Professional Documents

Culture Documents

HR Om11 ch06

Uploaded by

anakanakOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HR Om11 ch06

Uploaded by

anakanakCopyright:

Available Formats

Managing Quality

PowerPoint presentation to accompany

6

Heizer and Render

Operations Management, Eleventh Edition

Principles of Operations Management, Ninth Edition

PowerPoint slides by

Dr. Drs. Sunarno Handoyo. SH. SPd. MM

FAKULTAS EKONOMI DAN BISNIS

UNIVERSITAS MURIA KUDUS

© 2014 Pearson Education, Inc. 6-1

Outline

► Global Company Profile:

Arnold Palmer Hospital

► Quality and Strategy

► Defining Quality

► Total Quality Management

► Tools of TQM

► The Role of Inspection

► TQM in Services

© 2014 Pearson Education, Inc. 6-2

Learning Objectives

When you complete this chapter you

should be able to:

1. Define quality and TQM

2. Describe the ISO international quality

standards

3. Explain what Six Sigma is

4. Explain how benchmarking is used in TQM

5. Explain quality robust products and

Taguchi concepts

6. Use the seven tools of TQM

© 2014 Pearson Education, Inc. 6-3

Managing Quality Provides a

Competitive Advantage

Arnold Palmer Hospital

► Deliver over 12,000 babies annually

► Virtually every type of quality tool is

employed

► Continuous improvement

► Employee empowerment

► Benchmarking

► Just-in-time

► Quality tools

© 2014

© 2014

Pearson

Pearson

Education,

Education,

Inc.Inc. 6-4

Quality and Strategy

► Managing quality supports

differentiation, low cost, and

response strategies

► Quality helps firms increase sales

and reduce costs

► Building a quality organization is a

demanding task

© 2014 Pearson Education, Inc. 6-5

Two Ways Quality

Improves Profitability

Figure 6.1

Sales Gains via

• Improved response

• Flexible pricing

• Improved reputation

Improved Increased

Quality Profits

Reduced Costs via

• Increased productivity

• Lower rework and scrap costs

• Lower warranty costs

© 2014 Pearson Education, Inc. 6-6

The Flow of Activities

Organizational Practices

Leadership, Mission statement, Effective operating

procedures, Staff support, Training

Yields: What is important and what is to be

accomplished

Quality Principles

Customer focus, Continuous improvement, Benchmarking,

Just-in-time, Tools of TQM

Yields: How to do what is important and to be

accomplished

Employee Fulfillment

Empowerment, Organizational commitment

Yields: Employee attitudes that can accomplish

what is important

Customer Satisfaction

Winning orders, Repeat customers

Figure 6.2 Yields: An effective organization with

a competitive advantage

© 2014 Pearson Education, Inc. 6-7

Defining Quality

An operations manager’s objective

is to build a total quality

management system that identifies

and satisfies customer needs

© 2014 Pearson Education, Inc. 6-8

Defining Quality

The totality of features and

characteristics of a product or service

that bears on its ability to satisfy stated

or implied needs

American Society for Quality

© 2014 Pearson Education, Inc. 6-9

Different Views

► User-based: better performance,

more features

► Manufacturing-based: conformance

to standards, making it right the first

time

► Product-based: specific and

measurable attributes of the product

© 2014 Pearson Education, Inc. 6 - 10

Implications of Quality

1. Company reputation

► Perception of new products

► Employment practices

► Supplier relations

2. Product liability

► Reduce risk

3. Global implications

► Improved ability to compete

© 2014 Pearson Education, Inc. 6 - 11

Malcolm Baldrige National

Quality Award

► Established in 1988 by the U.S.

government

► Designed to promote TQM practices

► Recent winners include

Lockheed Martin Missiles and Fire Control, MESA

Products Inc., North Mississippi Health Services, City

of Irving, Concordia Publishing House, Henry Ford

Health System, MEDRAD, Nestlé Purina PetCare

Co., Montgomery County Public Schools

© 2014 Pearson Education, Inc. 6 - 12

Baldrige Criteria

Applicants are evaluated on:

CATEGORIES POINTS

Leadership 120

Strategic Planning 85

Customer Focus 85

Measurement, Analysis, and Knowledge 90

Management

Workforce Focus 85

Operations Focus 85

Results 450

© 2014 Pearson Education, Inc. 6 - 13

ISO 9000 International Quality

Standards

► International recognition

► Encourages quality management

procedures, detailed documentation, work

instructions, and recordkeeping

► 2009 revision emphasized sustained

success

► Over one million certifications in 178

countries

► Critical for global business

© 2014 Pearson Education, Inc. 6 - 14

ISO 9000 International Quality

Standards

► Management principles

► Top management leadership

► Customer satisfaction

► Continual improvement

► Involvement of people

► Process analysis

► Use of data-driven decision making

► A systems approach to management

► Mutually beneficial supplier relationships

© 2014 Pearson Education, Inc. 6 - 15

Costs of Quality

► Prevention costs - reducing the

potential for defects

► Appraisal costs - evaluating products,

parts, and services

► Internal failure costs - producing

defective parts or service before

delivery

► External failure costs - defects

discovered after delivery

© 2014 Pearson Education, Inc. 6 - 16

Costs of Quality

Total Total Cost

Cost

External Failure

Internal Failure

Quality Improvement

© 2014 Pearson Education, Inc. 6 - 17

Takumi

A Japanese character

that symbolizes a

broader dimension than

quality, a deeper process

than education, and a

more perfect method

than persistence

© 2014 Pearson Education, Inc. 6 - 18

Leaders in Quality

TABLE 6.1 Leaders in the Field of Quality Management

LEADER PHILOSOPHY/CONTRIBUTION

W. Edwards Deming Deming insisted management accept responsibility for building

good systems. The employee cannot produce products that on

average exceed the quality of what the process is capable of

producing. His 14 points for implementing quality improvement

are presented in this chapter.

Joseph M. Juran A pioneer in teaching the Japanese how to improve quality,

Juran believed strongly in top-management commitment,

support, and involvement in the quality effort. He was also a

believer in teams that continually seek to raise quality standards.

Juran varies from Deming somewhat in focusing on the

customer and defining quality as fitness for use, not necessarily

the written specifications.

© 2014 Pearson Education, Inc. 6 - 19

Leaders in Quality

TABLE 6.1 Leaders in the Field of Quality Management

LEADER PHILOSOPHY/CONTRIBUTION

Amarnd Feigenbaum His 1961 book Total Quality Control laid out 40 steps to quality

improvement processes. He viewed quality not as a set of tools

but as a total field that integrated the processes of a company.

His work in how people learn from each other’s successes led to

the field of cross-functional teamwork.

Philip B. Crosby Quality Is Free was Crosby’s attention-getting book published in

1979. Crosby believed that in the traditional trade-off between

the cost of improving quality and the cost of poor quality, the cost

of poor quality is understated. The cost of poor quality should

include all of the things that are involved in not doing the job right

the first time. Crosby coined the term zero defects and stated,

“There is absolutely no reason for having errors or defects in any

product or service.”

© 2014 Pearson Education, Inc. 6 - 20

Ethics and Quality

Management

► Operations managers must deliver

healthy, safe, quality products and

services

► Poor quality risks injuries, lawsuits,

recalls, and regulation

► Ethical conduct must dictate response

to problems

► All stakeholders much be considered

© 2014 Pearson Education, Inc. 6 - 21

Total Quality Management

► Encompasses entire organization from

supplier to customer

► Stresses a commitment by

management to have a continuing

companywide drive toward excellence

in all aspects of products and services

that are important to the customer

© 2014 Pearson Education, Inc. 6 - 22

Deming’s Fourteen Points

TABLE 6.2 Deming’s 14 Points for Implementing Quality Improvement

1. Create consistency of purpose

2. Lead to promote change

3. Build quality into the product; stop depending on inspections to catch

problems

4. Build long-term relationships based on performance instead of

awarding business on price

5. Continuously improve product, quality, and service

6. Start training

7. Emphasize leadership

© 2014 Pearson Education, Inc. 6 - 23

Deming’s Fourteen Points

TABLE 6.2 Deming’s 14 Points for Implementing Quality Improvement

8. Drive out fear

9. Break down barriers between departments

10. Stop haranguing workers

11. Support, help, and improve

12. Remove barriers to pride in work

13. Institute a vigorous program of education and self-improvement

14. Put everyone in the company to work on the transformation

© 2014 Pearson Education, Inc. 6 - 24

Seven Concepts of TQM

1. Continuous improvement

2. Six Sigma

3. Employee empowerment

4. Benchmarking

5. Just-in-time (JIT)

6. Taguchi concepts

7. Knowledge of TQM tools

© 2014 Pearson Education, Inc. 6 - 25

Continuous Improvement

► Never-ending process of continual

improvement

► Covers people, equipment, materials,

procedures

► Every operation can be improved

© 2014 Pearson Education, Inc. 6 - 26

Shewhart’s PDCA Model

Figure 6.3

4. Act 1. Plan

Implement Identify the

the plan, pattern and

document make a plan

3. Check 2. Do

Is the plan Test the

working? plan

© 2014 Pearson Education, Inc. 6 - 27

Continuous Improvement

► Kaizen describes the ongoing process

of unending improvement

► TQM and zero defects also used to

describe continuous improvement

© 2014 Pearson Education, Inc. 6 - 28

Six Sigma

► Two meanings

► Statistical definition of a process that is

99.9997% capable, 3.4 defects per

million opportunities (DPMO)

► A program designed to reduce defects,

lower costs, save time, and improve

customer satisfaction

► A comprehensive system for achieving

and sustaining business success

© 2014 Pearson Education, Inc. 6 - 29

Six Sigma

► Two meanings

Lower limits Upper limits

2,700 defects/million

► Statistical definition of a process that is

3.499.9997%

defects/million capable, 3.4 defects per

million opportunities (DPMO)

► A program designed to reduce defects,

lower costs, save time, and improve

customer satisfaction Mean

► A comprehensive system±3for achieving

and sustaining business ±6success

Figure 6.4

© 2014 Pearson Education, Inc. 6 - 30

Six Sigma Program

► Originally developed by Motorola,

adopted and enhanced by Honeywell

and GE

► Highly structured approach to process

improvement

6

► A strategy

► A discipline – DMAIC

► A set of 7 tools

© 2014 Pearson Education, Inc. 6 - 31

Six Sigma

1. Defines the project’s purpose, scope, and outputs,

identifies the required process information keeping

in mind the customer’s definition of quality

2. Measures the process and collects data

3. Analyzes the data ensuring

repeatability and reproducibility DMAIC Approach

4. Improves by modifying or

redesigning existing

processes and procedures

5. Controls the new process

to make sure performance

levels are maintained

© 2014 Pearson Education, Inc. 6 - 32

Implementing Six Sigma

► Emphasize defects per million opportunities

as a standard metric

► Provide extensive training

► Focus on corporate sponsor support

(Champions)

► Create qualified process improvement

experts (Black Belts, Green Belts, etc.)

► This cannot

Set stretch be accomplished without a

objectives

major commitment from top level

management

© 2014 Pearson Education, Inc. 6 - 33

Employee Empowerment

► Getting employees involved in product and

process improvements

► 85% of quality problems are due

to process and material

► Techniques

1) Build communication networks

that include employees

2) Develop open, supportive supervisors

3) Move responsibility to employees

4) Build a high-morale organization

5) Create formal team structures

© 2014 Pearson Education, Inc. 6 - 34

Quality Circles

► Group of employees who meet

regularly to solve problems

► Trained in planning, problem

solving, and statistical methods

► Often led by a facilitator

► Very effective when done properly

© 2014 Pearson Education, Inc. 6 - 35

Benchmarking

Selecting best practices to use as a

standard for performance

1. Determine what to benchmark

2. Form a benchmark team

3. Identify benchmarking partners

4. Collect and analyze benchmarking

information

5. Take action to match or exceed the

benchmark

© 2014 Pearson Education, Inc. 6 - 36

Best Practices for Resolving

Customer Complaints

Table 6.3

BEST PRACTICE JUSTIFICATION

Make it easy for clients to complain It is free market research

Respond quickly to complaints It adds customers and loyalty

Resolve complaints on first contact It reduces cost

Use computers to manage complaints Discover trends, share them, and align

your services

Recruit the best for customer service It should be part of formal training and

jobs career advancement

© 2014 Pearson Education, Inc. 6 - 37

Internal Benchmarking

▶ When the organization is large enough

▶ Data more accessible

▶ Can and should be established in a

variety of areas

© 2014 Pearson Education, Inc. 6 - 38

Just-in-Time (JIT)

Relationship to quality:

► JIT cuts the cost of quality

► JIT improves quality

► Better quality means less

inventory and better, easier-to-

employ JIT system

© 2014 Pearson Education, Inc. 6 - 39

Just-in-Time (JIT)

► ‘Pull’ system of production scheduling

including supply management

► Production only when signaled

► Allows reduced inventory levels

► Inventory costs money and hides

process and material problems

► Encourages improved process and

product quality

© 2014 Pearson Education, Inc. 6 - 40

Taguchi Concepts

► Engineering and experimental design

methods to improve product and

process design

► Identify key component and process

variables affecting product variation

► Taguchi Concepts

► Quality robustness

► Quality loss function

► Target-oriented quality

© 2014 Pearson Education, Inc. 6 - 41

Quality Robustness

► Ability to produce products uniformly in

adverse manufacturing and

environmental conditions

► Remove the effects of adverse

conditions

► Small variations in materials and

process do not destroy product quality

© 2014 Pearson Education, Inc. 6 - 42

Quality Loss Function

► Shows that costs increase as the

product moves away from what the

customer wants

Target-

► Costs include customer oriented

dissatisfaction, warranty quality

and service, internal

scrap and repair, and costs to

society

► Traditional conformance

specifications are too simplistic

© 2014 Pearson Education, Inc. 6 - 43

Quality Loss Function

High loss

L = D2C

Unacceptable where

Loss (to L= loss to

producing Poor society

organization,

customer, Fair D2 = square of

and society) the distance from

Good target value

Best C = cost of

Low loss Target-oriented quality

deviation

yields more product in

the “best” category

Target-oriented quality

brings product toward

Frequency the target value

Conformance-oriented

quality keeps products

within 3 standard

deviations

Lower Target Upper

Specification Figure 6.5

© 2014 Pearson Education, Inc. 6 - 44

TQM Tools

► Tools for Generating Ideas

► Check Sheet

► Scatter Diagram

► Cause-and-Effect Diagram

► Tools to Organize the Data

► Pareto Chart

► Flowchart (Process Diagram)

© 2014 Pearson Education, Inc. 6 - 45

TQM Tools

► Tools for Identifying Problems

► Histogram

► Statistical Process Control Chart

© 2014 Pearson Education, Inc. 6 - 46

Seven Tools of TQM

(a) Check Sheet: An organized

method of recording data

Hour

Defect 1 2 3 4 5 6 7 8

A /// / / / / /// /

B // / / / // ///

C / // // ////

Figure 6.6

© 2014 Pearson Education, Inc. 6 - 47

Seven Tools of TQM

(b) Scatter Diagram: A graph of the

value of one variable vs. another

variable

Productivity

Absenteeism

Figure 6.6

© 2014 Pearson Education, Inc. 6 - 48

Seven Tools of TQM

(c) Cause-and-Effect Diagram: A tool

that identifies process elements

(causes) that might effect an outcome

Cause

Materials Methods

Effect

Manpower Machinery

Figure 6.6

© 2014 Pearson Education, Inc. 6 - 49

Seven Tools of TQM

(d) Pareto Chart: A graph to identify and

plot problems or defects in descending

order of frequency

Frequency

Percent

A B C D E

Figure 6.6

© 2014 Pearson Education, Inc. 6 - 50

Seven Tools of TQM

(e) Flowchart (Process Diagram): A chart

that describes the steps in a process

Figure 6.6

© 2014 Pearson Education, Inc. 6 - 51

Seven Tools of TQM

(f) Histogram: A distribution showing the

frequency of occurrences of a variable

Distribution

Frequency

Repair time (minutes) Figure 6.6

© 2014 Pearson Education, Inc. 6 - 52

Seven Tools of TQM

(g) Statistical Process Control Chart: A chart

with time on the horizontal axis to plot

values of a statistic

Upper control limit

Target value

Lower control limit

Time

Figure 6.6

© 2014 Pearson Education, Inc. 6 - 53

Cause-and-Effect Diagrams

Material Method

(ball) (shooting process)

Grain/Feel Aiming point

(grip)

Size of ball

Air pressure Bend knees

Hand position

Balance

Lopsidedness

Follow-through

Missed

Training

free-throws

Rim size

Conditioning Motivation Rim height

Consistency Rim alignment Backboard

stability

Concentration

Machine

Manpower (hoop &

(shooter) Figure 6.7

backboard)

© 2014 Pearson Education, Inc. 6 - 54

Pareto Charts

Data for October

– 100

70 – – 93

– 88

60 – 54

Frequency (number)

Cumulative percent

– 72

50 –

40 –

Number of

30 – occurrences

20 –

12

10 –

4 3 2

0 –

Room svc Check-in Pool hours Minibar Misc.

72% 16% 5% 4% 3%

Causes and percent of the total

© 2014 Pearson Education, Inc. 6 - 55

Flow Charts

MRI Flowchart

1. Physician schedules MRI 7. If unsatisfactory, repeat

2. Patient taken to MRI 8. Patient taken back to room

3. Patient signs in 9. MRI read by radiologist

4. Patient is prepped 10. MRI report transferred to

5. Technician carries out MRI physician

6. Technician inspects film 11. Patient and physician

discuss

8

80%

1 2 3 4 5 6 7 11

9 10

20%

© 2014 Pearson Education, Inc. 6 - 56

Statistical Process Control

(SPC)

► Uses statistics and control charts to tell

when to take corrective action

► Drives process improvement

► Four key steps

► Measure the process

► When a change is indicated, find the

assignable cause

► Eliminate or incorporate the cause

► Restart the revised process

© 2014 Pearson Education, Inc. 6 - 57

Control Charts

Figure 6.8

Plot the percent of free throws missed

Upper control limit

40%

Coach’s target value

20%

| | | | | | | | | Lower control limit

0% 1 2 3 4 5 6 7 8 9

Game number

© 2014 Pearson Education, Inc. 6 - 58

Inspection

► Involves examining items to see if an

item is good or defective

► Detect a defective product

► Does not correct deficiencies in

process or product

► It is expensive

► Issues

► When to inspect

► Where in process to inspect

© 2014 Pearson Education, Inc. 6 - 59

When and Where to Inspect

1. At the supplier’s plant while the supplier is

producing

2. At your facility upon receipt of goods from your

supplier

3. Before costly or irreversible processes

4. During the step-by-step production process

5. When production or service is complete

6. Before delivery to your customer

7. At the point of customer contact

© 2014 Pearson Education, Inc. 6 - 60

Inspection

► Many problems

► Worker fatigue

► Measurement error

► Process variability

► Cannot inspect quality into a product

► Robust design, empowered

employees, and sound processes

are better solutions

© 2014 Pearson Education, Inc. 6 - 61

Source Inspection

► Also known as source control

► The next step in the process is your

customer

► Ensure perfect

product to your

customer

© 2014 Pearson Education, Inc. 6 - 62

Source Inspection

► Poka-yoke is the concept of

foolproof devices or techniques

designed to pass only acceptable

product

► Checklists ensure

consistency and

completeness

© 2014 Pearson Education, Inc. 6 - 63

Service Industry Inspection

TABLE 6.4 Examples of Inspection in Services

ORGANIZATION WHAT IS INSPECTED STANDARD

Jones Law Office Receptionist performance Phone answered by the

second ring

Billing Accurate, timely, and correct

format

Attorney Promptness in returning calls

Hard Rock Hotel Reception desk Use customer’s name

Doorman Greet guest in less than 30

seconds

Room All lights working, spotless

bathroom

Minibar Restocked and charges

accurately posted to bill

© 2014 Pearson Education, Inc. 6 - 64

Service Industry Inspection

TABLE 6.4 Examples of Inspection in Services

ORGANIZATION WHAT IS INSPECTED STANDARD

Arnold Palmer Hospital Billing Accurate, timely, and correct

format

Pharmacy Prescription accuracy,

inventory accuracy

Lab Audit for lab-test accuracy

Nurses Charts immediately updated

Data entered correctly and

Admissions completely

Olive Garden Busboy Serves water and bread within

Restaurant 1 minute

Busboy Clears all entrée items and

crumbs prior to dessert

Waiter Knows and suggest specials,

desserts

© 2014 Pearson Education, Inc. 6 - 65

Service Industry Inspection

TABLE 6.4 Examples of Inspection in Services

ORGANIZATION WHAT IS INSPECTED STANDARD

Nordstrom Department Display areas Attractive, well-organized,

Store stocked, good lighting

Stockrooms Rotation of goods, organized,

clean

Salesclerks Neat, courteous, very

knowledgeable

© 2014 Pearson Education, Inc. 6 - 66

Attributes Versus Variables

► Attributes

► Items are either good or bad, acceptable

or unacceptable

► Does not address degree of failure

► Variables

► Measures dimensions such as weight,

speed, height, or strength

► Falls within an acceptable range

► Use different statistical techniques

© 2014 Pearson Education, Inc. 6 - 67

TQM In Services

► Service quality is more difficult to

measure than the quality of goods

► Service quality perceptions depend on

1) Intangible differences between

products

2) Intangible expectations customers

have of those products

© 2014 Pearson Education, Inc. 6 - 68

Service Quality

The Operations Manager must

recognize:

► The tangible component of services

is important

► The service process is important

► The service is judged against the

customer’s expectations

► Exceptions will occur

© 2014 Pearson Education, Inc. 6 - 69

Service Specifications

© 2014 Pearson Education, Inc. 6 - 70

Determinants of Service

Quality

Table 6.5

Reliability involves consistency of performance and dependability

Responsiveness concerns the willingness or readiness of employees to provide service

Competence means possession of the required skills and knowledge to perform the

service

Access involves approachability and ease of contact

Courtesy involves politeness, respect, consideration, and friendliness

Communication means keeping customers informed and listening to them

Credibility involves trustworthiness, believability, and honesty

Security is the freedom from danger, risk, or doubt

Understanding/knowing the customer involves making the effort to understand the

customer’s needs

Tangibles include the physical evidence of the service

© 2014 Pearson Education, Inc. 6 - 71

Service Recovery Strategy

► Managers should have a plan for

when services fail

► Marriott’s LEARN routine

► Listen

► Empathize

► Apologize

► React

► Notify

© 2014 Pearson Education, Inc. 6 - 72

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or

transmitted, in any form or by any means, electronic, mechanical, photocopying, recording, or

otherwise, without the prior written permission of the publisher.

Printed in the United States of America.

© 2014 Pearson Education, Inc. 6 - 73

You might also like

- Chapter 6 Managing Quality (Sesi 3)Document68 pagesChapter 6 Managing Quality (Sesi 3)Nurmala SariNo ratings yet

- Chapter 6. Managing QualityDocument72 pagesChapter 6. Managing QualityAizen HarukaNo ratings yet

- HR Om11 Ch06 GE Chap 6 MDocument72 pagesHR Om11 Ch06 GE Chap 6 MNileshni DeviNo ratings yet

- Ch.6 Managing QualityDocument39 pagesCh.6 Managing QualityyusriyaniNo ratings yet

- Session 10Document38 pagesSession 10Zamin HassnainNo ratings yet

- Unit5 OpmDocument82 pagesUnit5 OpmMd AfzalNo ratings yet

- Managing Quality: © 2014 Pearson Education, IncDocument42 pagesManaging Quality: © 2014 Pearson Education, IncPalak SinghalNo ratings yet

- Quality Management and International StandardsDocument54 pagesQuality Management and International StandardsVania FlorenciaNo ratings yet

- Managing QualityDocument49 pagesManaging Qualitytemesgen yohannesNo ratings yet

- Heizer Om12 Ch06 FinalDocument73 pagesHeizer Om12 Ch06 FinalBahri Karam Khan100% (1)

- HR Om11 ch06Document73 pagesHR Om11 ch06Adam OngNo ratings yet

- Managing QuialityDocument31 pagesManaging QuialityZainNo ratings yet

- Quality Management and International Standards: Weeks 3 (Chapter 6)Document17 pagesQuality Management and International Standards: Weeks 3 (Chapter 6)Faizal AkbarNo ratings yet

- 6.quality ManagementDocument80 pages6.quality Managementangeladeocampo27No ratings yet

- 3-2 Managing QualityDocument21 pages3-2 Managing QualityNaiha AnumNo ratings yet

- Ch6 StudentsDocument64 pagesCh6 StudentsSinethemba SibekoNo ratings yet

- Total Quality ManagementDocument83 pagesTotal Quality Managementfakhar alamgirNo ratings yet

- Heizer Pom11 PPT 06Document76 pagesHeizer Pom11 PPT 06Bavithira ChandranNo ratings yet

- 4 Apunts EMPRESA Teoria Part4 2020 2021 EN r0Document31 pages4 Apunts EMPRESA Teoria Part4 2020 2021 EN r0vibracions boNo ratings yet

- Quality ManagementDocument77 pagesQuality ManagementAisyah RamliNo ratings yet

- Chapter 5 Quality Management and ControlDocument72 pagesChapter 5 Quality Management and ControlKirubel KefyalewNo ratings yet

- HR Om11 ch05Document80 pagesHR Om11 ch05FADHIA AULYA NOVIANTYNo ratings yet

- Session 9-10 OmDocument70 pagesSession 9-10 OmDeekshaNo ratings yet

- Operating Management Chapter 6Document53 pagesOperating Management Chapter 6melekkbass10No ratings yet

- Quality and InnovationDocument61 pagesQuality and InnovationahyaniluthfianasariNo ratings yet

- Manajemen Mutu: (Heizer/Render - Operations Management, 8e - © 2006 Prentice Hall, Inc)Document72 pagesManajemen Mutu: (Heizer/Render - Operations Management, 8e - © 2006 Prentice Hall, Inc)FrankyLinkNo ratings yet

- Topic 9 Quality MGMTDocument79 pagesTopic 9 Quality MGMTmhdjNo ratings yet

- Konsepmutu - Istiti 2018Document68 pagesKonsepmutu - Istiti 2018yuniarsy100% (1)

- Operations Management: - Managing QualityDocument72 pagesOperations Management: - Managing QualityMonique MoniqueNo ratings yet

- Managing Quality 14012021 112347pm 10022021 104850pmDocument36 pagesManaging Quality 14012021 112347pm 10022021 104850pmnuman choudharyNo ratings yet

- Managing QualityDocument60 pagesManaging QualitykinawihNo ratings yet

- Chapter 6-Managing QualityDocument41 pagesChapter 6-Managing QualityThu PhamNo ratings yet

- Introduction To QualityDocument41 pagesIntroduction To QualitySureshNo ratings yet

- Improving Service: 14 Quality and ProductivityDocument49 pagesImproving Service: 14 Quality and ProductivityjoeNo ratings yet

- CH - 5Document43 pagesCH - 5ende workuNo ratings yet

- A5 - TQMDocument7 pagesA5 - TQMevelyn102231No ratings yet

- Chapter 6 POM EditedDocument59 pagesChapter 6 POM Editedanon_69908377No ratings yet

- Session 6 DemingDocument14 pagesSession 6 DemingALINo ratings yet

- Operations and Productivity: 1 - 1 © 2014 Pearson Education, IncDocument66 pagesOperations and Productivity: 1 - 1 © 2014 Pearson Education, Incsrcn06No ratings yet

- Quality ManagementDocument28 pagesQuality Managemententertainment lastsNo ratings yet

- Ch05 - Design of Goods and ServicesDocument86 pagesCh05 - Design of Goods and ServicesFayza FauziahNo ratings yet

- OM ch06-TQMDocument72 pagesOM ch06-TQMkhan aghaNo ratings yet

- Chapter Nineteen: EFQM Excellence Paul HagueDocument7 pagesChapter Nineteen: EFQM Excellence Paul HagueKesalNo ratings yet

- Quality Management: Compiled by MusariwaDocument57 pagesQuality Management: Compiled by MusariwaChirembaNo ratings yet

- Management of Quality: Mcgraw-Hill/IrwinDocument40 pagesManagement of Quality: Mcgraw-Hill/IrwinBudi NugrohoNo ratings yet

- The Deming 14 Point PhilosophyDocument5 pagesThe Deming 14 Point PhilosophyWawex DavisNo ratings yet

- Design of Goods and ServicesDocument59 pagesDesign of Goods and ServicesAnnam InayatNo ratings yet

- Unit 1Document168 pagesUnit 1Tasmiya TabrezNo ratings yet

- Operations and Productivity: Dr. Drs. Sunarno Handoyo. Sh. Spd. MM Fakultas Ekonomi Dan Bisnis Universitas Muria KudusDocument67 pagesOperations and Productivity: Dr. Drs. Sunarno Handoyo. Sh. Spd. MM Fakultas Ekonomi Dan Bisnis Universitas Muria KudusYopi TheaNo ratings yet

- Operations and ProductivityDocument43 pagesOperations and ProductivityToni Nih ToningNo ratings yet

- TQM Lecture 1Document18 pagesTQM Lecture 1Saira ChaudharyNo ratings yet

- What Is TQM?Document43 pagesWhat Is TQM?nimra100% (1)

- Foundations of TQMDocument37 pagesFoundations of TQMJhon Luansing JarinaNo ratings yet

- Operations Quality ManagementDocument39 pagesOperations Quality ManagementHimanshu KharayatNo ratings yet

- Chapter 5Document31 pagesChapter 52023418704No ratings yet

- Operations As A Competitive Weapon: Muslim E. HarahapDocument52 pagesOperations As A Competitive Weapon: Muslim E. HarahapAngela ChristinaNo ratings yet

- Human Resource Management: Gary DesslerDocument36 pagesHuman Resource Management: Gary DesslerNehal NabilNo ratings yet

- ISO 9001 Awareness ProgramDocument67 pagesISO 9001 Awareness ProgramSudhaNo ratings yet

- PPT3-Managing QualityDocument29 pagesPPT3-Managing QualityIka FitriNo ratings yet

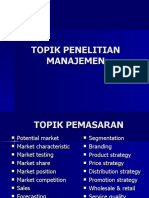

- Topik Penelitian ManajemenDocument7 pagesTopik Penelitian ManajemenanakanakNo ratings yet

- HR Om11 ch05Document86 pagesHR Om11 ch05Anggi AngelitaNo ratings yet

- HR Om11 ch03Document103 pagesHR Om11 ch03Yopi TheaNo ratings yet

- Forecasting: Dr. Drs. Sunarno Handoyo. Sh. Spd. MM Fakultas Ekonomi Dan Bisnis Universitas Muria KudusDocument124 pagesForecasting: Dr. Drs. Sunarno Handoyo. Sh. Spd. MM Fakultas Ekonomi Dan Bisnis Universitas Muria KudusYopi TheaNo ratings yet

- HR Om11 ch01Document67 pagesHR Om11 ch01Ruchi MishraNo ratings yet

- Optimal Output and Pricing Strategies for FirmsDocument18 pagesOptimal Output and Pricing Strategies for Firmsendiolalain aNo ratings yet

- Opportunity Analysis, Market Segmentation, and Market TargetingDocument17 pagesOpportunity Analysis, Market Segmentation, and Market TargetingSabbir H OsmanyNo ratings yet

- IMchap 14Document28 pagesIMchap 14Harish KumarNo ratings yet

- Managerial Accounting Chapter on Absorption vs Variable CostingDocument30 pagesManagerial Accounting Chapter on Absorption vs Variable Costing18071052 Nguyễn Thị MaiNo ratings yet

- Tut 5 - Group 2 - VINAMILKDocument33 pagesTut 5 - Group 2 - VINAMILKmai linhNo ratings yet

- SAES-Z-002 Regulated Vendors List For Process Automation SystemsDocument14 pagesSAES-Z-002 Regulated Vendors List For Process Automation SystemsZubair RaoofNo ratings yet

- Pert & CPM: ProblemDocument4 pagesPert & CPM: ProblemHamza MasoodNo ratings yet

- Chapter 6-Process Costing: LO1 LO2 LO3 LO4 LO5 LO6 LO7 LO8Document68 pagesChapter 6-Process Costing: LO1 LO2 LO3 LO4 LO5 LO6 LO7 LO8Jose Dula IINo ratings yet

- RDocument161 pagesRJignesh PandyaNo ratings yet

- Customer Acquisition TemplateDocument20 pagesCustomer Acquisition TemplateJia LaoNo ratings yet

- Unified Banking Process FrameworkDocument42 pagesUnified Banking Process FrameworkMiles Teg100% (1)

- Iso 3834-1 (2021)Document14 pagesIso 3834-1 (2021)melisbb100% (1)

- Grocery Store Business PlanDocument48 pagesGrocery Store Business PlanJoseph QuillNo ratings yet

- Aldi-A German Retailing Icon: FINAL CASE ANALYSIS - Sales & Operation PlanningDocument6 pagesAldi-A German Retailing Icon: FINAL CASE ANALYSIS - Sales & Operation PlanningSARGAM JAINNo ratings yet

- Senior High School Grade 11: Principles of Marketing Second Quarterly AssessmentDocument4 pagesSenior High School Grade 11: Principles of Marketing Second Quarterly AssessmentErrocel Shane DolorNo ratings yet

- Sop 4Document2 pagesSop 4Leon Hong83% (6)

- 09-Samss-089 2018Document27 pages09-Samss-089 2018Allan LindoNo ratings yet

- Worldwide Sporting Goods Order ReportDocument2 pagesWorldwide Sporting Goods Order ReportleciellemonNo ratings yet

- Chapter 1: Product Management - Introduction To Product Management UnitDocument2 pagesChapter 1: Product Management - Introduction To Product Management UnitSyrill CayetanoNo ratings yet

- Implementation Plan For Third Party Logistics Providers (3Pls)Document2 pagesImplementation Plan For Third Party Logistics Providers (3Pls)Robby Setiabudi TjangNo ratings yet

- Supply Chain Management: Vision & StrategyDocument21 pagesSupply Chain Management: Vision & Strategywendy priana negaraNo ratings yet

- J-DMS: Project HarmonyDocument1 pageJ-DMS: Project HarmonyMary DenizeNo ratings yet

- The Equipment Maintenance Management in Manufacturing EnterprisesDocument4 pagesThe Equipment Maintenance Management in Manufacturing EnterprisesMacammad Qabdu WasamaNo ratings yet

- Cost Strategic Management - Chap3Document28 pagesCost Strategic Management - Chap3Alber Howell MagadiaNo ratings yet

- MSE407 Manufacturing Systems: Single-Stage Inventory ControlDocument44 pagesMSE407 Manufacturing Systems: Single-Stage Inventory ControlShinjiNo ratings yet

- Consider The Following Excerpts From A New York Times ArticleDocument1 pageConsider The Following Excerpts From A New York Times ArticleAmit PandeyNo ratings yet

- Quality Control in Manufacturing.Document13 pagesQuality Control in Manufacturing.Tazammul JamadarNo ratings yet

- Combining ERP and Internet for Competitive AdvantageDocument28 pagesCombining ERP and Internet for Competitive Advantagemari1386No ratings yet

- Weld Overlay Procedure For InconelDocument3 pagesWeld Overlay Procedure For InconelArash Mohamadi100% (2)

- Standardizing OSS/BSS Systems with TAM FrameworkDocument2 pagesStandardizing OSS/BSS Systems with TAM FrameworkRio Puja Laksana100% (1)