Professional Documents

Culture Documents

Differential Pressure Transmitter

Uploaded by

Zainab Kadhem0 ratings0% found this document useful (0 votes)

104 views14 pagesThe differential pressure transmitter senses the difference in pressure between two ports and produces an output signal proportional to the calibrated pressure range. It has two housings - the bottom houses the pressure sensing diaphragm and the top houses electronics that amplify the sensor signal to 4-20 mA or 0-5/10 V for transmission. Common applications include flow metering, filters in water treatment, sprinkler systems, and remote sensing of heating systems. Calibration involves applying minimum and maximum pressures and adjusting the transmitter output to match through a HART communicator.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe differential pressure transmitter senses the difference in pressure between two ports and produces an output signal proportional to the calibrated pressure range. It has two housings - the bottom houses the pressure sensing diaphragm and the top houses electronics that amplify the sensor signal to 4-20 mA or 0-5/10 V for transmission. Common applications include flow metering, filters in water treatment, sprinkler systems, and remote sensing of heating systems. Calibration involves applying minimum and maximum pressures and adjusting the transmitter output to match through a HART communicator.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

104 views14 pagesDifferential Pressure Transmitter

Uploaded by

Zainab KadhemThe differential pressure transmitter senses the difference in pressure between two ports and produces an output signal proportional to the calibrated pressure range. It has two housings - the bottom houses the pressure sensing diaphragm and the top houses electronics that amplify the sensor signal to 4-20 mA or 0-5/10 V for transmission. Common applications include flow metering, filters in water treatment, sprinkler systems, and remote sensing of heating systems. Calibration involves applying minimum and maximum pressures and adjusting the transmitter output to match through a HART communicator.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 14

Differential Pressure Transmitter

• The most common and useful industrial

pressure measuring instrument is the

differential pressure transmitter.

• This equipment will sense the difference in

pressure between two ports and produce an

output signal with reference to a calibrated

pressure range.

• The industrial differential pressure transmitters are

made of two housings.

• Pressure sensing element is housed in the bottom half,

and the electronics are housed at the top half.

• It will have two pressure ports marked as “High” and

“Low”.

• It is not compulsory that the high port will be always at

high pressure and the low port always at low pressure.

• This labelling has its relation to the effect of the port on

the output signal.

Differential pressure transmitter construction:

• Direct Pressure sensing element (located in the

lower housing).

The majority of industrial DP Transmitters are fitted

with diaphragm as the pressure sensing element.

This diaphragm is a mechanical device. It is placed

in between the two pressure inlet ports.

The diaphragm will be deflected by the applied

pressure.

• Electronic Unit: The electrical signal generated

at the lower chamber by the sensor is in the

range of milli-volt only.

This signal is to be amplified to 0-5V or 0-10V range

or is to be converted to 4-20mA for onward

transmission to a remote instrument.

This upper housing is the Transmitter portion of the

DP Transmitter which houses the Electronic Unit.

• 2-Wire 4-20mA Current Transmitter:

A DC output current is generated which is directly

proportional to the pressure range of the Differential

Pressure Transmitter.

The lower range is 4mA, and the upper range is 20mA.

This controlled current output is not affected by load

impedance variation and supply voltage fluctuations.

This 4-20mA output is superimposed with digital

communications of BRAIN or HART FSK protocol.

Industrial applications of Differential Pressure Transmitters:

There are unlimited industrial applications of Differential Pressure

Transmitters.

• Oil and Gas flow metering in onshore, offshore and subsea

applications.

• Water and effluent treatment plants. It is largely used to monitor

filters in these plants.

• It is used to monitor Sprinkler Systems.

• Remote sensing of Heating Systems for Steam or Hot Water.

• Pressure drops across valves can be monitored.

• Pump control monitoring.

Differential Pressure Transmitter Calibration

Procedure

• Set up the differential pressure transmitter, HART communicator,

power supply, hand pump, and the multimeter as below (calibration

setup Diagram).

• Make sure the equalizing valve manifold is closed.

• Apply a pressure to the transmitter equal to a lower range pressure

(usually it correspond to 4 mA in the transmitter output). For example

we have 0 to 100 mBar calibrated range, then the lower range

pressure is 0, or let’s say we have -2 psig to 5 psig then we have lower

range pressure equal to -2 psig.

• Read the pressure in the transmitter LCD (or in the HART

communicator). Adjust (if any) through the HART communicator so

that the output of the transmitter (on LCD) is the same with the

applied pressure.

• Read the mA output of the transmitter by using a multimeter.

Adjust (if any) through the HART communicator so that the output

of the transmitter (on multimeter) is 4 mA.

• Apply a pressure to the transmitter equal to an upper range

pressure (usually it correspond to 20 mA in the transmitter output).

• Read the pressure in the transmitter LCD (or in the HART

communicator). Adjust (if any) through the HART communicator so

that the output of the transmitter (on LCD) is the same with the

applied pressure.

• Read the mA output of the transmitter by using a multimeter.

Adjust (if any) through the HART communicator so that the output

of the transmitter (on multimeter) is 20 mA.

Typical tools required:

• 24 VDC power supply

• Multimeter digital

• Pneumatic hand pump (up to 600 psig)

• Hydraulic hand pump (up to 10.000 psig)

• Low pressure hand pump

• High precision digital test gauge

• HART communicator

• Screwdriver toolkit

You might also like

- Cement CalculationsDocument25 pagesCement CalculationsKristi MicheleNo ratings yet

- Visual Optics 1,2.......Document468 pagesVisual Optics 1,2.......henok birukNo ratings yet

- HX35 WDocument2 pagesHX35 WGypsyRNo ratings yet

- Control & Protection Solutions: Control Systems & Products For Process, Engines, Compressors and PumpsDocument105 pagesControl & Protection Solutions: Control Systems & Products For Process, Engines, Compressors and PumpsDennis Daniel100% (1)

- Hydrodynamic or Full Fluid Film LubricationDocument59 pagesHydrodynamic or Full Fluid Film LubricationAbhishek Singh ChauhanNo ratings yet

- Ebae 161 92 Ram Pump JenningsDocument6 pagesEbae 161 92 Ram Pump JenningsGaguk Triosona PraditaNo ratings yet

- Hydrocarbon Turbo ExpandersDocument20 pagesHydrocarbon Turbo ExpandersPakde NdokNo ratings yet

- Turbo charger: A brief history and overviewDocument22 pagesTurbo charger: A brief history and overviewPragyan Kumar0% (1)

- JBJ Techniques LTD Screw PumpsDocument49 pagesJBJ Techniques LTD Screw Pumpsreach_arindomNo ratings yet

- EagleBurgmann ESPU6 Circulation Pump enDocument2 pagesEagleBurgmann ESPU6 Circulation Pump enserdarNo ratings yet

- Spur Gears-Lewis FormulaDocument1 pageSpur Gears-Lewis FormulaDedi Kartiwa100% (1)

- Air Starting System Slide Set 3Document11 pagesAir Starting System Slide Set 3Jigar PatelNo ratings yet

- ABB-DMI Type DC Machines Operating and Maintenance InstructionsDocument48 pagesABB-DMI Type DC Machines Operating and Maintenance InstructionsElafanNo ratings yet

- SASAKURA FRESH WATER GENERATOR STARTUP GUIDEDocument2 pagesSASAKURA FRESH WATER GENERATOR STARTUP GUIDEDen EdiNo ratings yet

- Manual FM160 CompressorDocument61 pagesManual FM160 CompressorSeekPTNo ratings yet

- Amot ValvesDocument10 pagesAmot Valvesenop75No ratings yet

- GE Steam Turbine Extraction Check Valves DesignDocument8 pagesGE Steam Turbine Extraction Check Valves DesignGaneshmohite123No ratings yet

- MAN-Service Experience Small Bore Four-Stroke Engines PDFDocument20 pagesMAN-Service Experience Small Bore Four-Stroke Engines PDFvangeliskyriakos8998No ratings yet

- Basic PLCDocument77 pagesBasic PLCrpshvju100% (1)

- SKF Angular Contact Ball Bearings - Your Key To Longer Service LifeDocument44 pagesSKF Angular Contact Ball Bearings - Your Key To Longer Service LifeBrunoNo ratings yet

- Industrial Steam Turbines PDFDocument56 pagesIndustrial Steam Turbines PDFmember1000No ratings yet

- Acudyne 1000 - Brochure - FormulaciónDocument12 pagesAcudyne 1000 - Brochure - FormulaciónWendy González Luna100% (1)

- Axial Alignment and Thermal Growth Effects On Turbomachinery Trains With Double-Helical GearingDocument12 pagesAxial Alignment and Thermal Growth Effects On Turbomachinery Trains With Double-Helical GearingAnton HidayatNo ratings yet

- "About Mr. Slim Air Conditioners Training" For Pme Staff 21st September 2015Document165 pages"About Mr. Slim Air Conditioners Training" For Pme Staff 21st September 2015Tun Lin AungNo ratings yet

- Types of Lubrication: BoundaryDocument20 pagesTypes of Lubrication: BoundaryAbishek Abi100% (1)

- Pneumatics: by Clifford Mayhew ST Helens CollegeDocument46 pagesPneumatics: by Clifford Mayhew ST Helens CollegesaishvNo ratings yet

- Flushing ProcedureDocument3 pagesFlushing ProcedureRex ValenciaNo ratings yet

- Bladder Accumulator SpecificationsDocument24 pagesBladder Accumulator SpecificationsSrikanth ReddyNo ratings yet

- Manual Técnico Aire Acondicionado Mitsubishi Electric MSZ-GEDocument48 pagesManual Técnico Aire Acondicionado Mitsubishi Electric MSZ-GElucasNo ratings yet

- (Paper) (Balancing of Integral Gear-Driven Centrifugal Compressors)Document8 pages(Paper) (Balancing of Integral Gear-Driven Centrifugal Compressors)aref_tmuNo ratings yet

- 1812 e Vtbs P 01 019 en Voith Turbo Bhs Turbo Gear UnitsDocument20 pages1812 e Vtbs P 01 019 en Voith Turbo Bhs Turbo Gear Units0506780% (1)

- Drive Selection of Rolling MillsDocument4 pagesDrive Selection of Rolling MillsCihan OzturkNo ratings yet

- Instrumentation and Power Training: Pressure InstrumentsDocument27 pagesInstrumentation and Power Training: Pressure InstrumentsAfzal AsifNo ratings yet

- ABB MotorsDocument22 pagesABB MotorsKhaled HassanNo ratings yet

- BSI Standards Publication: Uninterruptible Power Systems (UPS)Document100 pagesBSI Standards Publication: Uninterruptible Power Systems (UPS)Suresh KrishnanNo ratings yet

- Science Grade 10: Department of EducationDocument17 pagesScience Grade 10: Department of EducationLeiNo ratings yet

- Radial Flow Gas TurbinesDocument20 pagesRadial Flow Gas TurbinesAnggita Dwi LiestyosiwiNo ratings yet

- Mitsubishi Air ConditionerDocument68 pagesMitsubishi Air ConditionerbrianatburleighNo ratings yet

- Piston Stress AnalysisDocument13 pagesPiston Stress Analysisducatiss900100% (3)

- GOLDEN Deep Well Turbine PumpsDocument3 pagesGOLDEN Deep Well Turbine PumpskfctcoNo ratings yet

- RIT Capstone Analyzes High Vibration in Kosovo Power Plant Steam TurbineDocument55 pagesRIT Capstone Analyzes High Vibration in Kosovo Power Plant Steam TurbineFarhad YahyaieNo ratings yet

- J-Series IM20140521E TornilloDocument210 pagesJ-Series IM20140521E TornilloFernando David RamirezNo ratings yet

- CompAir L23 - L29 - RS Compressor Brochure PDFDocument8 pagesCompAir L23 - L29 - RS Compressor Brochure PDFbulentbulutNo ratings yet

- Everflow Turbine Leaflet 1Document2 pagesEverflow Turbine Leaflet 1Bidyapati BiswalNo ratings yet

- Grebe - Capacitor Switching and Its Impact On Power Quality Draft Paper 0000 PDFDocument7 pagesGrebe - Capacitor Switching and Its Impact On Power Quality Draft Paper 0000 PDFrmendozaing100% (1)

- Steam TurbineDocument25 pagesSteam TurbineIshan JunejaNo ratings yet

- Manual For 1215 Kva Rig AlternatorDocument18 pagesManual For 1215 Kva Rig Alternatorprem080910No ratings yet

- Doosan Skoda Product BrochureDocument16 pagesDoosan Skoda Product BrochureSai Shankar Lakshminarayanan100% (1)

- Failure of Cooling Fan Shaft BearingsDocument7 pagesFailure of Cooling Fan Shaft BearingsGuru Raja Ragavendran NagarajanNo ratings yet

- Emerson Webinar on Refrigerant Glide EffectsDocument26 pagesEmerson Webinar on Refrigerant Glide EffectspaldopalNo ratings yet

- Instruction Manual: Nash Type Vacuum PumpsDocument16 pagesInstruction Manual: Nash Type Vacuum Pumpsdiscovery channelNo ratings yet

- Crankshaft Deflection OctoberDocument1 pageCrankshaft Deflection OctoberJose OrtizNo ratings yet

- 5f, H 3pd 1Document28 pages5f, H 3pd 1daneshiiNo ratings yet

- Air CompressorDocument51 pagesAir CompressorsalicurriNo ratings yet

- Axial Thrust Dummy PistonDocument12 pagesAxial Thrust Dummy Pistondeevan rajNo ratings yet

- Reciprocating Air CompressorDocument19 pagesReciprocating Air Compressorrajeesh4meNo ratings yet

- Bibby CouplingsDocument25 pagesBibby CouplingsKemoy JohnsonNo ratings yet

- OPTIMIZED SOLUTION FOR COMPRESSED AIR TREATMENTDocument20 pagesOPTIMIZED SOLUTION FOR COMPRESSED AIR TREATMENTigor_sandulenkoNo ratings yet

- VIBXPERT Catalog - English PDFDocument72 pagesVIBXPERT Catalog - English PDFMuammad SanwalNo ratings yet

- Polymer-Based Bearing Materials The Role of Fillers and Fibre ReinforcementDocument7 pagesPolymer-Based Bearing Materials The Role of Fillers and Fibre Reinforcementlessard1620No ratings yet

- SKF Thermal Imager TMTI 2Document2 pagesSKF Thermal Imager TMTI 2Catanescu Alexandru-LaurentiuNo ratings yet

- Axial Vibration DamperDocument2 pagesAxial Vibration Damperanon_643160229No ratings yet

- MAN B&W MC Engine VIT Fuel Pump OperationDocument16 pagesMAN B&W MC Engine VIT Fuel Pump OperationAayush AgrawalNo ratings yet

- AllignmentDocument2 pagesAllignmentVishnu Vardhan . CNo ratings yet

- What Is A Pressure Transmitter ?: Differential Pressure Pressure Measuring InstrumentDocument11 pagesWhat Is A Pressure Transmitter ?: Differential Pressure Pressure Measuring InstrumentPriNo ratings yet

- College of Oil and Gas Engineering Chemical and Refining Dep EngDocument11 pagesCollege of Oil and Gas Engineering Chemical and Refining Dep EngMohammad G NaserNo ratings yet

- Design of Adders and Subtractors for Binary NumbersDocument17 pagesDesign of Adders and Subtractors for Binary NumbersZainab KadhemNo ratings yet

- Lab Template Exp6electronicsDocument3 pagesLab Template Exp6electronicsZainab KadhemNo ratings yet

- Chapter 4 - Part 1: Applications of Boolean Algebra: Minterms and Maxterms ExpansionsDocument11 pagesChapter 4 - Part 1: Applications of Boolean Algebra: Minterms and Maxterms ExpansionsZainab KadhemNo ratings yet

- College of Engineering: ENGG612: ElectromagneticsDocument1 pageCollege of Engineering: ENGG612: ElectromagneticsZainab KadhemNo ratings yet

- Program Structure: Bachelor of Science in Electronics and Communications Engineering (2014-2015 Curriculum)Document5 pagesProgram Structure: Bachelor of Science in Electronics and Communications Engineering (2014-2015 Curriculum)Zainab KadhemNo ratings yet

- AayanDocument11 pagesAayanZunaira SafdarNo ratings yet

- 1946 Shanley The Column Paradox J Aero SciDocument1 page1946 Shanley The Column Paradox J Aero Scitraders joeNo ratings yet

- Chap 1Document17 pagesChap 1Esiyak MengeshaNo ratings yet

- Latest Progress in TGD: The Geometry of World of Classical Worlds and Emergence of Unitary S-MatrixDocument77 pagesLatest Progress in TGD: The Geometry of World of Classical Worlds and Emergence of Unitary S-MatrixLuciano FagundesNo ratings yet

- Steel SpecificationsDocument18 pagesSteel SpecificationssurenderbuddhaNo ratings yet

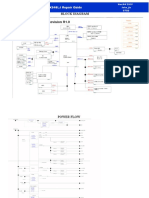

- Asus X540LJ Repair GuideDocument6 pagesAsus X540LJ Repair GuideCarlos GomesNo ratings yet

- Technical Data Sheet for B38G CompressorDocument4 pagesTechnical Data Sheet for B38G CompressorIssouf Tidiane TRAORENo ratings yet

- Chapter 8: Blood Rheology: Christina KolyvaDocument24 pagesChapter 8: Blood Rheology: Christina Kolyvaclacsik bikin asikNo ratings yet

- Maths Mensuration Surface Area ConesThe title "TITLEMaths Mensuration Surface Area ConesDocument12 pagesMaths Mensuration Surface Area ConesThe title "TITLEMaths Mensuration Surface Area ConesWafi Bin Hassan The InevitableNo ratings yet

- Effect of Temperature and Cooling Rates on the α+β Morphology of Ti-6Al-4V Alloy Effect of Temperature and Cooling Rates on the α+β Morphology of Ti-6Al-4V AlloyDocument8 pagesEffect of Temperature and Cooling Rates on the α+β Morphology of Ti-6Al-4V Alloy Effect of Temperature and Cooling Rates on the α+β Morphology of Ti-6Al-4V AlloysaltbathNo ratings yet

- Bio462 Exp 1Document5 pagesBio462 Exp 12023491958No ratings yet

- Electronicbekm 2023Document159 pagesElectronicbekm 2023Bekir MouradNo ratings yet

- Better Late Than Never EssayDocument8 pagesBetter Late Than Never Essaybmakkoaeg100% (2)

- Inorganic ChemistryDocument3 pagesInorganic ChemistryLong ENo ratings yet

- BES 314 FINAL QUIZ TAKE HOMEDocument2 pagesBES 314 FINAL QUIZ TAKE HOMEahmad ryan0% (1)

- SprinkCALC III Report - Bld7.Riser1Document30 pagesSprinkCALC III Report - Bld7.Riser1Igor CvijovicNo ratings yet

- Brønsted-Lowry Theory of Acids and BasesDocument4 pagesBrønsted-Lowry Theory of Acids and Basescayla mae carlosNo ratings yet

- VLBS LOAD RING User InstructionsDocument3 pagesVLBS LOAD RING User InstructionsGianluca PiccinettiNo ratings yet

- Notice Inviting Quotation HLL KFC Ducting PDFDocument6 pagesNotice Inviting Quotation HLL KFC Ducting PDFAjeshNo ratings yet

- Upgrade As You Grow Aesthetic Platform: LuminaDocument2 pagesUpgrade As You Grow Aesthetic Platform: Luminachash75No ratings yet

- Lightolier RFL Recessed Fluorescent Lighting Catalog 1981Document52 pagesLightolier RFL Recessed Fluorescent Lighting Catalog 1981Alan MastersNo ratings yet

- St. Michael's School Syllabus for Class 8Document14 pagesSt. Michael's School Syllabus for Class 8Aila ParkarNo ratings yet

- GLOBE PFG-red planetary geared vane motors for industrial applicationsDocument26 pagesGLOBE PFG-red planetary geared vane motors for industrial applicationsTarcio TomNo ratings yet

- 2nd Formula Green - 2017 PDFDocument49 pages2nd Formula Green - 2017 PDFApurva ChakrabortyNo ratings yet

- Project Group 10Document26 pagesProject Group 10amitgourav9No ratings yet