Professional Documents

Culture Documents

Principal Requirements of Design Process

Uploaded by

Sumit SinghOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Principal Requirements of Design Process

Uploaded by

Sumit SinghCopyright:

Available Formats

Principal Requirements of design process

Submitted by: Sumit Singh Roll no: MPE/09/2021 (M.Tech (Production)(Part time Semester: 5

Understanding the Problem

Surveys show that poor product definition is a factor in 80% of all timeto-market delays. Sometimes a lot of time and money can be wasted solving the wrong problem.

Quality Function Deployment (QFD)

QFD is a popular product design technique. QFD is organized to develop major pieces of information necessary to understanding the problem. Using QFD, Toyota was able to reduce the costs of bringing a new car model to market by over 60% and to decrease the time required for its development by 33%. Toyota achieved the above results while improving the quality of the product.

(The House of Quality (HOQ

Applying the QFD steps builds the house of quality. HOQ is a house of many rooms, each containing valuable information.

QFD Steps

Step 1: Identify the customers: determine exactly WHO they are. Customers can be internal or external to the company. For many products, the most important customers are the consumers, the people who will buy the product and tell other consumers about its quality (or lack thereof).

Step 2: Determine the customers requirements: ?WHAT do the customers want

Typically, as customer surveys show, the consumers want a product that works as it should, lasts along time, is easy to maintain, looks attractive, and has many features. Typically, the production customer wants a product that is easy to manufacture and assemble, uses available resources, uses standard parts and methods, uses existing facilities, and produces a minimum of scarps and rejected parts. Typically, the marketing/sales customer wants a product that meets consumers requirements; is easy to package, store, and transport; is attractive; and is suitable for display.

Collection methods for customer requirements

Observations = observing customers using the existing product. Surveys = questionnaires through email, over the telephone, or in face to face interviews Focus groups = a specially designed meeting with a carefully chosen group of 7 to 10 potential customers.

Step 3: Determine relative importance of the requirements: WHO versus WHAT

Relative importance can be evaluated by generating a weighting factor for each requirement. Traditionally, the customers are asked to rate each requirement on a scale from 1 to 10. A better method, the fixed sum method, is to tell each customer that they have 100 points to distribute among the requirements.

Step 5: Generate engineering specifications: ?HOW will the customers requirements be met

Engineering specifications are the restatement of the design problem in terms of parameters that can be measured and have target values. Parameters are developed in this step and the target values for these parameters are developed in step 8.

Step 6: Relate customers requirements to engineering specifications: HOW to measure ?WHAT This is the central part of HOQ. Strong relationship Medium relationship Weak relationship Blank = no relationship

Step 7: Set engineering targets: HOW MUCH is ?good enough

1.

2.

Target values are used to evaluate the products ability to satisfy customers requirements. Two actions: To ascertain how the competitors (step 4) meets the engineering specifications, and To establish the targets for the new product.

Step 8: Identify relationships between engineering requirements: How are the HOWs ?dependent on each other

Engineering specifications may be dependent on each other. It is best to realize these dependences early in the design process. Negative (-1) Strong negative (-3) Strong positive (9) Positive (3)

A Reduced HOQ Form

QFD can be applied at all phases

Conclusions

The QFD technique ensures that the problem is well understood. The HOQ automatically documents and records the evolution of the product design. The HOQ is an excellent communication tool for the design team. The QFD technique can be applied at any of the design phases.

You might also like

- 3 PDFDocument8 pages3 PDFAbdul NadeeNo ratings yet

- A.S. Khangura and S.K. Gandhi Design and Development of The Refrigerator With Quality FunctionDocument5 pagesA.S. Khangura and S.K. Gandhi Design and Development of The Refrigerator With Quality FunctionVinay RajputNo ratings yet

- Linking These Phases Provides A Mechanism To Deploy The Customer Voice Through To Control of Process OperationsDocument10 pagesLinking These Phases Provides A Mechanism To Deploy The Customer Voice Through To Control of Process OperationsSiddharth KalsiNo ratings yet

- Welcome: in A Few WordsDocument11 pagesWelcome: in A Few WordsSasiKumar PetchiappanNo ratings yet

- Quality Function DeploymentDocument10 pagesQuality Function DeploymentA DAY IN THANNINo ratings yet

- Deployment: in A Few WordsDocument11 pagesDeployment: in A Few WordsSasiKumar PetchiappanNo ratings yet

- Qresst: in A Few WordsDocument11 pagesQresst: in A Few WordsSasiKumar PetchiappanNo ratings yet

- Product and Service DesignDocument38 pagesProduct and Service DesignCharisa SamsonNo ratings yet

- Product Design Assignment: Review Chapter 5 & Chapter 6: Kukuh Faedlur Rahman 14522125Document4 pagesProduct Design Assignment: Review Chapter 5 & Chapter 6: Kukuh Faedlur Rahman 14522125kukuhricardoNo ratings yet

- Assinment 4.OMDocument3 pagesAssinment 4.OMAdiba SyamlanNo ratings yet

- How To Build A House of Quality (QFD) : Reading Time: About 8 MinDocument14 pagesHow To Build A House of Quality (QFD) : Reading Time: About 8 MinCuenta PokemonNo ratings yet

- Quality Function DeploymentDocument40 pagesQuality Function DeploymentVaswee Dubey100% (1)

- Quality Function Deployment (QFD) PDFDocument28 pagesQuality Function Deployment (QFD) PDFIlman FaiqNo ratings yet

- Ranking of Customer Requirements in A Competitive EnvironmentDocument13 pagesRanking of Customer Requirements in A Competitive EnvironmentNizam Sudin Dan KhatijahNo ratings yet

- Resumen DiseñoDocument14 pagesResumen DiseñoDiana CaroNo ratings yet

- MEC531 Chapter 1 Mechanical Design ProcessDocument80 pagesMEC531 Chapter 1 Mechanical Design ProcessIlman FaiqNo ratings yet

- Subject: Quality Planning and Analysis: (Assignment No.1)Document9 pagesSubject: Quality Planning and Analysis: (Assignment No.1)Sarfraz NawazNo ratings yet

- Homework On QFD (HOUSE OF QUALITY)Document15 pagesHomework On QFD (HOUSE OF QUALITY)Logan PikmanNo ratings yet

- Tools and Techniques For TQM: Dr. Ayham Jaaron Second Semester 2010/2011Document51 pagesTools and Techniques For TQM: Dr. Ayham Jaaron Second Semester 2010/2011mushtaque61No ratings yet

- Chapter 4: Product and Service Design: 1. Key QuestionDocument5 pagesChapter 4: Product and Service Design: 1. Key QuestionRedoy HossainNo ratings yet

- RJS Product & Service DesignDocument36 pagesRJS Product & Service DesignramjanmsinghNo ratings yet

- Som Assignment-2Document17 pagesSom Assignment-2Saurav RanaNo ratings yet

- Quality Function DeploymentDocument14 pagesQuality Function DeploymentAniketKarade100% (1)

- 10 Quality Function DeploymentDocument35 pages10 Quality Function DeploymentUmair WaqasNo ratings yet

- Product and Service DesignDocument4 pagesProduct and Service Designjth55936zwohocomNo ratings yet

- Six Sigma Treqna Base Manual Ed1 PDFDocument356 pagesSix Sigma Treqna Base Manual Ed1 PDFMarius Alexandru100% (2)

- Cost Estimation in Agile Software Development: Utilizing Functional Size Measurement MethodsFrom EverandCost Estimation in Agile Software Development: Utilizing Functional Size Measurement MethodsNo ratings yet

- IE-23-Quality Function Deployment in Banking PDFDocument7 pagesIE-23-Quality Function Deployment in Banking PDFMamunur Rashid100% (1)

- Rekayasa Kualitas Rekayasa Kualitas Pertemuan 4: Teknik IndustriDocument15 pagesRekayasa Kualitas Rekayasa Kualitas Pertemuan 4: Teknik IndustriDeni Deri SetianaNo ratings yet

- To Study Taguchi'S Stretegy For Design of Experiments.: A Seminar Report ONDocument54 pagesTo Study Taguchi'S Stretegy For Design of Experiments.: A Seminar Report ONashwani kaushikNo ratings yet

- QFD Presentation FinalDocument52 pagesQFD Presentation FinalAshokNo ratings yet

- Customer Need Identification ProcessDocument26 pagesCustomer Need Identification ProcessSabir Ali100% (1)

- Homework On QFD (HOUSE OF QUALITY)Document15 pagesHomework On QFD (HOUSE OF QUALITY)Logan PikmanNo ratings yet

- QFD As A Tool For Business Excellence Through TQMDocument9 pagesQFD As A Tool For Business Excellence Through TQMseventhhemanthNo ratings yet

- Product Design PresentationDocument64 pagesProduct Design PresentationAnthony Royupa0% (1)

- Manufacture Product Design and Process SelectionDocument23 pagesManufacture Product Design and Process SelectionShah Maqsumul Masrur TanviNo ratings yet

- The Eight Stages of New Product DevelopmentDocument3 pagesThe Eight Stages of New Product DevelopmentJasmene KachrooNo ratings yet

- 15me835 PLCM Module 3Document24 pages15me835 PLCM Module 3prashanth prabhuNo ratings yet

- Quality Function Deployment Article Ronald G. BayDocument16 pagesQuality Function Deployment Article Ronald G. BayKhubaib IftikharNo ratings yet

- Management System ManufactureDocument11 pagesManagement System ManufactureKanzul FadhilNo ratings yet

- The Product DesignDocument7 pagesThe Product DesignRahul ItankarNo ratings yet

- Unit 4 TQM NotesDocument35 pagesUnit 4 TQM NotesHarish100% (1)

- 2516 (3) TQM Tools and TechniquesDocument51 pages2516 (3) TQM Tools and TechniquesAshish SinghaniaNo ratings yet

- QFD Mehmet Salih GoceriDocument80 pagesQFD Mehmet Salih GocericennetimturkiyemNo ratings yet

- DT Notes Unit 1,2,3Document83 pagesDT Notes Unit 1,2,3Akriti JaiswalNo ratings yet

- Assignment 5Document20 pagesAssignment 5api-723710078No ratings yet

- Benefits of QFD: 1-Write A Short Essay (About 500 Words) On QFD As An Approach To Requirements Development and AnalysisDocument17 pagesBenefits of QFD: 1-Write A Short Essay (About 500 Words) On QFD As An Approach To Requirements Development and AnalysisAnuj JaiswalNo ratings yet

- Possibilities of Product Quality Planning Improvement Using Selected Tools of Design For Six SigmaDocument6 pagesPossibilities of Product Quality Planning Improvement Using Selected Tools of Design For Six SigmaGilberto HernándezNo ratings yet

- Identification Customer NeedDocument34 pagesIdentification Customer NeedHapsoro Agung JatmikoNo ratings yet

- Chapter 2Document67 pagesChapter 2antonskatelbjbNo ratings yet

- Product DevtDocument26 pagesProduct DevtRalph Gene Trabasas FloraNo ratings yet

- MGT311 Assignment 1Document7 pagesMGT311 Assignment 1Hut MutNo ratings yet

- Fundamentals of Design and ManufacturingDocument8 pagesFundamentals of Design and ManufacturingManasNo ratings yet

- Case Study 3 Software Industry IT Six Sigma ProjectDocument14 pagesCase Study 3 Software Industry IT Six Sigma Projectvikrambakshi67No ratings yet

- Target Costing: If You Cannot Find The Time To Do It Right, How Will You Find The Time To Do It Over?Document17 pagesTarget Costing: If You Cannot Find The Time To Do It Right, How Will You Find The Time To Do It Over?Sumit HukmaniNo ratings yet

- INDU 440 NotesDocument30 pagesINDU 440 NotesObelay SkinCareNo ratings yet

- Microsoft Word - Quality Function DeploymentDocument9 pagesMicrosoft Word - Quality Function DeploymentMuhammad Tahir NawazNo ratings yet

- LSS TQM PresentationDocument37 pagesLSS TQM PresentationRitu ShahNo ratings yet

- BCETDocument1 pageBCETSumit SinghNo ratings yet

- Btme 505 Automobile EngineeringDocument2 pagesBtme 505 Automobile EngineeringSumit SinghNo ratings yet

- Manik ProjectDocument43 pagesManik ProjectSumit SinghNo ratings yet

- Continous CastingDocument3 pagesContinous CastingSumit SinghNo ratings yet

- Principal Requirements of Design ProcessDocument16 pagesPrincipal Requirements of Design ProcessSumit SinghNo ratings yet

- Gating 4Document7 pagesGating 4Sumit SinghNo ratings yet

- Smart City Project ModulesDocument3 pagesSmart City Project Modulesdeepika balichwal0% (1)

- History of Russian Monopulse Radar by LeonovDocument7 pagesHistory of Russian Monopulse Radar by LeonovDhimas AfihandarinNo ratings yet

- Characteristics of A ProductDocument8 pagesCharacteristics of A ProductCamilo OrtegonNo ratings yet

- 2 RadioDocument83 pages2 RadioSri MurthyNo ratings yet

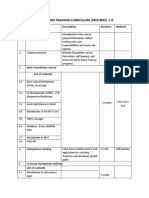

- Outsystems Training Curriculum (Freshers)Document3 pagesOutsystems Training Curriculum (Freshers)Chethan BkNo ratings yet

- BulkSMS Api 6.1Document54 pagesBulkSMS Api 6.1Shashank WadhwaNo ratings yet

- Development of Underground Land in MalaysiaDocument17 pagesDevelopment of Underground Land in MalaysiaNorAisyahJamalludinNo ratings yet

- A Guide For Translator-1Document210 pagesA Guide For Translator-1Dinda Rahma Nisya100% (1)

- Modified Schedule For Class Test - II Session 2020-21 ODD SemesterDocument3 pagesModified Schedule For Class Test - II Session 2020-21 ODD SemesterGobhiNo ratings yet

- Data Warehousing: Caselet: University Health System-BI in Health CareDocument8 pagesData Warehousing: Caselet: University Health System-BI in Health CareDAnielNo ratings yet

- TSB FUE038 Air Drain Case Replacement Rev 1Document5 pagesTSB FUE038 Air Drain Case Replacement Rev 1Cristhian HuilcapazNo ratings yet

- PWR Picopsu 160 XT ManualDocument5 pagesPWR Picopsu 160 XT ManualyudiherdianaNo ratings yet

- Spin Master BRCH en A00523Document6 pagesSpin Master BRCH en A00523Hendra GunawanNo ratings yet

- Conference Programme 2023-01-09Document60 pagesConference Programme 2023-01-09supiboboNo ratings yet

- Hydra Pro Print ManualDocument40 pagesHydra Pro Print ManualAndy BramallNo ratings yet

- Pressure Vessels 2 PDFDocument24 pagesPressure Vessels 2 PDFDasari VenkateshNo ratings yet

- WB146 5 PDFDocument10 pagesWB146 5 PDFLuisAlbertoVerdejoTapia100% (1)

- 330D and 336D Excavator Hydraulic System - Attachment: Machine Component LocationsDocument2 pages330D and 336D Excavator Hydraulic System - Attachment: Machine Component LocationsJoel RodríguezNo ratings yet

- ECZ Computer Studies P1 Past Paper 2015 2016 2017Document65 pagesECZ Computer Studies P1 Past Paper 2015 2016 2017Bricious Mulimbi100% (1)

- Supplier Quality ManualDocument19 pagesSupplier Quality ManualDurai Murugan100% (2)

- Ci10049lDocument2 pagesCi10049lHương TrầnNo ratings yet

- FW: KPN Travels - Online Ticket Booking DetailsDocument2 pagesFW: KPN Travels - Online Ticket Booking Detailsprojectproject2010100% (1)

- High Voltage High Current OpampDocument19 pagesHigh Voltage High Current Opampjanjan22No ratings yet

- Spirent TestCenter Command Sequencer V3Document61 pagesSpirent TestCenter Command Sequencer V3sumabang0% (1)

- Asme SB466Document9 pagesAsme SB466Stéphane LevasseurNo ratings yet

- What Is An Information System?Document13 pagesWhat Is An Information System?aepatil74No ratings yet

- Marine Radar M-1835 - SerienDocument6 pagesMarine Radar M-1835 - SerienRifalMkNo ratings yet

- ICTs For EducationDocument138 pagesICTs For EducationJavier MidenceNo ratings yet

- CV Ionel Contra 20220825Document1 pageCV Ionel Contra 20220825Heather HansenNo ratings yet

- Job Description CNC Machinist (Advanced) : Key Skills and CompetenciesDocument2 pagesJob Description CNC Machinist (Advanced) : Key Skills and CompetenciesRaya DuraiNo ratings yet