Professional Documents

Culture Documents

Lecture 2

Uploaded by

Ahmed0 ratings0% found this document useful (0 votes)

5 views12 pagesCopyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views12 pagesLecture 2

Uploaded by

AhmedCopyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 12

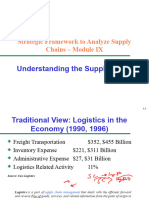

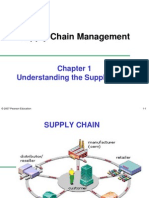

Supply Chain Management

Chapter 1

Understanding the Supply Chain

© 2007 Pearson Education 1-1

Importance of Supply Chain

Decisions – Wal-Mart

Leader in using supply chain design, planning, and operation.

Heavy investment on transportation and information infrastructure to

facilitate the effective flow of goods, information and funds.

Supply chain is designed with clusters of stores around distribution centers

to facilitate frequent replenishment in a cost-effective manner.

Frequent replenishment allows stores to match supply and demand more

effectively.

© 2007 Pearson Education 1-2

Importance of Supply Chain

Decisions – Wal-Mart

Leader in sharing information and collaborating with suppliers to bring

down costs and improve product availability.

Results are impressive:

– Annual Sales in 1980: $ 1 Billion

– Annual Sales in 2018: $ 495.76 Billion

© 2007 Pearson Education 1-3

Importance of Supply Chain

Decisions – Webvan

Large warehouses in several major cities in the United States with no

retail outlets.

Groceries were delivered to customer homes from those warehouses.

This design could not compete with traditional supermarket supply

chains in terms of cost.

Traditional supermarkets bring product to a supermarket close to the

consumer using full truckloads, resulting in very low transportation

costs.

© 2007 Pearson Education 1-4

Importance of Supply Chain

Decisions – Webvan

Traditional supermarkets turn their inventory relatively fast and let

the customer perform most of the picking activity in the store.

Webvan turned its inventory marginally faster than supermarkets but

incurred much higher transportation costs for home delivery and high

labor costs to pick customer orders.

The result was a company that folded in 2001 within two years of a

very successful initial public offering.

© 2007 Pearson Education 1-5

Decision Phases of a Supply Chain

Successful Supply Chain Management requires many decisions

relating to the flow of Information, Product and Funds.

Each decision should be made to raise the Supply Chain Surplus.

Three categories or phases, depending on the frequency and time

frame of the decision:

1. Supply chain strategy or design

2. Supply chain planning

3. Supply chain operation

© 2007 Pearson Education 1-6

1. Supply Chain Strategy or

Design

Company decides how to structure the Supply Chain over the next

several years based on the marketing and pricing plans of a

product.

Decisions about the structure of the supply chain and what processes

each stage will perform.

Strategic Decisions include:

– Outsource or In-house Supply Chain.

– Location and Capacities.

– Products to be made or stored at various locations.

– Modes of transportation.

– Information Systems.

© 2007 Pearson Education 1-7

1. Supply Chain Strategy or

Design

Supply chain configuration must support its strategic objectives

and increase the Supply Chain surplus.

Supply chain design decisions are long-term and expensive to

reverse on short notice.

Uncertainty in anticipated market conditions need to be

considered.

© 2007 Pearson Education 1-8

2. Supply Chain Planning

Definition of a set of policies that govern short-term

operations

Time frame considered is from quarter to a year.

Planning must be done within the constraints created

in the Strategic Phase.

© 2007 Pearson Education 1-9

2. Supply Chain Planning

Planning decisions:

– Which markets will be supplied from which locations

– Planned buildup of inventories

– Subcontracting, backup locations

– Inventory policies

– Timing and size of market promotions

Planning establish parameters within which a supply chain will

function over a specified period of time.

Result is defined set of operating policies that govern short-

term operations.

© 2007 Pearson Education 1-10

3. Supply Chain Operation

Time horizon is weekly or daily.

Decisions regarding individual customer orders.

Supply chain configuration is considered fixed and planning policies

already determined.

Goal is to implement the operating policies as effectively as possible

Allocate orders to inventory or production, set order due dates, generate

pick lists at a warehouse, allocate an order to a particular shipment, set

delivery schedules, place replenishment orders

Much less uncertainty (short time horizon)

© 2007 Pearson Education 1-11

Examples of Supply Chain

Gateway and Apple: Two Different journeys into retailing

Zara: Apparel manufacturing and retail

W.W. Grainger and Mcmaster-Carr: MRO suppliers

Toyota: a global auto manufacturer

Amazon: Online sales

Macy’s: Omni-Channel retailing

© 2007 Pearson Education 1-12

You might also like

- Enterprise Supply Chain Management: Integrating Best in Class ProcessesFrom EverandEnterprise Supply Chain Management: Integrating Best in Class ProcessesNo ratings yet

- Chap 1Document45 pagesChap 1pink pinkNo ratings yet

- Supply Chain Management (3rd Edition)Document33 pagesSupply Chain Management (3rd Edition)Pranav VyasNo ratings yet

- Lean Distribution: Applying Lean Manufacturing to Distribution, Logistics, and Supply ChainFrom EverandLean Distribution: Applying Lean Manufacturing to Distribution, Logistics, and Supply ChainRating: 2.5 out of 5 stars2.5/5 (2)

- ! SCM Chopra Chapters 1-17Document406 pages! SCM Chopra Chapters 1-17Bibekananda Panda33% (6)

- Traditional View: Logistics in The Manufacturing FirmDocument32 pagesTraditional View: Logistics in The Manufacturing FirmRedwanul IslamNo ratings yet

- Chopra Scm5 Ch01 GeDocument33 pagesChopra Scm5 Ch01 GeJAVIER ENRIQUE MU„OZ QUIROZNo ratings yet

- Chopra3 PPT ch01Document25 pagesChopra3 PPT ch01osama haseebNo ratings yet

- Chapter 1 - Understanding The Supply ChainDocument30 pagesChapter 1 - Understanding The Supply ChainJyothi VenuNo ratings yet

- Strategic Framework To Analyze Supply Chains 1 - 1Document46 pagesStrategic Framework To Analyze Supply Chains 1 - 1Arka BandyopadhyayNo ratings yet

- Chapter 1Document33 pagesChapter 1Shahzaib MazherNo ratings yet

- SCM CH 1Document26 pagesSCM CH 1Dawit HusseinNo ratings yet

- 403 - Supply Chain Management 3e - Sunil Chopra, Peter MeindlDocument484 pages403 - Supply Chain Management 3e - Sunil Chopra, Peter MeindlRizkika Ramadhani100% (2)

- Chapter 1Document31 pagesChapter 1mohsinali100% (1)

- Revisi PPT7 - SCMDocument63 pagesRevisi PPT7 - SCMAbdul GhoniNo ratings yet

- Supply Chain Management: Strategy, Planning, and Operation: Seventh Edition, Global EditionDocument39 pagesSupply Chain Management: Strategy, Planning, and Operation: Seventh Edition, Global Editionasim100% (1)

- Supply Chain Case StudyDocument4 pagesSupply Chain Case Studyprocurement cellNo ratings yet

- Week 1 Introduction of Supply Chain ManagementDocument13 pagesWeek 1 Introduction of Supply Chain ManagementFirdavs SanakulovNo ratings yet

- SCM 1-18 PPTDocument801 pagesSCM 1-18 PPTMr Boda Saikiran IPENo ratings yet

- Understanding The Supply Chain: Powerpoint Presentation To Accompany Powerpoint Presentation To AccompanyDocument33 pagesUnderstanding The Supply Chain: Powerpoint Presentation To Accompany Powerpoint Presentation To AccompanySheena HarrienNo ratings yet

- Supply ChainDocument35 pagesSupply ChainRayhan Atunu0% (1)

- Understanding The Supply Chain: Powerpoint Presentation To Accompany Powerpoint Presentation To AccompanyDocument20 pagesUnderstanding The Supply Chain: Powerpoint Presentation To Accompany Powerpoint Presentation To AccompanysynwithgNo ratings yet

- Traditional View: Logistics in The Manufacturing FirmDocument36 pagesTraditional View: Logistics in The Manufacturing Firmgsatch4uNo ratings yet

- KUL 1 Chopra INTRO Sept2011Document48 pagesKUL 1 Chopra INTRO Sept2011Uge HolicNo ratings yet

- Decision Phases in Supply ChainDocument16 pagesDecision Phases in Supply ChainShowkat HossainNo ratings yet

- Understanding The Supply Chain: Powerpoint Presentation To Accompany Chopra and Meindl Supply Chain Management, 5EDocument37 pagesUnderstanding The Supply Chain: Powerpoint Presentation To Accompany Chopra and Meindl Supply Chain Management, 5EZohaib AhmadNo ratings yet

- Understanding The Supply Chain: Powerpoint Presentation To Accompany Chopra and Meindl Supply Chain Management, 5EDocument19 pagesUnderstanding The Supply Chain: Powerpoint Presentation To Accompany Chopra and Meindl Supply Chain Management, 5EHassan ArifNo ratings yet

- Chopra4 PPT ch01Document13 pagesChopra4 PPT ch01Neamat HassanNo ratings yet

- Chapter 2 Supply Chain Planning and Its DireverDocument43 pagesChapter 2 Supply Chain Planning and Its DireverEphrem FekaduNo ratings yet

- DR - Debmalya Ghosh: © 2007 Pearson Education 1-1Document23 pagesDR - Debmalya Ghosh: © 2007 Pearson Education 1-1Ruchi KumariNo ratings yet

- Chopra scm5 ch01Document23 pagesChopra scm5 ch01Shahed MahmudNo ratings yet

- Chopra scm5 ch01Document26 pagesChopra scm5 ch01Rizqy Ridho PNo ratings yet

- 1.1 What Is A Supply Chain?Document5 pages1.1 What Is A Supply Chain?chitraNo ratings yet

- Supply Chain Management (5th Edition)Document5 pagesSupply Chain Management (5th Edition)sojoud shorbajiNo ratings yet

- SCM 5 Strategic Fit - ContunuedDocument20 pagesSCM 5 Strategic Fit - Contunuedvaibhav chaurasiaNo ratings yet

- Chopra4 PPT ch03Document11 pagesChopra4 PPT ch03Neamat HassanNo ratings yet

- Chopra Scm7 Inppt 05 Working 4Document117 pagesChopra Scm7 Inppt 05 Working 4Mohammad TaimoorNo ratings yet

- Session5 Strategfitppt LSCM2022Document21 pagesSession5 Strategfitppt LSCM2022absa62781No ratings yet

- OML6 - Supply Chain ManagementDocument34 pagesOML6 - Supply Chain ManagementBENZINNo ratings yet

- Supply Chain Drivers and Metrics: © 2007 Pearson Education 3-1Document20 pagesSupply Chain Drivers and Metrics: © 2007 Pearson Education 3-1AsadNo ratings yet

- Chapter 1 - Understanding The Supply Chain-StDocument31 pagesChapter 1 - Understanding The Supply Chain-StXuân TrườngNo ratings yet

- Chapter 2 Supply Chain Performance Achieving Strategic Fit and ScopeDocument37 pagesChapter 2 Supply Chain Performance Achieving Strategic Fit and Scopeleake kinfuNo ratings yet

- Chapter 1 Understanding The Supply ChainDocument31 pagesChapter 1 Understanding The Supply ChainZawad AbrarNo ratings yet

- Chopra Scm5 Ch01 GeDocument31 pagesChopra Scm5 Ch01 Geফয়সাল হোসেন100% (1)

- Supply Chain Management - TQMDocument11 pagesSupply Chain Management - TQMsuriya kishoreNo ratings yet

- Project Supply Chain Management: Introduction To SC, SCM, in ProjectDocument35 pagesProject Supply Chain Management: Introduction To SC, SCM, in ProjectMuazam AliNo ratings yet

- Lec34 SCMAfshan FA22aDocument35 pagesLec34 SCMAfshan FA22aM JunaidNo ratings yet

- Supply Chain ManagementDocument21 pagesSupply Chain ManagementA KNo ratings yet

- Understanding The Supply ChainDocument32 pagesUnderstanding The Supply ChainGuarantee International CollegeNo ratings yet

- Lecture 2 - Supply Chain Performance Achieveing Strategic Fit and ScopeDocument28 pagesLecture 2 - Supply Chain Performance Achieveing Strategic Fit and ScopeNadine AguilaNo ratings yet

- SISLOG-2. Logistics StrategyDocument17 pagesSISLOG-2. Logistics StrategyGhani RizkyNo ratings yet

- Decision Phases SCMDocument4 pagesDecision Phases SCMsubhashm.dasariNo ratings yet

- Chain Decisions On The Success of A Firm. The Goal of A Supply Chain Should Be To Grow OverallDocument8 pagesChain Decisions On The Success of A Firm. The Goal of A Supply Chain Should Be To Grow OverallmelihNo ratings yet

- Module 3 - Supply Chain StrategiesDocument28 pagesModule 3 - Supply Chain StrategiesAreeba AmirNo ratings yet

- BUSINESS LOGISTICS FINAL EXAMDocument6 pagesBUSINESS LOGISTICS FINAL EXAMJessica LaguatanNo ratings yet

- Scoc Lecture 1Document33 pagesScoc Lecture 1Praveen SilvaNo ratings yet

- 5 Supply Chain Management and Customer ServiceDocument42 pages5 Supply Chain Management and Customer ServiceSandeep SonawaneNo ratings yet

- Achieving Strategic Fit and ScopeDocument10 pagesAchieving Strategic Fit and ScopeLaila RashedNo ratings yet

- Project Presentaion SCM Mam ReemaDocument12 pagesProject Presentaion SCM Mam ReemaSyed Husnain Ali ShahNo ratings yet

- Lecture 3Document15 pagesLecture 3AhmedNo ratings yet

- S.I Group PresentationDocument8 pagesS.I Group PresentationAhmedNo ratings yet

- Zara's Fast Fashion Strategy and Global SuccessDocument74 pagesZara's Fast Fashion Strategy and Global SuccessCairis CairisNo ratings yet

- Exercise 1Document1 pageExercise 1AhmedNo ratings yet

- Analysis of Supply Chain Models in A System of SysDocument7 pagesAnalysis of Supply Chain Models in A System of SysAhmedNo ratings yet

- Lecture 2 & 3Document27 pagesLecture 2 & 3AhmedNo ratings yet

- Self Sustainability AssignmentDocument3 pagesSelf Sustainability AssignmentAhmedNo ratings yet

- Taxation AssignmentDocument4 pagesTaxation AssignmentAhmedNo ratings yet

- Ims Corporate Profile 2020Document27 pagesIms Corporate Profile 2020AhmedNo ratings yet

- Ambulance Go!Document12 pagesAmbulance Go!AhmedNo ratings yet

- Columban College, Inc: The Following Are The Account Titles and Their Normal BalancesDocument3 pagesColumban College, Inc: The Following Are The Account Titles and Their Normal BalancesAriaiza SanpiaNo ratings yet

- Humawid, Francis Louie A PDFDocument1 pageHumawid, Francis Louie A PDFLUINo ratings yet

- 11th Accountancy Full Study Material English Medium 2023-24Document64 pages11th Accountancy Full Study Material English Medium 2023-24osama guyzz100% (1)

- Credit Collection Units 1 3Document46 pagesCredit Collection Units 1 3elle gutierrezNo ratings yet

- Loan Agreement TemplateDocument3 pagesLoan Agreement TemplateAdor IsipNo ratings yet

- RoundaboutDocument15 pagesRoundaboutMuhammad MuhaiminNo ratings yet

- Huawei Switch Bandwidth Limit Configure - GPON SolutionDocument6 pagesHuawei Switch Bandwidth Limit Configure - GPON SolutionHakim QaradaghiNo ratings yet

- History of Accounting Rex VillanuevaDocument3 pagesHistory of Accounting Rex Villanuevalgucabugao treasuryNo ratings yet

- APPS Rating and ReviewsDocument83 pagesAPPS Rating and ReviewsApurbh Singh KashyapNo ratings yet

- Demand Letter Ms LeonyDocument2 pagesDemand Letter Ms Leonyfe garcia macasaetNo ratings yet

- Week 2 Marketing Channels and Value NetworksDocument55 pagesWeek 2 Marketing Channels and Value NetworksDiego OchoaNo ratings yet

- HDFC Bank statement details transactions for MR MOHD UVAISDocument5 pagesHDFC Bank statement details transactions for MR MOHD UVAISMohd UvaisNo ratings yet

- Credit Card Hacking TutorialDocument3 pagesCredit Card Hacking TutorialIdoraxNo ratings yet

- Accounting Practice SetDocument33 pagesAccounting Practice SetANDAYA SHERLYN67% (3)

- GitHub - Rohitm17 - CCNA-v7 - This Contains The Content For The Beginners To Learn PracticallyDocument3 pagesGitHub - Rohitm17 - CCNA-v7 - This Contains The Content For The Beginners To Learn PracticallyapollokimoNo ratings yet

- Purple Futuristic Pitch Deck PresentationDocument30 pagesPurple Futuristic Pitch Deck PresentationEljine OchoaNo ratings yet

- Designing Next Generation Vehicle Communication Aws IotDocument48 pagesDesigning Next Generation Vehicle Communication Aws Iotdai fuonNo ratings yet

- TCIL 11 Inmarsat PresentationDocument48 pagesTCIL 11 Inmarsat PresentationMAX001122No ratings yet

- Ecommerce Report 2Document14 pagesEcommerce Report 2Riya SthaNo ratings yet

- Impact of Medicaid Extension and Local Spending For Health Care by Texas Senate DistrictDocument62 pagesImpact of Medicaid Extension and Local Spending For Health Care by Texas Senate Districtbee5834No ratings yet

- SCRIBD. TracFone Wireless Inc Subpoena Compliance DepartmentDocument5 pagesSCRIBD. TracFone Wireless Inc Subpoena Compliance DepartmentEmanuel McCrayNo ratings yet

- Choice of Mode of TransportationDocument20 pagesChoice of Mode of TransportationSrilalitha GirijaNo ratings yet

- Employee 1Document278 pagesEmployee 1Sourav Sen100% (1)

- Technical Support Notification - TLS4 Series Programming - Email Setup & Troubleshooting (576047-368)Document4 pagesTechnical Support Notification - TLS4 Series Programming - Email Setup & Troubleshooting (576047-368)rogeriofcrealNo ratings yet

- Fundamentals in Lodging Management - IntroductionDocument24 pagesFundamentals in Lodging Management - Introductionaireen clores100% (1)

- Vision, Mission and Values: ExcellenceDocument3 pagesVision, Mission and Values: ExcellenceromaNo ratings yet

- Hailey's Downloadable Marketing Dashboard - Sponsored by Improvado - IoDocument37 pagesHailey's Downloadable Marketing Dashboard - Sponsored by Improvado - IoFakhri HakimNo ratings yet

- The Endgame - A Thesis On The Future of Chainlink and Web 3.0Document44 pagesThe Endgame - A Thesis On The Future of Chainlink and Web 3.0GideonEmmanuelNo ratings yet

- Anatomy of Commercial IMSI Catchers and DetectorsDocument13 pagesAnatomy of Commercial IMSI Catchers and DetectorsTrain SlowNo ratings yet

- PHILHEALTHDocument13 pagesPHILHEALTHJo ReyesNo ratings yet