0% found this document useful (0 votes)

963 views10 pagesCase Study - Project Management

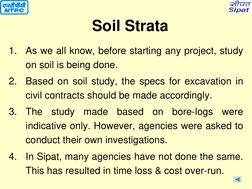

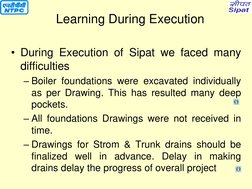

This document provides a case study and lessons learned from the Sipat Super Thermal Power Project. It identifies key aspects of project management that must be addressed including infrastructure, manpower, contracts, materials, execution, safety, quality, finance, and dispute resolution. Specific challenges that caused delays are discussed such as soil conditions, incapable subcontractors, lack of coordination, and not conducting underground works first. The importance of boundary management with local villages is also covered. Technical lessons learned during execution involve foundation designs, lack of timely drawings, drainage requirements, space constraints, and cable routing issues. Safety lessons from accidents are also noted.

Uploaded by

Jagdish VasaveCopyright

© Attribution Non-Commercial (BY-NC)

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

963 views10 pagesCase Study - Project Management

This document provides a case study and lessons learned from the Sipat Super Thermal Power Project. It identifies key aspects of project management that must be addressed including infrastructure, manpower, contracts, materials, execution, safety, quality, finance, and dispute resolution. Specific challenges that caused delays are discussed such as soil conditions, incapable subcontractors, lack of coordination, and not conducting underground works first. The importance of boundary management with local villages is also covered. Technical lessons learned during execution involve foundation designs, lack of timely drawings, drainage requirements, space constraints, and cable routing issues. Safety lessons from accidents are also noted.

Uploaded by

Jagdish VasaveCopyright

© Attribution Non-Commercial (BY-NC)

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

- Project Management Focus Areas: Lists the key management areas involved in the project, including infrastructure and contract management.

- Project Management Case Study Overview: Introduces the overall framework and topics covered in the project management case study for NTPC.

- Sipat Super Thermal Power Project: Provides insights and management challenges specific to the Sipat Super Thermal Power Project.

- Learning During Execution: Highlights the challenges encountered during the execution phase and the lessons learned from them.

- Closing: Concludes the presentation with a thank you note and visual imagery.