0% found this document useful (0 votes)

22 views62 pagesChapter 8 Lec 2

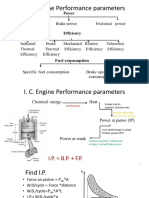

The document discusses internal combustion engine testing, focusing on measurement parameters such as engine performance, fuel consumption, and mechanical efficiency. It details various testing methods, including the Morse and motoring tests, and emphasizes the importance of a heat balance sheet in evaluating engine performance. Additionally, it compares performance metrics between spark ignition (SI) and compression ignition (CI) engines, highlighting efficiency and thermal losses at different loads and speeds.

Uploaded by

pragatikhanal7Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

22 views62 pagesChapter 8 Lec 2

The document discusses internal combustion engine testing, focusing on measurement parameters such as engine performance, fuel consumption, and mechanical efficiency. It details various testing methods, including the Morse and motoring tests, and emphasizes the importance of a heat balance sheet in evaluating engine performance. Additionally, it compares performance metrics between spark ignition (SI) and compression ignition (CI) engines, highlighting efficiency and thermal losses at different loads and speeds.

Uploaded by

pragatikhanal7Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd