Professional Documents

Culture Documents

Optimizing The Life of Ore Passes in A Deep-Level Gold Mine

Uploaded by

Motlatjo RakgothoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Optimizing The Life of Ore Passes in A Deep-Level Gold Mine

Uploaded by

Motlatjo RakgothoCopyright:

Available Formats

Optimizing the life of ore passes in a deep-level gold mine

by P.R. Brenchley* and J.D. Spies*

J o u r n a l

Synopsis

Main ore pass systems should last the life of a mine, and too often expensive and hazardous remedial measures are required to repair a damaged ore pass in an attempt to extend its life. In order to maximize the life expectancy of all ore passes at Moab Khotsong, wearing blocks and softer support systems, combined with basic rock engineering principles, have been implemented. Failure of an ore pass can have severe financial implications, both indirectly because the ore pass cannot deliver the broken rock either from level to level or directly in the shaft ore pass system to the required level for tramming to take place, and directly due to the cost of the repair work that is required. Several factors need to be taken into consideration so that production interruptions are eliminated or minimized. Investigations of damaged ore passes at Moab Khotsong and surrounding mines revealed some interesting mechanisms of damage, and some innovative methods of reducing or eliminating the damage have been implemented at Moab Khotsong. The system design was based on 30 years, experience in main shaft rock passes. The design was to counteract scaling, hang-ups and dust problems associated with main rock passes, and the objective was to increase the life of rockpasses. These problems, including the initial design aspects to try and eliminate the repair measures, are discussed in detail.

towards the ore reserves traverse several different rock types ranging from hangingwall quartzite with uniaxial compressive strength (UCS) values of 200 to 260 MPa, to footwall quartzite with an average UCS of 172 MPa. Tunnels have also been mined through various formations of shale with UCS varying from a high of 155 MPa down to 83 MPa. Virgin stress levels range from 71 MPa at 85 level, which is 2 604 m below surface, to 83 MPa on 101 level, which is 3 054 m below surface. A broad-base classification of a deep-level mine is one in which the virgin stress levels approach or exceed half of the UCS of the host rock; and quite clearly Moab Khotsong can be classified as a deep-level gold mine.

P a p e r

Mechanisms of damage

Scaling of ore passes occurs when one of the horizontal field stresses exceeds the strength of the rock mass, and the original shape of the ore pass, typically circular, changes to an oval shape. The extent of the scaling depends on the strength of the rock mass and the ratio of the horizontal stresses. The closer the ratio of the horizontal stresses is to unity, the more even the stress damage and the greater the extent of the scaling that takes place perpindicular to the major horizontal stress direction, as shown in Figure 1. The timing and effectiveness of the installed support also contribute to the extent of scaling. Various support types have been used, some successfully and some not so. Initially corundum wetcrete was sprayed over weld mesh and then pretensioned full column grout anchors were installed. These methods were not that successful. Investigation revealed that, although corundum was an ideal material because of its hardness, but due to its smooth nature, poor bonding with the wetcrete

Introduction

Moab Khotsong is planned to be among the deepest shafts in the world and is the deepest shaft in the Vaal River Basin, which is situated approximately 180 kilometres southwest of Johannesburg, South Africa. The mine is designed to exploit the Vaal Reef package, which is sited at 2 400 m to 3 200 m below surface, within the Moab Khotsong lease area. Several other mines in the vicinity are currently mining the Vaal Reef at depths of 1 300 m to 2 330 m below surface. Moab Khotsong is a single bratticed shaft, with a diameter of 10.75 m and a single drop from surface down to 3 132 m, making Moab Khotsong the longest single drop shaft in the world. The sinking of the shaft had its own set of unique problems, which have been dealt with in separate publications. The tunnels

The Journal of The South African Institute of Mining and Metallurgy VOLUME 106

* AngloGold Ashanti. The South African Institute of Mining and Metallurgy, 2006. SA ISSN 0038223X/3.00 + 0.00. This paper was first published at the SAIMM Colloquium, Design, Development and Operation of Rockpasses, 1617 November 2004.

NON-REFEREED PAPER JANUARY 2006

11

Optimizing the life of ore passes in a deep-level gold mine

as bedding planes, faults, dykes and geological horizons of varying strength (such as shale and siltstone), will probably result in inconsistent wear, which in turn results in impact and deflections zones. The thickness of and cohesion between bedding planes, as well as the varying mechanical properties of the strata layers, affect the wear rate and pattern in an ore pass. Softer strata will wear out more rapidly, which compromises the original design shape and interrupts the flow of ore. (see Figure 2.) The dip of the strata in relation to the ore pass is critical to the durability of the ore pass. (see Figure 3.)

Rock engineering factors

The magnitude and direction of the principle stress will influence the extent and mode of failure. The closer the horizontal stresses are to being equal, the less the extent of spalling or dog-earing. Dog-earing, which is the spalling of rock that occurs under high stress, takes place at 90 degrees to the direction of the major stress. (see Figure 4.) This scaling process (wear) will take place regardless of the chipping and scouring of the ore material; however, the flow of ore material will aggravate this wear process. Mining in the vicinity of ore passes will also cause stress changes and a stable ore pass could turn into an unstable ore pass in a short period of time. Flat angles, or low angles of intersection between the ore pass and the strata layers create wedges, which break under impact or wear, thus resulting in uneven ore pass walls, causing more impact and deflection zones. (see Figure 5.) Diameter, shape and excavation method are obvious methods affecting the stability of ore passes.

Figure 1Stress damage

was achieved. This then meant that under impact of falling or sliding rocks the corundum fragments would easily dislodge, and then the softer wetcrete would be exposed and rapid wear would result. It was also noticed that the stiff tendons installed into the ore pass sidewalls, also contributed to the extent of damage, as these stiff tendons would vibrate when hit by falling rock. This vibration would crack and eventually break up the grout annulus surrounding the tendon, which would then be easily dislodged by falling rock. Once the grout had been removed, the immediate sidewall of the ore pass would not have any confinement, would break off, and fall down the ore pass, thus exposing more of the support tendon. Thus the cycle repeats itself. Investigation of damaged ore passes revealed that additional factors such as impact zones and wear rate were influencing the operation of ore passes. Impact zones are areas that are constantly bombarded with ore material. Where the ore flow remained in contact with the walls of the ore pass, excessive wear occurred. The ability of the ore pass to withstand wear and abrasion determines its life expectancy. Weathering and also oxidation were also taking a toll on the ore pass. It was also noticed that the steeper the dipping ore passes the greater the damage and the higher the velocity of the ore flow, the more potential damage to the ore pass. Damage is also influenced by the particle size: as momentum is mass x velocity, the greater the mass the greater the momentum and thus the greater the potential for damage. Uneven wear was also taking place, as some host rock would wear at a slower rate than the surrounding rock, resulting in ledges being created. Ore material would then strike these ledges and be deflected to the opposite sidewall, where it would chip away at the softer layers. Stress orientation, fracturing, excavation shape and size and method, as well the rock strength influence the life of an ore pass.

Inclination

Local experience and inspection of vertical ore passes have found some unusual wear patterns, which indicate profound

Figure 2The effect of soft seams

F F

F F

Design considerations Geological factors

The more homogenous the outer walls of the ore pass then the more likely the ore pass will be stable. Imperfections such

Figure 3Dip of the strata in relation to the ore pass

The Journal of The South African Institute of Mining and Metallurgy

12

JANUARY 2006

VOLUME 106

NON-REFEREED PAPER

Optimizing the life of ore passes in a deep-level gold mine

J o u r n a l

Major horizontal field stress

Major horizontal field stress

P a p e r

Figure 4Dog earing

Factors at Work: Chipping Scouring Weak zones/wedges Weathering Stresses

Figure 5Wedge creation

dynamics at work. When ore is tipped into a vertical ore pass, the plug of ore compresses the column of air below it. As this air forces its way up, through the ore material to the low pressure above the plug of rock, it shifts the falling ore fragments laterally with sufficient energy to chip away at the permanently exposed walls. The side walls of the ore pass are struck with the full momentum of the falling ore, which will be close to terminal velocity. (see Figure 6.) A second aspect of the inclination of an ore pass is that the one side of the ore pass will be exposed to the flow of ore, and excessive wear will be experienced. The natural walls of an ore pass, or the artificial skin as well as any support members or civil construction that are exposed to the flow of ore, must withstand the abrasive nature of the ore material.

Mohs scale was devised in 1812 by German mineralogist Friedrich Mohs, and is use to compare the relative hardness of minerals. Quartz has a Mohs rating of 7, and Corundum has Mohs rating of 9. (see Table I.) Andesite is much harder than concrete and has been used to improve the durability of concrete, however its suitability for use in an ore pass is severely limited as it is much softer than the ore material rubbing against it. Corundum due to its hardness would appear to be ideal, but because of it smooth and almost polished nature, it bonds very poorly to the concrete, and is easily dislodged, thus exposing the concrete to the ore material. A concrete mix utilizing Andesite is still the preferred mix for use at Moab Khotsong. Ore pass wearing blocks are constructed in the footwall of inclined ore passes. This is discussed in detail further on.

Rock hardness

As mentioned previously ore passes traverse rock of varying strength, and it is typically in areas of lower rock strength that excessive wear occurs. Concrete on its own is much softer than rock and would offer no protection to the ore pass sides, therefore the ideal lining material should have a Mohs rating of 5 and should contain a good spread of fragments of a material harder than the ore being transported over it. The

The Journal of The South African Institute of Mining and Metallurgy

Support type

Previously high tensile support tendons were installed in ore passes, to provide protection for the mining crews working below and also to prevent the sidewalls from being damaged once the ore pass was commissioned. While the initial support resistance was suitable, it was soon noticed that these high tensile steel tendons were too stiff as, once struck

VOLUME 106 NON-REFEREED PAPER JANUARY 2006

13

Optimizing the life of ore passes in a deep-level gold mine

Low pressure Factors at work: Chipping Weathering Stresses

High pressure

Deflection wear zone

Impact zone & dead box

Figure 6Damage in vertical ore pass

16 mm High tensile steel, Katbars or destranded rope loops with sand based grout

Figure 7Effect of using high-tensile support tendons

Table I

Relative hardness of minerals (Mohs scale)

Hardness

1 2 3 4 5 6 7 8 9 10

Element

Talc Gypsum Calcite Fluorite Apatite Orthoclause Quartzite Topaz Corundum Diamond

Description

mild steel unit, of length to suit the ore pass diameter, and the grout mix is based on pure cement mix containing condensed silica fume, which helps to increase workability and pumpability while reducing shrinkage.

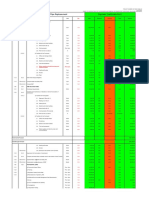

Moab Khotsong ore pass wearing blocks

Concrete? Andesite 5.5 Reef and footwall

by falling rock, shock waves were transmitted to the surrounding grout annulus and the host rock. The shock waves would then crack the grout and eventually cause the grout annulus to break up, thus exposing the unprotected ore pass sidewall to impact damage from falling rocks, as illustrated in steps 1 to 3 in Figure 7. These support tendons would not easily bend or wear, and thus would transmit the shock waves as the rocks passed by until the grout material was providing no function at all. The scaling process would then continue uncontrolled. The current support tendons used at Moab Khotsong in ore passes are 10 mm diameter

As mentioned previously, ore passes inclined at approximately 50 degrees, experienced excessive scaling and wear on the footwall of the ore pass. To reduce or eliminate this excessive wear, the installation of wear blocks was implemented. The spacing between the wear blocks was determined by the dip of the ore pass, the angle of influence and the angle of repose. Typical spacing between wearing blocks is 3.5 metres to 4.5 metres. The main purpose of the wearing blocks is to reduce the contact between the bare sides of the ore pass and the ore material, while maintaining the momentum of the ore flow below the rate at which it becomes airborne. As seen in Figure 8, cubbies are excavated in the footwall of the ore pass, and manganese steel units combined with andesite based concrete are cast into these cubbies. All steel is covered with the andesite concrete mix. Depending on the dimensions and the dip of the ore pass, wearing blocks can be installed in varying configurations, as shown in Figure 11.

The Journal of The South African Institute of Mining and Metallurgy

14

JANUARY 2006

VOLUME 106

NON-REFEREED PAPER

Optimizing the life of ore passes in a deep-level gold mine

PRINCIPAL: 1.) DENSE GROUTING TO STABILISE ROCK PASS PERIMETER 2.) WEARING BLOCKS TO REDUCE F/W WEARING AND SCALING

DEAD BOX AT THE ANGLE OF REPOSE

4.5 M

32- 38 SUPPORT TENDONS ANDESITE BASED CONCRETE 70 MPA GRIZZLEY BARS ROCKBOLTS

Figure 8 Moab ore pass wearing blocks

Grouted mild steel rods - diamond pattern

the accumulated rock acts as a natural skin on the footwall reducing the abrasive wear. Note that the mild steel tendons will wear away with the sidewalls without losing any integrity of the support. Depending on the dimensions and the inclination of the ore pass, wearing blocks were installed at various configurations, as indicated in Figure 11. The grizzly units are 380 mm x 380 mm cast manganese steel units, which then gives a combined unit dimension of 0.72 m x 1.44 m. These manganese steel units are pinned in place and reinforcing steel is installed. All the steel work is covered with andesite concrete, as shown in Figure 12. It was previously mentioned that impact damage to the sides and footwall of ore passes contributes to the extent of the damage; however, the intersection of one ore pass feeding into another ore pass, termed a dog leg can contribute greatly to the impact and wear rate in an ore pass. (see Figure 13.) In order to lessen the intensity and extent of this potential damage area, Moab wearing blocks were placed on the sidewall of an ore pass directly opposite the dog leg, as shown in Figure 14. This serves to protect the intersection between the two ore passes by breaking the momentum of the ore flow.

J o u r n a l

P a p e r

3. 5

TO

4. 5

Other considerations Winder installation

Angle of influence 3238 Dead box @ angle of repose

50

Wearing block

Figure 9Wearing block layout

In long and steep ore passes, a licensed winder is installed to facilitate transport of men and material to and from the working platforms. Channel tracks are installed to carry the conveyance, which transports material and equipment to the site. The safety and working platforms are also positioned by this conveyance. The channel tracks, as shown in Figure 15, are installed when the ore pass is longer than 40 metres vertical height and, or if the ore pass is steeply inclined. Equipping platforms can have several stages as shown in Figures 16 and 17. This will allow for separate work to be done simultaneously thus reducing the time without compromising on safety.

Conclusions

With proper risk identification, planning and focus from all relevant employees, damaged ore passes can be repaired. On some ore passes at Moab Khotsong, it was noted that increased or unacceptable wear was taking place after the ore passes were commissioned. Use of the ore passes was suspended, and the wearing blocks were installed and the ore passes recommissioned. The result is that several years later there have been no reports of damage in the ore passes, and the ore flows consistently and evenly. It is not always possible to place ore passes in the optimum site, and the installation of the wearing blocks has helped to minimize the damage that would probably have occurred if the ore passes were supported by traditional means. Damage in dog legs in ore passes can be minimized if the wearing blocks are positioned so as to cushion the impact of the rocks from the intersecting ore passes.

VOLUME 106 NON-REFEREED PAPER JANUARY 2006

50 Dead box @ angle of repose

Wearing block

Figure 10Functioning of weaving blocks

Figure 9, shows the layout prior to the commissioning of the ore pass, while Figure 10 below shows a sketch of how the wearing blocks should function. The dead box will be of the same material as the ore, and is the best natural wearing protection in an ore pass. Ore material does not become airborne due to impact with the sidewalls. Contact between the ore flow and the walls of the ore pass is minimized, as

The Journal of The South African Institute of Mining and Metallurgy

15

Optimizing the life of ore passes in a deep-level gold mine

Up to 55 inclination

55 to 65 inclination

Figure 11Wearing block configurations

Figure 12Grizzly segments

Figure 14Wearing blocks in a sidewall

Figure 13Layout of ore pass with dog leg

Figure 15Channel tracks

A well designed ore pass Dips at 55 to 65 above the horizontal Penetrates the strata as close to 90 as possible Is situated in de-stressed ground and in competent rock Takes cognizance of the direction and magnitude of principle stresses. Prior to commissioning the rock pass should be inspected and re-supported if necessary. This is vital for ore passes at depth. The rate of flow of rock down the ore pass must be controlled and monitored. If possible the ore pass should be kept full and bleed of as required.

References

JOUGHIN, W.C. and STACEY, T.R. The behaviour of ore passes in deep level tabular mines. 2nd International Seminar On Deep Level Mining, 2004. BRENCHLEY, P.R. and SPIES, J.D. The combination of layout design support and a quality control programme. 2nd International Seminar On Deep Level Mining, 2004. HAGEN, T.O. and ACHEAMPONG, E. Current design, support and maintenance of rock passes and assessment of practices applicable at depth. SARES 99, 2nd Southern African Rock Engineering Symposium, 1999. VAN JAARSVELD, P. Personal communication, 2004.

16

JANUARY 2006

VOLUME 106

NON-REFEREED PAPER

The Journal of The South African Institute of Mining and Metallurgy

You might also like

- Rock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesFrom EverandRock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesNo ratings yet

- Rock Blasting - A Practical Treatise On The Means Employed In Blasting Rocks For Industrial PurposesFrom EverandRock Blasting - A Practical Treatise On The Means Employed In Blasting Rocks For Industrial PurposesNo ratings yet

- Rock Fragmentation - GoldsearchDocument32 pagesRock Fragmentation - GoldsearchSimon SamNo ratings yet

- Forecast of Pressure and Working Conditions in Rock Tunnels ROCK TUNNELING WITH STEEL SUPPORT CHAPTER 5Document13 pagesForecast of Pressure and Working Conditions in Rock Tunnels ROCK TUNNELING WITH STEEL SUPPORT CHAPTER 5Johana JaramilloNo ratings yet

- Brief Overview Geotechnical Applications OF Rock MechanicsDocument144 pagesBrief Overview Geotechnical Applications OF Rock MechanicsSATYAM BHARTI100% (1)

- Stronger in Compression Than in TensionDocument4 pagesStronger in Compression Than in TensionMohamed MagedNo ratings yet

- The Squeezing Potential of Rocks Around Tunnels Theory and PredictionDocument27 pagesThe Squeezing Potential of Rocks Around Tunnels Theory and PredictionprazNo ratings yet

- 9 - Applications of RM in Rock Slope EngDocument24 pages9 - Applications of RM in Rock Slope EngAlex Fuentes Montesinos100% (1)

- Supports, Lining and VentilationDocument19 pagesSupports, Lining and VentilationgaddargaddarNo ratings yet

- Slope Paper 193Document12 pagesSlope Paper 193Ronan CayoNo ratings yet

- 8 Support and LiningDocument5 pages8 Support and LiningSubash PoudelNo ratings yet

- Perforacion de Rocas: Presentado PorDocument26 pagesPerforacion de Rocas: Presentado PorEsteban C. ZubietaNo ratings yet

- 5.1.6 Excavation Disturbed ZoneDocument6 pages5.1.6 Excavation Disturbed Zonekelvin chinNo ratings yet

- Time Dependent Behaviour of Rock in ExcavationDocument30 pagesTime Dependent Behaviour of Rock in ExcavationChinnaswamy GounderNo ratings yet

- Effects of Discontinuities On Rock Mass BehaviorDocument12 pagesEffects of Discontinuities On Rock Mass BehaviorMawriNo ratings yet

- Geological Considerations in TunnellingDocument8 pagesGeological Considerations in Tunnellingpaul macharia100% (1)

- 05 - Interaction of Rock, Drill and Explosives.Document5 pages05 - Interaction of Rock, Drill and Explosives.Jose RojasNo ratings yet

- Underground Mining-Caving MethodsDocument11 pagesUnderground Mining-Caving MethodsPuvanendran GajananNo ratings yet

- Rock BurstDocument2 pagesRock BurstIzhar Jiskani100% (1)

- 7.rock PropertiesDocument58 pages7.rock PropertiesBoos yousufNo ratings yet

- E3sconf Usme2018 00022Document9 pagesE3sconf Usme2018 00022Lubię Używać Twarz PolkNo ratings yet

- ROCK BURSTDocument48 pagesROCK BURSTMAX CRUXNo ratings yet

- 含软弱夹层厚煤层巷帮外错滑移机制与支护研究 黄庆享Document6 pages含软弱夹层厚煤层巷帮外错滑移机制与支护研究 黄庆享h junNo ratings yet

- Under Ground Metal Mining Assignment: Topic:-Support System Submitted ToDocument53 pagesUnder Ground Metal Mining Assignment: Topic:-Support System Submitted ToAyush tiwariNo ratings yet

- Under Ground Metal Mining Assignment: Topic:-Support System Submitted ToDocument55 pagesUnder Ground Metal Mining Assignment: Topic:-Support System Submitted ToANSHUL YADAVNo ratings yet

- M5 East - The Design of Australia's Longest Driven Motorway TunnelDocument7 pagesM5 East - The Design of Australia's Longest Driven Motorway TunnelHarold TaylorNo ratings yet

- Analysis of Rockfall HazardsDocument25 pagesAnalysis of Rockfall Hazardsdaren21No ratings yet

- Chapter 7 - Design and StabilityDocument7 pagesChapter 7 - Design and StabilityLupyana wa LupyanaNo ratings yet

- Chapter - 6 Engineering Geology of TunnelsDocument35 pagesChapter - 6 Engineering Geology of Tunnelsamsalu getaNo ratings yet

- The Design of Ore Pass ChutesDocument4 pagesThe Design of Ore Pass ChutesjefersonpimentelNo ratings yet

- Chapter 7 Introduction To Rock EngineeringDocument78 pagesChapter 7 Introduction To Rock EngineeringsyafiqNo ratings yet

- Lecture 16Document9 pagesLecture 16Rehman AbbasiNo ratings yet

- MPBT - Pertemuan 13Document43 pagesMPBT - Pertemuan 13Ardiansyah Ay11No ratings yet

- 04 - Rock Frature MechanismsDocument15 pages04 - Rock Frature MechanismsJose RojasNo ratings yet

- Roberts-M-K-C - Brummer-1988-Support-Requirements-In-Rockburst-ConditionsDocument8 pagesRoberts-M-K-C - Brummer-1988-Support-Requirements-In-Rockburst-Conditionskentong.leeNo ratings yet

- State of The Art - LaubscherDocument21 pagesState of The Art - LaubscherAndres Condore VásquezNo ratings yet

- Influence of Geological Conditions On deDocument29 pagesInfluence of Geological Conditions On deomeaveNo ratings yet

- Classifications WeakRockDocument13 pagesClassifications WeakRockrahulgeo05No ratings yet

- MassMin2000 OpenStopeMininginCanadaDocument19 pagesMassMin2000 OpenStopeMininginCanadawaryubabenjaminNo ratings yet

- Influence of Geological Conditions On Design and Construction of Tunnels2-LibreDocument29 pagesInfluence of Geological Conditions On Design and Construction of Tunnels2-LibreGEOMAHESHNo ratings yet

- Ore and Country Rock Strength: Rockmass ClassificationDocument12 pagesOre and Country Rock Strength: Rockmass ClassificationMichael AltamiranoNo ratings yet

- 1 s2.0 S1365160900000265 MainDocument10 pages1 s2.0 S1365160900000265 Mainmanumigh793coolNo ratings yet

- Behaviors of Overlying Strata in Extra Thick Coal Seams Using Top Coal Caving Method 2016 Journal of Rock Mechanics and Geotechnical EngineeringDocument10 pagesBehaviors of Overlying Strata in Extra Thick Coal Seams Using Top Coal Caving Method 2016 Journal of Rock Mechanics and Geotechnical Engineeringkatta_sridharNo ratings yet

- Analysis of Dynamic Evolution of Surrounding RockDocument17 pagesAnalysis of Dynamic Evolution of Surrounding RockArifuggaman ArifNo ratings yet

- Rock Characterization at El Teniente Mine PDFDocument15 pagesRock Characterization at El Teniente Mine PDFEmanuel NicolásNo ratings yet

- Tunnelling Mechanics and Hazards PDFDocument14 pagesTunnelling Mechanics and Hazards PDFSushil DhunganaNo ratings yet

- Principles of Rockbolting Design PDFDocument18 pagesPrinciples of Rockbolting Design PDFJaime BojorqueNo ratings yet

- Essential Salt PropertiesDocument3 pagesEssential Salt PropertiesEmmanuel OluVictory OmojuwaNo ratings yet

- Support Requirements in Rockburst Conditions : J. S. Afr. Inst. Min. Metal/.Document8 pagesSupport Requirements in Rockburst Conditions : J. S. Afr. Inst. Min. Metal/.Bhaskar ReddyNo ratings yet

- Tunnel and Road CuttingDocument20 pagesTunnel and Road CuttingKaren DarilaNo ratings yet

- Foundation Treatment in DamsDocument43 pagesFoundation Treatment in Damsdeadromeo100% (4)

- Lecture 2Document47 pagesLecture 2hawer sarwatNo ratings yet

- Chapter 2. Blasting Effects and Their ControlDocument14 pagesChapter 2. Blasting Effects and Their ControlLuis Iparraguirre Tandaypan100% (1)

- Blast Design and Assessment For Surface Mines and QuarriesDocument198 pagesBlast Design and Assessment For Surface Mines and QuarriesOmar Alex Meléndez HuamánNo ratings yet

- Underhand Cut and Fill Mining As Practiced in Therr Deeo Hard Rock Mines in The Unired States PDFDocument11 pagesUnderhand Cut and Fill Mining As Practiced in Therr Deeo Hard Rock Mines in The Unired States PDFwcamilo015No ratings yet

- Tunneling in Swelling RocksDocument7 pagesTunneling in Swelling Rocksmic85No ratings yet

- Block CavingDocument6 pagesBlock CavingMmm 123No ratings yet

- Fault and Joint Development in Brittle and Semi-Brittle Rock: The Commonwealth and International Library: Geology DivisionFrom EverandFault and Joint Development in Brittle and Semi-Brittle Rock: The Commonwealth and International Library: Geology DivisionNo ratings yet

- Fault and Joint Development: In Brittle and Semi-Brittle RockFrom EverandFault and Joint Development: In Brittle and Semi-Brittle RockNo ratings yet

- Water Pipe ReplacementDocument56 pagesWater Pipe ReplacementMotlatjo RakgothoNo ratings yet

- Final Drawing Les (1) - Page 1Document1 pageFinal Drawing Les (1) - Page 1Motlatjo RakgothoNo ratings yet

- 2022 10 07 GovernanceDocument6 pages2022 10 07 GovernanceMotlatjo RakgothoNo ratings yet

- Contractor:: Management System Electrical Inspection SheetDocument1 pageContractor:: Management System Electrical Inspection SheetMotlatjo RakgothoNo ratings yet

- Contractor:: Management System Structural Steel InspectionDocument1 pageContractor:: Management System Structural Steel InspectionMotlatjo RakgothoNo ratings yet

- Your Step-By-Step Update To A Wealth of Exciting BenefitsDocument8 pagesYour Step-By-Step Update To A Wealth of Exciting BenefitsMotlatjo RakgothoNo ratings yet

- Sewer Upgrade ProjectDocument9 pagesSewer Upgrade ProjectMotlatjo RakgothoNo ratings yet

- Proof of Transmittal: Concrete Mix DesignDocument1 pageProof of Transmittal: Concrete Mix DesignMotlatjo RakgothoNo ratings yet

- Contractor:: Management System Pre-Tiling Inspection Sheet (Walls)Document1 pageContractor:: Management System Pre-Tiling Inspection Sheet (Walls)Motlatjo RakgothoNo ratings yet

- PT 01108Document1 pagePT 01108Motlatjo RakgothoNo ratings yet

- Appendix A: Typical Concrete EncasingDocument1 pageAppendix A: Typical Concrete EncasingMotlatjo RakgothoNo ratings yet

- Investment Design GuidelinesDocument40 pagesInvestment Design GuidelinesMotlatjo RakgothoNo ratings yet

- Pre & Post Concrete InspectionDocument2 pagesPre & Post Concrete InspectionMotlatjo RakgothoNo ratings yet

- RBQ529Document2 pagesRBQ529Motlatjo RakgothoNo ratings yet

- Vision Elevators Company ProfileDocument8 pagesVision Elevators Company ProfileMotlatjo RakgothoNo ratings yet

- Historical Structural Steelwork Handbook Lib574 PDFDocument80 pagesHistorical Structural Steelwork Handbook Lib574 PDFMotlatjo RakgothoNo ratings yet

- SC10876B - Hoist DrawingDocument1 pageSC10876B - Hoist DrawingMotlatjo RakgothoNo ratings yet

- DG SSB GP Civl 111 XX 206 Bs1Document1 pageDG SSB GP Civl 111 XX 206 Bs1Motlatjo RakgothoNo ratings yet

- Autodesk Robot Structural Analysis Professional 2012 BrochureDocument6 pagesAutodesk Robot Structural Analysis Professional 2012 BrochureJonathan ReyesNo ratings yet

- 1 Vol 2 Part 3 Technical and General GuidelinesDocument137 pages1 Vol 2 Part 3 Technical and General GuidelinesMotlatjo Rakgotho100% (2)

- Finance Slides - 14 Aug 2012Document24 pagesFinance Slides - 14 Aug 2012Motlatjo RakgothoNo ratings yet

- Bending Schedule & ReinforcementDocument1 pageBending Schedule & ReinforcementMotlatjo RakgothoNo ratings yet

- Freyssinet Post Tension Ing - C RangeDocument36 pagesFreyssinet Post Tension Ing - C RangeMotlatjo RakgothoNo ratings yet

- LVenter PrEng ECSA Review ProcessDocument25 pagesLVenter PrEng ECSA Review ProcessMotlatjo RakgothoNo ratings yet

- Deflection On The Cantilever BeamDocument11 pagesDeflection On The Cantilever BeamArif AzizAnNo ratings yet

- Free Particle PropagatorDocument2 pagesFree Particle PropagatorstephenbankesNo ratings yet

- HeatDocument75 pagesHeatVanessaYanjanHarryNo ratings yet

- Chapter 4 PhyDocument94 pagesChapter 4 PhyDeneshwaran RajNo ratings yet

- Alcohols, Phenols and Ethers - MCQs Test - 3Document3 pagesAlcohols, Phenols and Ethers - MCQs Test - 3Prasant KumarNo ratings yet

- Chapter 6-Rainwater HarvestingDocument20 pagesChapter 6-Rainwater HarvestingJpmega Civil StructuralNo ratings yet

- Chem 40.1 Msds Exer 6Document7 pagesChem 40.1 Msds Exer 6Angela Sietereales RamosNo ratings yet

- CIP13 Concrete BlistersDocument2 pagesCIP13 Concrete Blisters7774R105No ratings yet

- Chemistry Sba LabDocument5 pagesChemistry Sba LabTawayna HemmingsNo ratings yet

- ABB Raw Mix Preparation PDFDocument8 pagesABB Raw Mix Preparation PDFrudye kardun100% (1)

- Mod 7 23-09-09 Extras PDFDocument23 pagesMod 7 23-09-09 Extras PDFU TubeNo ratings yet

- BFC 3042 Chapter 4bDocument10 pagesBFC 3042 Chapter 4bInahMisumiNo ratings yet

- Cape Biology Unit 2 Lab PDF FreeDocument4 pagesCape Biology Unit 2 Lab PDF FreeChanel clarksonNo ratings yet

- 1 - Introduction of EOR (TK)Document34 pages1 - Introduction of EOR (TK)Fathurrahman RasyidNo ratings yet

- Microwave Level SwitchDocument3 pagesMicrowave Level SwitchDidinAndresIINo ratings yet

- Dawlance Report1Document17 pagesDawlance Report1engr_dkNo ratings yet

- Design of Syphon AqueductDocument118 pagesDesign of Syphon AqueductGuru MurthyNo ratings yet

- Aakash Rank Booster Test Series For NEET Aakash Rank Booster Test Series For NEET-2020 2020Document12 pagesAakash Rank Booster Test Series For NEET Aakash Rank Booster Test Series For NEET-2020 2020VedNo ratings yet

- NGL Fractionation Using HYSYSDocument30 pagesNGL Fractionation Using HYSYSAhmad Deyab100% (3)

- 121Document39 pages121Hendra RuhunussaNo ratings yet

- 0420 - 118T3440 - Cooling WaterDocument2 pages0420 - 118T3440 - Cooling WaterfaisalnadimNo ratings yet

- Ni 1882Document81 pagesNi 1882estradeiroNo ratings yet

- 2015 JC2 H2 Carboxylic Acids and Derivatives Part 1 Tutorial (Teachers) UpdatedDocument18 pages2015 JC2 H2 Carboxylic Acids and Derivatives Part 1 Tutorial (Teachers) UpdatedJohnNo ratings yet

- Columbia Lighting Product Selection Guide Edition 3 1996Document116 pagesColumbia Lighting Product Selection Guide Edition 3 1996Alan MastersNo ratings yet

- DP FlowDocument47 pagesDP FlowGustavo PuenteNo ratings yet

- أجهزة قياس درجة الحرارة المستخدمة في دوائر التحكم الأوتوماتيكي PDFDocument10 pagesأجهزة قياس درجة الحرارة المستخدمة في دوائر التحكم الأوتوماتيكي PDFعيسى محمد حسنNo ratings yet

- Tinker Rasor - CP ProductsDocument22 pagesTinker Rasor - CP ProductsrachedNo ratings yet

- Bhutan Higher Secondary Education Certificate Examination December2014 Marking Scheme - ChemistryDocument3 pagesBhutan Higher Secondary Education Certificate Examination December2014 Marking Scheme - ChemistryTsheyang LhazomNo ratings yet

- Biotecnologia de Microalgas (1988 R) - (De La Noue and de Pauw) - The Potential of Microalgal Biotechnology A Review of Production and Uses of MicroalgaeDocument46 pagesBiotecnologia de Microalgas (1988 R) - (De La Noue and de Pauw) - The Potential of Microalgal Biotechnology A Review of Production and Uses of MicroalgaeAlexsandro ClaudinoNo ratings yet

- Linking Nature's Services To Ecosystems-Some General Ecological ConceptsDocument20 pagesLinking Nature's Services To Ecosystems-Some General Ecological ConceptsecologiafcaunlNo ratings yet