100% found this document useful (1 vote)

610 views71 pagesTypes and Properties of Paperboard

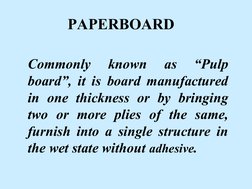

This document discusses different types of paperboard and their uses. It begins by defining paperboard as board manufactured from one or more plies of pulp brought together in a wet state without adhesive. It then describes the main types of paperboard - solid bleached sulfate board (SBS), folding box board (FBB), and recycled board. The document provides details on their production processes and characteristics, and explains their suitability for different printing and packaging applications. It also discusses factors that make paperboard a popular packaging medium and highlights some key quality control tests performed on paperboard.

Uploaded by

iiphyd2403Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

610 views71 pagesTypes and Properties of Paperboard

This document discusses different types of paperboard and their uses. It begins by defining paperboard as board manufactured from one or more plies of pulp brought together in a wet state without adhesive. It then describes the main types of paperboard - solid bleached sulfate board (SBS), folding box board (FBB), and recycled board. The document provides details on their production processes and characteristics, and explains their suitability for different printing and packaging applications. It also discusses factors that make paperboard a popular packaging medium and highlights some key quality control tests performed on paperboard.

Uploaded by

iiphyd2403Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

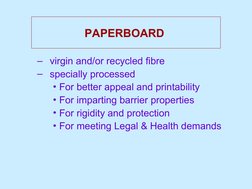

- Introduction to Paperboard: Introduces paperboard, its composition, and characteristics.

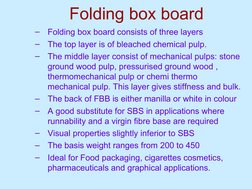

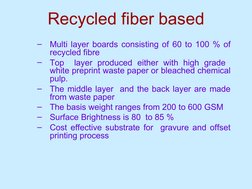

- Types of Paperboard: Describes different types of paperboards including Solid Bleached Sulphate Board, Folding Box Board, and Recycled Board.

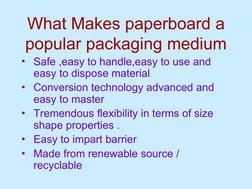

- Benefits of Paperboard: Highlights why paperboard is a popular packaging medium, focusing on flexibility and recyclability.

- Carton Board Types: Elaborates on various types of carton boards and their specific uses.

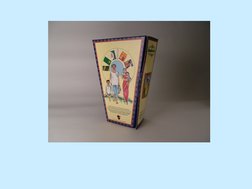

- Conventional Cartons: Examines the features and benefits of conventional cartons.

- Express Cartons: Details the design and advantages of express cartons, including tamper-proof features.

- Folding Cartons: Discusses the significance and applications of folding cartons in various industries.

- Developments in Paperboards: Describes recent advancements in paperboard technology and their industrial applications.

- Quality Control Tests: Lists and explains various quality control tests conducted on paperboards, including tensile strength and moisture content assessments.

- Optical Properties: Gives an overview of the optical properties important to paperboard evaluation, such as gloss and brightness.

- Physicochemical Properties: Discusses various physicochemical properties like chemical resistance and migration relevant to paperboards.