Professional Documents

Culture Documents

PH Motors

Uploaded by

Nius Pahala NainggolanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PH Motors

Uploaded by

Nius Pahala NainggolanCopyright:

Available Formats

ECE 3650 Electrical Machines Athula Rajapakse

1

Single-Phase Induction Motors

Construction

- Rotor: Same as in a three-phase induction motor

- Stator: Only a single distributed winding

Magnetic field created by the stator winding

- Unlike a three-phase distributed winding which produce a rotating magnetic field, a single-phase

winding can produce only a pulsating magnetic field.

- The field gets larger and then smaller but in the same direction

+ve half cycle -ve half cycle

Fig. 1

Animation: http://www-h.eng.cam.ac.uk/help/mjg17/ teach/rotate/phase-a.html

Single-phase Induction Motor Under Starting Conditions

- No starting torque since there is no rotating magnetic field.

Fig. 2

- Induced voltage due to transformer action produces currents in short circuited rotor bars.

- The resulting rotor flux is inline (but opposite in direction) with the stator flux.

- Net induced torque: 0 ) 180 sin( B B

s R

= = =

S R ind

B kB k t

However, if the rotor begins to rotate, an induced torque will be produced on the rotor.

- This can be explained using Double-Rvolving-Field Theory or the Cross-Filed Theory.

ECE 3650 Electrical Machines Athula Rajapakse

2

Double-Rvolving-Field Theory

Stationary pulsating magnetic field can be resolved into two rotating magnetic fields that are equal in

magnitude but rotating in opposite directions.

Fig. 3

Air gap field

j t B B

S

) cos(

max

e =

Field revolving in the clockwise direction

j t B i t B B

CW

) sin(

) cos(

max 2

1

max 2

1

e e =

Field revolving in the counter clockwise direction

j t B i t B B

CCW

) sin(

) cos(

max 2

1

max 2

1

e e + =

Total field

) ( ) ( ) ( t B t B t B

CCW CW S

+ =

et=0

o

et=45

o

et=90

o

et=150

o

et=180

o

et=270

o

ECE 3650 Electrical Machines Athula Rajapakse

3

Torque-Speed Characteristics

Fig. 4

Net torque is the difference between two torque speed curves

- Zero torque at zero speed No starting torque

The above representation is not quite accurate

- The simultaneous presence of two magnetic fields is not considered.

Three-phase Induction Motor

Fig. 5

When the rotor speed is negative

- Slip s > 1, rotor resistance is small Motor current is very large

- Very high rotor frequency f

R

= sf Rotor reactance X

2

>> R

2

/s

- Rotor current lags the rotor voltage by almost 90

o

- Rotor magnetic field is nearly 180

o

out of phase with stator magnetic field Very small torque

- Reduction in torque is partially compensated by the increased current

I 1 R 1

X 1

E 1

E2

I 1 '

R m X

m

I 2 R2

X2

N 1 :N 2

mechanical

output power

component

R

2

(1/s-1)

rotor

stator

R

2

(1-s)/s

ECE 3650 Electrical Machines Athula Rajapakse

4

Fig. 6

Fig. 7

ECE 3650 Electrical Machines Athula Rajapakse

5

Single-Phase Induction Motor

When the rotor is in motion,

- Backward flux wave see a slip > 1

- Component of rotor current induced by the backward field are greater than that at standstill, and

the power factor is lower.

- The direction of rotor magnetic field is almost opposite to the field produced by the stator currents

o Reduced backward flux wave.

- Forward flux wave see a slip < 1

- Component of currents induced by the forward field is less than that at standstill, and their power

factor is higher.

- The direction of rotor magnetic field is such that it increases magnitude of forward flux wave.

- When the speed increases

o the forward flux wave increases

o the backward flux wave decreases

Performance of the single-phase induction motor is considerably better than that would be predicted on the

basis of forward and backward flux waves.

Torque-Speed Characteristics

(a) without considering effect of rotor field (b) considering the effect of rotor field

Fig. 8

ECE 3650 Electrical Machines Athula Rajapakse

6

Starting of Single-Phase Induction Motors

Since single-phase induction motors produce no intrinsic starting torque, special arrangement is needed.

- Split phase windings

- Capacitor-type windings

- Shaded stator poles

Single-phase induction motors are classified according to the starting method.

All starting techniques are methods of making one of the two rotating fields in the machine stronger than

the other,

Split-Phase Winding

Fig. 9

Main winding and Auxiliary winding are 90

o

electrical apart along the stator.

Auxiliary Winding

- Switched out of the circuit at some set speed by a centrifugal switch

- Designed to have low X/R ratio

- Use smaller wire to achieve high R

- Current in the auxiliary winding leads the current in main winding

Fig. 10

ECE 3650 Electrical Machines Athula Rajapakse

7

Torque-Speed Characteristics

Fig. 11

Features

- Moderate starting torque

- Used for low starting torque applications

- Fans, pumps, blowers, etc.

- Inexpensive

- Available in the fractional horse power range

Direction of Rotation

- Direction is determined by the space angle of the auxiliary winding magnetic field

- 90

o

leading or 90

o

lagging

- Can be reversed by changing the connection of auxiliary winding while the main winding

connections are kept unchanged

Capacitor Start Motors

Fig 12

- Capacitor is connected in series with the auxiliary winding

- By proper selection of Capacitor value, the mmf of Auxiliary winding can be made equal to that of

Main winding

- Create a single uniform rotating magnetic field Behaves like a three-phase induction motor

ECE 3650 Electrical Machines Athula Rajapakse

8

Torque-Speed Characteristics

Fig. 13

Features

- Very high starting torque ~ 300% of the rated torque

- More expensive than split-phase motors

- Used in applications those require high starting torque

- Compressors, pumps, air conditioners, equipment start under load

Permanent Split Capacitor

Fig. 14

- Starting capacitor does a very good job in improving the torque speed characteristics

- Capacitor is left in the circuit even during the normal running conditions

- Operate just like a three-phase induction motor smooth torque

Features

- Simpler than capacitor start motor no centrifugal switch

- At normal loads, they are more efficient

- Higher power factor

- Smooth operation

- Lower starting torque than capacitor start motors

o capacitor size is selected to balance the currents at the normal load conditions

o Under starting conditions, current is very high and unbalanced

ECE 3650 Electrical Machines Athula Rajapakse

9

Capacitor Start, Capacitor Run Motors

Fig. 15

Two Capacitors are used to obtain

- Largest possible starting torque

- Best running conditions

- C

start

is switched out after a certain speed

Torque-Speed Characteristics

Fig. 16

- When starting C = C

run

+C

start

balances the winding currents yielding high starting torque

- The permanent capacitor C

start

is just enough to balance the currents at normal speeds

- C

run

= 10-20% of C

start

Direction of Rotation

- Direction of rotation of any capacitor-type motor can be reversed by changing the connections of

its auxiliary windings.

ECE 3650 Electrical Machines Athula Rajapakse

10

Shaded-Pole Induction Motors

Fig 17

- No auxiliary winding

- Has salient poles

- Each pole is split into two one portion is surrounded by a short circuited coil called shading ring

- Changing magnetic flux created by the main winding induces a voltage and therefore a current in

the shading ring

- The current in a shading ring creates a field that opposes the changes in the field that created it.

- This opposition retards the flux changes creating slight imbalance between the two oppositely

rotating flux waves

- Net rotation is from unshaded to the shaded portion of the pole face

- Direction of rotation cannot be easily changed.

Torque-Speed Characteristics

Fig 18

Features

- Less starting torque

- Less efficient

- Used only in very small motors ( 0.05 hp and less) with very low starting torque requirements

- The cheapest design when it can be used.

ECE 3650 Electrical Machines Athula Rajapakse

11

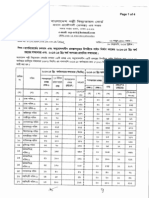

Comparison of single-phase induction motors

Ranking from best to worse in terms of starting and running characteristics

- Capacitor start, capacitor run motor

- Capacitor start motor

- Permanent split capacitor motor

- Split-phase motor

- Shaded pole motor

Circuit Model of a Single-Phase Induction Motor

We can use double revolving field theory to develop an equivalent circuit

- Only the case of running with main winding is considered

- Analysis of operation with both winding requires use of symmetrical components

Case -1 : When the motor is stalled

Fig. 19

- Motor appears like a single phase transformer with short circuited secondary

- Core loss can be lumped with the rotational losses (or with stray load losses)

- The machine magnetic field can be resolved into two equal and oppositely rotating magnetic fields

- Equivalent circuit can be split into two sections, each corresponding to the effects of one of the

two magnetic fields

Fig. 20

ECE 3650 Electrical Machines Athula Rajapakse

12

Case-2: When running

Effective rotor resistance depends on the slip

Two magnetic fields the slip is different for the two magnetic fields

Forward field:

s

R S

N

N N

s

=

Backward field:

s

N

N N

N

N N

s

s

R S

s

R S

B

=

+

=

= 2

) (

Fig. 21

Analysis of Single-Phase Induction Motor Performance Using the Equivalent Circuit

The net power and torque in the machine is the difference between forward and reverse components.

Fig. 22

M s

R

M s

R

F F F

jX jX

jX jX

jX R Z

+ +

+

= + =

) (

) )( (

2

2

2

2

M s

R

M s

R

B B B

jX jX

jX jX

jX R Z

+ +

+

= + =

) (

) )( (

2 ) 2 (

2 ) 2 (

2

2

B F

Z Z jX R

V

I

5 . 0 5 . 0

1 1

1

+ + +

=

ECE 3650 Electrical Machines Athula Rajapakse

13

Calculation of Output Power and Torque

Calculation of the current in rotor impedance branches in forward and backward components is tedious.

We can workaround by considering the air gap power.

- Air Gap Power (P

AG

)

- Induced torque

- Converted Power:

- Rotor copper loss (P

RCL

):

- Since the two current components are operating at two different frequencies:

- The net mechanical output:

Power Flow in a Single-Phase Induction Motor

Fig. 23

) 5 . 0 (

2

1 , F F AG

R I P =

) 5 . 0 (

2

1 , B B AG

R I P =

B AG F AG AG

P P P

, ,

=

) 5 . 0 (

2

1 , , F F RCL F RCL

R sI sP P = =

) 5 . 0 ( ) 2 ( ) 2 (

2

1 , , B B AG B RCL

R I s P s P = =

B RCL F RCL RCL

P P P

, ,

+ =

sync

AG

ind

P

e

t =

AG m ind conv

P s P ) 1 ( = = e t

rot conv out

P P P =

ECE 3650 Electrical Machines Athula Rajapakse

14

Example1:

A 2.4 kW, 120 V, 60 Hz, capacitor-start motor has the following impedances for the main and auxiliary

windings at starting:

Z

M

= 4.5 + j3.7 O

Z

A

= 9.5 + j3.5 O

Find the value of starting capacitance that will place the main and auxiliary winding currents in

quadrature at starting.

Example2:

A 1/3 hp, 110 V, 60 Hz, six-pole, split phase induction motor has the following impedances:

R

1

= 1.52 O X

1

= 2.10 O X

M

= 58.2 O

R

2

= 3.13 O X

2

= 1.56 O

The core losses of this motor are 35W, and the friction, windage and stray losses are 16W. The motor

is operating at the rated voltage and frequency with its starting winding open, and the motors slip is

5%. Find the following quantities:

(a) speed in rpm, (b) stator current in A

(c) stator power factor (d) input power

(e) air fap power, (f) converted power

(g) induced torque, (h) output power

(i) load torque, (j) Efficiency

ECE 3650 Electrical Machines Athula Rajapakse

15

Universal Motor

Torque of a DC motor

A ind

I K| t =

where | = flux per pole

I

A

= Armature current

If the direction of both filed winding and armature winding are reversed at the same time,

A A ind

I K I K | | t = = ) )( (

the direction of torque remains the same.

Fig. 24

If an alternating current is applied to both windings, the torque will still be unidirectional, but pulsating as

shown in Fig. 2.

Fig. 25

DC shunt motor

If both windings are connected to the same AC voltage source

- Very high inductance in the field coil causes current through it to lag behind armature current

- Field direction reversal is delayed relative to armature current reversal

- Instantaneous torque become negative during some intervals

- The average torque will be unacceptably low

ECE 3650 Electrical Machines Athula Rajapakse

16

DC Series Motor

When connected to an AC voltage source:

- The same current flow through the both windings

- Instantaneous torque is always positive

- Could be successfully used as an AC motor

Universal Motor

- In order to work with AC, field poles and stator frame need to be completely laminated

o Otherwise the Core Loss will be enormous

- When the poles and stator are laminated, a DC series motor is called a Universal Motor

o Can be run using AC or DC

- When the motor is run with AC, commutation is poorer: transformer voltages induced on the coils

results in sparking during the commutation

o Much shorter brush life

o Source of radio-frequency interference

o Poor commutation can be rectified by using a compensation winding

Fig. 26 Equivalent circuit and phasor diagram

Torque Speed Characteristics of Universal Motor

Fig. 27 Torque speed characteristics

with DC supply

with AC supply

Torque

Speed

ECE 3650 Electrical Machines Athula Rajapakse

17

Torque with AC current is less than that with DC

- Voltage drop across the reactance at 60 Hz or 50 Hz

- Small back emf ( |e K E

A

= )

- Smaller flux at a given speed

- Peak voltage of an AC system is \2 times the rms voltage

- To avoid saturation voltage rating has to be lowered

- Therefore, rms flux is significantly low

Characteristics of Universal Motor

- Universal motor is light weight

- Has sharply drooping torques speed characteristics

- Not suitable for constant speed applications

- Gives more torque per ampere than other type of single phase motors

- Operating speeds 1500-15000 rpm

Applications of Universal Motor

- Vacuum cleaners

- Hand drills

- Portable tools

- Kitchen appliances

Speed Control

Fig. 28 Torque speed characteristics at different terminal voltages

ECE 3650 Electrical Machines Athula Rajapakse

18

Speed Control Circuits

Fig. 29 Speed control with SCR (Thyristor)

Fig. 30 Speed control with TRIAC

Example:

A 120 V, 60 Hz, 2-pole, universal motor operates at a speed of 8000 rpm and on full load and

draws a current of 17.58 A at a lagging power factor of 0.912. The impedance of the series field

winding is 0.65 +j1.2 O. The impedance of the armature winding is 1.36 +j1.6 O. Determine (a)

the induced back emf in the armature, (b) the power output, (c) the shaft torque, and (d) the

efficiency if the rotational loss is 80 W.

You might also like

- A Presentation On Shaded Pole Induction Motor: Prepared By: Salunkhe KalpeshDocument20 pagesA Presentation On Shaded Pole Induction Motor: Prepared By: Salunkhe KalpeshKalpesh SalunkheNo ratings yet

- Novel Dual-Excitation Permanent Magnet Vernier Machine: Akio Toba Thomas A. LipoDocument6 pagesNovel Dual-Excitation Permanent Magnet Vernier Machine: Akio Toba Thomas A. LipoNenad Kostadinovic50% (2)

- MotorsDocument18 pagesMotorsAmado CamachoNo ratings yet

- Visual & Special Effects ProposalDocument10 pagesVisual & Special Effects ProposalMayur Dev SewakNo ratings yet

- Philippine Grid Code Amendment No.1 - Apr 2 2007Document125 pagesPhilippine Grid Code Amendment No.1 - Apr 2 2007rosario.md1052100% (1)

- AmpliTube 4.0.0 Ipad User ManualDocument152 pagesAmpliTube 4.0.0 Ipad User ManualValérie CharavelNo ratings yet

- Power Electronics and Electric Drives for Traction ApplicationsFrom EverandPower Electronics and Electric Drives for Traction ApplicationsNo ratings yet

- Brushless DC MotorDocument19 pagesBrushless DC MotorSanjeet KumarNo ratings yet

- BLDCDocument4 pagesBLDCmechtex Pvt LtdNo ratings yet

- Unit 3-Ac Machines PDFDocument129 pagesUnit 3-Ac Machines PDFhotty pantsNo ratings yet

- EE2403 Special Electrical MachinesDocument19 pagesEE2403 Special Electrical MachinesvasanthavananNo ratings yet

- Induction MotorsDocument25 pagesInduction Motorsapi-3827132100% (2)

- D C Machines-IntroductionDocument25 pagesD C Machines-Introductionprashanth6876050% (2)

- Stepper MotorDocument26 pagesStepper MotorSupriya Rakshit100% (1)

- Brushless D.C. Motors: Prepared By: Manuj Garg (2k13/EE/070) Mohit Goswami (2k13/EE/073)Document17 pagesBrushless D.C. Motors: Prepared By: Manuj Garg (2k13/EE/070) Mohit Goswami (2k13/EE/073)Manuj GargNo ratings yet

- PX7203-Special Electrical Machines PDFDocument11 pagesPX7203-Special Electrical Machines PDFvaishnavisriNo ratings yet

- DC MotorDocument53 pagesDC MotorK04Anoushka TripathiNo ratings yet

- Brushless DC MotorDocument6 pagesBrushless DC Motorpsksiva13No ratings yet

- Ac Series MotorDocument15 pagesAc Series MotorMani Balaji TNo ratings yet

- Stepper IntroDocument60 pagesStepper IntroAshok More100% (1)

- Alternator RewindDocument39 pagesAlternator RewindanwarNo ratings yet

- Cruise Control of Bruhless DC MotorDocument12 pagesCruise Control of Bruhless DC MotorVishal PhadtareNo ratings yet

- 3phase Induction Motor (Sukhpreet)Document17 pages3phase Induction Motor (Sukhpreet)Ankesh KunwarNo ratings yet

- Hysteresis MotorDocument27 pagesHysteresis MotorSubham GhoshNo ratings yet

- Induction Motors Unit 3Document26 pagesInduction Motors Unit 3babu KaroliNo ratings yet

- Week 71Document25 pagesWeek 71Raphael SebucNo ratings yet

- What Is An Alternator?: Battery Voltage Regulator AlternatorDocument5 pagesWhat Is An Alternator?: Battery Voltage Regulator AlternatorNeverhhhNo ratings yet

- Stepper Motor and DrivesDocument8 pagesStepper Motor and DrivesLasantha Abeykoon100% (2)

- Unit - V: Single Phase Induction Motors and Special MachinesDocument49 pagesUnit - V: Single Phase Induction Motors and Special MachinessasikalasivakumarNo ratings yet

- Project 1 Synchronous MachineDocument34 pagesProject 1 Synchronous MachineDivya Kumar SharmaNo ratings yet

- Squirrel Cage and Wound RotorDocument4 pagesSquirrel Cage and Wound RotorACouh CHi JOshNo ratings yet

- A.C. Series MotorDocument16 pagesA.C. Series MotorM BNo ratings yet

- Universal Motors: Presented by Meraj WarsiDocument13 pagesUniversal Motors: Presented by Meraj WarsiMeraj WarsiNo ratings yet

- Ac Motor Control k2636 - Rev2Document12 pagesAc Motor Control k2636 - Rev2kobiNo ratings yet

- AC Synchronous GeneratorDocument8 pagesAC Synchronous Generatoraswardi8756No ratings yet

- DC Compound MotorDocument6 pagesDC Compound Motorvishnu vishnuNo ratings yet

- Electromagnetic Induction: Sardar Patel Institute of Technology 1Document22 pagesElectromagnetic Induction: Sardar Patel Institute of Technology 1krushiNo ratings yet

- 开关磁阻电机的ANSOFT建模方法Document28 pages开关磁阻电机的ANSOFT建模方法Nuwantha FernandoNo ratings yet

- Sinkron Motor - AtmiDocument87 pagesSinkron Motor - AtmiHaryo Probo100% (1)

- Unit 3Document5 pagesUnit 3Narasimman DonNo ratings yet

- Advanced Speed Control Techniques of Brushless DC MotorDocument17 pagesAdvanced Speed Control Techniques of Brushless DC Motorsrinupid100% (1)

- 5.chapter Five - Ignition and Fuel Injection SystemsDocument21 pages5.chapter Five - Ignition and Fuel Injection SystemsAhmed M MerzaNo ratings yet

- Brushless DC MotorDocument19 pagesBrushless DC MotorKhalid MahmudNo ratings yet

- Switched Reluctance Motor (SRM)Document8 pagesSwitched Reluctance Motor (SRM)Ömer Faruk AbdullahNo ratings yet

- How Does A Universal Motor WorkDocument3 pagesHow Does A Universal Motor WorkJeremiah NayosanNo ratings yet

- Construction of Three Phase Induction MotorDocument18 pagesConstruction of Three Phase Induction MotorRajeev ValunjkarNo ratings yet

- PMBLDC Motor DriveDocument55 pagesPMBLDC Motor DriveSushant SinghNo ratings yet

- Induction Motor Construction and OperationDocument36 pagesInduction Motor Construction and Operationkyaw winNo ratings yet

- 3 Phase Induction Motor Speed Control Using PIC PDFDocument18 pages3 Phase Induction Motor Speed Control Using PIC PDFAmmar Al-Kindy100% (2)

- No Load and Block Rotor Test: Premier Trading CorporationDocument11 pagesNo Load and Block Rotor Test: Premier Trading CorporationKsr Akhil100% (1)

- Modelling and Simuation of BLDC Motor in MATLAB GUIDocument5 pagesModelling and Simuation of BLDC Motor in MATLAB GUIvishiwizardNo ratings yet

- Lab MachineDocument9 pagesLab MachineAnonymous ryvoPIDNo ratings yet

- Synchronous MotorsDocument25 pagesSynchronous MotorsParvesh NainNo ratings yet

- Mosfet Igbt BJT Difference and ApplicationDocument5 pagesMosfet Igbt BJT Difference and ApplicationSangammeshwra AbNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- 8085 - Lecture - Stepper Motor Interfacing - Prof. RAMDocument6 pages8085 - Lecture - Stepper Motor Interfacing - Prof. RAMKumar AnjeetNo ratings yet

- Single Phase Induction MotorsDocument11 pagesSingle Phase Induction MotorsSafnas KariapperNo ratings yet

- 8 Single-Phase Induction Motors - AC Motors - Electronics TextbookDocument8 pages8 Single-Phase Induction Motors - AC Motors - Electronics TextbookSchuldich SchwarzNo ratings yet

- Single-phase induction motors: 3-φmotor runs from 1-φ power, but does not startDocument6 pagesSingle-phase induction motors: 3-φmotor runs from 1-φ power, but does not startkaler-ukNo ratings yet

- AE Written ResultDocument1 pageAE Written ResultmaakbdNo ratings yet

- Weekly Report 21th Oct 2018Document5 pagesWeekly Report 21th Oct 2018maakbdNo ratings yet

- Simple Understanding of Load Flow AnalysisDocument2 pagesSimple Understanding of Load Flow AnalysismaakbdNo ratings yet

- My Weekly Report On 7th October 2018Document2 pagesMy Weekly Report On 7th October 2018maakbdNo ratings yet

- AM (Tech) Written Exam NoticeDocument1 pageAM (Tech) Written Exam NoticemaakbdNo ratings yet

- Weekly Report On 14th October 2018Document2 pagesWeekly Report On 14th October 2018maakbdNo ratings yet

- New at CityDocument1 pageNew at CitymaakbdNo ratings yet

- (Trka: @Gq@Eetq QTRDocument2 pages(Trka: @Gq@Eetq QTRmaakbdNo ratings yet

- PGCBDocument1 pagePGCBmaakbdNo ratings yet

- For YouDocument1 pageFor YoumaakbdNo ratings yet

- Last TimeDocument1 pageLast TimemaakbdNo ratings yet

- Barishal InfoDocument1 pageBarishal InfomaakbdNo ratings yet

- EGCBDocument1 pageEGCBmaakbdNo ratings yet

- Back Door OpenDocument1 pageBack Door OpenmaakbdNo ratings yet

- All Grid InfoDocument1 pageAll Grid InfomaakbdNo ratings yet

- Ruber Garden 2Document1 pageRuber Garden 2maakbdNo ratings yet

- Ruber Garden 3Document1 pageRuber Garden 3maakbdNo ratings yet

- Kzwo-Jvj Cwem BV MK Ix RVBVJ Awdm MP I Wkí e KQV GVMDocument2 pagesKzwo-Jvj Cwem BV MK Ix RVBVJ Awdm MP I Wkí e KQV GVMmaakbdNo ratings yet

- Scan 0002Document2 pagesScan 0002maakbdNo ratings yet

- Driver NiogDocument1 pageDriver NiogmaakbdNo ratings yet

- 2280Document1 page2280maakbdNo ratings yet

- Barishal Informed AllDocument1 pageBarishal Informed AllmaakbdNo ratings yet

- Barishal ConcerningDocument1 pageBarishal ConcerningmaakbdNo ratings yet

- Ruber Garden 1Document1 pageRuber Garden 1maakbdNo ratings yet

- Please Send ThisDocument1 pagePlease Send ThismaakbdNo ratings yet

- Contact Info of Barishal PbsDocument1 pageContact Info of Barishal PbsmaakbdNo ratings yet

- Barishal ContractorDocument1 pageBarishal ContractormaakbdNo ratings yet

- Target 0001Document4 pagesTarget 0001maakbdNo ratings yet

- File 0064Document1 pageFile 0064maakbdNo ratings yet

- Welq T 'BW 'B e KQV Av'v Qi Z - : BV MK Ix RVBVJ AwdmDocument1 pageWelq T 'BW 'B e KQV Av'v Qi Z - : BV MK Ix RVBVJ AwdmmaakbdNo ratings yet

- Bernd Ketterer Graphite Powder ProcessingDocument20 pagesBernd Ketterer Graphite Powder ProcessingNasos MasourasNo ratings yet

- M68HC11EDocument242 pagesM68HC11EAbderrahim BelissaouiNo ratings yet

- HVDC Fault Location PresentationDocument66 pagesHVDC Fault Location PresentationAmila Pathirana100% (1)

- IBM System x3650 M3, 7945K1G - 7945K1GDocument3 pagesIBM System x3650 M3, 7945K1G - 7945K1GAdalberto BarbosaNo ratings yet

- 40CCF Zen CassetteDocument2 pages40CCF Zen CassetteErwin MaldoNo ratings yet

- USB Pinout and WiringDocument4 pagesUSB Pinout and WiringnelsonhooverNo ratings yet

- Electric Duct Heater: Specification and Installation InstructionsDocument8 pagesElectric Duct Heater: Specification and Installation InstructionsDonald VelosoNo ratings yet

- PLC HoneyWellDocument44 pagesPLC HoneyWellJeremy100% (2)

- Feeder Protection Relay FormatDocument4 pagesFeeder Protection Relay FormatUmapathiNo ratings yet

- Parametric Study of Slotted Ground Microstrip Patch Antenna: Sara Mahmoud, W. Swelam, Mohamed HassanDocument8 pagesParametric Study of Slotted Ground Microstrip Patch Antenna: Sara Mahmoud, W. Swelam, Mohamed HassanIOSRjournalNo ratings yet

- Pulse and Digital CircuitsDocument2 pagesPulse and Digital Circuitsshaik ahammad hussainNo ratings yet

- Markemimaje Smartdate 5Document198 pagesMarkemimaje Smartdate 5alfredo campos bartoloNo ratings yet

- Telsen Radiomag No.1Document36 pagesTelsen Radiomag No.1Rick MendelezNo ratings yet

- 261Document11 pages261Solaiappan KtNo ratings yet

- Cmos Check Sum ErrorDocument3 pagesCmos Check Sum Erroryogeshdhuri22No ratings yet

- 18 Advantages and Disadvantages of Cell PhonesDocument7 pages18 Advantages and Disadvantages of Cell PhonesVarman JNo ratings yet

- ARFCN GSM SpecsDocument7 pagesARFCN GSM SpecsEyotreNo ratings yet

- Amigos Comparto El Metodo de F4 para SM G610M Bin 3Document2 pagesAmigos Comparto El Metodo de F4 para SM G610M Bin 3Braulio Sanchez100% (1)

- Ttp223-Ba6 C80757Document8 pagesTtp223-Ba6 C80757Sahar ShahidNo ratings yet

- AKAI Midi Keyboard ManualDocument7 pagesAKAI Midi Keyboard ManualcdschNo ratings yet

- All About OFDMDocument7 pagesAll About OFDMDheyauldeen NajimNo ratings yet

- Ev ChargersDocument29 pagesEv ChargersAjay Yadav100% (1)

- ZX95 2536C S+ DashboardDocument6 pagesZX95 2536C S+ DashboardAugusto RadaelliNo ratings yet

- Chemistry Test 2 Review With AnswersDocument4 pagesChemistry Test 2 Review With AnswersAmanda ClayNo ratings yet

- Transformer:-: Equipment Used To Raise or Lower The Potential Difference of An Alternating Current SupplyDocument20 pagesTransformer:-: Equipment Used To Raise or Lower The Potential Difference of An Alternating Current SupplynazurahNo ratings yet

- A Comparison of Liquid-Filled and Dry-Type Transformers For Industrial ApplicationsDocument5 pagesA Comparison of Liquid-Filled and Dry-Type Transformers For Industrial Applicationsmilad rouhiniaNo ratings yet

- Overlapping Contact 800t Td006 en PDocument8 pagesOverlapping Contact 800t Td006 en PDony SaputraNo ratings yet