Professional Documents

Culture Documents

HD0390 Ii

HD0390 Ii

Uploaded by

omerbinsohail0 ratings0% found this document useful (0 votes)

5 views2 pagesThe document summarizes improvements made to the HD0390 polyethylene resin. HD0390 II was developed to replace butene with hexene and optimize comonomer placement, resulting in improved impact strength over the original HD0390. Testing showed HD0390 II achieved a more efficient lamella dispersion and higher crystallinity than HD0390, allowing it to pass a 90cm drop test where HD0390 failed. Further validation on commercial machines and application parts is needed to fully evaluate HD0390 II's performance.

Original Description:

Original Title

HD0390_II

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document summarizes improvements made to the HD0390 polyethylene resin. HD0390 II was developed to replace butene with hexene and optimize comonomer placement, resulting in improved impact strength over the original HD0390. Testing showed HD0390 II achieved a more efficient lamella dispersion and higher crystallinity than HD0390, allowing it to pass a 90cm drop test where HD0390 failed. Further validation on commercial machines and application parts is needed to fully evaluate HD0390 II's performance.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views2 pagesHD0390 Ii

HD0390 Ii

Uploaded by

omerbinsohailThe document summarizes improvements made to the HD0390 polyethylene resin. HD0390 II was developed to replace butene with hexene and optimize comonomer placement, resulting in improved impact strength over the original HD0390. Testing showed HD0390 II achieved a more efficient lamella dispersion and higher crystallinity than HD0390, allowing it to pass a 90cm drop test where HD0390 failed. Further validation on commercial machines and application parts is needed to fully evaluate HD0390 II's performance.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 2

HD0390 II (Impact Improved) 100

Drop Impact Strength (cm)

HD0490 (gas phase process) exhibits better impact 93

performance compare to original HD0390 (slurry

process). 90

87

85

New HD0390 II is prepared by replacing butene with

hexene and optimizing comonomer placement in

80

molecular chain. Series1

HD0390 HD0390 II HD0490

We have made it possible to achieve a more efficient

dispersion within the lamella structure, which can result

in improved impact properties.

HD0390 HD0390 II

Particle size (mm) 0.35 0.35

Melt Index (2 kg) (g/10 min) 4.29 4.08

Melting temperature Tm (oC) 132.5 133.1 HD0390 II HD0390

Passed Failed

Crystallinity (%) 77.4 82.6 90cm 90cm 1

Conducting long trials on commercial machines will evaluate the actual performance of the new HD0390 II

(difference in clamping force).

Larger parts usually undergo greater thermal gradients during the molding process, resulting in uneven cooling

and, consequently, residual stresses. Validation is important on application parts.

A better local alternative that can reduce the lead time.

No need to invest more resources in searching for other alternatives.

Can fine-tune HD0390 II to meet the Critical-to-Quality (CTQ) requirements of the application as closely as

possible.

You might also like

- AP Chem CH 7 Practice QuizDocument8 pagesAP Chem CH 7 Practice QuizOmprakash LatiyalNo ratings yet

- US Navy Foundry Manual 1958Document264 pagesUS Navy Foundry Manual 1958Pop Adrian100% (8)

- Analytical Chemistry Quiz MaterialDocument11 pagesAnalytical Chemistry Quiz MaterialAltaf Ur RehmanNo ratings yet

- BIACORE 3000 Instrument HandbookDocument350 pagesBIACORE 3000 Instrument HandbookFederico Carrión100% (1)

- Comparison ThermalDocument1 pageComparison ThermalABDUL REHMAN PIPRANINo ratings yet

- Applications of Infrared SpectrometryDocument32 pagesApplications of Infrared SpectrometryNgurah MahasviraNo ratings yet

- Understanding Oil Analysis TestsDocument15 pagesUnderstanding Oil Analysis Testsjohn thome100% (1)

- Tech Trol Gold Synthetic LubricantDocument2 pagesTech Trol Gold Synthetic LubricantAzhar1109No ratings yet

- Cloropreno WRT Sales SpecDocument2 pagesCloropreno WRT Sales SpecCarlos Romero MuñozNo ratings yet

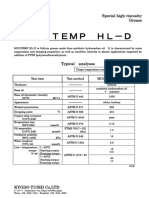

- Multemp HL-DDocument1 pageMultemp HL-DVishal AmleNo ratings yet

- Hempaline Defend 630: Product DescriptionDocument3 pagesHempaline Defend 630: Product DescriptionSalas VinicioNo ratings yet

- Hempaline Defend 630: Product DescriptionDocument3 pagesHempaline Defend 630: Product DescriptionJorge Alberto MontalatNo ratings yet

- Datasheet CG60Document3 pagesDatasheet CG60ouss oussNo ratings yet

- GulfSea de Compressor Oil SeriesDocument2 pagesGulfSea de Compressor Oil SeriesObydur RahmanNo ratings yet

- SKF LGHP 2 GreaseDocument2 pagesSKF LGHP 2 GreaseANILNo ratings yet

- Uniflor 8922elDocument1 pageUniflor 8922elGunen LgNo ratings yet

- VBC Synrol 211Sq: DescriptionDocument1 pageVBC Synrol 211Sq: DescriptionSinh LeNo ratings yet

- Gulf FidelityDocument1 pageGulf FidelityBudi SetiawanNo ratings yet

- Properties of Commercially Pure Titanium and Titanium AlloysDocument27 pagesProperties of Commercially Pure Titanium and Titanium AlloysZhu DanielNo ratings yet

- Asonic HQ 72-102 - EnglishDocument2 pagesAsonic HQ 72-102 - EnglishCleiton Luiz CordeiroNo ratings yet

- Turbo-Coat Acrylic Conformal Coating: Product InformationDocument5 pagesTurbo-Coat Acrylic Conformal Coating: Product InformationSarmad HussainNo ratings yet

- Shell - GTL Sarawax Sx105Document2 pagesShell - GTL Sarawax Sx105pequemecNo ratings yet

- RP MOTO TOWN 4T 20W50 EN tcm14-56018Document1 pageRP MOTO TOWN 4T 20W50 EN tcm14-56018TakNo ratings yet

- Eastman Turbo Oil 2197 PDFDocument2 pagesEastman Turbo Oil 2197 PDFstas2moskalenkoNo ratings yet

- 8100 X-Power 10W60 (EN)Document1 page8100 X-Power 10W60 (EN)Márton MolnárNo ratings yet

- MSDS Titanlene-801YYDocument1 pageMSDS Titanlene-801YYSyuhadaNo ratings yet

- NBR 6240 TdsDocument2 pagesNBR 6240 TdsYorgieNo ratings yet

- Yemchio Transparente PDFDocument1 pageYemchio Transparente PDFSantiago López AlarcónNo ratings yet

- Yemchio Transparente PDFDocument1 pageYemchio Transparente PDFSantiago López AlarcónNo ratings yet

- Gotra TMDocument1 pageGotra TMAbdul RahmadNo ratings yet

- Chevron Texatherm PDS1 LoDocument1 pageChevron Texatherm PDS1 LoAustin UdofiaNo ratings yet

- Soluble Textile Oils TXDocument2 pagesSoluble Textile Oils TXMajed DawaNo ratings yet

- Influence of Waxes On BitumenDocument24 pagesInfluence of Waxes On BitumenJuan CamposNo ratings yet

- Specifications Asfalto 50-80-2023Document1 pageSpecifications Asfalto 50-80-2023H JNo ratings yet

- MAK - Thermic Fluid ADocument3 pagesMAK - Thermic Fluid AannamalailubesNo ratings yet

- TDS - Pla Pro HT - Rev 2.0Document2 pagesTDS - Pla Pro HT - Rev 2.0okta wijayaNo ratings yet

- TDS 3M Scotch-Weld Epoxy Adhesive DP100 GENERALDocument8 pagesTDS 3M Scotch-Weld Epoxy Adhesive DP100 GENERALAkbar Perwira UtamaNo ratings yet

- Texol Texotherm HT Series Irhdr8Document2 pagesTexol Texotherm HT Series Irhdr8Vusal HasanovNo ratings yet

- TDS 化学技术说明书Document2 pagesTDS 化学技术说明书adam sumardinataNo ratings yet

- 1482825639balmerol Protosteel 680Document2 pages1482825639balmerol Protosteel 680durgaprasad.svanmoppesNo ratings yet

- Kapton HN Data SheetDocument5 pagesKapton HN Data Sheet谢朋亨No ratings yet

- Kumho KHS: HSR (High Styrene Resin Masterbatch)Document2 pagesKumho KHS: HSR (High Styrene Resin Masterbatch)Greg PanganNo ratings yet

- Elite Evolution Long Life 5W-30: LubricantsDocument1 pageElite Evolution Long Life 5W-30: Lubricantstehnicar1No ratings yet

- Araldite Av138 hv998Document7 pagesAraldite Av138 hv998Nautique SolutionsNo ratings yet

- Hercules EngDocument1 pageHercules EngTAREK HAMADNo ratings yet

- BIHOL 32-46-68 Hydraulic Oil (HETG)Document1 pageBIHOL 32-46-68 Hydraulic Oil (HETG)azimchemNo ratings yet

- Servoprime G: Description ApplicationDocument1 pageServoprime G: Description Applicationmax job13No ratings yet

- TDS L2057216Document3 pagesTDS L2057216erolsarNo ratings yet

- TGF - (M) 32 Extreme Pressure Gas Turbine OilDocument3 pagesTGF - (M) 32 Extreme Pressure Gas Turbine OilQuy NguyenNo ratings yet

- Balmerol Ultima Plus PremiumDocument2 pagesBalmerol Ultima Plus Premium86satheshNo ratings yet

- 057-Pap 061Document13 pages057-Pap 061Adhi satyaNo ratings yet

- Kluberquiet BQH 72-102Document2 pagesKluberquiet BQH 72-102Yisus Torres MNo ratings yet

- Kanatol 400 (M)Document2 pagesKanatol 400 (M)buildguard7No ratings yet

- High Voltage Grease: Approvals Rohs Compliant (2015/863/eu) : YesDocument2 pagesHigh Voltage Grease: Approvals Rohs Compliant (2015/863/eu) : YestlnferreiraNo ratings yet

- Parthan SL 680: Fully Synthetic Gear OilDocument2 pagesParthan SL 680: Fully Synthetic Gear OilprimnnitNo ratings yet

- DTM Bonding Primer: Protective & Marine CoatingsDocument4 pagesDTM Bonding Primer: Protective & Marine CoatingsAna CabreraNo ratings yet

- For Better Building: Diamond Cements (Prop. Heidelbergcement India LTD) Damoh UnitDocument1 pageFor Better Building: Diamond Cements (Prop. Heidelbergcement India LTD) Damoh UnitAjay SinghNo ratings yet

- Ultra High Spec Grade - Amorim TD1120Document2 pagesUltra High Spec Grade - Amorim TD1120hendro suprianto nugrohoNo ratings yet

- Asonic HQ 72-102: High-Temperature Lubricating Grease For Low-Noise Rolling BearingsDocument2 pagesAsonic HQ 72-102: High-Temperature Lubricating Grease For Low-Noise Rolling BearingsShaleh AhmadNo ratings yet

- ACE 2010 - YL056F Akzo Powder CoatingDocument3 pagesACE 2010 - YL056F Akzo Powder CoatingNitin BalapureNo ratings yet

- Specifiaction - PROKDocument5 pagesSpecifiaction - PROKAjit AgrawalNo ratings yet

- Tecna SCS 37 0T LF - en - 1.1Document1 pageTecna SCS 37 0T LF - en - 1.1Yassine LachhabNo ratings yet

- Effects of Accelerated Curing On Styrene-Butadiene Rubber PMMDocument21 pagesEffects of Accelerated Curing On Styrene-Butadiene Rubber PMMKwan Wai HoeNo ratings yet

- Tecna Scs 37 0t LF - en - 1.1Document1 pageTecna Scs 37 0t LF - en - 1.1Yassine LachhabNo ratings yet

- TDS Turbonycoil TN600 1E19Document2 pagesTDS Turbonycoil TN600 1E19Emad The EnthusiastNo ratings yet

- A Material Point Method For Snow SimulationDocument11 pagesA Material Point Method For Snow SimulationLonlon VictorioNo ratings yet

- Momentum ProbsDocument53 pagesMomentum Probsmajji satishNo ratings yet

- Popular Kheti: Foliar Feeding of Plant NutrientsDocument6 pagesPopular Kheti: Foliar Feeding of Plant NutrientsgokulNo ratings yet

- Periodic Properties (GYCH)Document6 pagesPeriodic Properties (GYCH)Mohit GargNo ratings yet

- A Nomograph For Correction of Boiling Points: Kent State University, KentDocument2 pagesA Nomograph For Correction of Boiling Points: Kent State University, Kentthrowaway456456No ratings yet

- Neet Tot GT-4Document23 pagesNeet Tot GT-4TEJUS KUMAR NARISIPURAM AIITJNo ratings yet

- Basic Organic ChemistryDocument78 pagesBasic Organic Chemistry2E (04) Ho Hong Tat AdamNo ratings yet

- Lab Report Basic Organic Chemistry CHM20Document3 pagesLab Report Basic Organic Chemistry CHM20Muhd Mirza HizamiNo ratings yet

- Bioresources.: Greaseproof Paper Products: A Review Emphasizing Ecofriendly ApproachesDocument27 pagesBioresources.: Greaseproof Paper Products: A Review Emphasizing Ecofriendly ApproachesavgpaulNo ratings yet

- Microwave Vacuum Drying For Advanced Process TechnologyDocument7 pagesMicrowave Vacuum Drying For Advanced Process TechnologyĐóLàTôiNo ratings yet

- Icho1986-1994p Technical and PhysicalDocument38 pagesIcho1986-1994p Technical and PhysicalAlexandra AlgueraNo ratings yet

- 6 - IJIRSET - Paper - Solar Powered Atmospheric Water Generator - FINAL PDFDocument9 pages6 - IJIRSET - Paper - Solar Powered Atmospheric Water Generator - FINAL PDFCatalina DincaNo ratings yet

- Catalogo General PatDocument1 pageCatalogo General PatWilliam Dante Mescco SaireNo ratings yet

- Questions On Gases and SolutionsDocument12 pagesQuestions On Gases and SolutionsChemist Mohamed MohyNo ratings yet

- Wastewater Treatment - Three Steps To Achieving Discharge ComplianceDocument2 pagesWastewater Treatment - Three Steps To Achieving Discharge ComplianceBramJanssen76No ratings yet

- ME246 Fall 2016 Exam2 SolutionDocument5 pagesME246 Fall 2016 Exam2 SolutionJaneNo ratings yet

- Daftar Pustaka Pengaruh Inhibitor Anodik NaNO3 Dan Na2CrO4 Terhadap Korosi Dan Fatik Korosi Pada Aluminium Paduan AA 7050 Di Lingkungan 3.5% NaClDocument4 pagesDaftar Pustaka Pengaruh Inhibitor Anodik NaNO3 Dan Na2CrO4 Terhadap Korosi Dan Fatik Korosi Pada Aluminium Paduan AA 7050 Di Lingkungan 3.5% NaClPramesti Ayu Dwi WulandariNo ratings yet

- Carisma CRC Uk Cat 99a4660100 Rev 07 2020pdf PDFDocument60 pagesCarisma CRC Uk Cat 99a4660100 Rev 07 2020pdf PDFSenad BajrićNo ratings yet

- Gravimetric Analysis and SeparationDocument10 pagesGravimetric Analysis and SeparationAnonymous 3Cp7yCIyQNo ratings yet

- Mechanics &properties of Matter II Internal: Both of The Momentum and Total Kinetic Energy Are ConservedDocument5 pagesMechanics &properties of Matter II Internal: Both of The Momentum and Total Kinetic Energy Are Conservedmadhuri santhoshiNo ratings yet

- MN It ConferenceDocument5 pagesMN It ConferenceEdison ChandraseelanNo ratings yet

- Whirlpool AWG 1112Document16 pagesWhirlpool AWG 1112and andrewNo ratings yet

- Cygnus 4plus Operating ManualDocument141 pagesCygnus 4plus Operating Manualdzul effendiNo ratings yet

- Dynamics Study MaterialDocument57 pagesDynamics Study MaterialJeyson Joseph Amaro RojasNo ratings yet