Professional Documents

Culture Documents

Design Process Layouts Under 40 Characters

Uploaded by

Sarahjane Terrado0 ratings0% found this document useful (0 votes)

23 views16 pagesThe document discusses various factors to consider when designing process and service facility layouts. It outlines procedures for designing process layouts which include listing work centers, obtaining facility drawings, identifying material and personnel flows, using analytical methods to develop a layout, and evaluating and modifying the layout. It also discusses important physical facilities for service layouts like factory buildings, lighting, climate control, ventilation, and work-related welfare facilities.

Original Description:

Production management

Original Title

DESIGN OF PROCESS LAYOUT

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses various factors to consider when designing process and service facility layouts. It outlines procedures for designing process layouts which include listing work centers, obtaining facility drawings, identifying material and personnel flows, using analytical methods to develop a layout, and evaluating and modifying the layout. It also discusses important physical facilities for service layouts like factory buildings, lighting, climate control, ventilation, and work-related welfare facilities.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

23 views16 pagesDesign Process Layouts Under 40 Characters

Uploaded by

Sarahjane TerradoThe document discusses various factors to consider when designing process and service facility layouts. It outlines procedures for designing process layouts which include listing work centers, obtaining facility drawings, identifying material and personnel flows, using analytical methods to develop a layout, and evaluating and modifying the layout. It also discusses important physical facilities for service layouts like factory buildings, lighting, climate control, ventilation, and work-related welfare facilities.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 16

DESIGN OF PROCESS LAYOUT

The analysis involved in the design of production lines

and assembly lines relates primarily to timing,

coordination, and balance among individual stages in the

process.

For process layouts, the relative arrangement of

departments and machines is the critical factor because of

the large amount of transportation and handling involved.

PROCEDURE FOR DESIGNING PROCESS

LAYOUTS

1.Listand describe each functional work centre.

2. Obtain a drawing and description of the facility being

designed.

3. Identify and estimate the amount of material and

personnel flow among work centres

4. Use structured analytical methods to obtain a good

general layout.

5. Evaluate and modify the layout, incorporating details

such as machine orientation, storage area location, and

equipment access.

SERVICE LAYOUT

Service facility layout will be designed

based on degree of customer contact and

the service needed by a customer.

The following are the most important

physical facilities to be organized:

1. Factory building

2. Lighting

3. Climatic conditions

4. Ventilation

5. Work-related welfare facilities

FACTORY BUILDING

A.Design of the Building

Flexibility

Product and equipment

Expansibility

The following factors should be borne in mind if the future

expansion of the concern is to be provided for:

(i) The

area of the land which is to be acquired should be large

enough to provide for the future expansion needs of the firm and

accommodate current needs.

(ii) The design of the building should be in a rectangular shape.

Rectangular shapes facilitate expansion on any side.

(iii)If vertical expansion is expected, strong foundations,

supporters and columns must be provided.

(iv) If horizontal expansion is expected, the side walls must be

made non-load-bearing to provide for easy removal.

B. Types of Buildings

SINGLE-STOREY BUILDINGS

Most of the industrial buildings

manufacturing which are now designed

and constructed are single storeyed,

particularly where lands are available at

reasonable rates.

Advantages of single-storey building are:

1. There is a greater flexibility in layout and production routing.

2. The maintenance cost resulting from the vibration of

machinery is reduced considerably because of the housing of the

machinery on the ground.

3. Expansion is easily ensured by the removal of walls.

4. The cost of transportation of materials is reduced because of

the absence of materials handling equipment between floors.

5. All the equipment is on the same level, making for an easier

and more effective layout supervision and control.

6. Greater floor load-bearing capacity for heavy equipment is

ensured.

7. The danger of fire hazards is reduced because of the lateral

spread of the building.

Limitations

Single-storey buildings suffer from some

limitations. These are:

1. High cost of land, particularly in the

city.

2. High cost of heating, ventilating and

cleaning of windows.

3. High cost of transportation for moving

men and materials to the factory which is

generally located far from the city.

MULTI-STOREY BUILDINGS

Advantages

When constructed for industrial use, multi-

storey buildings offer the following advantages:

1. Maximum operating floor space (per sq. ft.

of land). This is best suited in areas where land

is very costly.

2. Lower cost of heating and ventilation.

3. Reduced cost of materials handling because

the advantage of the use of gravity for the flow

of materials.

Limitations

Following are the disadvantages of multi-storey building:

1. Materials handling becomes very complicated. A lot of time

is wasted in moving them between floors.

2. A lot of floor space is wasted on elevators, stairways and

fire escapes.

3. Floor load-bearing capacity is limited, unless special

construction is used, which is very expensive.

4. Natural lighting is poor in the centres of the shop,

particularly when the width of the building is somewhat great.

5. Layout changes cannot be effected easily and quickly.

Generally speaking, textile mills, food industries, detergent

plants, chemical industries and software industry use these

types of buildings.

LIGHTING

CONTROL OF LIGHTING

In order to make the best use of lighting in the work place, the following

points should be taken into account:

1. For uniform light distribution, install an independent switch for the row

of lighting fixtures closest to the windows. This allows the lights to be

switched on and off depending on whether or not natural light is sufficient.

2. To prevent glare, avoid using highly shiny, glossy work surfaces.

3. Use localized lighting in order to achieve the desired level for a

particular fine job.

4. Clean light fixtures regularly and follow a maintenance schedule so as

to prevent flickering of old bulbs and electrical hazards due to worn out

cables.

5. Avoid direct eye contact with the light sources. This is usually achieved

by positioning them property. The use of diffusers is also quite effective.

CLIMATIC CONDITIONS

Control of the climatic conditions at the

workplace is paramount importance to the

workers health and comfort and to the

maintenance of higher productivity. With

excess heat or cold, workers may feel very

uncomfortable, and their efficiency drops.

In addition, this can lead to accidents.

• WORKING IN A HOT ENVIRONMENT

• WORKING IN A COLD ENVIRONMENT

VENTILATION

Ventilation is the dynamic parameter that

complements the concept of air space. For

a given number of workers, the smaller

the work premises the more should be the

ventilation.

WORK-RELATED WELFARE FACILITIES

Work-related welfare facilities offered at or

through the workplace can be important factors..

• drinking water

• sanitary facilities

• first-aid and medical facilities

• rest facilities

• feeding facilities

• recreational facilities

• child-care facilities

quiz

You might also like

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneFrom EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNo ratings yet

- Production Operation Management: Final HandoutsDocument20 pagesProduction Operation Management: Final HandoutsSarahjane TerradoNo ratings yet

- POM - Service Facility Layout Organization of FacilitiesDocument55 pagesPOM - Service Facility Layout Organization of FacilitiesMae Ann KongNo ratings yet

- Industrial Plant Design - Lecture 2Document22 pagesIndustrial Plant Design - Lecture 2Billy JhunNo ratings yet

- Building Construction Report-1Document39 pagesBuilding Construction Report-1Kanak YadavNo ratings yet

- SC 401 Lecture 03-1 CONSTRUCTION SITE LAYOUTDocument20 pagesSC 401 Lecture 03-1 CONSTRUCTION SITE LAYOUTJoseph BaruhiyeNo ratings yet

- Topic 2 Warehousing Layout and PlanningDocument3 pagesTopic 2 Warehousing Layout and PlanningmainaNo ratings yet

- Topic 2 Site SelectionDocument18 pagesTopic 2 Site Selectionjohn nderituNo ratings yet

- Lecture Notes On Industrial Engg & Quality ControlDocument35 pagesLecture Notes On Industrial Engg & Quality ControlB CHETHANANo ratings yet

- Plant Location and Layout FactorsDocument17 pagesPlant Location and Layout FactorsNaresh Babu NBNo ratings yet

- Week - 5 LAQ - Operations ManagementDocument5 pagesWeek - 5 LAQ - Operations Managementbabitha76260No ratings yet

- Standard Layout of An IndustryDocument14 pagesStandard Layout of An Industrynadimduet1No ratings yet

- Group 3: Plant Layout and Industrial SafetyDocument16 pagesGroup 3: Plant Layout and Industrial Safetylove ofmylifeNo ratings yet

- INDUSTRIAL BUILDING CLADDING METAL SHEETINGDocument3 pagesINDUSTRIAL BUILDING CLADDING METAL SHEETINGAmirul Rasyid Shansul Bahri100% (1)

- Site SelectionDocument8 pagesSite SelectionUsman IsrarNo ratings yet

- 02-2 Plant Layout & Piping SystemDocument10 pages02-2 Plant Layout & Piping SystemLady Abegail AbraoNo ratings yet

- Modularization Chemical PlantDocument4 pagesModularization Chemical Plantmora287No ratings yet

- 02-2 Plant Layout & Piping SystemDocument10 pages02-2 Plant Layout & Piping SystemJhoann CastroNo ratings yet

- Plant Layout To Start A New Bank BranchDocument15 pagesPlant Layout To Start A New Bank Branchshraddha mehtaNo ratings yet

- MANAGEMENT5 SCIENCE Unit 3Document9 pagesMANAGEMENT5 SCIENCE Unit 3Pavan KumarNo ratings yet

- Physical FacilitiesDocument18 pagesPhysical FacilitiesChristine Apolo100% (2)

- Topic 4.0 - IbsDocument34 pagesTopic 4.0 - IbsJuliet JepeliNo ratings yet

- Topic3 PPT Djj42022 Plant Layout Line BalancingDocument70 pagesTopic3 PPT Djj42022 Plant Layout Line Balancinghani adliNo ratings yet

- Business Org and ManagementDocument28 pagesBusiness Org and ManagementQuelly TolentinoNo ratings yet

- Lecture No 5 PDLDocument3 pagesLecture No 5 PDLGoummeli6 SocratesNo ratings yet

- Structural Systems in HousingDocument9 pagesStructural Systems in HousingzuhaNo ratings yet

- Plant Layout and Location FactorsDocument2 pagesPlant Layout and Location FactorsThey See Soon EngNo ratings yet

- CooooDocument8 pagesCooooMohammed AbduNo ratings yet

- Food Plant LayoutDocument148 pagesFood Plant LayoutManu Bhatia100% (1)

- Unit IDocument45 pagesUnit IRajarajan P.CNo ratings yet

- Mcdonald K Juma section 4Document45 pagesMcdonald K Juma section 4mcdonald jumaNo ratings yet

- BOI Guidelines For Factory Building PDFDocument16 pagesBOI Guidelines For Factory Building PDFRuwan PiyarathnaNo ratings yet

- Architectural Design: Must Incorporate An Accurate Description ofDocument25 pagesArchitectural Design: Must Incorporate An Accurate Description ofAnonymous JNXucSr7mZNo ratings yet

- Unit:3 Plant Layout and Material HandlingDocument14 pagesUnit:3 Plant Layout and Material HandlingKhushboo JariwalaNo ratings yet

- MODULE 1 - Plant Location N LayoutDocument17 pagesMODULE 1 - Plant Location N LayoutjibinNo ratings yet

- Unit 1 TopicsDocument25 pagesUnit 1 TopicsAamirNo ratings yet

- Industrial LitratureDocument28 pagesIndustrial LitratureAnwar MohammedNo ratings yet

- WS Lab ManualDocument93 pagesWS Lab ManualShahbazNo ratings yet

- Unit 1Document40 pagesUnit 1vgshankar26100% (1)

- Chapter 2 - Part 2Document17 pagesChapter 2 - Part 2Elizabeth NelsonNo ratings yet

- Module - 1 - Viii CDocument39 pagesModule - 1 - Viii CSamyuktha SureshNo ratings yet

- Food Processing Design BuildDocument6 pagesFood Processing Design Buildalexafin740% (1)

- Plant Layout and Material HandlingDocument27 pagesPlant Layout and Material HandlingShreyas JyothishNo ratings yet

- Unit 3 MSDocument9 pagesUnit 3 MSSandeep SagarNo ratings yet

- Plant Design FactorsDocument13 pagesPlant Design FactorsAnnyessienNo ratings yet

- Plant layout design factors & typesDocument26 pagesPlant layout design factors & typesAli MahmoudNo ratings yet

- Chapter 6 7 Fambus ReviewerDocument7 pagesChapter 6 7 Fambus RevieweralexandercpanganibanNo ratings yet

- PLANT LOCATION AND LAYOUT FACTORSDocument17 pagesPLANT LOCATION AND LAYOUT FACTORSShuaib AktharNo ratings yet

- Layout 3Document16 pagesLayout 3lemaitinhNo ratings yet

- Precast Structures Plant Layout and DesignDocument102 pagesPrecast Structures Plant Layout and Designgokul vvNo ratings yet

- Factors Influencing Plant LayoutDocument10 pagesFactors Influencing Plant LayoutKaushal PatelNo ratings yet

- Unit 4Document6 pagesUnit 4SingarayyaNo ratings yet

- Factory Layout OptimizationDocument6 pagesFactory Layout OptimizationAbhinav KumarNo ratings yet

- Industrial Engineering - Unit-2Document13 pagesIndustrial Engineering - Unit-2Gera Happy paulNo ratings yet

- IEM Unit 1Document21 pagesIEM Unit 1M.suresh SureshNo ratings yet

- Facility LayoutDocument24 pagesFacility LayoutShahenaNo ratings yet

- Industrial StructuresDocument33 pagesIndustrial StructuresSharon ShineNo ratings yet

- Building Construction ReportDocument44 pagesBuilding Construction ReportSurayyn Selvan100% (2)

- Chapter 2 - Plant Location, Plant Layout and Line Balancing (Betul)Document40 pagesChapter 2 - Plant Location, Plant Layout and Line Balancing (Betul)Kesava Dass50% (2)

- OSH HOME EXAMINATIONDocument10 pagesOSH HOME EXAMINATIONammukuttycellowNo ratings yet

- Handshake, Intination, Phone Etiquette, MannerismDocument26 pagesHandshake, Intination, Phone Etiquette, MannerismSarahjane TerradoNo ratings yet

- Assignment #1Document2 pagesAssignment #1Sarahjane TerradoNo ratings yet

- Chapter 1.1 Production SystemDocument28 pagesChapter 1.1 Production SystemSarahjane TerradoNo ratings yet

- Strategic Pricing ObjectivesDocument19 pagesStrategic Pricing ObjectivesSarahjane TerradoNo ratings yet

- Plant Location and Layout: OutlineDocument26 pagesPlant Location and Layout: OutlineSarahjane TerradoNo ratings yet

- Manners at the BuffetDocument42 pagesManners at the BuffetSarahjane TerradoNo ratings yet

- Plant Location and Layout: OutlineDocument26 pagesPlant Location and Layout: OutlineSarahjane TerradoNo ratings yet

- Table Setting and Etiquette PowerPoint PresentationDocument33 pagesTable Setting and Etiquette PowerPoint PresentationSarahjane Terrado100% (3)

- Human Behavior in Organization Chapter 1 and 2Document4 pagesHuman Behavior in Organization Chapter 1 and 2Sarahjane TerradoNo ratings yet

- Manners and Etiquette EssentialsDocument22 pagesManners and Etiquette EssentialsSarahjane Terrado100% (1)

- Chapter 1 and 2Document39 pagesChapter 1 and 2Sarahjane TerradoNo ratings yet

- CareerDocument45 pagesCareerSarahjane TerradoNo ratings yet

- The Nature and Scope of Organizational BehaviorDocument28 pagesThe Nature and Scope of Organizational BehaviorSarahjane TerradoNo ratings yet

- Definition and Process: 1. The SenderDocument2 pagesDefinition and Process: 1. The SenderSarahjane TerradoNo ratings yet

- Leadership Styles & TheoriesDocument4 pagesLeadership Styles & TheoriesSarahjane TerradoNo ratings yet

- Chapter3: CommunicationDocument24 pagesChapter3: CommunicationSarahjane TerradoNo ratings yet

- Chapter 5 ControlDocument8 pagesChapter 5 ControlSarahjane TerradoNo ratings yet

- Community Assessment Tools enDocument24 pagesCommunity Assessment Tools enSarahjane TerradoNo ratings yet

- NSTP 123Document36 pagesNSTP 123Sarahjane TerradoNo ratings yet

- What Is Organizing ?Document28 pagesWhat Is Organizing ?Sarahjane TerradoNo ratings yet

- NSTP 456Document19 pagesNSTP 456Sarahjane TerradoNo ratings yet

- Principles of ManagementDocument35 pagesPrinciples of ManagementSarahjane TerradoNo ratings yet

- First Aid Safety Measures for Convulsions, Seizures, Cardiac Arrest, Stroke, Heart Attack & NosebleedsDocument10 pagesFirst Aid Safety Measures for Convulsions, Seizures, Cardiac Arrest, Stroke, Heart Attack & NosebleedsSarahjane TerradoNo ratings yet

- The Business Organizations PPPDocument31 pagesThe Business Organizations PPPSarahjane TerradoNo ratings yet

- Evolution of MANAGEMENTDocument57 pagesEvolution of MANAGEMENTSarahjane TerradoNo ratings yet

- AREAS OF MANAGEMENTDocument39 pagesAREAS OF MANAGEMENTSarahjane TerradoNo ratings yet

- DEMODocument30 pagesDEMOSarahjane TerradoNo ratings yet

- Accounting Fundamentals at Bulacan State UniversityDocument129 pagesAccounting Fundamentals at Bulacan State UniversitySarahjane TerradoNo ratings yet

- Finetek-Sb RF Capacitance Admittance Level Switch PDFDocument6 pagesFinetek-Sb RF Capacitance Admittance Level Switch PDFGopalakrishnan RajuNo ratings yet

- List of PartsDocument7 pagesList of Partsmohammad etemad moghadamNo ratings yet

- TorchSA-30 June 2023 B2C EMAILDocument85 pagesTorchSA-30 June 2023 B2C EMAILChristiaanNo ratings yet

- GE Fuji AF 300 VFD ManualDocument44 pagesGE Fuji AF 300 VFD ManualAnderson GonçalvesNo ratings yet

- dvpns50p PDFDocument78 pagesdvpns50p PDFHanif Rathore PrinceNo ratings yet

- Lycoming Engine Order Form: (If Different)Document2 pagesLycoming Engine Order Form: (If Different)Michel LefebvreNo ratings yet

- Adrián Lugo Bendezú (Senior, University of Puerto Rico Río Piedras Campus) Mentor: Tristan Goulden (AOP)Document1 pageAdrián Lugo Bendezú (Senior, University of Puerto Rico Río Piedras Campus) Mentor: Tristan Goulden (AOP)jpNo ratings yet

- Specifications For Concrete Construction ACI 301-20: Field Reference ManualDocument6 pagesSpecifications For Concrete Construction ACI 301-20: Field Reference ManualIRFAN NAZIR50% (2)

- Turkstream Pipeline PrecommissioningDocument2 pagesTurkstream Pipeline PrecommissioningWayne BerreyNo ratings yet

- CISSP Review QuestionsDocument87 pagesCISSP Review QuestionsGsk SkNo ratings yet

- M650. User Manual. 2009, Carmanah Technologies Corporation. Revised June - M650 - UserManual - RevADocument76 pagesM650. User Manual. 2009, Carmanah Technologies Corporation. Revised June - M650 - UserManual - RevAPaul PerazaNo ratings yet

- Experiment No.4: 1X2 DecoderDocument12 pagesExperiment No.4: 1X2 DecoderRohit PanwarNo ratings yet

- 6G ReportDocument33 pages6G ReportJesin John LMC19MCA003No ratings yet

- B&R 2005 Modules - Cpus - Cp260: Model Number Short Description Image CpuDocument9 pagesB&R 2005 Modules - Cpus - Cp260: Model Number Short Description Image CpuahmedcoNo ratings yet

- Accumulator Technology. Accumulator Ator at Te Te T Chnolog: Product CatalogueDocument148 pagesAccumulator Technology. Accumulator Ator at Te Te T Chnolog: Product CatalogueJamin SmtpngNo ratings yet

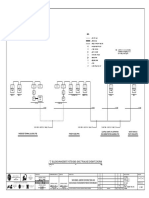

- Building Management System (BMS) Basic Trunkline Schematic Diagram 2Document3 pagesBuilding Management System (BMS) Basic Trunkline Schematic Diagram 2Anonymous NcB95G6XwNo ratings yet

- LogDocument705 pagesLogSandura PangulimaNo ratings yet

- CW Survey Planning Guide: Xanthos N. Angelides 5 April 2000Document14 pagesCW Survey Planning Guide: Xanthos N. Angelides 5 April 2000kumarabhi09100% (1)

- Dr. Dela Zerna - AT in The ClassroomDocument28 pagesDr. Dela Zerna - AT in The ClassroomAnonymous okusLzNo ratings yet

- Design ManagementDocument3 pagesDesign ManagementGlay xxNo ratings yet

- Implementing High Availability andDocument226 pagesImplementing High Availability andiliyasmanerNo ratings yet

- NOVO CORPORATION Security Catalogue Highlights Russian Market LeaderDocument85 pagesNOVO CORPORATION Security Catalogue Highlights Russian Market LeaderFurat KafirNo ratings yet

- John Sloman EconomicsDocument4 pagesJohn Sloman Economicsdevyansh.dhall2807No ratings yet

- Control PSP Audio & Video with Remote, Headphones, CameraDocument1 pageControl PSP Audio & Video with Remote, Headphones, CameravadivelanNo ratings yet

- Essential Design Handbook SampleDocument32 pagesEssential Design Handbook SampleCarolina ZamoraNo ratings yet

- 03 3.3 Truth Tables Logic Formulas Logic Circuits 28-54Document43 pages03 3.3 Truth Tables Logic Formulas Logic Circuits 28-54oliNo ratings yet

- Fourth Edition: Descriptive Analytics II: Business Intelligence and Data WarehousingDocument61 pagesFourth Edition: Descriptive Analytics II: Business Intelligence and Data WarehousingramhanNo ratings yet

- 722k UserGuideDocument165 pages722k UserGuideSrikanth MarepalliNo ratings yet

- Epm Tips Issues 73 102 1612164Document178 pagesEpm Tips Issues 73 102 1612164Caio Leonardo LimaNo ratings yet

- Iso 3548-2 - 2020Document16 pagesIso 3548-2 - 2020jesoneliteNo ratings yet