Professional Documents

Culture Documents

Dust Explosions

Uploaded by

Aun Abbas0 ratings0% found this document useful (0 votes)

24 views28 pagesThe document discusses dust explosions and electrostatic ignitions. It explains that dust explosions require a fuel, oxygen, and an ignition source. Common ignition sources include mechanical actions, overheating, open flames, static electricity, and welding. Static electricity is a major cause of dust explosions and can result from contact charging, frictional charging, double layer charging, induction charging, and transport charging during the handling of solids. Various types of electrostatic discharges like sparks, propagating brush discharges, brush discharges, corona discharges, and conical pile discharges can ignite explosive dusts if their energy exceeds the minimum ignition energy. The document provides steps to prevent electrostatic ignitions during solids handling.

Original Description:

dust explosions

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses dust explosions and electrostatic ignitions. It explains that dust explosions require a fuel, oxygen, and an ignition source. Common ignition sources include mechanical actions, overheating, open flames, static electricity, and welding. Static electricity is a major cause of dust explosions and can result from contact charging, frictional charging, double layer charging, induction charging, and transport charging during the handling of solids. Various types of electrostatic discharges like sparks, propagating brush discharges, brush discharges, corona discharges, and conical pile discharges can ignite explosive dusts if their energy exceeds the minimum ignition energy. The document provides steps to prevent electrostatic ignitions during solids handling.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

24 views28 pagesDust Explosions

Uploaded by

Aun AbbasThe document discusses dust explosions and electrostatic ignitions. It explains that dust explosions require a fuel, oxygen, and an ignition source. Common ignition sources include mechanical actions, overheating, open flames, static electricity, and welding. Static electricity is a major cause of dust explosions and can result from contact charging, frictional charging, double layer charging, induction charging, and transport charging during the handling of solids. Various types of electrostatic discharges like sparks, propagating brush discharges, brush discharges, corona discharges, and conical pile discharges can ignite explosive dusts if their energy exceeds the minimum ignition energy. The document provides steps to prevent electrostatic ignitions during solids handling.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 28

Dust Explosions

Safe handling of solids

Dust Explosion Control

Introduction

Basic concepts of dust explosions

Ignition sources

Electrostatic ignitions

Solids Handling

The safe handling of solids is becoming more important

because the production and the processing of solids is

increasing.

More chemicals are being produced and handled as

solids to eliminate reactions with volatile and hazardous

solvents.

Emphasis to produce products as powders (versus

liquids).

More chemicals are transported in reusable “super

sacks”

Flammable gases & vapors

When dealing with flammable

gases and vapors, the

generally accepted major

requirements for a fire or

explosion are fuel, oxygen

and ignition.

In chemical industry they try

to eliminate or reduce one or

more of the sides of the

triangle.

Explosive Dusts Hexagon

For Dust explosions there is a

more complex situation

needed before an explosion

occurs.

Fuel – any dust such as,

chemicals, grain, wood dust,

flour, polymers, lint etc.

Moisture – when fuel contains a

higher moisture content, then the

dust burning process is

extinguished.

Explosive Dust Hexagon (cont)

Dust and Air Suspension:

Particles must be below a certain minimum size to

be able to be suspended.

Particle loading (concentration) must be between

certain limits:

– Lower 20 to 60 g/m3

– Upper 2 to 6 kg/m3

Dust loading must be fairly uniform to be explosive.

Effects of suspension

In the upper picture a bin

(with a vent) that

contains dust is ignited.

In the lower picture, an

additional pile of dust

was located in the path

of the venting flame.

The dust become

suspended and caused a

secondary explosion.

Prevention of Dust Explosions

Eliminate fuel

Prevent dust suspensions

Add moisture

Keep fuel below LFL

Reduce oxygen below MOC

Eliminate ignition sources

Flammable Dusts

Acetamide Milk

Adipic Acid Nylon

Aluminum Paper

Barley Polystyrene

Carbon Starch

Cellulose Steel

Coffee Sucrose

Corn Wheat

Epoxy Resin Wood

Iron Zinc

Minimum Ignition Energies

Dusts Versus Vapors

Aluminum 10 mJ Acetone 1 mJ

Corn (2%moisture) 110 mJ Acrolein 0.1 mJ

Epoxy Resin <10 mJ Benzene 0.2 mJ

Milk Powder 50 mJ Carbon Disulfide <0.1 mJ

Sugar 30 mJ Heptane 0.2 mJ

Sulphur <10 mJ Toluene 0.2

mJ

Elimination of suspensions

Good housekeeping – If dust is not lying around it

cannot get suspended which results in an explosive

situation.

Dust on beams is especially a problem since an

explosion in one part of the facility will cause the dust to

be suspended and exacerbate the hazard.

Often moisture is added to solids to minimize

suspensions and also to reduce explosivity.

Keeping fuel below LFL

Venting of area and/or hooding used to collect dust.

The collected dust is sent to a collections system such

as a bag house, cyclone or electrostatic precipitator to

remove and collect the dust.

Pelletize solids to minimize amount of material in air

suspendable size range.

Inerting the area where dust will be present to reduce

oxygen to below MOC. Often not practical in large

systems.

Common Ignition Sources

A United Kingdom study of dust explosions and

fires cited the following causes of ignition

sources

Mechanical 18% Welding 7%

Overheating 17% Electrical 3%

Open flames 15% Other 29%

Static Electricity 11%

Static Electricity Discharges

Static electricity is the fourth largest cause of

ignition sources in dust explosions.

Because of the nature of solids, the handling

and transportation of solids can actually be the

cause of the static electricity

Dust Explosion Control

Introduction

Basic concepts of dust explosions

Ignition sources

Electrostatic ignitions

Accumulation of charges

Electrostatic discharges

Deadly Dust II (Video)

Fundamentals of Static Electricity

Handling solids often leads to the accumulation of static

electricity. This accumulation can lead to a spark that

then serves as an ignition source.

One method to prevent static electricity is to prevent the

accumulation of charge.

Charge Accumulation:

Contact and Frictional

Double layer

Induction

Transport

Contact and Frictional Charging

Dust transport

e.g. pneumatic transport of powders/solids

Pouring powders

e.g. pouring solids down chutes or troughs

Gears and belts

e.g. transporting charges from one surface to

another

Double layer charging

Caused by friction at interfaces on a microscopic

scale.

Liquid-liquid

Solid-liquid

Solid-solid

Gas-liquid

Gas-solid

Induction charging

Occurs when an isolated

conductor is subject to an electric

field. Charges of different polarity

are induced on opposite sides. If

an earthed electrode touches or

approaches the body then the

charges closest to electrode flow

away leaving the body with a net

charge of opposite sign.

Occurs by walking across carpet.

Nonconductive shoes are a

problem.

Charging by Transport

Results from a charged dust, liquid or solid

particles settling onto a surface and transporting

their charges to this new surface.

The rate of charge accumulation is a function of

the rate of transportation.

Lightening is an example of this type of charging

phenomenon.

Dust Explosion Control

Introduction

Basic concepts of dust explosions

Ignition sources

Electrostatic ignitions

Accumulation of charges

Electrostatic discharges

Deadly Dust II (Video)

Electrostatic Ignitions

Static electric ignitions are the result of transferring the accumulated

charges to another surface via a discharge.

The accumulated charge may be safely leaked away to earth by

grounding.

If energy of discharge exceeds MIE then fire or explosion can occur.

Static electric Discharges

Sparks

Propagating brush

Brush

Corona

Conical pile (Maurer)

Spark discharges

Discharges between two

conductors.

Very energetic with

energies ranging up to

10 Joules.

Can ignite flammable

gases and dusts

Propagating brush discharge

Occur between a conductor

and a non-conductive lining.

Very energetic, can be greater

than 100 Joules.

Major contributor to static

electricity ignitions.

If breakdown voltage of lining

is less than 4 kV, then

propagating brush discharges

are not possible because

charge will pass through lining.

Brush discharge

Occurs between non-conductor

and a conductor.

Energetic < 5mJ

Nonconductive lining or surface

must have a breakdown

voltage greater than 4kV and a

thickness greater than 2mm.

Can ignite flammable vapors

but rarely ignites flammable

dusts.

Nonconductive coating can be

a layer of the powdered solid

Corona discharge

Corona discharge similar to

brush discharge but occurs

when electrode more pointed.

Occurs over a longer period of

time than a spark and may

give faint glow and hissing

sound.

Can cause ignition of

flammable gas mixtures with

low MIE.

Usually considered non-

incendive to dusts.

Conical pile discharge (Maurer discharge)

Occur between sliding solids and

charged air.

Vessels larger than 1 m3.

Nonconductive particles with

resistance greater than

1010Ohm•m

Particles larger than 1mm

diameter

Relatively fast filling rate, greater

than 0.5 kg/s

Energetic ~ 1 Joule

Can ignite flammable dusts and

vapors

Preventing Electrostatic Ignitions

Handout gives a

thought process

procedure to

prevent

electrostatic

ignitions from dust

or dust/flammable

vapor systems.

You might also like

- Materials that Cause Dust ExplosionsDocument24 pagesMaterials that Cause Dust ExplosionsManirulNo ratings yet

- The Natural vs. Human Causes of Air Pollution : Environment Textbooks | Children's Environment BooksFrom EverandThe Natural vs. Human Causes of Air Pollution : Environment Textbooks | Children's Environment BooksRating: 4 out of 5 stars4/5 (1)

- Combustible Dust Explosion Pentagon & OSHA Equipment Deflagration HazardsDocument6 pagesCombustible Dust Explosion Pentagon & OSHA Equipment Deflagration HazardsRelene WeiNo ratings yet

- Dust Collection Systems and Solutions for Every Budget: Complete Guide to Protecting Your Lungs and Eyes from Wood, Metal, and Resin Dust in the WorkshopFrom EverandDust Collection Systems and Solutions for Every Budget: Complete Guide to Protecting Your Lungs and Eyes from Wood, Metal, and Resin Dust in the WorkshopNo ratings yet

- Ee 6Document58 pagesEe 6Crazy HelloNo ratings yet

- Dust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesFrom EverandDust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesNo ratings yet

- Basic Dust Explosion PDFDocument32 pagesBasic Dust Explosion PDFMauricioNo ratings yet

- The Basis of Dust Explosion Protection by R StahlDocument32 pagesThe Basis of Dust Explosion Protection by R StahlBigbearBigbearNo ratings yet

- Dust ExplosionsDocument40 pagesDust ExplosionsAbhishek VaidyaNo ratings yet

- The Risks of Static ElectricityDocument9 pagesThe Risks of Static ElectricityhalsonNo ratings yet

- Flame RetardantsDocument26 pagesFlame RetardantsL.N.CHEMICAL INDUSTRY100% (1)

- Identification, Classification and Assessment of HazardsDocument27 pagesIdentification, Classification and Assessment of HazardsSeid AragawNo ratings yet

- Flame Retardants For Textiles - GLOGUARD SERIESDocument26 pagesFlame Retardants For Textiles - GLOGUARD SERIESL.N.CHEMICAL INDUSTRYNo ratings yet

- Environmental CHEMISTRY (209) 22Document47 pagesEnvironmental CHEMISTRY (209) 22Maaz WaseemNo ratings yet

- Guidance For Plant Engineers StaticelectricityDocument9 pagesGuidance For Plant Engineers Staticelectricityimamers100% (2)

- Dust Explosion VeDocument10 pagesDust Explosion VeSalva McNo ratings yet

- What Are The Types and Causes of Fire Hazards in Textile IndustryDocument4 pagesWhat Are The Types and Causes of Fire Hazards in Textile IndustryMuhammad Asif Idrees100% (3)

- Kong Long Huat Chemicals SDN BHD MSDS - Urea BI GHSDocument14 pagesKong Long Huat Chemicals SDN BHD MSDS - Urea BI GHSngpp.purc01No ratings yet

- Fundamentos ATEXDocument20 pagesFundamentos ATEXNelson_1492No ratings yet

- Treatment of Air Pollutants and Control MethodsDocument17 pagesTreatment of Air Pollutants and Control MethodsWonda 005No ratings yet

- Ee 2Document47 pagesEe 2umadanapallyNo ratings yet

- Pollution Effects on Overhead InsulatorsDocument14 pagesPollution Effects on Overhead InsulatorsSiva KumarNo ratings yet

- AtexDocument60 pagesAtexWendi Junaedi100% (1)

- Final Report Smoke PrecipitatorDocument7 pagesFinal Report Smoke PrecipitatorSiti Anis IzzatieNo ratings yet

- Particulate MatterDocument26 pagesParticulate MatterDAISYLIN ANBU SUJITHA SNo ratings yet

- OSHA Dust Explosion Assessment and NEPDocument71 pagesOSHA Dust Explosion Assessment and NEPjovanivanNo ratings yet

- Dust Explosion Hazard AssessmentDocument9 pagesDust Explosion Hazard AssessmentCarlos JiménezNo ratings yet

- Electrostatic PrecipitatorDocument77 pagesElectrostatic Precipitatorsurender_kr4858No ratings yet

- Course Id: ENV - 206 Sec-02: Submitted byDocument9 pagesCourse Id: ENV - 206 Sec-02: Submitted byMD. JULFIKER HASANNo ratings yet

- Air Pollution SourcesDocument25 pagesAir Pollution Sourcesanjaneya mishraNo ratings yet

- Essential Guide to ATEX RegulationsDocument28 pagesEssential Guide to ATEX RegulationsSameh EzzatNo ratings yet

- Lecture 1-Introduction of AerosolsDocument11 pagesLecture 1-Introduction of AerosolsBharat AggarwalNo ratings yet

- Electricidad Estatica en Plantas SXDocument16 pagesElectricidad Estatica en Plantas SXsergiovm2012100% (1)

- Dust Explosion Fundamentals Ignition Criteria and Pressure DDocument10 pagesDust Explosion Fundamentals Ignition Criteria and Pressure Dmtrj59No ratings yet

- Explosion Protection For Dust Collection Systems Handling Metal DustDocument5 pagesExplosion Protection For Dust Collection Systems Handling Metal DustDileesh DineshanNo ratings yet

- Environmental Issues Neet ChallengingDocument1 pageEnvironmental Issues Neet Challengingminhaz TauqeerNo ratings yet

- Air Quality ManagementDocument32 pagesAir Quality ManagementamruthaNo ratings yet

- Effect of Power Plant On EnvironmentDocument7 pagesEffect of Power Plant On EnvironmentnabeelNo ratings yet

- ATEXDocument12 pagesATEXMinh Tú PhạmNo ratings yet

- Mine ExplosionDocument8 pagesMine Explosionersunilsingh1No ratings yet

- Dust Testing For DSEAR and ATEX Complian PDFDocument16 pagesDust Testing For DSEAR and ATEX Complian PDFSawita LertsupochavanichNo ratings yet

- Air Pollution Control EquipmentDocument34 pagesAir Pollution Control EquipmentJanice OmadtoNo ratings yet

- Environmental Aspects of Power Generation: (Produced by Biomass)Document55 pagesEnvironmental Aspects of Power Generation: (Produced by Biomass)Arul SankaranNo ratings yet

- Nitrogen Injection Fire Prevention System For Oil Filled Transformers Ijariie3150Document10 pagesNitrogen Injection Fire Prevention System For Oil Filled Transformers Ijariie3150sabahiraq100% (1)

- HSC Chemistry Lesson Plan 25Document7 pagesHSC Chemistry Lesson Plan 25Ali HaidarNo ratings yet

- Hazardous Area Classification: Dusts and MistsDocument15 pagesHazardous Area Classification: Dusts and MistsborrowmanaNo ratings yet

- ESP Operation GuideDocument71 pagesESP Operation GuideJCSNo ratings yet

- Flammable MaterialsDocument25 pagesFlammable MaterialsAnggik Pratama100% (1)

- Cleanheat Background Paper EnglishDocument8 pagesCleanheat Background Paper EnglishKartik DhimanNo ratings yet

- Air Quality and Control: Lecture No. 5Document4 pagesAir Quality and Control: Lecture No. 5Illumi ZaoldyeckNo ratings yet

- Fire and Explosion PDFDocument96 pagesFire and Explosion PDFanpuselvi125100% (1)

- Smog and Its Types - Chemistry HHWDocument16 pagesSmog and Its Types - Chemistry HHWNeeraj MathurNo ratings yet

- The Troposphere The Ionosphere : Compare Between The Following TermsDocument1 pageThe Troposphere The Ionosphere : Compare Between The Following TermsMohamed ahmedNo ratings yet

- MT - TOPIC 03 - Construction Site PremisesDocument69 pagesMT - TOPIC 03 - Construction Site PremisesGreen ArcNo ratings yet

- PM 2.5, PM 10 Reduction Study: By, Sayan Biswas Abhishek Verma Anand VishnuDocument12 pagesPM 2.5, PM 10 Reduction Study: By, Sayan Biswas Abhishek Verma Anand VishnuSayan BiswasNo ratings yet

- Air Pollution Control MethodsDocument54 pagesAir Pollution Control Methodsarun aryaNo ratings yet

- AY 2122 Sem 1 A334 P04 PracticeQuestionsDocument3 pagesAY 2122 Sem 1 A334 P04 PracticeQuestionsLim Liang XuanNo ratings yet

- Testing To Assess Explosion Characteristics of Dust CloudsDocument10 pagesTesting To Assess Explosion Characteristics of Dust CloudsJuan Palomo (Pajarito)No ratings yet

- Environmental Unit 7Document7 pagesEnvironmental Unit 7juanaprennaNo ratings yet

- Moving Rotating EquipmentDocument35 pagesMoving Rotating EquipmentAun AbbasNo ratings yet

- Lubrication and LubricantsDocument25 pagesLubrication and LubricantsAun AbbasNo ratings yet

- Johri Window ModelDocument2 pagesJohri Window ModelAun AbbasNo ratings yet

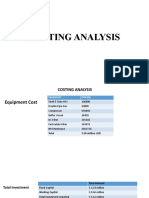

- COSTING ANALYSIS (Autosaved)Document4 pagesCOSTING ANALYSIS (Autosaved)Aun AbbasNo ratings yet

- Hazard and Operability Study (Hazop)Document22 pagesHazard and Operability Study (Hazop)Aun AbbasNo ratings yet

- Lab 4 Aun Abbas Che 10Document2 pagesLab 4 Aun Abbas Che 10Aun AbbasNo ratings yet

- Osama ShabirDocument1 pageOsama ShabirAun AbbasNo ratings yet

- Simiultaneous Heat and Mass TransferDocument5 pagesSimiultaneous Heat and Mass TransferAun AbbasNo ratings yet

- Heat Release RateDocument24 pagesHeat Release Rateh4harish100% (1)

- Principles and Applications Of: PyrometallurgyDocument19 pagesPrinciples and Applications Of: PyrometallurgyChamel Jamora RuperezNo ratings yet

- Production of Sucroesters Using Solvent-FreeDocument8 pagesProduction of Sucroesters Using Solvent-FreeAlfonso Dominguez GonzalezNo ratings yet

- Diffusion Explained: Movement of MoleculesDocument3 pagesDiffusion Explained: Movement of MoleculesJames TangNo ratings yet

- Landfill Leachate Migration Through Shallow Unconfined AquifersDocument6 pagesLandfill Leachate Migration Through Shallow Unconfined AquifersUche Jonathan-MetuhNo ratings yet

- Two Year CRP 2022-24 PT-1 A Lot Advnace - Paper - 1-SET-ADocument15 pagesTwo Year CRP 2022-24 PT-1 A Lot Advnace - Paper - 1-SET-AAdhyayan DNo ratings yet

- Ap4073 Sensors and Actuators L T P CDocument1 pageAp4073 Sensors and Actuators L T P Cjames RNo ratings yet

- Vol 2Document559 pagesVol 2erbhaveshparmarNo ratings yet

- ENV220/925 Water Quality and Ecological Engineering SolutionsDocument6 pagesENV220/925 Water Quality and Ecological Engineering Solutionshi911hiNo ratings yet

- Synthesis and use of zinc oxide nanoparticlesDocument7 pagesSynthesis and use of zinc oxide nanoparticlesTigerNo ratings yet

- NEET UG Physics Properties of Liquid of Solid MCQs PDFDocument63 pagesNEET UG Physics Properties of Liquid of Solid MCQs PDFasdfghjNo ratings yet

- Best Practice-Rans Turbulence Modeling in Ansys CFDDocument95 pagesBest Practice-Rans Turbulence Modeling in Ansys CFDMohiNo ratings yet

- Polarizer NoteDocument1 pagePolarizer NoteChu Pau LoongNo ratings yet

- Protein purification pre-class exerciseDocument4 pagesProtein purification pre-class exerciseKathleen GomezNo ratings yet

- A Heterocylic (212 C Part 2)Document138 pagesA Heterocylic (212 C Part 2)Moamen MohamedNo ratings yet

- OscillationDocument34 pagesOscillationApex Institute100% (2)

- Solved Problems Electrostatics PDFDocument47 pagesSolved Problems Electrostatics PDFPraneetha InumarthiNo ratings yet

- AkzoNobel Asphalt TB Bitumen Emulsion Tcm45-36500Document24 pagesAkzoNobel Asphalt TB Bitumen Emulsion Tcm45-36500Waleed Louri100% (2)

- Vibration Analysis and Control Exam QuestionsDocument4 pagesVibration Analysis and Control Exam QuestionsAshokNo ratings yet

- Pharmaceutical EmulsionsDocument28 pagesPharmaceutical EmulsionsEph RemNo ratings yet

- He - Ne LASERDocument20 pagesHe - Ne LASERPardeep BhambhuNo ratings yet

- Physical Science Quiz 1Document1 pagePhysical Science Quiz 1Alison BarreroNo ratings yet

- HKDSE Physics Part - 2 MechanicsDocument17 pagesHKDSE Physics Part - 2 MechanicsdexterNo ratings yet

- Chem 40 Enzyme KineticsDocument85 pagesChem 40 Enzyme KineticsJustine Grace Mariano100% (1)

- HT Handling Instructions SHTXXDocument12 pagesHT Handling Instructions SHTXXChrisNo ratings yet

- MATLS 4I03 Assignment 2Document3 pagesMATLS 4I03 Assignment 2RoyNo ratings yet

- Differential Scanning Calorimetry (DSC)Document9 pagesDifferential Scanning Calorimetry (DSC)DanielNo ratings yet

- Organic Chemistry: CarbanionDocument12 pagesOrganic Chemistry: CarbanionDiana DedoNo ratings yet

- Hosford A Generalized Isotropic Yield Criterion PDFDocument3 pagesHosford A Generalized Isotropic Yield Criterion PDFWilberFabiánNo ratings yet

- Floating Roof CribbingDocument8 pagesFloating Roof CribbingDavid RodriguesNo ratings yet