Professional Documents

Culture Documents

20me53i Week6 Day3 Session1

Uploaded by

raju0 ratings0% found this document useful (0 votes)

43 views6 pagesThe document outlines the typical 4 stage process for advanced manufacturing (AM):

1) CAD software is used to create a 3D digital model of the part.

2) The CAD file is converted to an STL file format which describes the external surfaces and geometry of the part.

3) The STL file is transferred to the AM machine and may be manipulated to optimize size, position, and orientation for printing.

4) The AM machine is set up and configured based on build parameters like material type, energy source, layer thickness, and timing before initiating the printing process.

Original Description:

ww

Original Title

20ME53I_WEEK6_DAY3_SESSION1

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document outlines the typical 4 stage process for advanced manufacturing (AM):

1) CAD software is used to create a 3D digital model of the part.

2) The CAD file is converted to an STL file format which describes the external surfaces and geometry of the part.

3) The STL file is transferred to the AM machine and may be manipulated to optimize size, position, and orientation for printing.

4) The AM machine is set up and configured based on build parameters like material type, energy source, layer thickness, and timing before initiating the printing process.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

43 views6 pages20me53i Week6 Day3 Session1

Uploaded by

rajuThe document outlines the typical 4 stage process for advanced manufacturing (AM):

1) CAD software is used to create a 3D digital model of the part.

2) The CAD file is converted to an STL file format which describes the external surfaces and geometry of the part.

3) The STL file is transferred to the AM machine and may be manipulated to optimize size, position, and orientation for printing.

4) The AM machine is set up and configured based on build parameters like material type, energy source, layer thickness, and timing before initiating the printing process.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 6

Department of Collegiate and Technical Education

STEPS IN GENERIC AM PROCESS

ADVANCED MANUFACTURING( V Semester)

Mechanical Engineering

Advanced Manufacturing– 20ME53I

Steps in Generic AM process

Advanced Manufacturing– 20ME53I

Stage 1: CAD

All RP parts must start from a software model that fully describes

the external geometry. This can involve the use of almost any

professional CAD solid modelling software, but the output must be

a 3D solid or surface representation. Reverse engineering

equipment (e.g., laser scanning) can also be used to create this

representation.

Stage 2: Conversion to STL

Nearly every AM machine accepts the STL file format, which has

become a de facto standard, and nearly every CAD system can

output such a file format. This file describes the external closed

surfaces of the original CAD model and forms the basis for

calculation of the slices.

Advanced Manufacturing– 20ME53I

Stage 3: Transfer to RP Machine and STL File

Manipulation

The STL file describing the part must be transferred to the RP

machine. Here, there may be some general manipulation of the file

so that it is the correct size, position, and orientation for building.

Stage 4: Machine Setup

The RP machine must be properly set up prior to the build process.

Such settings would relate to the build parameters like the material

constraints, energy source, layer thickness, timings, etc.

Advanced Manufacturing– 20ME53I

REFERENCES

o Additive manufacturing of metals by Li yang-Keng Hsu,

Donald Godfrey

o Additive manufacturing technology by Ian Gibson, David Rosen

o Various sources of internet

Thank you

Advanced Manufacturing– 20ME53I

You might also like

- 07 Final Rapid Prototype ReportDocument16 pages07 Final Rapid Prototype ReportpallaviNo ratings yet

- Module - 5Document92 pagesModule - 5Anand ANo ratings yet

- Unit 1 ADMDocument43 pagesUnit 1 ADMCHINTAKINDI VENKATAIAH RAGHUVAMSHINo ratings yet

- 20me53i Week6 Day3 Session1Document9 pages20me53i Week6 Day3 Session1rajuNo ratings yet

- R P, T, F: Apid Rototyping Ooling AND AbricationDocument26 pagesR P, T, F: Apid Rototyping Ooling AND AbricationSreejith S NairNo ratings yet

- 18me4105 - Additive Manufacturing Key & Scheme of Evaluation Dec-2022Document13 pages18me4105 - Additive Manufacturing Key & Scheme of Evaluation Dec-2022srinivas kanakalaNo ratings yet

- Rapid Prototyping Notes by Shashidhar 2Document132 pagesRapid Prototyping Notes by Shashidhar 2sharma devarajuNo ratings yet

- Use of Rapid Prototyping in Rapid ToolingDocument11 pagesUse of Rapid Prototyping in Rapid ToolingSudhanwa KulkarniNo ratings yet

- Unit 1Document35 pagesUnit 1narasimhanaiduNo ratings yet

- Rapid PrototypingDocument123 pagesRapid PrototypingSyed irfan100% (2)

- Research Article: CAD Interface For Automatic Robot Welding ProgrammingDocument0 pagesResearch Article: CAD Interface For Automatic Robot Welding ProgrammingKarthi KeyanNo ratings yet

- Rapid PrototypingDocument6 pagesRapid PrototypingVijay KannanNo ratings yet

- Stereo Lithography PresentationDocument28 pagesStereo Lithography PresentationJayanth RajNo ratings yet

- L9-TA202A-Additive Manufacturing IDocument57 pagesL9-TA202A-Additive Manufacturing IjthyfgdNo ratings yet

- Sathyabama University: Sprx1032 - Rapid Prototyping Course MaterialDocument22 pagesSathyabama University: Sprx1032 - Rapid Prototyping Course MaterialRaghuNo ratings yet

- UNIT1,3Document14 pagesUNIT1,3Sagar BatraNo ratings yet

- Rapid Prototyping: Department of Mechanical Engineering, The Ohio State UniversityDocument41 pagesRapid Prototyping: Department of Mechanical Engineering, The Ohio State Universityvikram1092No ratings yet

- Module 1 Additive ManufacturingDocument125 pagesModule 1 Additive ManufacturingMaheshNo ratings yet

- Additive Manufacturing: Presented by Bharath Devasoth Assistant Professor Department of Mechanical EngineeringDocument123 pagesAdditive Manufacturing: Presented by Bharath Devasoth Assistant Professor Department of Mechanical Engineeringbharath devasothNo ratings yet

- AMTA UNIT 1 CompleteDocument11 pagesAMTA UNIT 1 CompleteAdula RajasekharNo ratings yet

- Advanced Manufacturing Systems Assignment 1 FaraiDocument10 pagesAdvanced Manufacturing Systems Assignment 1 Faraifatsoe1No ratings yet

- Rapid Prototyping: Process Advantage, Comparison and ApplicationDocument8 pagesRapid Prototyping: Process Advantage, Comparison and ApplicationSai Manikanta TholetiNo ratings yet

- Lecture Notes Iare PDFDocument103 pagesLecture Notes Iare PDFTaj Siddiq Los BlancosNo ratings yet

- Unit - 1Document40 pagesUnit - 1rajeshNo ratings yet

- Rapid Technology in Dental Biomechanics Vrtanoski Gligorce, Andonovic VladanDocument6 pagesRapid Technology in Dental Biomechanics Vrtanoski Gligorce, Andonovic VladanGligorcheNo ratings yet

- 3D Printing BasicsDocument40 pages3D Printing BasicsBalaji VasudevanNo ratings yet

- Seminar SawDocument36 pagesSeminar SawNimesh C SNo ratings yet

- RPTDocument4 pagesRPTSARAN PRASANTHNo ratings yet

- Application of Cad in RP TechnologyffDocument13 pagesApplication of Cad in RP TechnologyffPushkar FegadeNo ratings yet

- Rapid Pro To Typing PrimerDocument13 pagesRapid Pro To Typing Primersinghsujit1No ratings yet

- Additive MFGDocument18 pagesAdditive MFGEmerald InnovatesNo ratings yet

- AdditivemanufacturingDocument121 pagesAdditivemanufacturingGaurish M SamantNo ratings yet

- Additive Manufacturing UNIT-1Document11 pagesAdditive Manufacturing UNIT-1ENGINEERING MECHANICSNo ratings yet

- Unit 1 PDFDocument56 pagesUnit 1 PDFDaily SerialsNo ratings yet

- THE PRACTICAL USE OF SIMULATION IN THE Sheet Metal Forming IndustryDocument17 pagesTHE PRACTICAL USE OF SIMULATION IN THE Sheet Metal Forming IndustryripanumariusionutNo ratings yet

- 1 Overview of Rapid Prototyping: o o o o o oDocument15 pages1 Overview of Rapid Prototyping: o o o o o oVaisakh SomakumarNo ratings yet

- CAD/CAM TechnologyDocument16 pagesCAD/CAM Technologyishaq kazeemNo ratings yet

- Rapid PrototypingDocument36 pagesRapid PrototypingmechanicalbooNo ratings yet

- Additive Manufacturing: Presented by Nazma AmrinDocument23 pagesAdditive Manufacturing: Presented by Nazma AmrinSai SrinivasNo ratings yet

- 10 - CH 24Document14 pages10 - CH 24darshan008No ratings yet

- Interface Formats: Mathematical RepresentationDocument7 pagesInterface Formats: Mathematical RepresentationvinaysammNo ratings yet

- What Is A Prototype?Document5 pagesWhat Is A Prototype?animeshkumarvermaNo ratings yet

- Recent Advances in Rapid PrototypingDocument15 pagesRecent Advances in Rapid PrototypingSatish HSNo ratings yet

- PLM PDM CPCDocument8 pagesPLM PDM CPCVijay RichardNo ratings yet

- Unit IDocument52 pagesUnit IRoshliNo ratings yet

- ME1355-CAD / CAM Laboratory: Lab ManualDocument42 pagesME1355-CAD / CAM Laboratory: Lab ManualVeeria Chandran S100% (1)

- AMTA UNIT5 CompleteDocument20 pagesAMTA UNIT5 CompleteAdula RajasekharNo ratings yet

- Computer Aided Design and Manufacturing Module 5 - Vikranth KannanthDocument35 pagesComputer Aided Design and Manufacturing Module 5 - Vikranth KannanthRavi Shankar mrNo ratings yet

- Syllabus AMTDocument2 pagesSyllabus AMTSyed Farooq PatilNo ratings yet

- Unit 2,4Document24 pagesUnit 2,4GooftilaaAniJiraachuunkooYesusiinNo ratings yet

- E-Manufacturing One-Off Intricate Castings Using Rapid Prototyping TechnologyDocument8 pagesE-Manufacturing One-Off Intricate Castings Using Rapid Prototyping TechnologyZaheer AhamedNo ratings yet

- 50 - Vladan Andonovik1Document4 pages50 - Vladan Andonovik1GligorcheNo ratings yet

- Paper On: IndexDocument4 pagesPaper On: Indexamar_bhupali1507No ratings yet

- Tutorial: Rapid Prototyping TechnologiesDocument10 pagesTutorial: Rapid Prototyping TechnologiesFilip SvnikolicNo ratings yet

- Cad CamDocument36 pagesCad Camqmggymypk8No ratings yet

- Current Techniques and Methodologies in Rapid PrototypingDocument15 pagesCurrent Techniques and Methodologies in Rapid PrototypingLudor EngineeringNo ratings yet

- Lecture 4 Rapid Prototyping PDFDocument75 pagesLecture 4 Rapid Prototyping PDFsafin kaosarNo ratings yet

- Chang 2004Document8 pagesChang 2004Hoda HosnyNo ratings yet

- Striving For CAMDocument9 pagesStriving For CAMbshahidhNo ratings yet

- 20me53i Week6 Day3 Session1Document7 pages20me53i Week6 Day3 Session1rajuNo ratings yet

- 20me53i Week6 Day3 Session1Document6 pages20me53i Week6 Day3 Session1rajuNo ratings yet

- 1.STL Files Contains - .: Advanced Manufacturing and Technology and Code 20ME53I 2022-23Document2 pages1.STL Files Contains - .: Advanced Manufacturing and Technology and Code 20ME53I 2022-23rajuNo ratings yet

- LIC's Jeevan Lakshya (T-933) : Benefit IllustrationDocument3 pagesLIC's Jeevan Lakshya (T-933) : Benefit IllustrationrajuNo ratings yet

- Coursera XWQU3SNPPuuiDocument1 pageCoursera XWQU3SNPPuuirajuNo ratings yet

- Syllabus ETR 2019 20 Part BDocument62 pagesSyllabus ETR 2019 20 Part BrajuNo ratings yet

- W7S1Document16 pagesW7S1rajuNo ratings yet

- File 1614263265 Brochure FileDocument1 pageFile 1614263265 Brochure FilerajuNo ratings yet

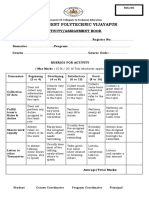

- ACTIVITY BOOK Format - AUG-22Document1 pageACTIVITY BOOK Format - AUG-22rajuNo ratings yet

- JioMart Invoice 16592485700077599ADocument3 pagesJioMart Invoice 16592485700077599ArajuNo ratings yet

- Tax Invoice/Bill of Supply/Cash Memo: (Original For Recipient)Document1 pageTax Invoice/Bill of Supply/Cash Memo: (Original For Recipient)rajuNo ratings yet

- Exercise 1Document34 pagesExercise 1rajuNo ratings yet

- ME606 - Engineering Costing & EstimatingDocument3 pagesME606 - Engineering Costing & EstimatingrajuNo ratings yet

- Materials Selection For Hip Prosthesis by The Method of Weighted PropertiesDocument13 pagesMaterials Selection For Hip Prosthesis by The Method of Weighted PropertiesrajuNo ratings yet

- Design Considerations For Connecting Rod: B. Sriharsha, P. Sudhakar RaoDocument6 pagesDesign Considerations For Connecting Rod: B. Sriharsha, P. Sudhakar RaorajuNo ratings yet

- Client ID LQ2729 Ledger For EQ From 2020-12-21 To 2020-12-28Document2 pagesClient ID LQ2729 Ledger For EQ From 2020-12-21 To 2020-12-28rajuNo ratings yet

- Corrigendum STA RecttDocument1 pageCorrigendum STA RecttrajuNo ratings yet

- 06 PlateTheory 01 PlateTheory PDFDocument5 pages06 PlateTheory 01 PlateTheory PDFrajuNo ratings yet

- FD07 Mu Ba Ni 2020Document1 pageFD07 Mu Ba Ni 2020rajuNo ratings yet

- Report Name: District Wise CM Janatha Darshan Complains Date and Time: Saturday, August 22, 2020 9:10:58 AM +05:30 User IdDocument2 pagesReport Name: District Wise CM Janatha Darshan Complains Date and Time: Saturday, August 22, 2020 9:10:58 AM +05:30 User IdrajuNo ratings yet

- Instructions / Checklist For Filling KYC FormDocument19 pagesInstructions / Checklist For Filling KYC FormrajuNo ratings yet