0% found this document useful (0 votes)

89 views25 pagesUnderstanding Ship's Structural Stresses

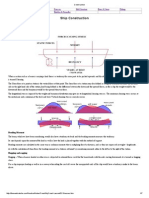

This document discusses stresses on ship structures. It describes static stresses caused by uneven weight distribution, which can cause hogging or sagging. It also discusses stresses from waves in a seaway, which increase bending moments. The stresses include vertical and longitudinal shear forces as well as bending stresses. Bending stresses are calculated using the bending moment, distance from the neutral axis, and second moment of area. The ship bends similar to a beam subjected to these various stresses.

Uploaded by

Juan GonzalesCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

89 views25 pagesUnderstanding Ship's Structural Stresses

This document discusses stresses on ship structures. It describes static stresses caused by uneven weight distribution, which can cause hogging or sagging. It also discusses stresses from waves in a seaway, which increase bending moments. The stresses include vertical and longitudinal shear forces as well as bending stresses. Bending stresses are calculated using the bending moment, distance from the neutral axis, and second moment of area. The ship bends similar to a beam subjected to these various stresses.

Uploaded by

Juan GonzalesCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd