100% found this document useful (1 vote)

1K views95 pagesBioreactor Design Principles and Components

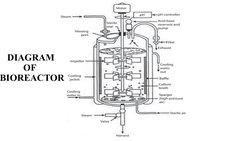

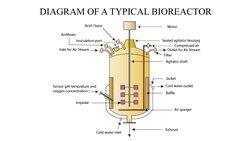

A bioreactor is a device that provides optimal conditions for cell growth and product formation. It consists of features like agitation, oxygen delivery, temperature and pH control systems. The bioreactor design depends on the organism and desired product. It aims to improve productivity and lower costs. Common components include a fermenter vessel, cooling/heating systems, aeration, seals, baffles, impellers, spargers, ports, foam control and sensors/valves to control the environment. Larger bioreactors are used for industrial applications while smaller ones are used for research.

Uploaded by

shubham sabaleCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

1K views95 pagesBioreactor Design Principles and Components

A bioreactor is a device that provides optimal conditions for cell growth and product formation. It consists of features like agitation, oxygen delivery, temperature and pH control systems. The bioreactor design depends on the organism and desired product. It aims to improve productivity and lower costs. Common components include a fermenter vessel, cooling/heating systems, aeration, seals, baffles, impellers, spargers, ports, foam control and sensors/valves to control the environment. Larger bioreactors are used for industrial applications while smaller ones are used for research.

Uploaded by

shubham sabaleCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

- Bioreactor Introduction

- Bioreactor Design

- Features and Components of Bioreactors

- Bioreactor Types

- Specific Parts of Bioreactor