Professional Documents

Culture Documents

Composite Design: 11.1 General Remarks

Uploaded by

firmanrusydiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Composite Design: 11.1 General Remarks

Uploaded by

firmanrusydiCopyright:

Available Formats

11

11.1

Composite Design

GENERAL REMARKS

The use of steel-concrete composite construction began around 1926. During recent years, composite design has been widely applied in building construction. In general, composite design provides the following advantages as compared with noncomposite design: 1. Efcient use of material. As a result of composite design, the size and weight of steel beams can be reduced by as much as 15 to 30%. The cost of reproong can be reduced in addition to the cost reduction of steel beams. 2. Greater stiffness. The stiffness of the composite section can be increased. This reduces the deection of the member as compared with the noncomposite beam. 3. Extra usable space. The use of shallow beams can reduce building heights. It is also possible to increase column spacings to provide larger usable space within a structure. 4. Saving in labor and other construction material. Savings in labor, facing material, piping, and wiring can be realized. The conventional steel-concrete composite construction as now used in buildings and bridges is a series of T-beams. It is composed of three essential elements: 1. A reinforced concrete slab 2. Steel beams 3. Shear connectors Figure 11.1 shows a composite beam section in which the reinforced concrete slab acts as the compression ange of the T-section. Shear connectors can resist the horizontal shear and provide vertical interlocking between concrete slab and steel beams to produce a composite section that acts as a single unit. Types of shear connectors include studs, channels, stiffened angles, and at bars, as shown in Fig. 11.2. The most often-used connectors are shear studs. In building construction the studs are welded through the steel deck into the structural steel framing; in bridge construction the studs are welded directly to the framing.

600

11.2

STEEL-DECK-REINFORCED COMPOSITE SLABS

601

Figure 11.1 Composite construction.

In the past, the construction was usually done with wood forming and the slab was reinforced with bars. For the last 30 years, steel deck has been used as the forming material for building construction and wood is only used for bridges even though steel deck is also often used on bridges too. 11.2 STEEL-DECK-REINFORCED COMPOSITE SLABS

For steel-deck-reinforced composite slabs, the cold-formed steel deck serves in four ways. It acts as a permanent form for the concrete, provides a working platform for the various trades, provides the slab reinforcing for positive bending, and provides bracing for the steel frame by acting as a diaphragm. The placement of the steel deck is done in a fraction of the time required for wood

Figure 11.2 Types of shear connectors.11.1

602

COMPOSITE DESIGN

forming, so it is no surprise that wood has been replaced in steel-framed building construction. Steel deck achieves its composite bonding ability by embossments or indentations formed in the deck webs or by the deck shape (Fig. 11.3). In the past, successful composite deck was made by welding transverse wires across the deck ribs (Fig. 11.4) or by punching holes in the deck to allow concrete to ll the ribs (Fig. 11.5). Research sponsored by the Steel Deck Institute and by the American Iron and Steel Institute has shown that the shear studs used to make the beams composite also greatly enhance the composite behavior of the steel deck.11.18,11.21 The performance of the composite deck slab is as a one-way reinforced slab and the slab is designed with conventional reinforced concrete procedures. It is only necessary to provide reinforcement for shrinkage and sometimes, depending on the loading, for negative bending over the interior supports. The Steel Deck Institute drew on the extensive research done at Iowa State University, University of Waterloo, Lehigh University, Virginia Polytechnic Institute and State University, West Virginia University, Washington University at Seattle, and from other studies done both in the United States and overseas, to produce the uniform design method shown in the 1977 Composite Deck Design Handbook.1.324 This document contains requirements and recommendations on materials, design, connections, and details of construction with some additional information on special cases. Since 1984, engineers have also used the ASCE Standard Specication for the Design and Construction of Composite Steel Deck Slabs prepared by the Steel Deck with Concrete Standard Committee.1.170 In 1991, the ASCE Standard was revised and divided into two separate Standards: (1) Standard for the Structural Design of Composite Slabs, ANSI/ASCE 3-91 11.53 and (2) Standard Practice for Construction and Inspection of Composite Slabs, ANSI/ASCE 9-91.11.54 Both Standards were approved by ANSI in December 1992. These two Standards and their Commentaries focus on the usage of composite steel-deck-reinforced slabs. Standard 3-91 addresses the design of composite slabs and Standard 991 focuses on construction practices and inspection. These two standards are being updated to incorporate the latest research. 11.3 COMPOSITE BEAMS OR GIRDERS WITH COLD-FORMED STEEL DECK In building construction, one of the economical types of roof and oor construction is to combine the steel-deck-reinforced slab with the supporting steel beams or girders as a composite system. When the composite construction is composed of a steel beam and a solid slab, as shown in Fig. 11.1, the slip between beam and slab is usually small under working load; therefore the effect of slip can be neglected. For this case, full interaction between beam and slab can be expected, and full ultimate

11.3

COMPOSITE BEAMS OR GIRDERS WITH COLD-FORMED STEEL DECK

603

Figure 11.3 Composite systems containing embossments or indentations. (a ) Type No. 1.1.96,11.2 (b ) Type No. 2.11.3 (c ) Type No. 3.11.4

604

COMPOSITE DESIGN

Figure 11.4 Composite system with T-wires.11.5

Figure 11.5 Composite system containing punched holes.

Figure 11.6 Composite beam using steel-deck-reinforced concrete slab.1.96

11.3

COMPOSITE BEAMS OR GIRDERS WITH COLD-FORMED STEEL DECK

605

Figure 11.7 Composite joist using steel-deck-reinforced concrete slab.1.96

load can be achieved if adequate shear connectors are provided. This type of composite beam can be designed by the AISC Specication.1.148 Since 1978 the AISC Specication1.148 has included some specic provisions for the design of composite beams or girders with cold-formed steel deck, as shown in Figs. 11.3a and 11.6. These provisions are based on the studies conducted previously by Fisher, Grant, and Slutter at Lehigh University.1.95,11.21,11.22 This specication provides general requirements and design formulas for deck ribs oriented perpendicular or parallel to steel beams. The application of such design rules is well illustrated in Refs. 11.2311.25. In addition to the above, the current AISC Specication also recognizes partial composite action because for some cases it is not necessary, and occasionally it may not be feasible, to provide full composite action.1.148,11.23 In 1989, Heagler prepared the SDI LRFD Design Manual for Composite Beams and Girders with Steel Deck.11.51 This Manual contains a large number of design tables covering a wide range of beam, deck and slab combinations that have been analyzed as composite beams using the provisions of the AISC LRFD Manual of Steel Construction.11.52 As far as other countries are concerned, the Canadian Sheet Steel Building Institutes Criteria for the Design of Composite Slabs11.26 are being used in Canada. In Switzerland, design recommendations have been prepared by Badoux and Crisinel.11.27 A book on composite design was written by Bucheli and Crisinel in 1982.11.28 References 11.4211.44, 11.46, and 11.48 present the additional work and developments on composite design using steel deck in Canada, United Kingdom, Switzerland, and the Netherlands. In 1999, the International Conference on Steel and Composite Structures was held in the Netherlands to discuss recent research on composite structures. In addition to the use of conventional steel beams, composite open-web steel joists with steel deck, as shown in Fig. 11.7, have been studied by Cran and Galambos.11.29,11.30

606

COMPOSITE DESIGN

With regard to shear connectors, special connectors have been developed in the past by various individual companies for use in composite construction. Several studies have been made to investigate the composite action of coldformed steel beams and columns with concrete.11.17,11.49,11.50 References 11.5511.75 report on the results of recent projects on composite slabs and construction.

You might also like

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsFrom EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsNo ratings yet

- Pre Stressed ConcreteDocument19 pagesPre Stressed ConcretemynameisgunaNo ratings yet

- 04 Footing DesignDocument29 pages04 Footing DesignJoshua OrcalesNo ratings yet

- Loading On Tall StructuresDocument14 pagesLoading On Tall Structureschetan talawarNo ratings yet

- Prestressed Concrete: Engr. Jaypee Cueva PensonDocument18 pagesPrestressed Concrete: Engr. Jaypee Cueva PensonYang RhiaNo ratings yet

- Two Way SlabDocument19 pagesTwo Way SlabAllysa Joy MoralesNo ratings yet

- Session 1 - Lateral Loads - NSCP 2015Document49 pagesSession 1 - Lateral Loads - NSCP 2015HahahahahahahahahaNo ratings yet

- Ce411 ReviewerDocument15 pagesCe411 ReviewerrafaelNo ratings yet

- AISC Steel Properties (Metric-English)Document6 pagesAISC Steel Properties (Metric-English)KevinNo ratings yet

- A.3 - 24 Acetic Acid-Water-Isopropyl Ether System (L-L Extraction)Document2 pagesA.3 - 24 Acetic Acid-Water-Isopropyl Ether System (L-L Extraction)Penny GildoNo ratings yet

- Numerical Solutions - Module 5 - Incremental SearchDocument6 pagesNumerical Solutions - Module 5 - Incremental SearchDenzel GalaponNo ratings yet

- Lecture 4 - Reinforced Concrete - Bond, Development LengthDocument55 pagesLecture 4 - Reinforced Concrete - Bond, Development LengthChristopher PaladioNo ratings yet

- Lateral Loads (WindSeismic)Document16 pagesLateral Loads (WindSeismic)Erika PitoyNo ratings yet

- Transport Planning & Design Manual ... - Hku LibrariesDocument235 pagesTransport Planning & Design Manual ... - Hku LibrariesAmul ShresthaNo ratings yet

- Steel and Timber Design - Chapter 1Document10 pagesSteel and Timber Design - Chapter 1Wilfredo OchavezNo ratings yet

- AISC 14.1 Properties ViewerDocument2 pagesAISC 14.1 Properties ViewerJay GalvanNo ratings yet

- Alternative Building MaterialsDocument18 pagesAlternative Building MaterialsShiela Louisianne AbañoNo ratings yet

- Roof TypesDocument16 pagesRoof TypesAnkita AnkitaNo ratings yet

- Plans & Specs.Document124 pagesPlans & Specs.Jebone Stein Web JuarbalNo ratings yet

- LCA Oftallbuildings:stillalongwaytogoDocument3 pagesLCA Oftallbuildings:stillalongwaytogoNicolas Pardo AlvarezNo ratings yet

- 3672 Part 2Document31 pages3672 Part 2Mukhtiar Ali Jamali100% (1)

- Basement ProvisionsDocument193 pagesBasement ProvisionsAlexi ALfred H. TagoNo ratings yet

- Economics of Plant Design (Report)Document10 pagesEconomics of Plant Design (Report)Hamizah Mieza100% (1)

- Early Christian Architecture, APAP-1Document2 pagesEarly Christian Architecture, APAP-1Deva Roshan ANo ratings yet

- New Base Isolation Technique For Earthquake Resistant ConstrDocument27 pagesNew Base Isolation Technique For Earthquake Resistant Constrravi1625No ratings yet

- A Comparison of Concrete Steel and Timber Construction EssayDocument4 pagesA Comparison of Concrete Steel and Timber Construction EssayJordan Kurt S. Gu100% (3)

- LECTURE 01 - Introduction To The Properties of Building MaterialsDocument9 pagesLECTURE 01 - Introduction To The Properties of Building MaterialsEverson Murungweni0% (1)

- Design of StructuresDocument299 pagesDesign of StructuresSri vaishnavaNo ratings yet

- 1997jan StruclDocument7 pages1997jan StruclEdzon LacayNo ratings yet

- Composite Structures: Dr. Hesham Fawzy Shaabn Professor, Zagazig UniversityDocument18 pagesComposite Structures: Dr. Hesham Fawzy Shaabn Professor, Zagazig UniversityAbdualahGameelNo ratings yet

- Cdep 1Document68 pagesCdep 1Anonymous NMytbMiDNo ratings yet

- The Morphology of Tensile Structure SystemsDocument13 pagesThe Morphology of Tensile Structure SystemsChris AlcausinNo ratings yet

- Literature Case Study: Row Housing On ContoursDocument20 pagesLiterature Case Study: Row Housing On ContoursLokesh Singh100% (1)

- Objectives: Elective Ii (Sustainable Architecture)Document7 pagesObjectives: Elective Ii (Sustainable Architecture)Divyanshu ThakurNo ratings yet

- Building Design PDFDocument7 pagesBuilding Design PDFkbkwebsNo ratings yet

- Column DesignDocument4 pagesColumn DesignRafsanjani AbasNo ratings yet

- Case Study Bosco Verticale - Milan, Italy - Kashish SadariaDocument8 pagesCase Study Bosco Verticale - Milan, Italy - Kashish SadariaKashish SadariaNo ratings yet

- Unit I: Climate and Human ComfortDocument66 pagesUnit I: Climate and Human ComfortAtshayaNo ratings yet

- Composite ConstructionDocument26 pagesComposite ConstructionPatrick MalelangNo ratings yet

- Difference Between Client. Consultant. and ContractorDocument2 pagesDifference Between Client. Consultant. and ContractorSalman ShujaNo ratings yet

- Rofe - Church Reform The ReformDocument6 pagesRofe - Church Reform The Reformwireframe22No ratings yet

- A Project Report On Foundation of Geodesic DomeDocument2 pagesA Project Report On Foundation of Geodesic DomeVinay Soni100% (1)

- Assessment Report Format Sample For Old BuildingsDocument5 pagesAssessment Report Format Sample For Old BuildingsAndrew Araha0% (1)

- Highway Chapter 3Document19 pagesHighway Chapter 3ST. JOSEPH PARISH CHURCHNo ratings yet

- FDB PPT 4Document25 pagesFDB PPT 4alifNo ratings yet

- Quiz No 2 - Set DDocument2 pagesQuiz No 2 - Set DMayoune Nasinopa GalvezNo ratings yet

- Church of Our Lady Lourdes AnalysisDocument29 pagesChurch of Our Lady Lourdes AnalysisAnnie Goh100% (3)

- EQube ECBC BEE-hotel Capitol PresentationDocument31 pagesEQube ECBC BEE-hotel Capitol PresentationrsahayNo ratings yet

- Advantages and Disadvantages of Load Bearing Wall SystemDocument1 pageAdvantages and Disadvantages of Load Bearing Wall SystemRichard Fernandez80% (5)

- Class V - Forced Convection - External Flow - Cylinders & Spheres - Formulae & ProblemsDocument17 pagesClass V - Forced Convection - External Flow - Cylinders & Spheres - Formulae & ProblemsSai Ashok Kumar ReddyNo ratings yet

- Difference Between Long Column and Short ColumnDocument4 pagesDifference Between Long Column and Short Columnnaim khanNo ratings yet

- Cobiax Folder Big5 EDocument2 pagesCobiax Folder Big5 Emadamarin_21No ratings yet

- Concrete HistoryDocument4 pagesConcrete Historytest100% (1)

- Unit 1 A - VDocument36 pagesUnit 1 A - VMugesh VairavanNo ratings yet

- Advantages CFSTDocument14 pagesAdvantages CFSTprajjwal patidarNo ratings yet

- Steel ConDocument22 pagesSteel Consantosh bharathyNo ratings yet

- Axially Loaded Thin-Walled Square Concrete-Filled Steel Tubes Stiffened With Diagonal Binding RibsDocument1 pageAxially Loaded Thin-Walled Square Concrete-Filled Steel Tubes Stiffened With Diagonal Binding Ribswenbo wangNo ratings yet

- Concrete Filled With High Strength Steel Box Column For Tall Building-Behavior & DesignDocument20 pagesConcrete Filled With High Strength Steel Box Column For Tall Building-Behavior & DesigntaosyeNo ratings yet

- Composite Cold-Formed Steel-Concrete Structural System Composite Cold-Formed Steel-Concrete Structural SystemDocument27 pagesComposite Cold-Formed Steel-Concrete Structural System Composite Cold-Formed Steel-Concrete Structural SystemVladimirNo ratings yet

- Composite Materials 2Document200 pagesComposite Materials 2Taimoor NasserNo ratings yet

- COMAU Handbook Smart5 NJ4Document120 pagesCOMAU Handbook Smart5 NJ4Cris Rocha100% (1)

- Design Criteria Stru.Document9 pagesDesign Criteria Stru.Ar John Bernard AbadNo ratings yet

- Resume PremDocument4 pagesResume PrempremNo ratings yet

- Industrial AutomationDocument46 pagesIndustrial AutomationBibin M Abraham67% (6)

- Power and Distribution Transformers Sizing Calculations 2Document10 pagesPower and Distribution Transformers Sizing Calculations 2hashimelecNo ratings yet

- CENG216 - Analysis of Arches - L03 Practice ProblemsDocument7 pagesCENG216 - Analysis of Arches - L03 Practice Problemsosmanconteh894No ratings yet

- Contoh Motivation LetterDocument1 pageContoh Motivation LetterWismoyo Indra ZoelmanNo ratings yet

- 26 08 00 Commissioning Electrical Systems 10Document3 pages26 08 00 Commissioning Electrical Systems 10Anonymous mNQq7ojNo ratings yet

- You May Supply Supplementary Information If Necessary (A Maximum of 500 Characters)Document3 pagesYou May Supply Supplementary Information If Necessary (A Maximum of 500 Characters)noor hasanNo ratings yet

- PlanholdersDocument4 pagesPlanholdersAdam Abraham0% (1)

- Ebearing News - IsO Adopts SKF Bearing Life CalculationsDocument3 pagesEbearing News - IsO Adopts SKF Bearing Life CalculationsOscar Salazar100% (1)

- Motor Restarting AnalysisDocument10 pagesMotor Restarting AnalysisRitaban222No ratings yet

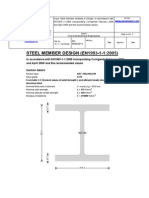

- Sachpazis Steel Member Analysis & Design (EN1993-1!1!2005)Document6 pagesSachpazis Steel Member Analysis & Design (EN1993-1!1!2005)Costas SachpazisNo ratings yet

- 37 Resume TemplatesDocument44 pages37 Resume TemplatesramNo ratings yet

- Final Even Sem Exam-May-2017Document17 pagesFinal Even Sem Exam-May-2017Vara PrasadNo ratings yet

- Kerala MTech SeatDocument63 pagesKerala MTech Seattirursachin0% (1)

- Bob Herron Electric LTDDocument8 pagesBob Herron Electric LTDকাফী ওয়াহিদNo ratings yet

- Iec60470 (Ed2 0) enDocument8 pagesIec60470 (Ed2 0) endream catcherNo ratings yet

- Steam Tracing 101Document2 pagesSteam Tracing 101fawmer61100% (1)

- Design of Portal Frames: by Dr. G.S.Suresh, Professor, Civil Engineering Department, NIE, MysoreDocument22 pagesDesign of Portal Frames: by Dr. G.S.Suresh, Professor, Civil Engineering Department, NIE, MysoreS Muneer HussainNo ratings yet

- Static Equipment Training ModulesDocument3 pagesStatic Equipment Training ModulesMohit SinghNo ratings yet

- NST2602 SGDocument148 pagesNST2602 SGTshepi Carol DavidsNo ratings yet

- Redundant and Voting SystemDocument10 pagesRedundant and Voting SystemGnanaseharan ArunachalamNo ratings yet

- Necessity For Ethics in Social EngineeringDocument14 pagesNecessity For Ethics in Social EngineeringMatt BaileyNo ratings yet

- Signals and Systems Course PlanDocument6 pagesSignals and Systems Course Planaarthi.lj5371No ratings yet

- Modern Day DevelopmentDocument2 pagesModern Day DevelopmentJimiel Chifamba83% (6)

- GRP Duct Material For Irrigation Works-ADM SpecificationDocument5 pagesGRP Duct Material For Irrigation Works-ADM Specificationbuddy1971No ratings yet

- External Pressure CalculationsDocument40 pagesExternal Pressure Calculationsmisterdavi50% (2)

- Continuous Improvement Leader in Macon GA Resume Bennie GrayDocument2 pagesContinuous Improvement Leader in Macon GA Resume Bennie GrayBennieGrayNo ratings yet