0% found this document useful (0 votes)

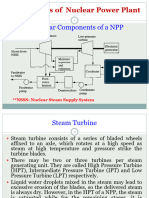

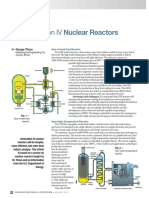

59 views41 pagesOverview of BWR, RBMK, LMFBR, and CANDU Systems

The document provides an overview of various nuclear reactor systems including RBMK, LMFBR, and CANDU, detailing their design features, operational parameters, and safety mechanisms. It highlights the unique characteristics and challenges of each reactor type, such as the RBMK's positive void coefficient and the LMFBR's use of liquid metals as coolants. Additionally, it discusses the CANDU reactor's use of heavy water and its online refueling capability.

Uploaded by

plyx xyCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

59 views41 pagesOverview of BWR, RBMK, LMFBR, and CANDU Systems

The document provides an overview of various nuclear reactor systems including RBMK, LMFBR, and CANDU, detailing their design features, operational parameters, and safety mechanisms. It highlights the unique characteristics and challenges of each reactor type, such as the RBMK's positive void coefficient and the LMFBR's use of liquid metals as coolants. Additionally, it discusses the CANDU reactor's use of heavy water and its online refueling capability.

Uploaded by

plyx xyCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd