100% found this document useful (1 vote)

1K views11 pagesCold Work Permit

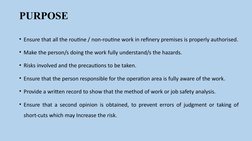

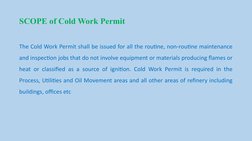

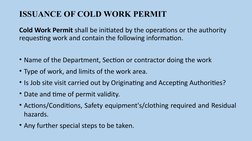

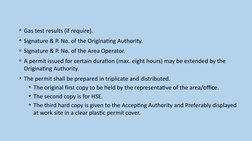

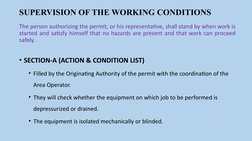

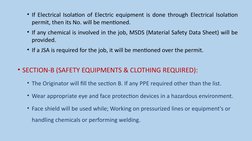

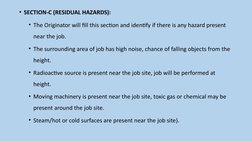

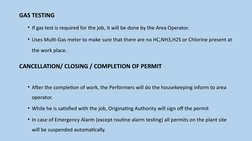

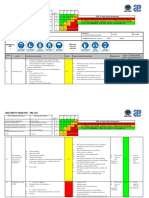

The document outlines the purpose, scope, and issuance process for a Cold Work Permit. A Cold Work Permit is required for routine and non-routine maintenance jobs that do not involve heat, flames, or other ignition sources. It contains information about the work being done, hazards, and safety precautions. The originating authority and area operator must approve the permit and ensure conditions are safe before work begins. The permit is valid for up to 8 hours and may require resubmission if conditions change.

Uploaded by

Muneeb Ur RehmanCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

1K views11 pagesCold Work Permit

The document outlines the purpose, scope, and issuance process for a Cold Work Permit. A Cold Work Permit is required for routine and non-routine maintenance jobs that do not involve heat, flames, or other ignition sources. It contains information about the work being done, hazards, and safety precautions. The originating authority and area operator must approve the permit and ensure conditions are safe before work begins. The permit is valid for up to 8 hours and may require resubmission if conditions change.

Uploaded by

Muneeb Ur RehmanCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd