Professional Documents

Culture Documents

Chapter - 3: 3.1 Heat Sink Designing

Uploaded by

Satyajit RastogiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter - 3: 3.1 Heat Sink Designing

Uploaded by

Satyajit RastogiCopyright:

Available Formats

CHAPTER 3

DESIGNING AND CALCULATIONS

3.1 HEAT SINK DESIGNING:

A heat sink (or heatsink) is an object that absorbs and dissipates heat from another object using thermal contact (either direct or radiant). Heat sinks are used in a wide range of applications where efficient heat dissipation is required; major examples include refrigeration, heat engines.

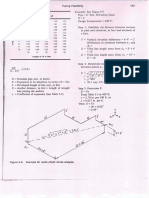

Fig.9 Heat sink functions by efficiently transferring thermal energy ("heat") from an object at high temperature to an another object at a lower temperature with greater heat capacity. This rapid transfer of thermal energy quickly brings the first object into thermal equilibrium with the second, lowers the temperature of the first object, making the heat sink a cooling device.

19

Efficient function of a heat sink relies on rapid transfer of thermal energy from the first object to the heat sink, and the heat sink to the second object. The most common design of a heat sink is a metal device with many fins. The high thermal conductivity of the metal combined with its large surface area result in the rapid transfer of heat energy to the surrounding, cooler, air. This cools the heat sink and whatever it is in direct thermal contact with. Use of fluids (for example coolants in refrigeration) and thermal interface material (in cooling electronic devices) ensures good transfer of thermal energy to the heat sink. Similarly a fan may improve the transfer of thermal energy from the heat sink to the surrounding.

PERFORMANCE:

Heat sink performance (including free convection, forced convection, liquid cooled, and any combination thereof) is a function of material, geometry, and overall surface heat transfer coefficient. Generally, forced convection heat sink thermal performance is improved by increasing the thermal conductivity of the heat sink materials, increasing the surface area and by increasing the overall area heat transfer coefficient (usually by increase fluid velocity, such as adding fans, pumps, etc.). Heat sink height,H = 0.1m Fin width, L = 0.11m Fin thickness, = 1.5 Fin length, = 0.09m Heat sink width, W = 0.09m No. of fins, = 16

Volumetric flow rate of heat sink fan = 0.12

/sec =

Air velocity between , V=

V=

= 18.93m/s

20

Spacing between fins

b =

= 4.4

3.2 DESIGN OF THE COOLING MODULE:

In the table below you can see some Peltier factors for different pairs of metals. Peltier factors for different metal pairs: Fe-constantan T, K 273 299 403 513 593 833 P, mV 13.0 15.0 19.0 26.0 34.0 52.0 T, K 292 328 478 563 613 718 Table-2 Cu-Ni P, mV 8.0 9.0 10.3 8.6 8.0 10.0 Pb-constantan T, K 293 383 508 578 633 713 P, mV 8.7 11.8 16.0 18.7 20.6 23.4

21

For Fe - constantan pair T = 273K P = 13mv heat load 2 N[S I Tc - R K (Th Tc)]

V = 2 N [S (Th Tc) + I R ] N = 1, S = 13mv = 13

I = 3.6 A , Tc = 7

= 273+7 = 280K

= 60

= 273+60 = 333K , 22 W,

= 80.4 W-

80.4- 22 = 60.9 W-

R= 2.476

A = lbh = 20208 mm = 220.8 = 3.2 = 3.2

L = 2cm = 2

2 N[S I Tc -

R K (Th Tc)]

21[ 13

3.6280

2.476

60.9

(333-

280)]

22

7.4 watt

V = 2 N [S (Th Tc) + I R ] = 2 1 [ 13 (333-280) + 3.6 2.476

= 12 V =

= 0.17

Fe- constanatan pair P= 15 mv 2 N[S I Tc - R K (Th Tc)]

V = 2 N [S (Th Tc) + I R ] N = 1, S = 15 mv = 15

I = 3.6 A , Tc = 7

= 273+7 = 280K

= 60

= 273+60 = 333K , 22 W,

= 80.4 W-

80.4- 22 = 60.9 W-

R= 2.476

A = lbh = 20208 mm = 220.8

23

= 3.2 = 3.2 L = 2cm = 2

2 N[S I Tc -

R K (Th Tc)]

21[ 15

3.6280

2.476

60.9

(333-

280)]

11.72 Watt

V = 2 N [S (Th Tc) + I R ] = 2 1 [ 15 (333-280) + 3.6 2.476

= 12 V

= 0.27

Now, for P = 19 mv

2 N[S I Tc -

R K (Th Tc)]

21[ 19

3.6280

2.476

60.9

(333-

280)]

20.36

V = 2 N [S (Th Tc) + I R ]

24

= 2 1 [ 19

(333-280) + 3.6 2.476

= 12V

=0.48

For copper nickel pair: For P = 8mv = 401 , = 91

= 310 W-

2 N[S I Tc -

R K (Th Tc)]

21[ 8

3.6280

2.476

310

(333-280)]

negative For P = 9 mv 21[ 9 negative For P = 10.3 mv 21[ 10.3 3.6280 2.476 310 3.6280 2.476 310

(333-280)]

(333-

280)]

negative

25

Since

is coming out to be negative for all three values of P, therefore this pair is neglected.

For Lead - constantan pair: For P =8.7 mv 35 W-

,

W-

22 W-

21[ 8.7 negative

3.6280

2.476

13

(333-280)]

Therefore, neglected. For P = 11.8 mv 21[ 11.8 3.6280 2.476 13

(333-

280)]

= 5.32 Watt

V = 2 N [S (Th Tc) + I R ] = 2 1 [ 11.8 (333-280) + 3.6 2.476

= 12 V

=0.12

For P = 16 mv

26

21[ 16

3.6280

2.476

13

(333-280)]

V = 2 N [S (Th Tc) + I R ] = 2 1 [ 16 (333-280) + 3.6 2.476

= 12 V =

= 0.34

Fe-constantan

P(mV) COP P(mV)

Cu-Ni

COP

Pb-constantan

P(mV) COP

13

0.17

8.0

8.7

15

0.27

9.0

11.8

0.12

19

0.48

10.3

16

0.34

Table-3

Thus, after the calculation , we got Fe- constanatan pair as the most efficient.

27

CALCULATING FOR DT(MAX): 403K - 19(p) 299k - 15(p) 403k-299k = 104k 104 4mV 1 - 4/104=0.039mV 338 15+1.5=16.5mV So, we calculated for P = 16.5 mV = 16.5 V

2 N[S I Tc -

R K (Th Tc)]

21[ 16.5

3.6280

2.476

13

(333-

280)]

14.96 Watt

V = 2 N [S (Th Tc) + I R ] = 2 1 [ 16.5 (333-280) + 3.6 2.476

= 12 V =

= 0.35

So, we took P = 16.5 mv

constanatan pair for design.

65

and

and Fe-

28

3.2.1 CALCULATING PELTIER HEAT:

Peltier heat(Q)=Q P= peltier factor Q= I T P

Q=3.6 60 60=12960C Fe-constantan pair: P(mV) 13 15 19 QP 12960 13=168.48J 12960 15=194.4J 12960 19=246.24J

CU-Ni pair: P(mV) 8 9 10.3 QP 12960 8=103.68J 12960 9=116.64J 12960 10.3=133.48J

Pb-constantan pair: P(mV) 8.7 11.8 16 QP 112.75 152.92 207.36

CALCULATING FOR DT(MAX): 403K - 19(p) 299k - 15(p)

29

403k-299k=104k 104 4mV 1 - 4/104=0.039mV 338 15+1.5=16.5mV Therefore, QP= 12960 16.5=213.84J So,we assumed Fe-constantan for our design.

3.3 SPECIFICATIONS OF COOLING MODULE:

DT(max) of module= 65 degree Celsius Max.power(watt)= 6 watt Max. current(A)= 3.6A Max.voltage(V)=12 Max power consumption=I(max) V(max)=43.2watt

Temperature difference= T(hot)-T(cold)=36-7 = 29degree Celsius. : Ratio of the modules operating temperature difference to the DT max of the module= =0.46 for lowest power consumption: I= 1.5 A I max = 3.6 A = 0.42 Length breadth height(in cm)= = 220.8

30

31

You might also like

- Steel SectionDocument33 pagesSteel Sectionuthaya kumar100% (2)

- Solved Problems in Heat TransferDocument16 pagesSolved Problems in Heat TransferAngelica Joyce Benito100% (3)

- ELECTRONICS Formulas and ConceptsDocument22 pagesELECTRONICS Formulas and ConceptsHarold Antonio100% (2)

- Chapter 12 Radiation Heat Transfer: H T T T TDocument18 pagesChapter 12 Radiation Heat Transfer: H T T T TKerem GönceNo ratings yet

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Pipe Line Flexibility Manual CalculationDocument20 pagesPipe Line Flexibility Manual CalculationKagira Drawing Soltuion100% (3)

- Asme B16.21 (2005) PDFDocument22 pagesAsme B16.21 (2005) PDFLevi Porter100% (1)

- 11 ExtrusionDocument60 pages11 Extrusionsuhas deshpande100% (15)

- MATERIAL Mechanical DesignDocument11 pagesMATERIAL Mechanical DesignanisNo ratings yet

- 1 - 30 QestionsDocument63 pages1 - 30 Qestionssmdali14No ratings yet

- Midas CatalogueDocument38 pagesMidas CatalogueChaudharyShubhamSachanNo ratings yet

- 257 - Trelleborg Bending StiffenersDocument8 pages257 - Trelleborg Bending StiffenersantidemosNo ratings yet

- Astm 5930 PDFDocument5 pagesAstm 5930 PDFSaurabhNo ratings yet

- MicROLOGIC SETTINGDocument6 pagesMicROLOGIC SETTINGiqkhanukNo ratings yet

- Boiler CalculationDocument37 pagesBoiler CalculationFmJoy Dioko100% (2)

- Design of Reactangular Under Ground Water Tank: Name of Work:-PknDocument27 pagesDesign of Reactangular Under Ground Water Tank: Name of Work:-PknEr Jeya PrakashNo ratings yet

- 4.1.3 Step-by-Step CalculationDocument11 pages4.1.3 Step-by-Step Calculationmohamed nizal100% (1)

- Condenser Without SubcoolingDocument19 pagesCondenser Without SubcoolingtatvaNo ratings yet

- Heat PinchDocument6 pagesHeat PinchYeeXuan TenNo ratings yet

- NHBC Standards 2018 PDFDocument392 pagesNHBC Standards 2018 PDFnpNo ratings yet

- Olivia ReportDocument8 pagesOlivia ReportDhadkan D KCNo ratings yet

- Workbook Workbook Workbook Workbook Workbook: Try Yourself QuestionsDocument14 pagesWorkbook Workbook Workbook Workbook Workbook: Try Yourself QuestionsShubham mishraNo ratings yet

- Nov Dec 2017Document22 pagesNov Dec 2017arr2604No ratings yet

- Mathcad - Pond Hex - FinalDocument6 pagesMathcad - Pond Hex - FinalMohammed A IsaNo ratings yet

- AHMT Assignment 01Document7 pagesAHMT Assignment 01shubham0% (1)

- 2019 Me 349Document6 pages2019 Me 349SherryNo ratings yet

- Heat Removal From A Triangular Finned Flat-Plate Solar-Energy CollectorDocument9 pagesHeat Removal From A Triangular Finned Flat-Plate Solar-Energy CollectorResearcherzNo ratings yet

- Proposal ExampleDocument4 pagesProposal ExampleEce YağmurNo ratings yet

- 2017-02-08Document7 pages2017-02-08Chris KangNo ratings yet

- PTD Assignment 2 - Andreas K 217069363Document9 pagesPTD Assignment 2 - Andreas K 217069363Andreas KanimeNo ratings yet

- Eect of Expansion-Compression Ratio On Performance of The Miller CycleDocument5 pagesEect of Expansion-Compression Ratio On Performance of The Miller CycleÂńűJőőďžýNo ratings yet

- Heat Loss in FinsDocument26 pagesHeat Loss in FinsRemo Ram100% (1)

- Me22 E02 Tumangan M2a1Document4 pagesMe22 E02 Tumangan M2a1Jihoo JungNo ratings yet

- Thermal PropertiesDocument13 pagesThermal Propertiesoreaby05No ratings yet

- LAB10 Heat Conduction ReportDocument8 pagesLAB10 Heat Conduction ReportSyfNo ratings yet

- Chapter 4Document36 pagesChapter 4siva sachaphibulkijNo ratings yet

- Cooling EquipmentDocument15 pagesCooling EquipmentRomelyn Suyom PingkianNo ratings yet

- Benemérita Universidad Autónoma de Puebla: Tarea: EjerciciosDocument4 pagesBenemérita Universidad Autónoma de Puebla: Tarea: EjerciciosDiego MoralesNo ratings yet

- sm3 086Document1 pagesm3 086Sadie HnatowNo ratings yet

- Homework 4 SolutionDocument4 pagesHomework 4 SolutionAnonymous lsQX3wNo ratings yet

- University of Zakho College of Engineering Mechanical DepartmentDocument10 pagesUniversity of Zakho College of Engineering Mechanical DepartmentMasoud doskiNo ratings yet

- Chapter01 2130Document15 pagesChapter01 2130Ricardo Henrique BuzolinNo ratings yet

- Assignment1 SolutionDocument6 pagesAssignment1 SolutionMirza Aqeel AhmedNo ratings yet

- Lance Nielson-Konzen NENG 605 HW1Document5 pagesLance Nielson-Konzen NENG 605 HW1Lance Nielson-KonzenNo ratings yet

- Forced ConvectionDocument10 pagesForced ConvectionMarNo ratings yet

- 2016 Heat and Mass Transfer Practical ManualDocument8 pages2016 Heat and Mass Transfer Practical ManualPortia ShilengeNo ratings yet

- Perpindahan Panas: TugasDocument7 pagesPerpindahan Panas: TugasFirdaNo ratings yet

- Heat Transfer Problems PDFDocument16 pagesHeat Transfer Problems PDFTareq DahbNo ratings yet

- Heat Chap15 055Document14 pagesHeat Chap15 055Kerem GönceNo ratings yet

- Lab Report H3Document14 pagesLab Report H3Safin Rafin HaqNo ratings yet

- Solutions HW 7Document5 pagesSolutions HW 7sam9montgomeryNo ratings yet

- HMT SeminarDocument4 pagesHMT SeminarBhavesh JainNo ratings yet

- Production of Stearic Acid From LardDocument18 pagesProduction of Stearic Acid From LardyhujeeraNo ratings yet

- 11B - Chapter 11, Secs 11.4 - 11.7 BlackDocument15 pages11B - Chapter 11, Secs 11.4 - 11.7 BlackrajindoNo ratings yet

- Natural ConvectionDocument10 pagesNatural ConvectionMarNo ratings yet

- HeDocument18 pagesHeRima MelatiNo ratings yet

- ME3122 Tutorial 1 - Conduction-SolutionsDocument9 pagesME3122 Tutorial 1 - Conduction-SolutionsUnknown uploaderNo ratings yet

- Laminar Viscous Flow Heat Transfer UnitDocument4 pagesLaminar Viscous Flow Heat Transfer Unitalgan7No ratings yet

- Physical Electronics: Handbook of Vacuum PhysicsFrom EverandPhysical Electronics: Handbook of Vacuum PhysicsA. H. BeckNo ratings yet

- Logical progression of twelve double binary tables of physical-mathematical elements correlated with scientific-philosophical as well as metaphysical key concepts evidencing the dually four-dimensional basic structure of the universeFrom EverandLogical progression of twelve double binary tables of physical-mathematical elements correlated with scientific-philosophical as well as metaphysical key concepts evidencing the dually four-dimensional basic structure of the universeNo ratings yet

- Ped PPT 31Document5 pagesPed PPT 31Axit PatelNo ratings yet

- KilnCooler TechnologyDocument6 pagesKilnCooler TechnologyJosé MoránNo ratings yet

- RETA Steel PipeDocument5 pagesRETA Steel PipeBehnam AshouriNo ratings yet

- Assignment 5.1Document2 pagesAssignment 5.1Rica Sampilingan RentoriaNo ratings yet

- Making Structure More Sustainable: Unbonded P-T I-Sects (Voided Slab) Maturity SensingDocument32 pagesMaking Structure More Sustainable: Unbonded P-T I-Sects (Voided Slab) Maturity SensingGokul KgsNo ratings yet

- West Bengal Schedule Rates of Sanitary & Plumbing Works 2015Document125 pagesWest Bengal Schedule Rates of Sanitary & Plumbing Works 2015Arunashish Mazumdar100% (11)

- VSL CCT Pot BearingsDocument8 pagesVSL CCT Pot BearingsalsvsuryaNo ratings yet

- Inventaa Hollow WallsDocument6 pagesInventaa Hollow WallsSumedh GuptaNo ratings yet

- Kevin Macneil: SkillsDocument3 pagesKevin Macneil: SkillskevinNo ratings yet

- Littelfuse Fuse 325 326 Datasheet PDFDocument4 pagesLittelfuse Fuse 325 326 Datasheet PDFChristopher RiceNo ratings yet

- Hazen-Williams Equation For Pipe Friction and Pressure Drop - Fluid Flow Hydraulic and PneumaticDocument1 pageHazen-Williams Equation For Pipe Friction and Pressure Drop - Fluid Flow Hydraulic and Pneumaticahmed salemNo ratings yet

- HONDA - Partial List of Steel Materials at Area A & B - RBEDocument23 pagesHONDA - Partial List of Steel Materials at Area A & B - RBERhine EsperanzateNo ratings yet

- Restoration of Town Hall in Kolkata For Adaptive Reuse: A Case StudyDocument13 pagesRestoration of Town Hall in Kolkata For Adaptive Reuse: A Case StudyDEEP MondalNo ratings yet

- Arcelor - Composite FloorsDocument36 pagesArcelor - Composite Floorspate84100% (1)

- Tube Fittings BMT SuperlokDocument66 pagesTube Fittings BMT SuperlokmsajanjNo ratings yet

- Maamoura and Baraka Development Project: Utilities Area Pipe Rack Structure & Foundation Calculation NoteDocument52 pagesMaamoura and Baraka Development Project: Utilities Area Pipe Rack Structure & Foundation Calculation NoteAHMED AMIRANo ratings yet

- Terwa 1D SystemDocument57 pagesTerwa 1D SystemMircea Remus AndoneNo ratings yet

- Nid Design BriefDocument7 pagesNid Design BriefRachel BeniNo ratings yet

- Kaman Fluid Power CatalogDocument275 pagesKaman Fluid Power CatalogjmartinezmoNo ratings yet

- Analyses and Use of Software Ansys and Franc2d For Fracture MechanicsDocument8 pagesAnalyses and Use of Software Ansys and Franc2d For Fracture MechanicsPradeep KunduNo ratings yet

- Norsok Compact CL2500 Flanges With IX Ring AISI 4140 PTFE Coat and Galvanized Bolting, PCS GC100 (KA1)Document1 pageNorsok Compact CL2500 Flanges With IX Ring AISI 4140 PTFE Coat and Galvanized Bolting, PCS GC100 (KA1)Leonidas GalanisNo ratings yet

![Mathematical Tables: Tables of in G [z] for Complex Argument](https://imgv2-1-f.scribdassets.com/img/word_document/282615796/149x198/febb728e8d/1714993295?v=1)