Professional Documents

Culture Documents

EMAL Contractor EHS Requirements Summary

Uploaded by

Venkadesh PeriathambiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EMAL Contractor EHS Requirements Summary

Uploaded by

Venkadesh PeriathambiCopyright:

Available Formats

EMAL Contractor EHS Requirements

EMAL CONTRACTORS EHS REQUIREMENTS

Rev.00- October 2009

EMAL Contractor EHS Requirements

IMPORTANT SAFETY NOTICE

The electro-magnetic fields generated in the production of aluminium may cause malfunction of heart pacemakers or other electronic medical implants. Visitors to site fitted with these types of devices are prohibited from entering the EMAL Industrial Area. All visitors fitted with hear pacemakers or other electronic medical implants must inform the EMAL Security Department on arrival at the main Security Gate.

Rev.00- October 2009

EMAL Contractor EHS Requirements

INDEX 1. Introduction 2. Disclaimer 3. Contractual Obligations 4. EMAL Core Values 5. EMAL EHS Policy 6. Contractor Site Access & Work Process/ Requirements 7. Safety Violations & Black Point System 8. Incident Communication, reporting and investigation 9. Personal Protective Equipments 10. Permit to Work 11. Lockout & Tagout 12. Working at Height (including portable ladders) 13. Confined Space 14. Mobile Equipment 15. Lifting Equipment 16. Hot Work 17. Signs, Signals & Barricades 18. Abrasive Wheels 19. Electrical Safety 20. Excavation, Digging and Perforation 21. Housekeeping & removal of material 22. Cartridge operating fixing tools 23. Grit blasting 24. Working over water 25. Occupational Health 26. Environment 27. Fire Protection 28. Security Arrangements 29. Attachments

Rev.00- October 2009

EMAL Contractor EHS Requirements

1. INTRODUCTION

This booklet is issued to contractors carrying out work within EMAL. It outlines Safety Health & Environmental requirements and procedures, which the Contractor is required to follow when undertaking work.

The booklet is produced primarily for the use of Contractors Management and supervisory staff who are required to ensure that the safety, Health and Environmental requirements and procedures are brought to the notice of all contractors employees and those requirements are and procedures are strictly followed.

If there is any doubt or misunderstanding about the content of the booklet, the contractor should consult EMAL Representative for clarification. Where the contractors require special precautions or more detailed guidance on Safety procedures, he should discuss this with the EMAL Representative prior to the commencement of work. 2. DISCLAIMER 2.1. This booklet provides summary of EMAL EHS requirements for contractors. It has been prepared to facilitate EHS implementation by contractors when working in EMAL, however it does not, in any way, relieve the contractors from their contractual requirements to comply comprehensively with all EMAL EHS procedures and standards. Relevant EMAL EHS Standards and procedures shall be consulted for further details on specific issues.

2.2. The Contractor and the Contractors employees shall conform in all aspects of their legal duties ad responsibilities as laid down by various U.A.E Authorities. The following Safety, Health and Environmental requirements and procedures do not relieve the contractor from his legal or contractual obligations.

Rev.00- October 2009

EMAL Contractor EHS Requirements

3. CONTRACTUAL OBLIGATIONS 3.1. The contractor will ensure that all equipment, plant, machinery and apparatus brought onto or used in EMAL are safe and without risk to health and safety or the environment and is maintained to an acceptable standard. All necessary test and examination certificates must be available for verification at all times.

3.2. EMAL retains the right to stop any operation, activity or erection of plant/ equipment, etc., if it is considered to be detrimental to safety and health of site personnel or (others). EMAL will not accept any responsibility for all increased cost arising out of such action.

3.3. The contractor and contractors employees will obey all written or verbal instructions given by EMALs representative and / or Area PTW Issuing Authority in respect to Safety & Health of site personnel (or others).

3.4. EMAL retains, the right to remove the Security Clearance of any person not complying with requirements, or any person in a Supervisory capacity who permits such non- compliance.

Rev.00- October 2009

EMAL Contractor EHS Requirements

4. EMAL CORE VALUES o SAFETY FIRST LAST & ALWAYS o PROTECTION OF THE ENVIRONMENT o EVERYTHING CAN BE IMPROVED o INVESTING IN TODAY FOR TOMORROW o WE RESPECT INDIVIDUALS AND THEIR DIFFERENCES

It is mandatory for every EMAL employee as well as contractors to comply and follow the above five EMAL core values in all their activities and work. To help EMAL realize its vision, we expect that all contractors will embed these core values in their workforce and activities, resulting in a synergized effort for the achievement of greater objectives.

Rev.00- October 2009

EMAL Contractor EHS Requirements

5. ENVIRONMENTAL, HEALTH AND SAFETY POLICY

We at EMAL are committed to continuous improvement and sustainable development. We believe all accidents are preventable and we will work ceaselessly to ensure that our business activities cause no harm to employees, contractors, visitors or community members, and have the minimum possible impact on the environment. We are committed to achieving Environmental, health and Safety excellence through the implementation of an effective Environmental, Health and safety management system, and more specifically by:

Creating a workplace culture where protection of peoples health, safety and the environment is paramount and this is reflected in the behaviour of all concerned.

Ensuring all EMALs management systems and procedures reflect current best practice, specially in the areas of Health, Safety and the Environment.

Ensuring all employees understand the Health, Safety and Environmental requirements and impacts of their work, and their obligations in relation to this policy.

Ensuring that all employees have the skills, knowledge and resources to allow them to work safely, without impact on their health and the environment.

Ensuring that all activities under EMALs control comply with this policy and all applicable statutory requirements.

Ensuring the environmental, health and safety aspects and impacts of our activities are fully understood, and managed in accordance with best practices.

Promoting Environmental, Health and Safety awareness amongst employees, contractors, visitors, customers and the wider community.

EMAL Policy requires all its employees and contractors to behave consistently with the requirements of this policy. Specifically: All employees area authorized to refuse to perform any act they judge to be unsafe No employee may be instructed to perform an unsafe act or work in breach of this policy All employees are required to stop any activity that they judge is unsafe or in breach of EMAL policy. No employee shall incur any punishment or suffer any negative consequences as a result of following this policy. No employee or contractor is permitted to act in breach of this policy and any such occurrences may lead to disciplinary measures being taken against those accountable for this breach.

Rev.00- October 2009

EMAL Contractor EHS Requirements

6. CONTRACTOR SITE ACCESS & WORK REQUIREMENTS 6.1. Before hiring In order to guarantee that the potential tenderers have all information, know all requirement and site conditions, the purchasing/ supply chain department will attach to the project/ contract enquiry, the following documentation:

EMALs EHS policy EMAL EHS Standards Technical specifications Other info sent by the contract administrator H&S Prequalification Questionnaire (HS.SAF.09.F01)

6.1.1. Contractor prequalification Prequalification is a mandatory requirement for all contractors who wish to work for EMAL with the exception of the conditions stated for Service Providers. Contracts can only be awarded by EMAL to pre-qualified contractors. The H&S Pre-Qualification Questionnaire (HS.SAF.09.F01) is to be sent with the enquiry documents to all proposed tenderers, if they are not already pre-qualified.

To be placed on an approved contractor list, a contractor must obtain at least 40% rating in EHS prequalification.

The following categories will be assigned to the contractors based on their pre-qualification ratings:

Exceed expectations for rating greater than 75% Acceptable for rating equal to or greater than 40% Not Acceptable for rating less than 40%

Rev.00- October 2009

EMAL Contractor EHS Requirements

6.1.2. EHS Standards Purchasing/ Supply chain department shall send a CD containing all EMAL EHS Standards to the potential tenderers along with the contract enquiry. 6.1.3. Plant Visit For big projects or when requested by the project/ contract administrator, all proposed tenderers shall visit the plant before sending the offer. 6.2. During hiring Once the Contractor is selected, the purchasing department will request the contractor to meet following EMAL requirements and submit appropriate documentation related to the following to EMAL EHS department, at least 15 days prior to the start of the project. 6.2.1. EHS Plan/ Method Statement EHS Plan to their scope of work comprising of identified hazards and their control measures in accordance with EMAL standards. Risk Assessments shall also be submitted along with this EHS Plan. 6.2.2. Contractor Site Representative and EHS Representative The Contractor shall nominate a Site representative and a EHS Representative and notify EMAL in writing before start of the project. Prior to that, CV of Contractor EHS representative shall be shared with EMAL EHS for review and approval. If required, EMAL can ask for an interview of EHS representative before approval. 6.2.3. Contractor employee list The contractor shall submit a complete list of its employees who will work on EMAL project. Attachment 1 (Form HS.SAF.09.F02) shall be used for this purpose. 6.2.4. MSDS (Material Safety Datasheets)

Rev.00- October 2009

EMAL Contractor EHS Requirements

The contractor shall provide EMAL a list of all chemicals along with their MSDSs, which are to be used during the works. Attachment 2 (Form HS.SAF.09.F03) shall be used for this purpose. Material safety datasheets (MSDS) shall also be available at the workplace. The use of particular chemicals must be validated by EMAL Occupational Health Service. If additional products are to be brought to site, the contractor shall request for EMAL approval prior to the mobilization of the product on EMAL premises. 6.2.5. Inventory of all equipments and machines The contractor shall provide EMAL EHS with a complete list of all equipments and machines to be used on the project along with relevant documentation. Attachment 3 (Form HS.SAF.09.F04) shall be used for the purpose. The documentation shall include a copy of the manufacturer instructions, and shall be available in the workplace, equipment certification (if applicable) and legal inspections of all equipments and machines to be used in the project/ contract (welding machines, power generators, compressed air equipments, etc.).

Quarterly Inspections shall be done on all equipments and machines and an inspection tag shall be posted in accordance with EMAL Electrical Safety Code / Portable electrical tools standard.

No explosives shall be allowed on site other than cartridges used in cartridge operated fixing tools.

EMAL can verify and inspect any equipment, inspection record. 6.2.6. Inventory of all standard free moving mobile equipments. The contractor shall provide EMAL a complete list of all standard free moving mobile equipments and their related documentation (Police Registration document, valid third party certification, latest inspection record, operator license and operators third party certification etc.) through Attachment 4 (Form HS.SAF.09.F05)

Rev.00- October 2009 10

EMAL Contractor EHS Requirements

6.2.7. Fall Prevention PPEs The contractor shall provide complete list of all fall prevention PPEs to be used on the project to EMAL. These include harnesses, lanyards, hooks etc. Attachment 5 (Form HS.SAF.09.F06) shall be used for the purpose. 6.2.8. Lifting Tools (below the hook devices) The contractor shall provide complete list of all lifting tools to be used on the project to EMAL EHS. These include Lifting/ rigging tools and accessories like slings, wire ropes, U-bolts and other such accessories. Attachment 6 (Form HS.SAF.09.F07) shall be used for the purpose. 6.2.9. EHS Training & Certification EMAL EHS will provide a Train the Trainer program for contractors. To attend this Train the Trainer program, the contractor employee/ EHS representative should have relevant EHS qualification and experience. Once the contractor EHS representative successfully completes this program, a badge/ certificate is issued, authorizing the EHS representative from contractor to train and induct contractor employees for EMAL contract.

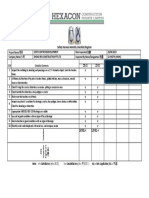

Each contractor shall provide relevant training as per the following table prior to the commencement of work as detailed in their EHS specification sheet. Certificates of these trainings shall be made available to EMAL EHS.

Topic Theoretical training Health & Safety Principles (UAE Law) Forklifts Cranes Aerial Lifts Loaders Other Standard Mobile 1h YES YES YES YES YES Practical training YES YES YES YES YES YES YES YES YES YES YES YES YES YES YES TEST Badge

Equipments

Rev.00- October 2009

11

EMAL Contractor EHS Requirements

Topic

Theoretical training

Practical training

TEST

Badge

LOTOV (Lockout & Tagout & Verification)AP levelSee 2h YES -

LOTOV EMAL Standard Confined Entrants Mobile Equipments (general 2h YES SpaceAuthorized 2h YES -

overview of the EMAL Mobile Equipment requirements) Working at Height (If they are going PPEs) Molten Metal overview (if they are going to work inside Molten Metal areas) Electrical SafetyPortable to use fall prevention & Pedestrian

2h

2h

YES

2h

YES

Equipments. (If they are going to work with portable electrical

2h

YES

equipments). Heat stress control Other training (required by the Contract/ Project administrator or HS department). YES YES

6.2.10. Medical Check-up Certificates Each contractor has to submit to the EHS department, Medical check-up certificates for all its workers in accordance with EMAL medical services standards. Medical checks shall be done on an annual basis. 6.2.11. Access to the Site If all documentation is correct and as per EMAL standards, only then the contractor will receive a Contractor Site Access Permit (Attachment 7 Form HS.SAF.09.F08) authorizing the contractor to enter EMAL premises.

Rev.00- October 2009

12

EMAL Contractor EHS Requirements

The access permit shall be signed by the relevant authorities from different departments/ areas such as Contract Administrator, EHS department and Security. EHS will keep a copy of the Access permit and all documentation in the contractors file.

The following persons shall be required to carry EMAL authorization card in their possession at all times during their work.

Operators of mobile cranes Drivers/ operators of mobile plant (mechanically propelled vehicles) Banksman for mobile cranes and heavy vehicles. Persons authorized to use cartridge operated fixing tools Fire watchers Persons authorized to change abrasive wheels Persons entering into Potline Area

Alcoholic and non-Alcoholic prescription drugs shall not be permitted onto EMALs premises. Persons suspected to be under the influence of alcohol or drugs shall not be permitted onto EMALs premises. 6.3. During Work 6.3.1. Method Statements and Task Risk Assessments A mandatory requirement to receive Permit-To-Work for any task is Method Statement and Task Risk Assessment for that particular task. 6.3.2. Permit to work Before starting the work the contractor shall request the Permit to Work. (See EMAL Permit to Work Standard).

Rev.00- October 2009

13

EMAL Contractor EHS Requirements

6.3.3. Pre- Work Briefing The first day of the work, all workers shall receive a pre-work briefing about the risk of the area, emergency instructions, environment issues, reminders of the special permits for special activities (if it is required). 6.3.4. Health & Safety Targets The EHS department and the Contract/ project administrator will define EHS targets for each contractor and subcontractor. The targets will be defined according to the number of people, work durations and type of work.

The compliance level of the EHS targets will be used for the post work evaluation. The contractor or subcontractor will be required to:

Self- Inspections Risk Notifications Job Observations Toolbox Meetings Participate in EMAL EHS Meetings and programs Near Miss communication.

The Contractor shall also report its EHS Statistics every Sunday to the Contract Administrator and EHS department. These statistics shall include the following information from the start of the project:

Manhours worked Number of Self-inspections Number of Risk notifications raised Job observations Incidents including nearmisses

6.3.5. EHS Incidents

Rev.00- October 2009

14

EMAL Contractor EHS Requirements

All incidents shall be communicated to EMAL in accordance with EMAL Incident Management system. 6.4. After the work - Post Work evaluation After the completion of a project, the EHS department together with the project owner/ contract administrator and contractor, will review the contractor performance. 7. SAFETY VIOLATIONS AND BLACK POINT SYSTEM 7.1. General 7.1.1. Any Environment, Health or safety violation detected during the contractor or subcontractor work execution shall be communicated to the EHS department according to the EMAL Health & Safety Notification standard. Once the EHS department receives the notification, it will classify the violation and will assign the appropriate number of black points and notify the contractor with a copy to the contract administrator. 7.1.2. The maximum number of black points allowed within a working year is 23, after which the contractor can be blacklisted from EMAL for 2 years, meaning the contractor will not be allowed any further contract for this duration. 7.1.3. In case a contractor reaches 24 black points within a working year, a panel will be formed comprising of EHS, Purchasing and relevant department/s to decide the further course of action for the contractor. 7.1.4. The total number of black points accumulated by the contractor during a contract shall be kept as a record in purchasing department and will determine contractors future suitability for EMAL. 7.1.5. For every safety violation issued to the contractor, an action plan will be required by the contractor to address the root cause of the violation and rectify it, failing which the grade of safety violation will be raised.

NOTE: More details on safety violations and the process to raise them can be found in EMAL Safety Notification Standard.

Rev.00- October 2009

15

EMAL Contractor EHS Requirements

7.2. Classification of Safety Violations 7.2.1. Low Risk Minor flaws or faults in the following equipments, conditions or tools, such as: o Portable tools o Welding equipments, power generators, compressed air equipments, etc o Portable electrical equipments o Portable ladders o Restrooms, warehouse, containers, etc o Residual containers, not properly identified, etc.

Lack of: o Housekeeping o Incident reporting o Secondary containers for residuals

Smoking in non designated areas Over speeding for the first time. First non-compliance of PPEs Other safety violations classified as low risk by the EMAL EHS department

7.2.2. High Risk The non compliance of the safety rules, requirements related to the following:

o Medical aptitudes o Equipment or personal identification o Inspection of a fall prevention PPE o Equipment maintenance o Lockout and tagout

Rev.00- October 2009

16

EMAL Contractor EHS Requirements

o Use

of

mobile

equipments

without

the

proper

certification o Recurrence of a low risk by the same person o Over speeding for a second time

Lack of maintenance, inspection or third party certification related to the following:

o Lifting devices (slings, chains, tools, etc) o Lifting equipments (Cranes, hoists, etc.)

Other safety violations classified as high risk by the EMAL EHS department

7.2.3. Very High Risk Failure to stop work immediately when asked by EMAL because of high risk for people or equipments Non compliance of a safety rule, procedure that generates a high potential for a fatality or disabling injury. Violating speed limit for a third time. Soils, water or air contamination. Work execution without EHS plan approval. Other safety violations classified as very high risk by the EMAL EHS department

NOTE: The above lists of unsafe events, conditions or acts for determining different grades of safety violations, are not exhaustive and any decision of EMAL EHS in this regard shall be deemed final. 7.3. Table of Black Points The number of black points given for each grade of violation are detailed in the following table:

Rev.00- October 2009

17

EMAL Contractor EHS Requirements

Type of Violation Low Risk Violations First Notification Second Notification Third Notification High Risk Violations First Notification Second Notification Third Notification Very High Risk Violations First Notification Second Notification

Number of Black Points

1 2 4

4 6 10

10 14

(NOTE: The decision of EMAL EHS in assigning number of black points to a violation will be final.) 8. INCIDENT COMMUNICATION, RECORDKEEPING & INVESTIGATION 8.1. All incidents (with or without injury must be communicated, and properly investigated). The non-reporting of an EHS incident is considered as a serious fault and disciplinary actions could be taken. 8.2. In case of an incident, the worker or co worker must activate the emergency response, 2111 or immediately notify to his supervisor. The Senior Production Person, for the area, shall take immediate control, on arrival at the scene. 8.3. An immediate investigation (preliminary investigation) shall be conducted by the supervisor concerned. Attachment 8 (Form HS.SAF.03.F05) will be used to record the preliminary investigation. The contractor EHS representative will deliver a copy of the Preliminary Investigation to EMAL Contract Administrator and EHS Department within 24hours of the incident. 8.4. A formal Incident investigation must be conducted and recorded in the EMAL Incident Management System for all incidents with injuries.

Rev.00- October 2009

18

EMAL Contractor EHS Requirements

8.5. In EMAL The Incidents are Classified in: Incident Without Injuries o Near Miss o Damage Incident Incident with Injuries o First Aid o Medical Treatment o Restricted Work o Lost Time Injury o Fatality 8.6. Incident Reporting Flowchart NO Did the employee experience an injury or illness? YES NO Is the injury or illness work related? Yes Is the injury or illness a new case? YES NO Does the injury or illness meet the general recorded criteria or the application to specific cases? YES NO Update the previously recorded injury or illness entry if necessary

Do not record the injury or illness

Record the injury or illness

Rev.00- October 2009

19

EMAL Contractor EHS Requirements

9. PERSONAL PROTECTION EQUIPMENT (PPE) 9.1. General PPE requirements 9.1.1. All PPE must comply with European (EN) or the American National Standards Institute (ANSI) safety standards. 9.1.2. Contractors shall provide EMAL a list of all the PPEs and their specifications that will be used for the works for approval. 9.1.3. All PPE shall be of a safe design and construction for the work to be performed. 9.1.4. There is a need to ensure that people with long hair, protect their hair from contact with moving parts of tools and machinery. It is forbidden to work outside of the office with long hair, unless it has been tied up out of the way. 9.1.5. It is forbidden to work outside of the offices wearing jewellery in the form of bracelets, necklaces and earrings. These must be removed prior to going out onto the site. 9.2. Provision and suitability of PPE 9.2.1. The company shall issue safety equipment free of charge to employees, dependant on the nature of their work. 9.2.2. Visitors to site shall be informed of PPE requirements before visiting site. 9.2.3. The company will take into consideration the health of people wearing PPE and its ergonomic effects. Employees should inform the company if they start to have difficulty wearing any of their PPE due to health reasons. 9.3. Compatibility 9.3.1. The PPE selected must fit the individual properly. 9.3.2. If more than one item of PPE is being worn, the different items of PPE must be compatible with each other to ensure the risks are still being adequately controlled.

Rev.00- October 2009

20

EMAL Contractor EHS Requirements

9.4. Assessment and identification of site and task PPE requirements There are various ways in which site and task PPE requirements will be identified and these are as follows: 9.4.1. Mandatory site PPE (outside of offices in designated areas) All personnel entering designated PPE areas will be required to wear the following items of PPE: Hard hat Safety glasses Protective clothing/overalls. In Hot Work areas, flame retardant garments certified with the EN 531:1995 level D2 is required. Safety boots with methatarsal protection 9.4.2. PPE identified by mandatory signage There are areas on site that will require you to wear additional PPE when entering specified zones, for example hearing protection zones or respiratory protection zones. These will be identified by mandatory (blue and white) signage. 9.4.3. PPE identified by risk assessment Certain tasks, for example working with substances, will require the wearing of additional PPE. This additional PPE requirement will have been identified by risk assessment and the information passed to employees by supervisors or contract administrators.

10. PERMIT TO WORK (PTW) Permit to work (PTW) will be required for all construction, modification, maintenance, or inspection. Works that do not require PTW must be approved by the department head and by the Safety Department. In such cases, the Department is required to list the work and maintain proper record. All contractor jobs will require a PTW.

Rev.00- October 2009

21

EMAL Contractor EHS Requirements

10.1. Issuing Authority (IA) A competent person possessing the necessary experience, and technical knowledge, appointed in writing by EMAL to issue, and cancel permits to work within the terms of their authorization. An Issuing Authority will be always an EMAL employee. 10.2. Receiving Authority (RA) 10.2.1. A contractor competent person possessing the necessary experience, and technical knowledge, appointed in writing by EMAL to receive and clear PTW.

10.2.2. For contractors, a letter shall be submitted by all contracting companies stating competency of persons supervising all on-site activities. Each supervisors letter shall be kept on file by EMAL EHS Department who will ensure that the list of Receiving Authorities on the EHS Homepage on EMAL intranet is updated.

10.2.3. The EHS department shall conduct a test for all contractor supervisors applying to receive permits at EMAL. This shall be done prior to any entry of the contractor supervisors name on the Safety Homepage on EMAL intranet.

10.2.4. In the event of a contractor coming to site for the purpose of consulting, attending to a breakdown or doing an ad-hoc, once off task, the contractor will only be allowed to work under EMAL supervision.

10.2.5. The Contractor Receiving Authority is responsible: that the authorized employees comply with all requirements indicated in the PTW. Is responsible to lead and prepare the Pre-work check list.

Rev.00- October 2009

22

EMAL Contractor EHS Requirements

10.3. Permit to Work Process 10.3.1. The PTW has one sheet and all permits will be numbered. The PTW sheet has three paper copies (white, yellow and pink).

10.3.2. The PTW will be completed by the issuing authority. Once the PTW is completed the issuing authority and the receiving authority will sign the PTW. The issuing authority will keep the original of the PTW (white copy) and he will give the other two copies (yellow & pink) to the receiving authority.

10.3.3. Before the commencement of any work under a PTW, the content and work hazards and countermeasures (Pre- work check list Attachment 9 Form HS.SAF.01.F02) will be explained to the working party.

10.3.4. The receiving authority will give the pink copy of the PTW to a competent person. This copy must be in the workplace.

10.3.5. Once the job is completed the CP will give back the pink copy to the RA. The receiving authority will give back the two copies (yellow & pink) to the issuing authority and he will sign the white copy of the PTW in the clearance box. The issuing authority will sign the PTW cancellation box in the original paper (white)

10.3.6. A PTW will be valid until clearance and cancellation. A PTW once issued, will be retained in the custody of the Receiving Authority, until Clearance.

10.3.7. Receiving authority shall ensure the changes in the surroundings and other environmental conditions at the work place. The responsibility of checking the isolation status rests with isolating/issuing authority till the PTW is cancelled. Where the Receiving Authority changes, then a Transfer record must be completed. See Attachment 10.

Rev.00- October 2009

23

EMAL Contractor EHS Requirements

10.3.8. If during the work execution, changes are experienced in the work conditions, the PTW will be cancelled until the normal condition will be restored. If the PTW is cancelled, then a new PTW will be needed. The PTW could be suspended and re-issued using the transfer procedure. 10.4. Pre- Work Check List A Pre-Work Check List will be required for all jobs even when permit to work is not required. See Attachment 9. The contractor receiving authority and the contractor workers will complete the Pre-Work check list before starting the work. The contractor receiving authority will sign the pre-work check list, with the sign the receiving authority is confirming that the hazards and countermeasures were explained and understood to the workers. 11. LOCKOUT, TAGOUT & VERIFY (LOTOV) The EMAL Lockout, Tagout & Verification Program, describe the requirements to guarantee a Zero Energy state for all Construction, Inspection or Maintenance Jobs. It must be remembered that for certain tasks, it may not be possible to guarantee zero energy. These jobs must be inventoried and the work procedure approved by the HS department and Department Manager. 11.1. Isolating Authority (IsA) A EMAL competent person designated by the owner of the area, with the necessary experience, and technical knowledge for isolating equipment and for implementing a tag out and lockout procedure. 11.2. Authorized Person (AP) 11.2.1. A EMAL or contractor competent person with sufficient technical knowledge and practical experience who has been approved to carry out a task on Plant or Apparatus that has been previously isolated by an Isolating Authority (IsA)

Rev.00- October 2009

24

EMAL Contractor EHS Requirements

11.2.2. All EMAL and contractor employees with the exception of the administrative personal must receive specific training about the energy control program to assure the program is properly understood.

11.2.3. Refresher training will be required every two years or before if the program changes or if it is considered because of increasing number of incidents, violations or other reasons. LOTOV Tags & Locks The necessary elements for an equipment/ facility isolation are: o Safety tags (Isolation tags, Personal and

11.3.

Verification/Identification tags) o Safety Locks (Isolation Locks and Personal Locks) 11.3.1. LOTOV Tags Only tags are acceptable where no physical means of locking isolation devices exists. The safety tag has three main purposes: Isolation tag (red) Indicates that the energy isolation devices or verification device are in the safe position. For example, supply valve is closed, vent valve is open, etc Equipment Identification and 0 energy verification tag (yellow). Indicates the piece of equipment or equipment to be worked on and confirms that the energy isolation devices were verified and the equipment is at zero energy. If it has not been possible to verify the equipment, then a verification tag should still be attached for identification, but this should be noted on the tag. In these cases the tag will be yellow with brand red diagonal stripes. Personal Tags (blue) Indicates that there are people working on the equipment out of service because of construction, inspection or

Rev.00- October 2009

25

EMAL Contractor EHS Requirements

maintenance. The personal tags are exclusively for personal use and nobody could attach a personal tag of other employee. The manipulation of a personal tag of another employee will be considered a serious safety violation and disciplinary actions could be taken. The contractor personal tags will be identified with the word CONTRACTOR in print letters.

A safety tag is as restrictive as a safety lock.

Rev.00- October 2009

26

EMAL Contractor EHS Requirements

11.3.2. LOTOV locks The purpose of the locks is to hold energy isolation device in the safe position to prevent unexpected activation of an energy source, unexpected start-up or unexpected release of stored energy. The locks are classified by colours and with different means Personal Lock (Blue) Isolation Lock (Red)

All locks shall be one key locks 11.4. Isolation Process

11.4.1. Isolations must be referenced in the Permit to work. 11.4.2. The Operations Team, use normal stop procedures to shut down the Plant or Apparatus and release the Plant or Apparatus for Work. 11.4.3. An IsA will isolate (de-energize, tag out and lockout) the equipment. At same time will verify the absence of energy and will attach the equipment identification and 0 energy verification tag in the equipment or piece of equipment to manipulate. 11.4.4. The IsA will introduce the keys of the isolation locks inside the key safe and will close the Key safe with the control key. A Identification Tag stating the Plant or Apparatus will be affixed to the Key Safe

Rev.00- October 2009

27

EMAL Contractor EHS Requirements

11.4.5. The IsA will sign the tag out and lockout procedure/Isolation Certificate to confirm that the equipment isolation has been completed. 11.4.6. The Issuing Authority (IA) will attach one of the Key safe Keys to the PTW, and will issue this key along with the PTW 11.4.7. The IA will also issue the completed LOTOV procedure/Isolation Certificate to the Receiving Authority (RA).

11.4.8. The Receiving Authority will introduce the yellow copy of the PTW and the key of the group box inside a card safe in the workplace or other suitable location (workshop). They will close the card safe with their Personal Lock and Tag. Each member of the working party shall also secure the PTW/Key safe Key in the Card safe with a personal tag and lock. 11.4.9. The personal tags could only be removed by the owner of the tags when: o The work is completed o At the end of the shift

Rev.00- October 2009

28

EMAL Contractor EHS Requirements

o Other job is assigned or the person leaves the job before the job is completed 11.4.10. Before starting to work, the receiving authority and each

member of the crew shall verify that the equipment/ facility is isolated according to the LOTOV procedure.

NOTE: If a work in group isolation equipment continues for more than one shift, the responsibility of the group isolation will be done by a Permit to Work transference (see EMAL PTW Procedure HS.SAF.01).

11.4.11.

The tags and locks removal will be according with this

sequence:

Each person will remove their personal tag and lock from the card safe. The RA will remove their personal tag and lock from the card safe and will return the PTW to an Issuing Authority. The RA shall then sign the white original copy of the PTW as work clearance.

The RA will give the yellow and pink copy of the PTW and the key of the Key safe to the IA. The IA shall sign the PTW cancellation. Once all of the Key safe Keys have been returned and all related permits cancelled, the IA shall release the group tags and locks from the Key safe and then remove the Isolation Locks from the energy isolation devices and restart the equipment. The Plant or Apparatus will then be returned to the Operations Team for safe return to service.

12. WORKING AT HEIGHTS Fall control shall be required for personnel exposed to heights greater than 1.8m or more and at lower heights if potentially hazardous situation exist. All employees must take a three-step systematic approach to protect them from fall.

Rev.00- October 2009

29

EMAL Contractor EHS Requirements

The first step is to assess the workplace and the work itself. Fall hazard shall be eliminated wherever possible by changing the sequence of the job, by working from ground level or by the use of special tools, equipments.

The second step also requires assessing the workplace and work processes. If fall hazard can not be completely eliminated during the first step, management must take a proactive approach to the prevention of fall by improving the workplace (collective protection). Early installation of stairs, guardrails, scaffolds, and travel restriction systems can ensure a safe work environment.

The third step is to use fall arresting equipment. Use fall arresting equipment, however, only after determining that potential fall cannot be eliminated by changing work procedures or workplace or collective protection can not be used. Equipment such harnesses, lanyards, shock absorbers, fall arresters, lifelines, anchorages and safety nets can reduce the risk of injury if a fall occurs. 12.1. Training 12.1.1. All contractor employees with the exception of the administrative staff shall receive specific training about the working at height program to ensure that the program is properly understood 12.1.2. Maintenance People or Those People Who Work At Heights: For these people, refresher training will be required every two years or before if the program changes or if it is considered because of increasing number of incidents, violations or other reasons. The training shall be documented and shall include the following topics/contents:

Use, visual inspection, and maintenance of fall arrest systems; Practical training in the use of fall prevention equipments. Must demonstrate competency in initial training

12.2. Scaffolds 12.2.1. Personal working on tubular or other scaffolds shall use a fall arrest system unless the scaffold complies with the fall prevention system requirements described in the Scaffolding EMAL Scaffolding standard.

Rev.00- October 2009

30

EMAL Contractor EHS Requirements

12.2.2. Scaffolds shall be erected and used in compliance with the EMAL scaffolding standard and under the supervision of a competent person in scaffold erection. 12.2.3. Before use the scaffold, the user must check the scafftag to verify that the scaffold was inspected and the scafftag signed by a competent scaffold inspector within seven days before the day of use. 12.2.4. A scaffold visual inspection shall be conducted by the user before each use. If for any reason a user considers a scaffold to be unsafe he shall immediately contact his supervisor. The supervisor shall

immediately remove the Scafftag and place barrier tape through the lower rungs of the 1st access ladder. The supervisor shall then notify the Scaffolding Supervisor. 12.3. Fall Arrest Equipment 12.3.1. The full body harness will meet ANSI (American National Standards Institute) or EN (European Norms) standards. Safety belts are prohibited. 12.3.2. A visual inspection shall be conducted by the user before each use of fall arrest equipment. 12.3.3. Every quarter, a document inspection by a competent person shall be performed on fall arrest equipment. Health and Safety Department will nominate the competent persons for fall arrest equipment inspection. 12.3.4. Fall arrest equipment inspected and rejected for further use shall be destroyed to prevent further use and inspection record shall be updated to include the method of disposition. 12.3.5. The inspector shall complete the inspection record (Attachment 11 Form HS.SAF.04.F03) and forward a copy of the completed form to the department EHS coordinator and another copy to the Health and Safety department.

Rev.00- October 2009

31

EMAL Contractor EHS Requirements

12.4. General Practices 12.4.1. Workers must avoid climbing on equipment such as pumps, exchangers, valve and wheels, transformers, electric motors, handrails, structures, or any other facilities not specifically designed for climbing 12.4.2. Climbing on conduit, cable trays, or other similar equipment is not permitted. 12.4.3. Climbing of vertical beams is not permitted. 12.4.4. Workers must not climb a ladder while another is above or below on the same ladder. 12.4.5. Personnel performing jobs from an aerial lift, scissor lift or basket shall use a fall arrest system attached to the basket. 12.4.6. Climbing onto the middle rail, top rail or working from the outside of the basket is prohibited while the person is attached to the aerial lift, scissor lift or basket anchorage point. 12.4.7. All work on flatbed trailers higher than 1.8m must be performed with full fall protection such as - safety nets, fall arrest systems, or full guardrail protection. 12.4.8. All work on flatbed trailers lower than 1.8m height shall be preferably performed with full fall protection, if this is not possible anyone who accesses the flatbed trailer must be required to wear a hardhat with chinstrap. 12.4.9. Climbing on top of a trailer load without fall protection is still prohibited. 12.5. Working at roof Working at roofs require a Fall Protection Plan (HS.SAF.04.F02) and roof work access permit. 12.6. Ladders 12.6.1. Portable manufactured ladders shall bear identification indicating that they meet the appropriate ladder construction requirements of ANSI (American National Standards Institute) or EN (European Norms) standards.

Rev.00- October 2009

32

EMAL Contractor EHS Requirements

12.6.2. The use of metallic ladders is forbidden inside the Reduction department, for electrical works or at proximity of live lines. For these works a wooden or fiber glass ladders shall be used. 12.6.3. Portable single ladders shall not be used to jump heights greater than 3.5m. 12.6.4. Portable single ladders shall not be longer than 5m. 12.6.5. Ladders shall not be placed in front of doors opening toward the ladder unless the door is blocked upon, locked, or guarded. 12.6.6. When ascending or descending, the climber must face the ladder and must keep three points of contact. Tools should be carried on a waist belt, in a shoulder bag or raised and lowered on a rope to ensure a person climbing up/down a ladder maintains an adequate grip on the ladder. 12.6.7. Ladders shall extend 1m above where a person can gain access at the top of the ladder. 12.6.8. Ladders shall be placed at a gradient of not less than 1:4 (i.e. one meter out horizontal for every four meters of height) and not greater that 1:6. 12.6.9. A portable ladder shall not be used by more than one person at the same time. 12.6.10. 12.6.11. All portable ladders shall be equipped with shoes. A portable ladder shall not be used as working surface. As

exception and when not possible to use a working platform, a scaffold or an aerial lift, the next requirements must be considered: 12.6.12. When persons feet are positioned above 1.8m the employee

shall use a fall-prevention/arrest system. 12.6.13. Every three months a component person from the department

should inspect and maintain a list of all ladders in their charge and record date of inspection and defects noted. See Attachment 12 (Form HS.SAF.05.01 - Portable Ladder Inspection and Identification List). Ladders adequate for using will be identified with a color code of the quarter as follows:

1st Q

Rev.00- October 2009

2nd Q

3rd Q

4th Q

33

EMAL Contractor EHS Requirements

13. CONFINED SPACES 13.1. Definition Means a space that: is large enough and so configured that an employee can bodily enter and perform assigned work; and Has limited or restricted means for entry or exit (for example, tanks, vessels, silos, storage bins, hoppers, vaults, and pits are spaces that may have limited means of entry.); and Is not designed for continuous employee occupancy.

13.2. Confined Space Entry Permit 13.2.1. A Confined Spaced Entry Permit shall be required to entry in any Confined Space. 13.2.2. Confined spaces shall be classified Class A or Class B confined spaces. All the confined spaces entrances shall be identified with a sign reading DANGER- PERMIT REQUIRED CONFINED SPACE, DO NOT ENTER

13.2.3. The confined space entry permit is described in Attachment 13 (Form HS.SAF.06.F01 - Confined space entry permit) and shall include: All personnel in confined spaces and attendant will carry portable lighting. at least one attendant outside the permit space into which entry is authorized for the duration of entry operations

Rev.00- October 2009

34

EMAL Contractor EHS Requirements

If hot works are done inside a confined space this one must be reclassified as Class A confined Space. Hot work permit will also be necessary and EMAL Hot Work standard shall be followed.

Either double insulated or ground fault circuit interrupter protected electrical tools and low current, low voltage (24 volt maximum) lighting systems shall be used in damp or metallic hazardous confined spaces.

Electrical and pneumatic tools shall be selected to eliminate sparks and other hazards as required by the conditions of the confined space.

Gas cylinders should not be used with in a confined space. Should there be condition arises where gas cylinders have to be used inside the confined spaces, special precautions are to be taken and it shall be approved by H & S Department. At no circumstances, CO2 fire extinguisher shall be taken into the confined space.

Internal combustion engines should never be used inside confined space.

13.3. Confined Space Training 13.3.1. Confined Space training for contractors shall be of two types: o Level 0: All contractor employees must receive a general overview of the EMAL Confined Space program. o Level 1: All contractor authorized entrants and attendants shall receive a specific training of the EMAL confined space program.

13.3.2. This training will be refreshed every two years. Each contractor must have an updated list of all authorized entrants and attendants. The certification shall contain each employee's name, the signatures or initials of the trainers, and the dates of training.

Rev.00- October 2009

35

EMAL Contractor EHS Requirements

13.3.3. The training shall establish employee proficiency in the duties required by this document and shall introduce examples of new or revised procedures.

13.3.4. Additional to this training, all authorized employees and attendants shall receive a specific pre-work meeting for the specific confined space, before entering. This information will be provided by the confined space issuing authority. This pre-work meeting is valid for six months in the class B confined spaces and only for each work in the class A confined spaces.

13.4. Duties of Authorized Entrants The employer shall ensure that all authorized entrants:

13.4.1. Know the hazards that may be faced during entry, including information on the mode, signs or symptoms, and consequences of the exposure 13.4.2. Properly use equipment as required. 13.4.3. Communicate with the attendant as necessary to enable the attendant to monitor entrant status and to enable the attendant to alert entrants of the need to evacuate the space as required by this document; 13.4.4. Alert the attendant whenever: The entrant recognizes any warning sign or symptom of exposure to a dangerous situation, or The entrant detects a prohibited condition; and

13.4.5. Exit from the permit space as quickly as possible whenever: An order to evacuate is given by the attendant or the entry supervisor, The entrant recognizes any warning sign or symptom of exposure to a dangerous situation, The entrant detects a prohibited condition, or An evacuation alarm is activated.

Rev.00- October 2009

36

EMAL Contractor EHS Requirements

13.5. Duties of Attendants.

The employer shall ensure that each attendant:

13.5.1. Knows the hazards that may be faced during entry, including information on the mode, signs or symptoms, and consequences of the exposure; 13.5.2. Is aware of possible behavioural effects of hazard exposure in authorized entrants; 13.5.3. Continuously maintains an accurate count of authorized entrants in the permit space. See Attachment 14 (Form No HS.SAF.06.F04 - Confined space entry/exit record). 13.5.4. Remains outside the permit space during entry operations until relieved by another attendant; 13.5.5. Communicates with authorized entrants as necessary to monitor entrant status and to alert entrants of the need to evacuate the space under described in this document; 13.5.6. Monitors activities inside and outside the space to determine if it is safe for entrants to remain in the space and orders the authorized entrants to evacuate the permit space immediately under any of the following conditions; o If the attendant detects a prohibited condition; o If the attendant detects the behavioral effects of hazard exposure in an authorized entrant; o If the attendant detects a situation outside the space that could endanger the authorized entrants; or o If the attendant cannot effectively and safely perform all the duties required for his position. 13.5.7. Summon rescue and other emergency services as soon as the attendant determines that authorized entrants may need assistance to escape from permit space hazards;

Rev.00- October 2009

37

EMAL Contractor EHS Requirements

13.5.8. Takes the following actions when unauthorized persons approach or enter a permit space while entry is underway: Warn the unauthorized persons that they must stay away from the permit space; Advise the unauthorized persons that they must exit immediately if they have entered the permit space; and Inform the authorized entrants and the entry supervisor if unauthorized persons have entered the permit space;

13.5.9. Performs non-entry rescues as specified by rescue procedure 13.5.10. Performs no duties that might interfere with the attendant's

primary duty to monitor and protect the authorized entrants.

14. MOBILE EQUIPMENTS

The Industrial Free Moving Mobile Equipments are classified in: 14.1. Standard Free Moving Mobile equipments Are operator controlled mobile equipment not constrained by Fixed rails and can include gasoline, propane, diesel, or electrically powered used for labor activities as, forklifts, aerial lifts, trucks, buggies, sweepers. All standard Free Moving Mobile Equipment must be identified with: Mobile Equipment number (according to the EMAL identification code). This identification must be painted or engraved in the Mobile Equipment and must be visible from 20m distance. The recommended dimensions for the identification are 21 x 30 cm.

NOTE: If the Mobile Equipment has official plate number, this identification eliminates the previous requirement.

SWL (Safe Working Load)

Rev.00- October 2009

38

EMAL Contractor EHS Requirements

. 14.2. Auxiliary Free Moving Mobile Equipments These are Industrial Free Moving mobile equipments used to transport people and equipment around site such as cars, 4x4, pick-ups and buses. The auxiliary Free Moving Mobile Equipments do not have to comply with the 100% of the requirements specified in this procedure (pre- use check list, audible backwards signal) but must be identified with Department, Contractor Company or a visible visitor vehicle pass. The Auxiliary Free Moving Mobile Equipment is not allowed to be driven inside the production buildings. The use of two wheels mobile equipment is forbidden inside EMAL site. This includes motorcycles and pedal cycles.

14.3. Free moving mobile equipment operators 14.3.1. The free moving mobile equipment operators shall pass the mobile equipment medical evaluation. Moreover the driving license of every driver should be checked prior to imparting of the training as per UAE law (HS.SAF.13.A02).The driving license should be of the appropriate category as the training category being imparted. 14.3.2. All Auxiliary Free moving mobile equipment operators shall be required to provide a valid official UAE driving license for the class of vehicle. 14.3.3. The Training for Standard free moving Mobile Equipment, shall include: Theoretical training o EMAL Mobile Equipment Program o General Safety rules and operating procedures o Equipment controls and safe work instructions. o Specific Mobile Equipment Instructions, including the manufacturer indications.

Rev.00- October 2009

39

EMAL Contractor EHS Requirements

o Concepts about working with loads

Practical training deployed by a competent person who has free moving mobile equipment knowledge, training and experience. Practical training shall include: o Mobile Equipment driving, steering and maneuvering o Vehicle pre operation check- list o Load Manipulation, stacking and un stacking o Vehicle stability o They have to pass a written test and an accreditation will be given to each authorized operator.

14.4. General Training All contractor employees who do not drive Mobile Equipments and work in areas where mobile equipment movement exists, will receive the same theoretical training that is required for the Free Moving Mobile Equipment operators.

14.5. Mobile Equipment Certification 14.5.1. An EMAL Authorization Certificate to drive shall be issued to each EMAL Mobile Equipment Operator which states Name, Employee Number, department, class of vehicle, plant area, and validity. 14.5.2. The EMAL Authorization Certificate for Standard Free Moving Mobile Equipment shall be issued by the Training department after confirming that the employees have the medical aptitude and have passed the theorical and practical training. 14.5.3. The EMAL Authorization Certificate for Auxiliary Free Moving Mobile Equipment shall be issued by the Security department after confirming that the employees have a valid UAE Driving License. 14.5.4. The Certificates shall then be forwarded to the H&S Department, and a new ID badge will be issued indication that the employee is authorized to drive on site, and category of vehicle.

Rev.00- October 2009

40

EMAL Contractor EHS Requirements

Driver Certification Badge

Photo

Driver Certification Badge

Type of M.E

Training (Last date) Training (Next date)

Name ID Deptt M.E

Note: Driver Certification Badge 14.6. Preventive Maintenance 14.6.1. Each contractor company will develop a preventive maintenance program for all free moving mobile equipment according to the Original Equipment Manufacturer (OEM) requirements and local legislation. 14.6.2. Mobile Equipment involved in incident shall not be repaired until incident report is submitted to EMAL EHS department. 14.6.3. After every Preventive Maintenance, the contractor will fix a sticker in the mobile equipment indicating the mobile equipment hours, km or date for the next scheduled preventive maintenance. 14.7. Pre use inspections, Check List 14.7.1. A pre use inspection shall be performed on free moving mobile equipment before each shift that the equipment is to be used to assure that the following parts, equipment, and accessories are in safe operating condition and free of apparent damage that could cause failure while in use. 14.7.2. The pre use inspection will be divided in minor and major findings. 14.7.3. If a Major finding is detected the mobile equipment shall be immediately locked out and tagged out according to the EMAL lockout & tagout procedure. If Minor findings are identified, then it will be written in the check list and communicated to the department mobile equipment

Rev.00- October 2009

41

EMAL Contractor EHS Requirements

responsible in order to include the equipment in the maintenance program. 14.7.4. Major finding are considered all items that could affect the safety of the Mobile equipment operator and/ or to the safety of the pedestrians, e.g. seatbelt, flashing lights, brakes etc. 14.7.5. Pre use inspection records are to remain with the free moving mobile equipment for the entire shift. Pre- use inspection records shall be verified by each operator using the free moving mobile equipment. Pre use inspection records shall be kept by the department mobile equipment responsible for a minimum of three months. 14.8. Other Requirements 14.8.1. Do not block recognized gangways and access ways unless a clear, safe diversion has been provided. 14.8.2. Only authorized routes must be used to and from work sites. Contractors vehicles are not allowed to cross the Hot Metal Roads. 14.8.3. No road shall be closed off without written approval from EMAL. A request for road closures shall be made at least 48 hours before the closure is required. EMAL Representative shall send a copy of the approved request to EMAL Security prior to closure of the road. 14.8.4. All free moving mobile equipments and auxiliary equipments must be equipped with seat belt. The number of passengers carried in company vehicles will be determined by the fixed seating provided. 14.8.5. As general rule, if the mobile equipment is equipped with a closed cabinet, the use of hardhat and safety glasses are not required. 14.8.6. The speed limits inside plant area are as follows:

Rev.00- October 2009

42

EMAL Contractor EHS Requirements

Outside Buildings Auxiliary Free Moving Mobile Equipments: Buses, trucks, cars Standard Free Moving Industrial Equipments (forklifts, aerial lifts, )

Inside Buildings

30

10

20

10

14.8.7. All vehicles should give prioritization to the Fire Brigade mobile equipments or ambulances 14.8.8. Over speeding violations will be communicated according to EMAL Safety Notification Standards. Moreover following steps would be taken in case of a violation: On first notification the operator/user would not be allowed to operate/drive inside EMAL premises for 1 month in12 months. On second notification the operator/user would not be allowed to operate/drive inside EMAL premises for 3 months in 12 months On third notification the operator/user would not be allowed to operate/drive inside EMAL premises for 6 months in 12 months and would have to pass through the mobile equipment training. 14.8.9. REVERSING WARNING: All free moving mobile equipment and any associated towed equipment having obstructed rear vision shall be fitted with an audible and or visible reverse warning system. Splash guards: shall be required on all free moving mobile

14.8.10.

equipment potentially exposed to molten substance splashes or in the area of potential molten substance splashes such as free moving mobile equipment used to charge, skim or carry molten splashes. Splash guards shall be designed and installed to keep molten substances from entering the cab or splashing the operator.

Rev.00- October 2009

43

EMAL Contractor EHS Requirements

14.8.11.

CABS All vehicles with cabs shall be equipped with

windshields and powered wipers. Cracked and broken glass shall be replaced. WARNING LIGHTS All free moving mobile equipments shall

14.8.12.

use flashing lights. If an Industrial Mobile Equipment does not have flashing light, the use of a waning flag will be required ROPS & FOPS All industrial mobile equipment shall be

14.8.13.

provided with ROPS and FOPS. Any exception must be approved by the Maintenance Senior Manager and HS Senior manager. Parking

14.8.14.

Auxiliary mobile equipment will always be parked in reversing position. Before any startup the auxiliary equipment driver shall have to sound the horn.

Parking violations would also be notified as per EMAL Safety Notification standard and the same criterion as for over speeding violation will be used.

14.9. Operational Guidelines 14.9.1. In darkness auxiliary mobile equipment operators should use hazard lights while they stop at any instant and should be extra careful while maneuvering. 14.9.2. The use of mobile phones whilst operating any mobile equipment shall be prohibited. The use of a hands free device whilst operating Auxiliary Free Moving Mobile Equipment shall be permitted. 14.9.3. No person shall be allowed to stand or pass under the elevated portion of any standard free moving mobile equipment, whether loaded or empty. 14.9.4. When standard free moving mobile equipment is left unattended, load engaging means shall be fully lowered, controls shall be neutralized,

Rev.00- October 2009 44

EMAL Contractor EHS Requirements

power shall be shut off, and brakes set. Wheels shall be blocked if the mobile equipment is parked on an incline. 14.9.5. Mobile equipment is unattended when the operator is 5m or more away from the vehicle which remains in his view or whenever the operator leaves the vehicle and it is not in his view. 14.9.6. When the operator of mobile equipment is dismounted and within 5m of the mobile equipment still in his view, the load engaging means shall be fully lowered, controls neutralized, and the brakes set to prevent movement. 14.9.7. A safe distance shall be maintained from the edge of ramps or platforms while on any elevated dock, or platform or freight car. 14.9.8. The safety distance shall be at least 1.8m from parallel edges or ramps 14.9.9. The safety distance shall be at least 3.1m in front of edges or ramps. 14.9.10. Brakes shall be set and wheel blocks shall be in place to

prevent movement of trucks, trailers while loading or unloading. 14.9.11. Fire aisles, access to stairways, and fire equipment shall be

kept clear. 14.10. Travelling All traffic regulations shall be observed. A safe distance shall

14.10.1.

be maintained approximately three mobile equipment lengths from the mobile equipment ahead. 14.10.2. The right of way shall be yielded to ambulances, fire trucks, or

other vehicles in emergency situations. 14.10.3. The driver shall be required to slow down and sound the horn

at cross aisles and other locations where vision is obstructed. 14.10.4. The driver shall be required to look in the direction of, and keep

a clear view of the path travel. 14.10.5. 14.10.6. Grades shall be ascended or descended slowly When ascending or descending grades in excess of 10

percent, loaded mobile equipment shall be driven with the load upgrade. On all grades the load and load engaging means shall be tilted back if applicable, and raised only as far as necessary to clear the road surface.

Rev.00- October 2009 45

EMAL Contractor EHS Requirements

14.10.7. 14.10.8.

Stunt diving and horseplay shall not be permitted Speed, the hand steering wheel shall be turned at a moderate,

even rate. 14.11. Mobile Equipment and Pedestrian Segregation Mobile Equipment and Pedestrian Segregation is a system to identify, develop and implement mobile equipment only and pedestrian only ways to reduce the chances of injury and address potential interferences. The segregation is color coded for easy recognition in the Inside areas and the Outside areas. The mobile equipment and pedestrian segregation in Inside areas and Outside areas would be color coded as per the specifications given in the EMAL Standard for Mobile Equipment. 14.11.1. Inside Areas

Solid Green RAL 6025

1.0 m

Safe Pedestrian Walkway: without potential interferences with mobile equipment or protected against the mobile equipment with physical barriers

So lid Green R AL 6025

1.0 m

Solid Green RAL 6025

1.0 m

0.2 m Yellow lin e (R AL 1023) w ith black (RAL 9017) strip es at 45 d eg rees Safe Pedestrian W alk way and caution m ark ing to segregate shared mobile equipm ent area. F or crossing instructions employees have to follow E MAL Mobile Equipment S tandard

Red line (RAL 3020) Red (RAL 9017) Safe Pedestrian Walkway and Red line to segregate from mobile equipment area. Physical barriers along with warning signs would be placed as per the risk assessment

0.2 m

0 .2 m

0.2 m

Y ello w ( R AL 10 2 3 ) & R ed ( R AL 90 1 7 ) Sa fe Pe de stria n C ro sswa lk be tw ee n two pe d e stria n wa lkwa ys th ro u gh sh a re d m ob ile e q uip m e n t a re a .

Rev.00- October 2009

46

EMAL Contractor EHS Requirements

0 .2 m

0.2 m

In w a r d o p e n in g c ro s s in g g a te s a s p e r r is k a sse ss me n t

Y e llo w (R A L 10 2 3 ) & R e d (R A L 9 01 7 ) Sa f e Pe d es t rian C ro s s w a lk b et w e en tw o p ed e s tr ia n w a lk w a ys th ro u g h s ha re d m o bile e q u ip m e n t ar ea .

14.11.2.

Outside Areas

Road

1.0 m

Safe Pedestrian Walkway made of tough tiles in outside area adjacent to the mobile equipment travel way

Pedestrian Crosswalk outside with white markings

1.0 m 1.0 m

Bicycle way

Warning/Cautious area for hazardous activities that involve pedestrians and mobile equipment at the same place at any given time

Road

O utside mobile equipm ent area with a bicycle way and adjacent pedestrian only walkway

Rev.00- October 2009

47

EMAL Contractor EHS Requirements

15. LIFTING EQUIPMENTS 15.1. Lifting equipment classification The lifting equipments are divided in two main categories. In each category different subcategories can be identified with different inspection requirements. Lifting gear o Chain Sling, wire rope sling, Fiber rope slings and synthetic slings. o Hooks, shackles , rings, eye bolts and swivels etc. o Special purpose lifting equipment o Lifting Beam/spreader Beams o Beam Clamp and Plate clamps. Lifting Appliances In EMAL the lifting appliances are classified according to the different inspection requirements in the following categories. webbing

o Fixed Lifting Equipments o Electric overhead travelling cranes o Special Purpose Lifting Equipments o Molten Aluminium and Bath Crucibles o Mobile Cranes & HIAB o Forklifts o Anode Elevators o Furnace Door Lifting Equipment o Powered Access Platforms o Vehicle Lifts in Garage o Passenger Lift Contractors have to submit a list of all free moving mobile equipments including lifting equipments as well as a separate list of lifting gears i.e. below the hook devices 15 days prior to the contractors mobilization.

Rev.00- October 2009

48

EMAL Contractor EHS Requirements

NOTE: This is a mandatory requirement to obtain Contractor Site Access permit. For more details, EMAL Contractor Management Standard shall be consulted. 15.2. Inspection Requirements: 15.2.1. Lifting Appliances: All Contractor lifting appliances need to be inspected by EMAL Inspection Services before being allowed entry into EMALs premises. It is contractors responsibility to inform and schedule inspection of its lifting appliances with the Inspection Service & EHS department of EMAL.

Following documents shall be submitted with the request for inspection, by the contractor, at least 4 days prior to the expected mobilization date of the lifting appliance: Valid 3rd Party certificate Valid Police registration Document Valid Insurance Details. Valid Operators Driving License/ 3rd party training & Manufacturers manual and certificates. Certification.

After the mobilization, the continuing inspection requirements for in-house and 3rd party inspections will be the same for contractors as detailed in EMAL Lifting Equipment Standard. 15.2.2. Lifting Gears: For lifting gears or below the hook devices, the contractor shall submit a complete list (as detailed in EMAL Contractor Management Standard) with necessary test certificates, manufacturers certificates and 3rd party inspection certificates before the lifting gears are mobilized on site. All contractor lifting gears shall be identifiable with a unique serial ID.

Rev.00- October 2009

49

EMAL Contractor EHS Requirements

Once mobilized, the on-going inspection requirements of in-house and third party inspections are as detailed in the next table.

Lifting Equipment Lifting gear Fixed Lifting Equipment Special Purpose Lifting equipments Mobile Cranes & HIABs Forklifts Power access platforms

Third Inspection

Party

Internal Inspection by EMAL Services Every 6 months Every 6 months Inspection

Visual Inspection by user Before use Before use

Every 6 months Every 12 months

Every 6 months

Every 6 months

Before use

Every year

NDT

every

year

on

Before use

crane hooks Every year Every 6 months Load test every year Before use Before use

15.3. Lifting gear safety Rules: 15.3.1. Slings, which are damaged or defective, shall be immediately returned to the inspection services department, who after marking the sling will destroy it. 15.3.2. Slings shall not be shortened with knots or bolts. 15.3.3. Slings legs shall not be kinked. 15.3.4. Slings shall be securely attached to their loads. 15.3.5. Employees shall keep clear of loads about to be lifted and of suspended loads. 15.3.6. Slings shall be padded or protected from sharp edges of load. 15.3.7. Hands and fingers shall not be placed between the sling and load at any time. 15.3.8. Sling should not be pulled from under a load when the load is resting on the sling.

Rev.00- October 2009

50

EMAL Contractor EHS Requirements

15.3.9. Slings must be stored on suitable racks, shelves or hooks off the ground and in clean, dry areas. 15.4. Safety Rules for Lifting Appliances (cranes, EOTC, hoists) 15.4.1. The rated load of the crane shall be plainly marked on each side of the crane, and if the crane has more than one hoisting unit, each hoist shall have its rated load marked on it or its load block, and this marking shall be clearly legible from the ground or floor. The rated load marking color shall be yellow background with black letters. 15.4.2. Only designated and certified personnel shall be permitted to operate a crane. All crane operators shall possess valid third party certification. 15.4.3. Sheave grooves shall be smooth and free from surface defects that could cause rope damage. 15.4.4. No less than two wraps of rope shall remain on the drum when the hook is in its extreme low position. 15.4.5. Rope end shall be anchored by a clamp securely attached to the drum, or by a socket arrangement approved by the crane or rope manufacturer. 15.4.6. Rope clips attached with U-bolts on the dead or short end of the rope. 15.4.7. When a newly installed rope has been in operation for an hour, the operation shall be stopped and all nuts on the clip bolts shall be realigned. 15.4.8. Hooks shall meet the manufacturers recommendations and shall not be overloaded. The hook shall conform to the cranes rated load capacity. 15.4.9. A preventative maintenance program shall be established and conducted as per the schedule. 15.4.10. All functional operating mechanism, air and hydraulic systems,

chains, rope slings, hooks, limit switches and other lifting equipment shall be visually inspected on daily basis prior to each use. A check list shall be completed. See Attachment V. 15.4.11. A thorough inspection of all ropes shall be made at least once

every six months by the inspection services department.

Rev.00- October 2009 51

EMAL Contractor EHS Requirements

15.4.12.

The hoist rope shall be free from kinks or twists and shall not

be wrapped around the load. 15.4.13. The load shall be well secured and properly balanced in the

sling or lifting device before it is lifted and/ or after it is lifted just a few inches. 15.4.14. The operator shall not leave his/ her position at the controls

while the load is suspended. 15.4.15. The operator will not be allowed to use mobile phone when the

crane is in operation. 15.4.16. At the beginning of each operators shift, the upper limit switch

of each hoist shall be tried out under no load. 15.4.17. For mobile cranes, a load chart must be posted in a

conspicuous position, easily visible to the operator. 15.4.18. All hooks must be equipped with a safety latch to prevent

accidental disconnection of the load. 15.4.19. For mobile cranes, when a load is being lifted, the area equal to

the boom radius of the crane will be barricaded and un-authorized personnel will not be allowed inside that radius. 16. HOT WORK Any work which generates spark, flame and/or heat. Hot work includes, but is not limited to, welding, cutting, burning, grinding, and any related heat-producing jobs that could ignite combustible materials or flammable atmospheres.

A Hot Work Permit shall be issued for all cutting, burning, welding and grinding work preformed outside of designated safe work areas which has the potential to promote ignition. 16.1. Designated Hot Work Area: Specific area designed or approved for hot work, such as maintenance shop or a detached outside location that is of non-combustible or fire-resistive construction, essentially free of combustible and flammable contents and suitably segregated from adjacent areas.

Rev.00- October 2009 52

EMAL Contractor EHS Requirements

16.2. Non - designated Hot Work Area: Areas where there is a presence/potential for presence of explosive atmospheres (mixtures of flammable gases, vapours, liquids, or dusts with air), or situations where explosive atmospheres that may develop inside uncleaned or improperly prepared tanks or equipment which have previously contained such materials, or areas where accumulation of combustible dusts may develop or any equipment which are part of the plant or areas near the storage of large quantities of exposed, readily ignitable materials such as baled paper, or cotton.

Area which is adjacent to fuel gas or fuel oil systems or fuel oil systems. 16.3. Other areas: Areas which are neither classified as designated hot work area nor as non designated hot work area. When a hot work has to be carried out in these areas, check list to be completed. If fire hazards are found whilst completing check list, then hot work permit shall be obtained. 16.4. Hot work receiving Authority: An EMAL or contractor competent person possessing necessary experience and knowledge and appointed in writing by EMAL to receive hot work permits. 16.5. Hot Work Training 16.5.1. Level 0: General Overview

All EMAL and contractor employees should receive a general overview of the EMAL Hot work procedure Level 1: Hot work operators

16.5.2.

All EMAL and contractor authorized hot work operators and fire watchers shall receive a specific training of the EMAL hot work procedure. This training will be refresher every two years. Each department must have an updated list of all authorized hot work operators and fire watchers. The certification shall contain each employee's name, the

Rev.00- October 2009 53

EMAL Contractor EHS Requirements

signatures or initials of the trainers, and the dates of training. See attachment II. 16.6. Hot Work Permit 16.6.1. Hot Work Permits will be required in non-designated areas. Hot

Work permit has an original and one copy (yellow) for the receiving authority, see attachment 15 (Hot Work Permit Form No. HS.SAF.14.F01). The permit (Yellow copy) must be posted at the location of the work being performed.

16.6.2.

If hot work has to be carried out in a location which is neither a Work area nor a non-designated hot work area,

designated hot

then the hot work operator/Maintenance personnel responsible for the activity shall complete a hot work check List. See attachment 16 (Form No. HS.SAF.14.F04 Hot Work Checklist). 16.6.3. While completing the check list, if any fire hazards are identified

in the vicinity of proposed hot work area, then hot work permit shall be obtained. 16.6.4. Hot work permit will not be required in the designated areas for

hot work being carried out which are not part of plant or process.

17. SIGNS, SIGNALS & BARRICADES 17.1. Safety Notice Boards At the entrance of each working area a safety notice board shall be placed as per following requirements; Be set up in prominent locations of the department that are clearly visible to all EMAL employees, contractor or visitors. Contain signs of all mandatory PPEs, prohibitions and warning signs of the main hazards of the department/ area. be safely supported and suitably placed to withstand bad weather conditions e.g. strong winds

Rev.00- October 2009

54

EMAL Contractor EHS Requirements

17.2. Barricades A barricade is a system designed to warn of a hazard and physically identify the hazards parameters. Barricades (also referred to as barriers) can be soft or hard, depending on the intended use and the nature of the hazard being protected. 17.2.1. Soft barricades: provide temporary warning or restricted access

and must not be used as edge protection. 17.2.2. Hard barricades: are used to protect against exposure to long-