0% found this document useful (0 votes)

893 views15 pagesBasic Safety Presentation

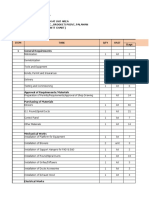

This document provides an overview of basic safety topics including why safety is important, what constitutes safe work practices, emergency evacuation procedures, hazard identification, personal protective equipment, electrical safety, lock out/tag out procedures, and safe lifting techniques. The key messages are that safety protects workers and their families, following proper safety protocols is required, and only trained personnel should perform certain maintenance tasks.

Uploaded by

Jay MarkCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

893 views15 pagesBasic Safety Presentation

This document provides an overview of basic safety topics including why safety is important, what constitutes safe work practices, emergency evacuation procedures, hazard identification, personal protective equipment, electrical safety, lock out/tag out procedures, and safe lifting techniques. The key messages are that safety protects workers and their families, following proper safety protocols is required, and only trained personnel should perform certain maintenance tasks.

Uploaded by

Jay MarkCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd