Professional Documents

Culture Documents

SVSW 004110 G16 0001 Rev.a Datasheet For Pump

Uploaded by

nguyenquoc1988Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SVSW 004110 G16 0001 Rev.a Datasheet For Pump

Uploaded by

nguyenquoc1988Copyright:

Available Formats

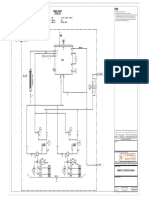

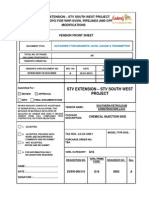

STV EXTENSION STV SOUTH WEST PROJECT (SVSW) EPCI FOR WHP-SVSW, PIPELINES AND CPP SuTuVangSouthWest MODIFICATIONS

S VENDOR FRONT SHEET

DOCUMENT TITLE

DATASHEET FOR PUMP

TOTAL NO. OF PAGES

(INCLUDING FRONTSHEETS)

06

VENDOR'S ORDER NO. VENDOR'S APPROVAL (NAME AND SIGNATURE)

VENDOR'S OWN DOCUMENT NO

REV. NO

DATE

SVSW-004110-G16-0001

15-01-2013

LE ANH VU

Submitted For : REVIEW INFO APPROVAL FINAL DOCUMENTATION

STV EXTENSION STV SOUTH WEST PROJECT

SOUTHERN PETROLEUM CONSTRUCTION J.S.C

REVIEW DOES NOT CONSTITUTE ACCEPTANCE OF DESIGN DETAILS, CALCULATIONS, TEST METHODS OR MATERIALS DEVELOPED OR SELECTED BY VENDOR NOR DOES IT RELIEVE VENDOR FROM FULL COMPLIANCE WITH CONTRACTUAL OR OTHER OBLIGATIONS.

VENDOR NAME :

PACKAGE DESCRIPTION:

CHEMICAL INJECTION SKID

1. ACCEPTED

2. ACCEPTED, PROCEED WITH WORK AND INCORPORATE COMMENTS AND RE-SUBMIT 3. NOT ACCEPTED. REVISE AND RE-SUBMIT. 4. FOR INFORMATION ONLY. NO SIGNATURE REQUIRED.

TAG NOS.: PBE-4218A/B PURCHASE ORDER NO: TBA

MODEL TYPE NOS.:

VDRL CATEGORY:

G16

VDRL PRIME CODE. SEQUENCE NO.: Rev.

REQUISITION NO. NAME : DATE : SIGNATURE :

SVSW-004110

G16

0001

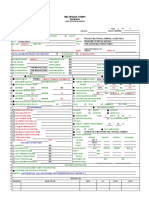

DATASHEET CORROSION INHIBITOR PUMPS ( API 675 )

STV EXTENSION - STV SOUTH WEST PROJECT ( SVSW ) EPCI FOR WHP - SVSW , PIPELINES AND CPP MODIFICATIONS

1 2 3 4 5 6 7 8 9 NO. MOTORS DRIVEN 1 ( ONE ) EACH PBE-4218A/B PBE-4218A/B PUMP MFR. PUMP MFR. NOTE 2 NOTE: INDICATES INFORMATION TO BE COMPLETED BY PURCHASER GENERAL OTHER DRIVER TYPE PUMP ITEM NO'S DRIVER ITEM NO'S DRIVER PROVIDED BY DRIVER MOUNTED BY DRIVER DATA SHEET NO. APPLICABLE TO: FOR SITE SERVICE PROPOSAL

Requisition No. Document No. Sheet no. Rev. No. Item Tag no. Service

: : : :

2013-3200-1W-0006 SVSW-004110-G16-0001 1 of 5 A

: PBE-4218A/B : CORROSION INHIBITOR SYSTEM

l PURCHASE

AS BUILT UNIT NO OF PUMPS REQUIRED SIZE AND TYPE 2 ( TWO ) 2 ( TWO )

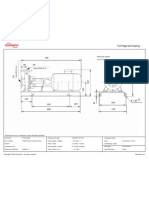

CUU LONG JOIN OPERATING COMPANY STV SOUTH WEST CORROSION INHIBITOR MILTON ROY AMERICAS MODEL XW11-38F4NNM1C5NN

14 MM / SINGLE HEAD SANDWICHED DIAPHRAGM mROY XW SERIES

MANUFACTUER

SERIAL NO.

o BY MANUFACTURER

GEAR ITEM NO'S GEAR PROVIDED BY GEAR MOUNTED BY GEAR DATA SHEET NO. -

10 PUMP ITEM NO'S 11 MOTOR ITEM NO'S 12 MOTOR PROVIDED BY 13 MOTOR MOUNTED BY 14 MOTOR DATA SHEET NO 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 LIQUID END 49 50 51 52 53 54 55 56 57 58 59 TYPE o DIAPHRAM DIA (mm) CONNECTIONS SUCTION DISCHARGE FLUSH

OPERATING CONDITIONS

( Note 6 )

LIQUID

( Note 6 ) CORROSION INHIBITOR

l CAPACITY @ PT ( l/h)

MAX 10 MIN 1.0 RATED 2.6

l TYPE OR NAME OF LIQUID l PUMPING TEMPER. (C)

NORMAL RATED 21 MIN RATED 0.042 RATED 0.5 ( Note 15 ) ACTUAL 10.8 20.96 AMBIENT

l DISCHARGE PRESSURE (barg):

MAX MIN

MAX 1.21 @ 16C

35 MAX

MIN 0.885

19 MIN

l SPECIFIC GRAVITY

SPECIFIC HEAT 10

l SUCTION PRESSURE (barg):

MAX

Cp (kJ/kg.C) MIN 12.5 MAX

l VISCOSITY (Cp)

l DIFFERENTIAL PRESSURE (barg):

MAX NPSH AVAILABLE (m) WITHOUT ACCELERATION HEAD MIN

CORROSIVE/ EXPLOSIVE AGENTS CHLORIDE CONCENTRATION (PPM) H2S CONCENTRATION (PPM) TOXIC

LIQUID

l FLAMABLE

OTHER

l TURNDOWN RATIO

10:1 10 LOCATION HEATED 0.23 @ 124 Barg 180 38.1

o o o n o o

PERFORMANCE - VENDOR TO COMPLETE 1 RATED CAPACITY (l/h) 3 AT RELIEF SETTING 47

SITE AND UTILITY DATA INDOOR

(Note 9)

NUMBER OF FEEDS NPSH REQUIRED (mWC) kw RATED 0.091

l OUTDOOR

UNDER ROOF D DIV 2 T-CLASS T3

l UNHEATED

1 GROUP

l ELEC. AREA CLASS

WINTERIZATION REQD SITE DATA (Note 5)

PLUNGER SPEED (spm) DIAMETER (mm) PUMP HEAD MAXIMUM PRESSURE (barg) 1/2"

DESIGN MAX

l TROPICALIZATION REQD

19 / 35 C

LENGTH OF STROKE (mm)

l RANGE OF AMBIENT TEMPS: MIN/MAX

207 186 207 UNUSUAL CONDITIONS DUST OTHER FUMES

o o o

HYDRO TEST PRESSURE (barg) MAX DISCH. W/JOB DRIVER (barg) MAX kw BASIS GEAR STRENGTH

l SALT ATMOSPHERE

l UTILITY CONDITIONS

(Note 5) HEATING CONTROL SHUTDOWN

CONSTRUCTION SIZE 1/2" 1/4" RATING 900 # 900 # FACING NPTF NPTF POSITION

HORI. Bottom HORI. Top

ELECTRICITY VOLTAGE HERTZ PHASE

DRIVERS 480 60 3

COOLING WATER TEMP C JECKET REQ'D PRESS. (BARG) PLUNGER NO REQ. DISCHARGE Ball 2 2 INSTRUMENT AIR PRESSURE (barg) SOURCE NA NA NA

INLET MAX MIN

RETURN

DESIGN

MAX r

l DIAPHRAM

86 mm SUCTION Ball 2

VALVE/FEED TYPE NUMBER

NORMAL N/A

MIN N/A

APPLICABLE SPECIFICATIONS:

l API 675 POSITIVE DISPLACEMENT PUMPS-CONTROLLED VOLUME l GOVERNING SPECIFICATION (IF DIFFERENT)

2013-3200-1L-0002

DATASHEET CORROSION INHIBITOR PUMPS ( API 675 )

STV EXTENSION - STV SOUTH WEST PROJECT ( SVSW ) EPCI FOR WHP - SVSW , PIPELINES AND CPP MODIFICATIONS

NOTE: INDICATES INFORMATION TO BE COMPLETED BY PURCHASER

Requisition No. Document No. Sheet no. Rev. No. Item Tag no. Service

: : : :

2013-3200-1W-0006 SVSW-004110-G16-0001 2 of 5 A

: PBE-4218A/B : CORROSION INHIBITOR SYSTEM

o TYPE l MANUAL

BY MANUFACTURER

60

o MATERIALS - VENDOR TO COMPLETE

SS 316L SS 316L PTFE PTFE CARBON STEEL (NON-WETTED PART ) N/A N/A N/A SS 316L SS 316L SS 316L SS 316L PTFE NAME PLATED UNITS

CONTROLS ( Note 4 ) SIGNAL l REMOTE l LOCAL

PNEUMATIC

61 LIQUID END 62 CONTOUR PLATE 63 HYDRAULIC DIAPHRAM 64 PROCESS DIAPHRAM 65 PLUNGER 66 LANTERN RING 67 PACKING GLAND 68 PACKING 69 VALVE 70 VALVE SEAT 71 VALVE GUIDE 72 VALVE BALL 73 VALVE GASKET 74 FRAME 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 TESTS 94 HYDROSTATIC 95 STEADY STATE ACCURACY 96 REPEATABILITY 97 LINEARITY 98 99 100 o CRANKECASE 101 o HYDRAULIC FLUID 102

l AUTOMATIC STROKE CONTROL:

l ELECTRONIC

PNEUMATIC (barg): MINIMUM ELECTRONIC (mA): MINIMUM MAXIMUM

OTHER PURCHASER REQUIREMENTS U.S CUSTOMARY

MAXIMUM

l SI

VENDOR FURNISHED PROCESS PIPING VENDOR REVIEW PIPING DRAWINGS l INTERNAL l EXTERNAL

124 ( for external PSV)

CAST IRON

l VENDOR FURNISHED PULSATION SUPPRESSION DEVICES l RELIEF VALVES BY PUMP MFRG

75 SPECIAL MATERIAL TESTS (2.13.1.3)

LOW AMBIENT TEMP. MATERIALS TESTS (2.13.5)

n RELIEF VALVE SETTING (barg)

QA INSPECTION AND TEST 3.1

VENDOR FURNISHED BACK-PRESSURE VALVE DOUBLE CHECK VALVE REQUIRED OIL-FILLED PRESSURE GAUGE REQUIRED VENDOR FURNISHED CONTROL PANEL

l COMPLIANT WITH INSPECTORS CHECK LIST l CERTIFICATION OF MATERIALS

FINAL ASSEMBLY CLEARANCES SURFACE AND SUBSURFACE EXAMINATIONS RADIOGRAPHY ULTRASONIC MAGNETIC PARTICLE LIQUID PENETRANT

BASEPLATE PREPARED FOR EXPOXY GROUT l PROVIDE TECHNICAL DATA MANUAL

PREPARATION FOR SHIPMENT DOMESTIC

l EXPORT

l EXPORT BOXING

l OUTDOOR STORAGE MORE THAN 6 MONTHS

WEIGHTS (KG) - VTA

l MFRS. STANDARD l CLEANLINESS PRIOR TO FINAL ASSEMBLY

HARDNESS OF PARTS, WELDS & HEAT AFFECTED ZONES FURISH PROCEDURES FOR OPTIONAL TESTS

o PUMP o BASE

43 INCL

o GEAR o DRIVER

DRIVERS

INCL

30

REQ'D

WIT (HOLD)

OBS

l MOTOR: o TYPE

NEMA COMPLIANT TO IEEE 841, FRAME 143TC BALDOR 841XL FAMILY S.C Induction 05F161W751G2 Yes NO RPM PHASE 1765 3

l l l l

o MANUFACTURER o MODEL NO. l CONSTANT SPEED o VARIABLE SPEED o KW l VOLTS l HERTZ

ENCLOSURE 0.75 (1HP) 460 60 TEFC

LUBRICATION FLUID o INTERMEDIATE

SERVICE FACTOR

ACCESSORIES Miltron Roy 103 n SPEED REDUCER MANUFACTURER SEPARATE l INTEGRAL 104 105 106 MODEL WORM GEAR 38 : 1 DOMANGE

FLEXIBLE

OTHER (SEE SEPARATE DATA SHEETS) GAS DRIVEN

STEAM TURBINE OTHER

RATIO 107 BASEPLATE UNDER 108 o COUPLING MANUFACTURER 109 o TYPE 110 111 REMARKS : 112 113 114 115 116 117 118

REFER SHEET 5 FOR NOTE

TEMP. CODE T3 IP56

l INGRESS PROTECTION

DATASHEET POUR POINT DEPRESSANT PUMPS ( API 675 )

STV EXTENSION - STV SOUTH WEST PROJECT ( SVSW ) EPCI FOR WHP - SVSW , PIPELINES AND CPP MODIFICATIONS

1 2 3 4 5 6 7 8 9 NO. MOTORS DRIVEN 1 ( ONE ) EACH PBE-4208A/B PBE-4208A/B PUMP MFR. PUMP MFR. NOTE 2 NOTE: INDICATES INFORMATION TO BE COMPLETED BY PURCHASER GENERAL OTHER DRIVER TYPE PUMP ITEM NO'S DRIVER ITEM NO'S DRIVER PROVIDED BY DRIVER MOUNTED BY DRIVER DATA SHEET NO. APPLICABLE TO: FOR SITE SERVICE PROPOSAL

Requisition No. Document No. Sheet no. Rev. No. Item Tag no. Service

: : : :

2013-3200-1W-0006 SVSW-004110-G16-0001 3 of 5 A

: PBE-4208A/B : PPD SYSTEM

l PURCHASE

AS BUILT UNIT NO OF PUMPS REQUIRED SIZE AND TYPE 2 ( TWO ) 2 ( TWO )

CUU LONG JOIN OPERATING COMPANY STV SOUTH WEST POUR POINT DEPRESSANT MODEL MBH101-8KPFCCM4SEST11C5XX

MILROYAL B HIGH PERFOMANCE DIAPHRAGM

MANUFACTUER MILTON ROY AMERICAS

SERIAL NO.

o BY MANUFACTURER

GEAR ITEM NO'S GEAR PROVIDED BY GEAR MOUNTED BY GEAR DATA SHEET NO. -

10 PUMP ITEM NO'S 11 MOTOR ITEM NO'S 12 MOTOR PROVIDED BY 13 MOTOR MOUNTED BY 14 MOTOR DATA SHEET NO 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 LIQUID END 49 50 51 52 53 54 55 56 57 58 59 o TYPE DIAPHRAM DIA (mm) VALVE/FEED TYPE NUMBER CONNECTIONS SUCTION DISCHARGE FLUSH

OPERATING CONDITIONS

( Note 6 )

LIQUID

( Note 6 ) POUR POINT DEPRESSANT

l l l l

CAPACITY @ PT ( l/h) MAX 20 MIN 2.00 RATED 16.5

l TYPE OR NAME OF LIQUID l PUMPING TEMPER. (C)

NORMAL RATED 26 MIN RATED 0.0306 RATED 0.5 ( Note 15 ) ACTUAL 11.7 20.96 AMBIENT

DISCHARGE PRESSURE (barg): MAX SUCTION PRESSURE (barg): MAX MIN

MAX 0.916 @ 16C

35

MIN

19 MIN

l SPECIFIC GRAVITY

SPECIFIC HEAT 20

MAX 0.904 @ 16C Cp (kJ/kg.C)

l VISCOSITY (Cp)

MIN

550

MAX

DIFFERENTIAL PRESSURE (barg): MAX NPSH AVAILABLE (m) WITHOUT ACCELERATION HEAD MIN

CORROSIVE/ EXPLOSIVE AGENTS CHLORIDE CONCENTRATION (PPM) H2S CONCENTRATION (PPM) TOXIC

LIQUID

l FLAMABLE

OTHER

TURNDOWN RATIO

10:1 20 LOCATION HEATED 0.347 @ 124 Barg 180 38.1

o o o n o o

PERFORMANCE - VENDOR TO COMPLETE 1 RATED CAPACITY (l/h) 3 AT RELIEF SETTING 49

SITE AND UTILITY DATA INDOOR

(Note 9)

NUMBER OF FEEDS NPSH REQUIRED (mWC) kw RATED 0.118

l OUTDOOR

UNDER ROOF D DIV 2 T-CLASS T3

l UNHEATED

1 GROUP

l ELEC. AREA CLASS

WINTERIZATION REQD SITE DATA (Note 5)

PLUNGER SPEED (spm) DIAMETER (mm) PUMP HEAD MAXIMUM PRESSURE (barg) 5/8"

DESIGN MAX

l TROPICALIZATION REQD

19 / 35 C

LENGTH OF STROKE (mm)

l RANGE OF AMBIENT TEMPS: MIN/MAX

217 186 217 UNUSUAL CONDITIONS DUST OTHER FUMES

o o o

HYDRO TEST PRESSURE (barg) MAX DISCH. W/JOB DRIVER (barg) MAX kw BASIS GEAR STRENGTH

l SALT ATMOSPHERE

UTILITY CONDITIONS

(Note 5) HEATING CONTROL SHUTDOWN

CONSTRUCTION SIZE 1/2" 1/2" RATING 900 # 900 # FACING NPTF NPTF POSITION

HORI. Bottom HORI. Top

ELECTRICITY VOLTAGE HERTZ PHASE

DRIVERS 480 60 3 INLET NA NA NA MAX MIN

COOLING WATER TEMP C JECKET REQ'D PRESS. (BARG) PLUNGER NO REQ. SUCTION Ball 2 DISCHARGE Ball 2 2 INSTRUMENT AIR PRESSURE (barg) SOURCE

RETURN

DESIGN

MAX r

l DIAPHRAM

NORMAL N/A

MIN N/A

APPLICABLE SPECIFICATIONS:

l API 675 POSITIVE DISPLACEMENT PUMPS-CONTROLLED VOLUME l GOVERNING SPECIFICATION (IF DIFFERENT)

2013-3200-1L-0002

DATASHEET POUR POINT DEPRESSANT PUMPS ( API 675 )

STV EXTENSION - STV SOUTH WEST PROJECT ( SVSW ) EPCI FOR WHP - SVSW , PIPELINES AND CPP MODIFICATIONS

NOTE: INDICATES INFORMATION TO BE COMPLETED BY PURCHASER

Requisition No. Document No. Sheet no. Rev. No. Item Tag no. Service

: : : :

2013-3200-1W-0006 SVSW-004110-G16-0001 4 of 5 A

: PBE-4208A/B : PPD SYSTEM

o TYPE l MANUAL

BY MANUFACTURER

o MATERIALS - VENDOR TO COMPLETE SS 316L 61 LIQUID END 60 62 CONTOUR PLATE 63 HYDRAULIC DIAPHRAM 64 PROCESS DIAPHRAM 65 PLUNGER 66 LANTERN RING 67 PACKING GLAND 68 PACKING 69 VALVE 70 VALVE SEAT 71 VALVE GUIDE 72 VALVE BALL 73 VALVE GASKET 74 FRAME 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 TESTS 94 HYDROSTATIC 95 STEADY STATE ACCURACY 96 REPEATABILITY 97 LINEARITY 98 99 100 101 102 103 104 105 106 107 108 109 110 111 REMARKS : 112 113 114 115 116 117 118

REFER SHEET 5 FOR NOTE REQ'D WIT (HOLD) OBS (HOLD) QA INSPECTION AND TEST LOW AMBIENT TEMP. MATERIALS TESTS (2.13.5) SS 316L PTFE PTFE CARBON STEEL (NON-WETTED PART ) N/A N/A N/A SS 316L SS 316L SS 316L SS 316L PTFE

CONTROLS ( Note 4 ) SIGNAL l REMOTE l LOCAL

PNEUMATIC

l AUTOMATIC STROKE CONTROL:

l ELECTRONIC

PNEUMATIC (barg): MINIMUM ELECTRONIC (mA): MINIMUM

NAME PLATED UNITS

MAXIMUM MAXIMUM

OTHER PURCHASER REQUIREMENTS U.S CUSTOMARY

l SI

VENDOR FURNISHED PROCESS PIPING VENDOR REVIEW PIPING DRAWINGS

INTERNAL l EXTERNAL 124 ( for external PSV)

CAST IRON

l VENDOR FURNISHED PULSATION SUPPRESSION DEVICES l RELIEF VALVES BY PUMP MFRG

75 SPECIAL MATERIAL TESTS (2.13.1.3)

n RELIEF VALVE SETTING (barg)

3.1

VENDOR FURNISHED BACK-PRESSURE VALVE DOUBLE CHECK VALVE REQUIRED OIL-FILLED PRESSURE GAUGE REQUIRED VENDOR FURNISHED CONTROL PANEL

l l

COMPLIANT WITH INSPECTORS CHECK LIST CERTIFICATION OF MATERIALS FINAL ASSEMBLY CLEARANCES SURFACE AND SUBSURFACE EXAMINATIONS RADIOGRAPHY ULTRASONIC MAGNETIC PARTICLE LIQUID PENETRANT

BASEPLATE PREPARED FOR EXPOXY GROUT l PROVIDE TECHNICAL DATA MANUAL

PREPARATION FOR SHIPMENT

l EXPORT BOXING l OUTDOOR STORAGE MORE THAN 6 MONTHS

DOMESTIC WEIGHTS (KG) - VTA

l EXPORT

l MFRS. STANDARD l

CLEANLINESS PRIOR TO FINAL ASSEMBLY HARDNESS OF PARTS, WELDS & HEAT AFFECTED ZONES FURISH PROCEDURES FOR OPTIONAL TESTS

o PUMP o BASE

130 INCL

o GEAR o DRIVER

DRIVERS

INCL

30

l MOTOR: o TYPE

NEMA COMPLIANT TO IEEE 841, FRAME 143TC BALDOR 841XL FAMILY S.C Induction 05F161W751G2 Yes NO RPM PHASE 1765 3

l l l l

o MANUFACTURER o MODEL NO. l CONSTANT SPEED o VARIABLE SPEED o KW l VOLTS l HERTZ

ENCLOSURE 0.75 (1HP) 460 60 TEFC

o o

CRANKECASE HYDRAULIC FLUID

LUBRICATION FLUID o INTERMEDIATE ACCESSORIES

SERVICE FACTOR

n SPEED REDUCER MANUFACTURER

l INTEGRAL MODEL RATIO BASEPLATE UNDER

COUPLING MANUFACTURER TYPE

Miltron Roy or Equa

OTHER (SEE SEPARATE DATA SHEETS) GAS DRIVEN

STEAM TURBINE OTHER

SEPARATE WORM GEAR 36 : 1 DOMANGE

FLEXIBLE

TEMP. CODE T3 IP56

l INGRESS PROTECTION

o o

DATASHEET POUR POINT DEPRESSANT PUMPS API 675 )

STV EXTENSION - STV SOUTH WEST PROJECT ( SVSW ) EPCI FOR WHP - SVSW , PIPELINES AND CPP MODIFICATIONS

1 2 3 4 5

Requisition No. Document No. Sheet no. Rev. No. Item Tag no. Service

: : : :

2013-3200-1W-0006 SVSW-004110-G16-0001 5 of 5 A

: PBE-4208A/B : PPD SYSTEM

6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57

1) Package VENDOR to complete the data sheet. 2) Refer to 2013-3269-3L-0006 "Specification for LowVoltage Induction Motor" and 2013-3269-3M-0002 "LV Induction Motor Datasheet" for motoil detail requirements. 3) Manual stroke adjustment shall be possible while pump is running. 4) The pump shall be of double diaphragm type 5) Refer to data sheet 2013-3291-6H-0001 (HOLD) for site condition and utility available 6) Refer to Process Datasheet No. 2012-3100-9M-0012 (HOLD) for process datasheet. 7) Seal/packing material to be compatible with the chemical specified. 8) Vendor to furnish NPSH calculations and acceleration head calculations. 9) Vendor to provide details of pump performance. 10) All motors to be kw-noise design. Motor and driven equipment to meet the noise level motor datasheet. 11) PSV and pulsation dampener to be supplied by vendor. 12) All material for pressure parts including attachments directly welded to pressure parts and load bearing parts shall be certified to BS EN 10204 type 3.1. All non-pressure parts shall be certified to BS EN 10204 type 2.2. 13) Vendor shall indicate materials of construction as per ASTM standard or equivalent. 14) Motor rated below 0.5 Hp shall be explosion prooftype 15) NPSHa is estimated without considering acceleration head loss

You might also like

- Centrifugal Pump Data Sheet for Yanbu Refinery ProjectDocument9 pagesCentrifugal Pump Data Sheet for Yanbu Refinery ProjectJanakiraman MalligaNo ratings yet

- Pump Data SheetDocument6 pagesPump Data SheetmihailspiridonNo ratings yet

- 2009 02 M HD 319 0Document5 pages2009 02 M HD 319 0ZoebairNo ratings yet

- Pumps Tech Data SheetDocument3 pagesPumps Tech Data SheetSumedha LiyanageNo ratings yet

- El Merk Project Contract No.: SC 4012100 Petrofac Job No.: JI - 195Document5 pagesEl Merk Project Contract No.: SC 4012100 Petrofac Job No.: JI - 195Marwa KoubaiesNo ratings yet

- MCPK 100-065-125 CCX Andalan 316Document5 pagesMCPK 100-065-125 CCX Andalan 316Efril dilen franciscoNo ratings yet

- Air Foam Chamber: Fire Fighting Equipment Data SheetDocument8 pagesAir Foam Chamber: Fire Fighting Equipment Data SheetMihir JhaNo ratings yet

- A10 HBR-01-GH-MEC-DTS-0001 Rev B2Document6 pagesA10 HBR-01-GH-MEC-DTS-0001 Rev B2ahmed.njahNo ratings yet

- bb1 DatasheetDocument14 pagesbb1 DatasheetMojtabaNo ratings yet

- V-2158-103-A-851 - 4 ITP For PumpDocument4 pagesV-2158-103-A-851 - 4 ITP For PumpMessaoud GoutasNo ratings yet

- Appendix3 25113Document189 pagesAppendix3 25113iezohreNo ratings yet

- Process Pumps: Made by KSBDocument16 pagesProcess Pumps: Made by KSBEdgar CalatayudNo ratings yet

- C9709 Foam ChamberDocument1 pageC9709 Foam Chamberkalimutu2010No ratings yet

- vs1 DatasheetDocument22 pagesvs1 DatasheetMojtabaNo ratings yet

- Fire pump sensing lines: installation and requirementsDocument1 pageFire pump sensing lines: installation and requirementsStory LoveNo ratings yet

- Sick Tanker Unloading PumpDocument3 pagesSick Tanker Unloading PumpSumantrra ChattopadhyayNo ratings yet

- Data Sheet Multiphase Pump BornermanDocument5 pagesData Sheet Multiphase Pump BornermanUmar Ijaz KhanNo ratings yet

- Chemical Injection SkidDocument1 pageChemical Injection SkidKalyankumar KrishnamoorthyNo ratings yet

- Technical Standard Specification - Mechanical Section 03 - Pumps, Compressors, Blowers, and CuttersDocument51 pagesTechnical Standard Specification - Mechanical Section 03 - Pumps, Compressors, Blowers, and CuttersRenju RadhakrishnapillaiNo ratings yet

- Diaphragm Pumps SOWDocument30 pagesDiaphragm Pumps SOWalliancemarine2011No ratings yet

- Hydrant Stand Post (Double) : Technical Data SheetDocument2 pagesHydrant Stand Post (Double) : Technical Data SheetshabahatNo ratings yet

- Specification For Fire Water PumpsDocument7 pagesSpecification For Fire Water PumpsSANDEEP KUMAR RAHEJA100% (1)

- Data Sheet Pompa HydrantDocument3 pagesData Sheet Pompa HydrantAnonymous 6S9tcbhNo ratings yet

- 1555-Gen-E-Mt-6100-Bulk MtoDocument24 pages1555-Gen-E-Mt-6100-Bulk MtosuhailfarhaanNo ratings yet

- Manufacturing Inspection Test Plan: 1. Fabrication & Pre RequisitesDocument1 pageManufacturing Inspection Test Plan: 1. Fabrication & Pre RequisitesAlesol EquipmentNo ratings yet

- Specification Datasheet For Instrument Air Compressor PackageDocument5 pagesSpecification Datasheet For Instrument Air Compressor PackageBarata RendengNo ratings yet

- Inspection Report For Pipeline Route Survey Sign Copy and Blank FormatDocument1 pageInspection Report For Pipeline Route Survey Sign Copy and Blank FormatVishvjeet Prakash TiwariNo ratings yet

- Bifold UpdatedDocument8 pagesBifold UpdatedGopinath GunasekaranNo ratings yet

- Erbil Refinery Diesel Filling Pump Data SheetDocument5 pagesErbil Refinery Diesel Filling Pump Data SheetSardar PerdawoodNo ratings yet

- Hy 19580Document6 pagesHy 19580kompany_dNo ratings yet

- G I Drawing For Droplet SeperatorDocument4 pagesG I Drawing For Droplet SeperatorPerumal KumarNo ratings yet

- 200/300 BAR INERT GAS Fire Suppression Systems: JUNE 2017Document7 pages200/300 BAR INERT GAS Fire Suppression Systems: JUNE 2017Amir Hossein SaberNo ratings yet

- Data Sheet For Tank-To-tank Transfer Pump (Rev.a) - Returned (P-1501)Document7 pagesData Sheet For Tank-To-tank Transfer Pump (Rev.a) - Returned (P-1501)Panisa BanimaNo ratings yet

- Pekerjaan CHF 5 Vol KW Dim (MM) II Procurement/Fabrication Weight Each (KG)Document9 pagesPekerjaan CHF 5 Vol KW Dim (MM) II Procurement/Fabrication Weight Each (KG)bagus handokoNo ratings yet

- MX Tank Foam RTK PDFDocument2 pagesMX Tank Foam RTK PDFNarendra Reddy BhumaNo ratings yet

- Booster Pump-TechPart - 2of2 BDocument71 pagesBooster Pump-TechPart - 2of2 BKatie RamirezNo ratings yet

- PMG-ENG-O-DSH-U00-001-W Rev 3 Fire Fighting & Safety Equipment Datasheet - Part6 PDFDocument1 pagePMG-ENG-O-DSH-U00-001-W Rev 3 Fire Fighting & Safety Equipment Datasheet - Part6 PDFAditya PranotoNo ratings yet

- W13018-YT01-GDF-457110 Rev 5-APVDocument8 pagesW13018-YT01-GDF-457110 Rev 5-APVJosé santanaNo ratings yet

- Outside Screw and Yoke (OS&Y) Gate Valve - Flanged: Technical FeaturesDocument42 pagesOutside Screw and Yoke (OS&Y) Gate Valve - Flanged: Technical FeaturesayaNo ratings yet

- Instrument Hookup Drawing OF LEVEL SWITCHDocument1 pageInstrument Hookup Drawing OF LEVEL SWITCHEdafe DicksonNo ratings yet

- Multiphase Flowmeter Package SpecificationDocument29 pagesMultiphase Flowmeter Package Specificationvamcodong100% (1)

- HRSG Equipment ListDocument20 pagesHRSG Equipment ListManuel Jesus Perez MelgarNo ratings yet

- SA-980-P-11448 - API 685 Tank Transfer Pump PZ - Vert02Document5 pagesSA-980-P-11448 - API 685 Tank Transfer Pump PZ - Vert02altipatlarNo ratings yet

- Technical Data NRL 02301Document8 pagesTechnical Data NRL 02301Attiq Ahmad ChoudhryNo ratings yet

- ChecklistDocument3 pagesChecklistAndy Noven KrisdiantoNo ratings yet

- Purchase Spec. For Nozzles Swage (Sa106b)Document4 pagesPurchase Spec. For Nozzles Swage (Sa106b)Daison PaulNo ratings yet

- Pump Specification Data SheetDocument3 pagesPump Specification Data SheetMelvin MagbanuaNo ratings yet

- Metering Pumps SpecDocument2 pagesMetering Pumps Spececsuperal100% (1)

- Occidental of Oman, Inc. Engineering Services Contract For Oman North OXY CONTRACT NO. SWL-CA-2013-24000039693-ADocument45 pagesOccidental of Oman, Inc. Engineering Services Contract For Oman North OXY CONTRACT NO. SWL-CA-2013-24000039693-ASakthikumar ChandrasekaranNo ratings yet

- Class 1: Pttep International Limited (Myanmar) Zawtika Development ProjectDocument10 pagesClass 1: Pttep International Limited (Myanmar) Zawtika Development ProjectfajarNo ratings yet

- Diesel Tanks SpecDocument2 pagesDiesel Tanks SpecVikrantNo ratings yet

- Technical - Query - JIND - 2april2020 (Ed. LAPI)Document1 pageTechnical - Query - JIND - 2april2020 (Ed. LAPI)Nyayu SitimayaNo ratings yet

- Document: Technical Specification: PBSIM & BFS Consulting EngineeringDocument15 pagesDocument: Technical Specification: PBSIM & BFS Consulting EngineeringAmar RajawatNo ratings yet

- SCP Series Technical DataDocument8 pagesSCP Series Technical DataJaldhij PatelNo ratings yet

- 15250-194-EN04-SP-005-Rev 0 (Specification For Atmospheric Storage Tank)Document22 pages15250-194-EN04-SP-005-Rev 0 (Specification For Atmospheric Storage Tank)sudokuNo ratings yet

- API STD 676-2009 - Hoja de RequisiciónDocument28 pagesAPI STD 676-2009 - Hoja de RequisiciónRicardo CastroNo ratings yet

- ISO Pump DataDocument9 pagesISO Pump DataJanakiraman MalligaNo ratings yet

- Hoja de Datos API-674Document5 pagesHoja de Datos API-674texwan_No ratings yet

- V383773001X00 PDFDocument4 pagesV383773001X00 PDFSIVANo ratings yet

- Data Sheet Tag 180-Pu-011eDocument8 pagesData Sheet Tag 180-Pu-011eSarah PerezNo ratings yet

- MAXROY Series A, B & D DatasheetDocument4 pagesMAXROY Series A, B & D Datasheetnguyenquoc1988No ratings yet

- Diaphram Plunger Injection PumpDocument8 pagesDiaphram Plunger Injection PumpengrtahirNo ratings yet

- Piping System Safety ChecklistDocument1 pagePiping System Safety Checklistnguyenquoc1988No ratings yet

- Mechanical Packages - Project ComparisonDocument10 pagesMechanical Packages - Project Comparisonnguyenquoc1988No ratings yet

- Appendix 5 - TC - Process 1Document2 pagesAppendix 5 - TC - Process 1nguyenquoc1988No ratings yet

- How To Use This Tool Bar: 1 To Place A Cloud, You First Have To Highlight The Cells or Regions To Be CloudDocument2 pagesHow To Use This Tool Bar: 1 To Place A Cloud, You First Have To Highlight The Cells or Regions To Be Cloudnguyenquoc1988No ratings yet

- STV SW Project Level Gauge DatasheetDocument4 pagesSTV SW Project Level Gauge Datasheetnguyenquoc1988No ratings yet

- Diesel Sigma S 10w API CDSFDocument1 pageDiesel Sigma S 10w API CDSFnguyenquoc1988No ratings yet

- SVSW 004110 G8 0001 Rev.a Datasheet For Chemical Storage TankDocument4 pagesSVSW 004110 G8 0001 Rev.a Datasheet For Chemical Storage Tanknguyenquoc1988100% (1)

- Vendor Data Review Responsibility Matrix (09jan12)Document9 pagesVendor Data Review Responsibility Matrix (09jan12)nguyenquoc1988No ratings yet

- Polyurethane Insulation Coating Specification for STV South West Project PipelinesDocument42 pagesPolyurethane Insulation Coating Specification for STV South West Project Pipelinesnguyenquoc1988100% (1)

- g06 013 Heavy Maintenance Components List ADocument2 pagesg06 013 Heavy Maintenance Components List Anguyenquoc1988No ratings yet

- List of HVAC SpecificationsDocument46 pagesList of HVAC Specificationsnguyenquoc1988100% (1)

- HST A TS M DS 0031 - Rev F01 Datasheet For MTG Housing LouversDocument1 pageHST A TS M DS 0031 - Rev F01 Datasheet For MTG Housing Louversnguyenquoc1988No ratings yet

- HRD Hot Water Pump P001Document6 pagesHRD Hot Water Pump P001nguyenquoc1988No ratings yet

- HRD Hot Water Pump P001Document6 pagesHRD Hot Water Pump P001nguyenquoc1988No ratings yet

- HST A TS M TR 0020 - Rev F01 TR For Microturbine Generator HousingDocument24 pagesHST A TS M TR 0020 - Rev F01 TR For Microturbine Generator Housingnguyenquoc1988No ratings yet

- Centrifugal PumpDocument2 pagesCentrifugal Pumpnguyenquoc1988No ratings yet

- Flange Calculation Sheet..Document2 pagesFlange Calculation Sheet..nguyenquoc198850% (2)

- PumpDocument1 pagePumpnguyenquoc1988No ratings yet

- Quoc IQDocument1 pageQuoc IQnguyenquoc1988No ratings yet

- PumpDocument10 pagesPumpnguyenquoc1988No ratings yet

- Seismic LoadDocument37 pagesSeismic Loadnguyenquoc1988No ratings yet

- Quoc IQDocument1 pageQuoc IQnguyenquoc1988No ratings yet

- Quoc IQDocument1 pageQuoc IQnguyenquoc1988No ratings yet

- Mechanical COG of EquipmentDocument1 pageMechanical COG of Equipmentnguyenquoc1988No ratings yet