Professional Documents

Culture Documents

STAINLESS STEEL CHAIN ADVANTAGES

Uploaded by

Serhat Doğu0 ratings0% found this document useful (0 votes)

30 views14 pagesStainless steel conveyor chains vary in quality based on factors like steel type and hardness, flatness, surface area, and pin material. Higher quality chains from AVE feature specialized alloys with precise flatness and radii for minimal gaps and pressure. Their template pins and pre-lubrication reduce erosion and friction for longer life. Customers pay more for AVE chains but benefit from increased productivity, less downtime, and reduced energy costs over the life of the chain.

Original Description:

Original Title

AVE_Chains

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentStainless steel conveyor chains vary in quality based on factors like steel type and hardness, flatness, surface area, and pin material. Higher quality chains from AVE feature specialized alloys with precise flatness and radii for minimal gaps and pressure. Their template pins and pre-lubrication reduce erosion and friction for longer life. Customers pay more for AVE chains but benefit from increased productivity, less downtime, and reduced energy costs over the life of the chain.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

30 views14 pagesSTAINLESS STEEL CHAIN ADVANTAGES

Uploaded by

Serhat DoğuStainless steel conveyor chains vary in quality based on factors like steel type and hardness, flatness, surface area, and pin material. Higher quality chains from AVE feature specialized alloys with precise flatness and radii for minimal gaps and pressure. Their template pins and pre-lubrication reduce erosion and friction for longer life. Customers pay more for AVE chains but benefit from increased productivity, less downtime, and reduced energy costs over the life of the chain.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 14

STAINLESS STEEL

CHAINS

The value of a chain is the value of its weakest flight

Introduction

Why a customer is calling us in order to buy

one of our Stainless Steel chains.

Which are the reasons making a chain

different from another one.

Which is the main reason for a chain having

the price it’s.

If all the chains are the same apparently,

why are so many differences on prices

Previous

LET’S SEE WHICH ARE THE DIFFERENCES

WE’VE TO TRANSMIT FROM OUR CHAINS

TO THE COMPETITOR’S ONES.

THOSE DIFFERENCES WOULD GIVE TO

THE END USER THE ADVANTAGES WE

DESCRIBE AS FOLLOWS.

WHY A CUSTOMER IS

ORDERING A CHAIN

IF IT’S A MACHINERY MAKER, IT’S ONLY

BECAUSE HE’S MAKING OR REPAIRING A

CONVEYOR.

IF IT’S AN END USER (BOTTLING), IT’S

USUALLY BECAUSE HE NEEDS TO REPAIR A

CONVEYOR OR TO SUBSTITUTE A CHAIN INTO

AN OLD CONVEYOR. AT BIG COMPANIES THE

TENDENCY IS TO USE THE ORIGINAL

EQUIPMENT GIVEN BY THE CONSTRUCTOR.

WHEN A CHAIN SHOULD BE

SUBSTITUTED

When due to the friction between the chain and

the carried product there’s a loose of thickness

at the upper part of the chain.

When due to the friction between the chain and

the sliding guide there’s a loose of thickness at

the bottom part of the chain.

When the step of the chain has suffered

enlargement, due to:

- Enlargement of the hinge

- Erosion on the hinge.

- Basically erosion at the pin on the central

part.

WHY THE CHAIN NEEDS

TO BE SUBSTITUTED

The erosion on the chains and principally

their enlargement produce:

increase on the sound level

increase on the electrical consumption

the chain is jumping over the sprocket

because the real step has changed, which

is in fact producing a loose on speed

principally canning falling down affecting

to the productivity of the line.

(it’s accepted as efficient on a technical

service a change between 15% and 20% of

the total chain installed. Information

given by several different end-users)

DETERMINING FACTORS

JUSTIFYING THE PRICE OF A CHAIN

QUALITY OF THE STEEL USED FOR

THE FLIGHT

TRANSVERSE FLATNESS OF THE

FLIGHT

LARGER CARRYING SURFACE

WRINKLING AT CARRYING

SURFACE

QUALITY OF THE PIN STEEL.

Different Types of

Stainless Steel

AISI 430 DIN 1.4015 ‘MAGNETIC’ STAINLESS

STEEL:

The most popular and cheap. Hardness of 17 – 20

HRC, not recommended for high performances or

large maintenance cycles. Due to these inconvenient

AVE is not using this type of Steel.

AISI 304 – DIN 1.4301 ‘AUSTENITIC’ STAINLESS

STEEL.

Known as 18/8. Is the most expensive one. It’s used

on applications where FDA standards are required

(food &/or chemical industries). A few producers are

using standard marketed material with thickness 3

mm and aprox. hardness 22 HRC. At AVE, we’re using

an special stainless steel alloy with thickness 3,15 &

flight hardness of 28 , 30 HRC which is being

produced specially for us.

SSC:

This alloy, out of Aisi standards, DIN 1.4017 is a

variation of the ferritic stainless steels, offering the

highest performance on high speed bottling/canning

lines. (30 HRC ±2)

Transverse & Longitudinal

Flatness of the Flight

It’s impossible to reach

the absolute flatness

Due to the fact that

mainly on lateral

transferences concavity is

causing bottling falls,

we’ve established as a

standard that we should

never obtain concave

chains.

The convexity degree

we’ve established as

standard on our

production is much better

than any other one at our

competitors as our

convexity value is the

minimum possible.

Larger Carrying Surface

When cutting 2 parallel chains on its transversal

way, will see that there’s a real space between both

chains (GAP), much more bigger than the one

supposed (Transversal Step – Chain Width)

In the case of our competitor chains, as they are

producing the chains with the chamfers at an angle

between 15 & 45º, the only thing they get is

simplifying the chain production.

However, our chains are made with radius,

minimizing the distance of the chain support

Our design is offering very important

consequences:

Reducing the pressure over the flight (which in

fact is a part of the lubrication objectives)

Reducing the space between parallel chains thus

increasing the stability of the product.

Wrinkling at Carrying Surface

The stainless steel finishing quality main aim is to make

easier the product sliding.

Wrinkling market standards are between 0,6 µm & 0,2 µm

Self-polishing after more or less time, depending on:

Product to be transported

Conveyor type: linear, accumulation, alignment

Steel Quality

Original chain wrinkleness

While the chain is working there’s a self-polishing of the

chain itself, which is made earlier or later, just

depending on the type of product being transported.

Our competitors are offering different wrinkling types

at different prices.

AVE is always offering as standard wrinkleness 0,30 µm

(+0 - 0,1 µm ) this is a way to simplify the stock at our

customer warehouses. We make easier the labour of

maintenance departments as well as optimize the

production at the transport lines.

Quality of the Pin Steel

Due to the continuous pass of the chain over the

sprockets and idler wheels the pin is suffering erosion

mainly on its central part.

The erosion at the pin is in direct proportion to the

stress over the chain and its speed, and in opposite

proportion to the conveyor length.

The highest strength of our pins SS302, allows these

chains having a longest life. (SSS series)

At the plants where our technical department has

decided to use chains with Template Stainless Steel

Pins, there has not been any case of pin erosion, thus

allowing us to say that AVE chains directly avoid any kind

of problem with pin erosion.

Up-to-date, and with the available information, only a

few marks offer this possibility as an ‘extra’ to be

noticed, while at AVE, we offer this quality as an

standard at all our chains as it’s showed into our

catalogue: “AISI 420 “ (SSC series)

All our chains are previously lubricated at origin.

What is a Customer Paying

when Buying AVE Chains

The unique chains offering all the

available ‘extras’ on the stainless steel

market chains as standard series.

Transversal and longitudinal flatness

Carrying surfaces strength

Optimized wrinkling.

Prelubricate and template pins

Why using AVE Chains

Because of its longer long life

Because productivity at the lines is increased

Because energetic consumption is reduced

Because lubrication needs are reduced

You might also like

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Chain Technologies and Its AdvancementsDocument4 pagesChain Technologies and Its AdvancementsMinaBasconNo ratings yet

- Ahmed-Group-Pole-Brochure - Swaged and Octogonal PDFDocument16 pagesAhmed-Group-Pole-Brochure - Swaged and Octogonal PDFAnonymous EVFw59No ratings yet

- What Exactly is Rolling? The Process and Key FactsDocument39 pagesWhat Exactly is Rolling? The Process and Key FactsAshish12312No ratings yet

- Development of Early Roller Chain Design GuideDocument15 pagesDevelopment of Early Roller Chain Design GuideCTN2010No ratings yet

- Adea Company BroucherDocument15 pagesAdea Company BroucherVelu SamyNo ratings yet

- Wire Rope Usha MartinDocument36 pagesWire Rope Usha MartinashiyNo ratings yet

- Die Max Die SpringsDocument16 pagesDie Max Die SpringsCarlos GranadaNo ratings yet

- Stainless EnstainlessDocument27 pagesStainless EnstainlessVinaya Almane DattathreyaNo ratings yet

- Case Study Applications of Six Sigma in Mild Steel and Stainless Steel Light Fabrication Processes PDFDocument7 pagesCase Study Applications of Six Sigma in Mild Steel and Stainless Steel Light Fabrication Processes PDFcement drNo ratings yet

- Swagelok Tubing SpecificationsDocument8 pagesSwagelok Tubing SpecificationsAugustine Owo UkpongNo ratings yet

- L10950 ECD CatalogDocument347 pagesL10950 ECD CatalogChristopher WhiteNo ratings yet

- Rigid Coupling 4Document9 pagesRigid Coupling 4Yosia HutasoitNo ratings yet

- Die Max Die SpringsDocument16 pagesDie Max Die SpringsYogesh PatelNo ratings yet

- Socket Weld Fitting GuideDocument7 pagesSocket Weld Fitting GuideMehman NasibovNo ratings yet

- ValvesDocument8 pagesValvespravin_2011No ratings yet

- Rexnord Metal Table Top ChainDocument36 pagesRexnord Metal Table Top ChainWhisnu AlbertusNo ratings yet

- Leespring EngguideDocument27 pagesLeespring EngguideAnonymous h6qnMVb8eNo ratings yet

- OneSteel Steel Pipe Final LoResDocument24 pagesOneSteel Steel Pipe Final LoResPhilip TeakleNo ratings yet

- Socket WeldDocument7 pagesSocket WeldahmedNo ratings yet

- Am ItDocument27 pagesAm Itakalbhor90No ratings yet

- Roller ChainDocument2 pagesRoller ChainSteven Jerome M. IngcoNo ratings yet

- Kuri CONQUERORDocument16 pagesKuri CONQUERORJosh WhiteNo ratings yet

- Consol Steel Belt - 2018Document12 pagesConsol Steel Belt - 2018Lavender ShenNo ratings yet

- SKF ChainDocument36 pagesSKF ChainVijay GohilNo ratings yet

- Catalogo Tecnico Stud WeldingDocument68 pagesCatalogo Tecnico Stud Weldingalexfc81No ratings yet

- Caleb Components Suppliers of Spring Steel FastenersDocument31 pagesCaleb Components Suppliers of Spring Steel FastenersSaliya Bandara RathnayakaNo ratings yet

- Design-Engg-mfg-testing of Bellows Expansion Joints - 442013144211Document33 pagesDesign-Engg-mfg-testing of Bellows Expansion Joints - 442013144211mujeeb84No ratings yet

- Lead Screw Nut Product GuideDocument32 pagesLead Screw Nut Product GuideGanesh JadhavNo ratings yet

- Drive For TodayDocument9 pagesDrive For TodayLTE002No ratings yet

- ACA DampersDocument24 pagesACA DampersHFandino1No ratings yet

- Tension Wheel Assemblies: Sicat 8WL5070 / 8WL5078 For Overhead Contact Line SystemsDocument4 pagesTension Wheel Assemblies: Sicat 8WL5070 / 8WL5078 For Overhead Contact Line SystemsVictor Manuel BonettoNo ratings yet

- Stud welding manufacturer profileDocument69 pagesStud welding manufacturer profileJuan OrmacheaNo ratings yet

- Your Global Flow Control Partner: International Product ProfileDocument16 pagesYour Global Flow Control Partner: International Product ProfileKevin EsquivelNo ratings yet

- REPUTE Tube Fittings Guide: Everything You Need to KnowDocument12 pagesREPUTE Tube Fittings Guide: Everything You Need to KnowspiritveluNo ratings yet

- Inverted Tooth Chains & Sprockets For Power Transmission - 601-306Document32 pagesInverted Tooth Chains & Sprockets For Power Transmission - 601-306Jhon Edison Guerrero GalindoNo ratings yet

- Jakob Metaalbalgkoppeling K Catalogus enDocument25 pagesJakob Metaalbalgkoppeling K Catalogus enFallo SusiloNo ratings yet

- Oil Tempered WireDocument20 pagesOil Tempered WireGizem AkelNo ratings yet

- Rega Notes 2Document10 pagesRega Notes 2tararichisponNo ratings yet

- 12 - SprocketsDocument24 pages12 - SprocketsJigneshkumar PatelNo ratings yet

- Substation Bus ConductorsDocument26 pagesSubstation Bus ConductorsherrtammNo ratings yet

- Sec Roc Drill Pipe and AdaptersDocument16 pagesSec Roc Drill Pipe and AdaptersSerkanAl50% (2)

- Structural FabricationDocument46 pagesStructural FabricationmithileshNo ratings yet

- Bray-B-1008 ProdProfile 06 07 2016Document13 pagesBray-B-1008 ProdProfile 06 07 2016Osvaldo Junges BomfimNo ratings yet

- Catálogo Rexnord IngenieríaDocument152 pagesCatálogo Rexnord IngenieríaCésar VásquezNo ratings yet

- Pipes FittingsDocument37 pagesPipes Fittingsanand bandekarNo ratings yet

- Bushan Power Steel PipeDocument16 pagesBushan Power Steel PipeKarthikeyan VisvakNo ratings yet

- Reclaimer ChainDocument4 pagesReclaimer ChainAmeer Ahmad RazaNo ratings yet

- Torque Setting Formula - GeorgeDocument4 pagesTorque Setting Formula - Georgegeorge_hemNo ratings yet

- Torque CalculatorDocument4 pagesTorque CalculatorNityananda Permadi TjokrodimurtiNo ratings yet

- MS 01 107Document12 pagesMS 01 107Floyd AnthonyNo ratings yet

- Bray Valves Profile I-5000 EL Profile 10 2015 LRDocument17 pagesBray Valves Profile I-5000 EL Profile 10 2015 LRChandravadanNo ratings yet

- Air DuctsDocument6 pagesAir DuctsmohamedroyaleyeuaeNo ratings yet

- Lift Chain 2001Document16 pagesLift Chain 2001Rimon GawandeNo ratings yet

- Tsubaki - Ansi Roller ChainDocument24 pagesTsubaki - Ansi Roller Chainaiyubi2No ratings yet

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Chainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosFrom EverandChainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- AVE Conveyor Product Training GuideDocument30 pagesAVE Conveyor Product Training GuideSerhat DoğuNo ratings yet

- Antonio Rey ExerciseDocument1 pageAntonio Rey ExerciseSerhat DoğuNo ratings yet

- AVE KVDocument4 pagesAVE KVSerhat DoğuNo ratings yet

- AVE DeslidurDocument5 pagesAVE DeslidurSerhat DoğuNo ratings yet

- Just Enough Spanish Grammar IllustratedDocument193 pagesJust Enough Spanish Grammar Illustratedtonydebeggar97% (61)

- Falseta Por Soleá Por Bulerías: Javier CondeDocument4 pagesFalseta Por Soleá Por Bulerías: Javier CondeSerhat DoğuNo ratings yet

- ArmoniaDocument263 pagesArmoniaJulio DelgadoNo ratings yet

- Fretboard MasteryDocument60 pagesFretboard MasterySerhat Doğu100% (4)

- Fuego Del FatuoDocument7 pagesFuego Del FatuoSerhat DoğuNo ratings yet

- Paco Pena - Granada en Flor (Zorongo and Variations) SampleDocument5 pagesPaco Pena - Granada en Flor (Zorongo and Variations) SampleSerhat DoğuNo ratings yet

- The Ultimate DVD Guide to Mastering Pentatonic and Hexatonic ScalesDocument77 pagesThe Ultimate DVD Guide to Mastering Pentatonic and Hexatonic ScalesSerhat Doğu100% (1)

- Object Oriented Programming With C July 2008 OldDocument1 pageObject Oriented Programming With C July 2008 OldPrasad C MNo ratings yet

- Purpose and Objectives of POMDocument2 pagesPurpose and Objectives of POMJayadatta Shreepada SNo ratings yet

- Alan Turing PresentationDocument42 pagesAlan Turing PresentationPaul Mu100% (1)

- R&D Update - Design Rules For Forming Aluminum Stampings-Part 1 - The FabricatorDocument5 pagesR&D Update - Design Rules For Forming Aluminum Stampings-Part 1 - The FabricatorSIMONENo ratings yet

- Introduction To NanophotonicsDocument49 pagesIntroduction To NanophotonicsArashiNo ratings yet

- Sandvik 2RE69 Stainless Steel DatasheetDocument9 pagesSandvik 2RE69 Stainless Steel DatasheetMuzammilNo ratings yet

- Seal Pot: Seal Fluid Supply TankDocument4 pagesSeal Pot: Seal Fluid Supply Tankmadhu gawadeNo ratings yet

- Manual de Utilizare Sursa de Alimentare 27.6 V5 A Pulsar EN54-5A17 230 VAC50 HZ Montaj Aparent LEDDocument40 pagesManual de Utilizare Sursa de Alimentare 27.6 V5 A Pulsar EN54-5A17 230 VAC50 HZ Montaj Aparent LEDGabriel SerbanNo ratings yet

- Unit 1 AP Classroom PDFDocument9 pagesUnit 1 AP Classroom PDFSara AbdelazizNo ratings yet

- Chapter 7: Advanced Modeling Techniques: Prof. Ming-Bo LinDocument42 pagesChapter 7: Advanced Modeling Techniques: Prof. Ming-Bo Linvimal_raj205No ratings yet

- Algebra 3 Principles and Sample Problems: 3.1 Probability 3.2 Statistics 3.3 Problems For SolutionsDocument24 pagesAlgebra 3 Principles and Sample Problems: 3.1 Probability 3.2 Statistics 3.3 Problems For SolutionsKrisha Jean MacalinoNo ratings yet

- Ds1307 Application NoteDocument17 pagesDs1307 Application NoteShamsunder31No ratings yet

- MS ExcelDocument37 pagesMS Excelravi100% (2)

- TARCOG Mathematical Models for Calculating Thermal Performance of Glazing SystemsDocument56 pagesTARCOG Mathematical Models for Calculating Thermal Performance of Glazing Systemsaaro_oraalNo ratings yet

- Grade: Third Grade Unit Title: Matter Course/Subject: Science Approximate Time Required: 1 WeekDocument6 pagesGrade: Third Grade Unit Title: Matter Course/Subject: Science Approximate Time Required: 1 Weekapi-272854858No ratings yet

- Ev 3 Solar StationDocument52 pagesEv 3 Solar Stationavira0002No ratings yet

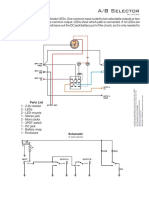

- A/B Selector: Parts ListDocument1 pageA/B Selector: Parts ListGiannis zmNo ratings yet

- A Computer Code For Fully-Coupled Rocket Nozzle Flows - PergamentDocument131 pagesA Computer Code For Fully-Coupled Rocket Nozzle Flows - PergamentSantiago PatitucciNo ratings yet

- Advanced Optical and Wireless Communicat PDFDocument952 pagesAdvanced Optical and Wireless Communicat PDFbhuvaneswariNo ratings yet

- MS2680-2017 Energy Efficiency and Use of Renewable Energy For Residential BuildingsDocument61 pagesMS2680-2017 Energy Efficiency and Use of Renewable Energy For Residential BuildingsChern Yue EweNo ratings yet

- Passive Solar HeatingDocument7 pagesPassive Solar HeatingccwebbizNo ratings yet

- GCE O Level Practice PaperDocument12 pagesGCE O Level Practice Paperjina910% (1)

- MiniProject Assignment 3Document3 pagesMiniProject Assignment 3Asadullah ChoudharyNo ratings yet

- ReportDocument54 pagesReportHurshVFadia100% (1)

- Why Astrology Is Science: Five Good Reasons: Tapan Das, PH.D., P.EngDocument56 pagesWhy Astrology Is Science: Five Good Reasons: Tapan Das, PH.D., P.EngNikhil TidkeNo ratings yet

- Electrical network management with MV substation control and Modbus communicationDocument45 pagesElectrical network management with MV substation control and Modbus communicationMaximiliano SanchezNo ratings yet

- r050212101 Object Oriented Analysis Design Through UmlDocument8 pagesr050212101 Object Oriented Analysis Design Through UmlSrinivasa Rao GNo ratings yet

- Upgrading To OAM 111212Document12 pagesUpgrading To OAM 111212Ravi ArNo ratings yet

- A Comparative Study of 6T, 8T and 9T SRAM CellDocument4 pagesA Comparative Study of 6T, 8T and 9T SRAM CellijaertNo ratings yet

- Acid Base and Redox Titration CalculationsDocument33 pagesAcid Base and Redox Titration CalculationsoscarbecNo ratings yet