ratings yet

- A Review On The Applications of Ultrasonic Technology in Membrane BioreactorsDocument15 pagesA Review On The Applications of Ultrasonic Technology in Membrane BioreactorsradNo ratings yet

- Conventional and Advanced Treatment Technologies For Palm Oil Mill Effluents: A Systematic Literature ReviewDocument20 pagesConventional and Advanced Treatment Technologies For Palm Oil Mill Effluents: A Systematic Literature ReviewradNo ratings yet

- Journal of Environmental Chemical Engineering: SciencedirectDocument16 pagesJournal of Environmental Chemical Engineering: SciencedirectradNo ratings yet

- 2.3.3 Degree of Freedom Recycle: DC1 Ethanol Water Ethanol WaterDocument7 pages2.3.3 Degree of Freedom Recycle: DC1 Ethanol Water Ethanol WaterradNo ratings yet