Professional Documents

Culture Documents

Rise and Fall of Mass Production

Uploaded by

Shreyas Satish0 ratings0% found this document useful (0 votes)

474 views7 pagesOriginal Title

Rise and fall of mass production

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

474 views7 pagesRise and Fall of Mass Production

Uploaded by

Shreyas SatishCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 7

Rise And Fall Of Mass Production

Introduction

•English Parliamentarian Henry Ellis commissioned for a car

from company P & L in Paris in 1894. Back then P & L was

just a machine tool based company which had just started

rolling out automobiles from their facility.

•The company got a jump on other competitors when

Mr.Levassor met Mr.Daimler, who is founder of Mercedes-

Benz. P&L got a licence from merc to manufacture to its

high-speed gasoline engine. The company followed CLASSIC

CRAFT-PRODUCTION system,,where only custom built,

hand assembled, craftmanship oriented cars were produced.

•Mr.Ellis made amendments in British law such that P&L

could produce automobiles running at 9.84 mph

•P&L and Evelyn Ellis are worth remembering, despite

their subsequent failure in future because they together

represent Craftmanship Production

•Panhard and Levassor was soon competing with scores of

companies which had similar production patterns.

•By 1905 Hundreds of companies from Europe and N

America started producing automobiles by craft

techniques and there was tight competition between

automobile companies

•After First World War, auto industry progressed to mass

production. And hundreds of craft production companies

perished. They tried to make a switch to mass production

but only few companies prevailed.

•The earlier companies started focusing on higher end,

luxury models,, and found a market for themselves.

•Best example for this Aston Martin. Over 65 years the

company has produced just 10,000 cars!!

Characteristics of Craft Production:

• Workforce was highly skilled

•Organizations were extremely decentralized

•General Purpose Machine tools used

•Very low production volumes

Causes for Failure of Craft Production

•Cost of cars were very high

•Consistency and reliability low

•Too much dependency on Chauffeurs and Mechanics

•No resources for small independent shops to undertake

R&D

MASS PRODUCTION

•With the entry of Henry Ford into the scenario after first world

war,, General design of cars and trucks with front engine IC

vehicle similar to nowadays vehicles came into production.

•Ford found a way to overcome problems in craft production,

and his technique increased product quality . This innovative

system was called Mass Production

•The key to mass production was Moving or continuous

assembly line along with consistent interchangeability of parts

and ease of fitting sub components.

•Advances in the machine tools and use of pre hardened metals

was instrumental in achieving mass production.

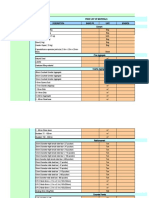

Minutes of Craft Mass Percentage

effort production Production reduction

Engine 594 226 62

Magneto 20 5 75

Axle 150 26.5 83

Components 750 93 88

into the vehicle

Craft Production versus Mass Production

•Henry Ford’s mass production ruled auto industry for

more than half a century

•Every industry in North America and Western Europe

adopted the techniques of mass production.

•The companies are so ingrained with these techniques

that they are finding it tough to move on and

implement Lean manufacturing techniques in their

plant

You might also like

- The Machine That Changed The World: How Lean Production Revolutionized The Global Car WarsDocument16 pagesThe Machine That Changed The World: How Lean Production Revolutionized The Global Car WarsManju DorennavarNo ratings yet

- Mashaweer: January 2021Document6 pagesMashaweer: January 2021Shambel Omar DemirNo ratings yet

- Dem 2010Document138 pagesDem 2010talhamiNo ratings yet

- Ch04 Reducing Complexity Through Standardization and ConsolidationDocument24 pagesCh04 Reducing Complexity Through Standardization and ConsolidationDanang FaisalNo ratings yet

- Industry Profile: Balaguer RollsDocument6 pagesIndustry Profile: Balaguer RollsMilling and Grain magazineNo ratings yet

- Implementation of Waste Assesment Model in Midas SafetyDocument15 pagesImplementation of Waste Assesment Model in Midas Safetytwinkle girlNo ratings yet

- Solar Boat Competition: Karnival Sains Teknologi Dan Alam Sekitar Peringkat Negeri Tahun 2014Document12 pagesSolar Boat Competition: Karnival Sains Teknologi Dan Alam Sekitar Peringkat Negeri Tahun 2014LilianLokeNo ratings yet

- Collaboration ToolsDocument4 pagesCollaboration Toolswemo alharbyNo ratings yet

- Production & Operation Management - General Motor Halol.. (Chevrolet)Document26 pagesProduction & Operation Management - General Motor Halol.. (Chevrolet)jajooabhi100% (9)

- Data For Atlas Honda Shekupura InternshipDocument9 pagesData For Atlas Honda Shekupura InternshipEmziarNo ratings yet

- Tractor Manufacturing Industry Value Chain Analysis: Primary ActivitesDocument2 pagesTractor Manufacturing Industry Value Chain Analysis: Primary ActivitesAni AbiNo ratings yet

- Roller Mill Grinders - Advantages, Limitations and How Roller Mill Grinders Are Changing For The BetterDocument4 pagesRoller Mill Grinders - Advantages, Limitations and How Roller Mill Grinders Are Changing For The BetterMilling and Grain magazineNo ratings yet

- Finalpresentation 140215143643 Phpapp02Document77 pagesFinalpresentation 140215143643 Phpapp02Noman GujjarNo ratings yet

- Seiici Fujita - Kaizen ManagementDocument38 pagesSeiici Fujita - Kaizen ManagementRimura ArkenNo ratings yet

- Nissan Leaf U.S. Marketing PlanDocument13 pagesNissan Leaf U.S. Marketing Planmar74No ratings yet

- MAS24118 SolutionDocument15 pagesMAS24118 SolutionAditiNo ratings yet

- Mid Exam ReviewDocument26 pagesMid Exam Reviewmora0% (1)

- Airvent FansDocument17 pagesAirvent FansPamela ValleNo ratings yet

- Grain SamplingDocument24 pagesGrain SamplingwickedwebNo ratings yet

- Systems For Production Have Existed Since Ancient TimesDocument30 pagesSystems For Production Have Existed Since Ancient TimesSurya PratapNo ratings yet

- Millat Tractor Report On Operational ManagementDocument35 pagesMillat Tractor Report On Operational ManagementSafianTaseerNo ratings yet

- Scooter India TurnaroundDocument15 pagesScooter India TurnaroundVinayak BhardwajNo ratings yet

- Cat CaseDocument3 pagesCat CaseFahad Chowdhury100% (1)

- Naseem FinalDocument13 pagesNaseem FinalimsluckyNo ratings yet

- Forklift Academy of IndiaDocument3 pagesForklift Academy of IndiaZainab08No ratings yet

- CastrolDocument11 pagesCastrolSaurabh AmbaselkarNo ratings yet

- SemiFinals Brief WiRED 4.0 Supply Chain Case Study PDFDocument2 pagesSemiFinals Brief WiRED 4.0 Supply Chain Case Study PDFAnkur GoyalNo ratings yet

- Nanophosphate® High Power Lithium Ion Cell ANR26650M1-B: ApplicationsDocument2 pagesNanophosphate® High Power Lithium Ion Cell ANR26650M1-B: ApplicationsmohsihummerNo ratings yet

- Birla CementDocument76 pagesBirla CementRym Nath100% (1)

- BiofuelsDocument16 pagesBiofuelsRamkrishnaSutharNo ratings yet

- Case Study Analysis of Nuclear Tube Assembly Room (A)Document7 pagesCase Study Analysis of Nuclear Tube Assembly Room (A)Justin HuynhNo ratings yet

- India's Tractors Industry 2014Document32 pagesIndia's Tractors Industry 2014alfonsematNo ratings yet

- Industrial Training Report Anil SainiDocument30 pagesIndustrial Training Report Anil Sainihimanshuvermac3053No ratings yet

- Jaguar Xe PresentationDocument20 pagesJaguar Xe PresentationChi LeNo ratings yet

- PRA Final ReportDocument99 pagesPRA Final ReportAvinash SharmaNo ratings yet

- Mahindra and Mahindra - Swaraj Tractor Division - Project Semester PresentationDocument43 pagesMahindra and Mahindra - Swaraj Tractor Division - Project Semester PresentationHarpreet Randhawa100% (2)

- Presentation On Ambuja LTD - Group 2Document53 pagesPresentation On Ambuja LTD - Group 2Nikita BhattNo ratings yet

- Five ForceDocument28 pagesFive ForceSulogna Kumar PanNo ratings yet

- Industrial Visit ReportDocument6 pagesIndustrial Visit ReportgaureshraoNo ratings yet

- Air DeccanDocument24 pagesAir DeccanJay AkhaniNo ratings yet

- Our Six Specific Objectives: How We're DoingDocument8 pagesOur Six Specific Objectives: How We're Doingking_jsrNo ratings yet

- Abrasive Water Jet MachiningDocument22 pagesAbrasive Water Jet Machiningpraneeth4aNo ratings yet

- MashaweerDocument10 pagesMashaweer4cca276dNo ratings yet

- Design of Fit Between Die and InsertDocument4 pagesDesign of Fit Between Die and InsertInnovative Research PublicationsNo ratings yet

- Suzuki ReportDocument10 pagesSuzuki ReportSaifullahMakenNo ratings yet

- Chap 02Document25 pagesChap 02amatulmateennoorNo ratings yet

- DMM08Document16 pagesDMM08xxxzzzzz0% (1)

- UniliverDocument38 pagesUniliversalmanahmedkhi1No ratings yet

- Atlas Honda ReportDocument26 pagesAtlas Honda ReportQamar TanauliNo ratings yet

- Continuous Casting Investments at USX Corporation: Group 9Document5 pagesContinuous Casting Investments at USX Corporation: Group 9Kartik NarayanaNo ratings yet

- Service ReoveryDocument4 pagesService ReoveryRahul ChaturvediNo ratings yet

- Chapter 8 - How Firms Make Decisions ProfDocument5 pagesChapter 8 - How Firms Make Decisions Profhussnain tararNo ratings yet

- History of AutomobilesDocument3 pagesHistory of AutomobilesBDineshPrabhu100% (1)

- TOYOTA ModelDocument12 pagesTOYOTA ModelNigel LimNo ratings yet

- Chapter 9 Case StudyDocument2 pagesChapter 9 Case StudyJemima LopezNo ratings yet

- Group 8 (Sitara Chemicals)Document24 pagesGroup 8 (Sitara Chemicals)Huda Qureshi Hashmi Qureshi0% (1)

- Introduction To AudiDocument5 pagesIntroduction To AudiRajesh Shah100% (1)

- Fldbee 01Document12 pagesFldbee 01Halim Bessouf100% (2)

- Ford Motors Draft Mubashshara Hussain CB009990@student - Apiit - LKDocument19 pagesFord Motors Draft Mubashshara Hussain CB009990@student - Apiit - LKAndrew StephanNo ratings yet

- General Motors and CaterpillarDocument41 pagesGeneral Motors and CaterpillarAnirban BiswasNo ratings yet

- Baytubes in HNBR BayerDocument12 pagesBaytubes in HNBR Bayerleonel messiNo ratings yet

- LABSHEET 2 Heat Treatment Edit 2Document5 pagesLABSHEET 2 Heat Treatment Edit 2tulasi baskaranNo ratings yet

- CV 20181212Document5 pagesCV 20181212Piyasan PraserthdamNo ratings yet

- 7.5 Metric NPKS (Nafco)Document6 pages7.5 Metric NPKS (Nafco)Nazmul HossainNo ratings yet

- PHD Information Brochure of AY 2022 23 2Document16 pagesPHD Information Brochure of AY 2022 23 2mahendrajadhav007mumbaiNo ratings yet

- Hydration of Blended Cement With High-Volume Slag and Nano-Silica (26.08.2023)Document17 pagesHydration of Blended Cement With High-Volume Slag and Nano-Silica (26.08.2023)Velchuri SairamNo ratings yet

- MOLDDocument22 pagesMOLDyusufj721No ratings yet

- Catalogom2044ts m2048tsDocument4 pagesCatalogom2044ts m2048tsChitMoeNo ratings yet

- Permabond AdhesivesDocument2 pagesPermabond AdhesivesPDDELUCANo ratings yet

- CH 4 The Theory of Production and CostDocument30 pagesCH 4 The Theory of Production and Costserway bookNo ratings yet

- Phase 2 - Thamotharan Project ReportDocument62 pagesPhase 2 - Thamotharan Project ReportThamo TharanNo ratings yet

- Rockwell Catalog1973 74Document18 pagesRockwell Catalog1973 74Roland ErdőhegyiNo ratings yet

- TDS - Wit-Pe 1000Document3 pagesTDS - Wit-Pe 1000kingazure31No ratings yet

- Estimation Pro. BetaDocument259 pagesEstimation Pro. Betaosei kwadwoNo ratings yet

- Construction Schedule - Iloilo Concepcion - Rev 04 - Amuma - 09 07 22Document3 pagesConstruction Schedule - Iloilo Concepcion - Rev 04 - Amuma - 09 07 22JOHN CARLO AZORESNo ratings yet

- Ivoclar Digital EquipmentDocument20 pagesIvoclar Digital EquipmentmiauNo ratings yet

- Steel Grating WeightDocument4 pagesSteel Grating WeightCane CirpoNo ratings yet

- 4 - Thailand 1233Document70 pages4 - Thailand 1233thanhnguyet.vietcraftNo ratings yet

- Astm A875 A875m 2021Document13 pagesAstm A875 A875m 2021OS LaboratoryNo ratings yet

- TVET 1 - Worksheet 7Document2 pagesTVET 1 - Worksheet 7Abrigondo, Vindel J.No ratings yet

- Internship Main Report FormatDocument25 pagesInternship Main Report FormatGoogle BoTNo ratings yet

- Coil To Coil Slitting LinesDocument2 pagesCoil To Coil Slitting LinesPurushottam KumarNo ratings yet

- Tds Novasil S 800 19 - 18gbDocument3 pagesTds Novasil S 800 19 - 18gbLusiNo ratings yet

- Homework 2Document11 pagesHomework 2michaquedasilvaNo ratings yet

- Production of Yarn From PlasticDocument11 pagesProduction of Yarn From PlasticS.R.ANEESHNo ratings yet

- SD NilDocument11 pagesSD Nilpsychoheal118No ratings yet

- Product-Sheet Filter NZB 03 2017Document2 pagesProduct-Sheet Filter NZB 03 2017Nduong NguyenNo ratings yet

- Report - 1 Noquis, John Christian R.Document7 pagesReport - 1 Noquis, John Christian R.jcr noquisNo ratings yet

- CP 636 CatalogueDocument1 pageCP 636 CatalogueMohammed KabiruddinNo ratings yet

- A Case Study of A Sri Lankan ManufacturingDocument11 pagesA Case Study of A Sri Lankan ManufacturingAlex J. Tocto BustamanteNo ratings yet