Professional Documents

Culture Documents

Pumps Tech Data Sheet

Uploaded by

Sumedha LiyanageOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pumps Tech Data Sheet

Uploaded by

Sumedha LiyanageCopyright:

Available Formats

Technical Datasheets for Fire Fighting System

Sr. No. Description Specification Offered

1. Main fire pump- Sprinkler System - Electrical Driven Pump

Horizontal Split casing Electrical Motor Driven

A Type

Pump

UL/FM Approved SPP, Peerles, Patterson,KSB

1 Make

or Equivalent Europ Make

2 Flow Rated : 5400 LPM

3 Differential Head / Pressure Rated : 95 Meter

4 Type of Suction : Positive suction

5 Liquid : Water

6 Pump Model : Vendor to Specify

7 NPSH Available, Rated : Vendor to Specify

B Performance

1 Speed, Rated 2900/3000 rpm

2 Impeller Diameter, Rated : Vendor to Specify

3 Impeller Diameter, Max : Vendor to Specify

4 Impeller Diameter, Min : Vendor to Specify

5 Suc/Del size : Vendor to Specify

6 Efficiency : Greater than 60%

7 Stages : Vendor to Specify

8 Pressure - Flow Curve : Vendor to Specify

9 Shutoff Head : < 140% of rated head

10 Max Allowable Working Pressure : 16bar

1.5 times of shutoff pressure or 16 kg/cm2

11 Hydrostatic Test Pressure :

whichever is higher

C Material of Construction

1 Impeller MOC : Bronze

2 Pump Shaft MOC AISI – 410 / Stainless Steel

3 Shaft Sleeve SS

4 Casing Wearing SS

5 Casing Cast iron

6 Shaft sealing : Gland Packing

D Drive Specifications

1 Type : Squirrel Cage Induction Motor

2 Enclosure : TEFC, IP-55,

3 Transmission : Directly Coupled

4 Power supply : 400 ±5%V, 3 Phase, 50 ±3% Hz.

5 Motor Rating (Kw) / Poles : Vendor to Specify

6 Motor Efficiency : Vendor to Specify

Required to be quoted with the system,

7 Control Panel For Pump & Motor : Audiovisual Annunciator in pump house when

any particular pump is switched on.

8 Pump & Motor Foundation : Mounte in common base

All the necessary electrical wiring from main

utilities to the pump house and within pump

9 Wiring : house to be provided by vendor with the

system, should also consider distribution

boards, starters, circuit breakers/HRC fuses.

All Material to be supplied should be new and

with necessary approval certificates along with

10 Certificate : Manufacturers Test Certificates duly signed

and stamped, no material supplied will be

acceptable without these documents.

11 Weight of Pump set (kg) : Vendor to Specify

E Ancillaries

1 Vibration pads : Vendor to Specify

2 Expansion bellow : Required (Both Suction and Delivery Side)

3 Coupling guard : Required

4 Foundation bolts : Required

2. Main Sprinkler pump - Diesel Engine

A Type Horizontal Diesel engine driven Pump

UL/FM Approved SPP, Peerles, Patterson,KSB

1 Make

or Equivalent Europ Make

2 Flow, Rated : 5400 LPM

3 Differential Head / Pressure Rated : 95 Meter

4 Type of Suction : Positive suction

5 Liquid : Water

6 Pump Model : Vendor to Specify

7 NPSH Available, Rated : Vendor to Specify

B Performance

1 Speed, Rated : 2900/3000 rpm

2 Impeller Diameter, Rated : Vendor to Specify

3 Impeller Diameter, Max : Vendor to Specify

4 Impeller Diameter, Min : Vendor to Specify

5 Suc/Del size : Vendor to Specify

6 Efficiency : Greater than 60%

7 Stages : 1

8 Pressure - Flow Curve : Vendor to Specify

9 Shutoff Head : < 140 % of rated head

1.5 times of shutoff pressure or 16bar

10 Max Allowable Working Pressure :

whichever is higher

1.5 times of shutoff pressure or 16 kg/cm2

11 Hydrostatic Test Pressure :

whichever is higher

C Material of Construction

1 Impeller : Bronze

2 Pump Shaft : AISI – 410 / Stainless Steel

3 Shaft Sleeve : SS

4 Casing Wearing : SS

5 Casing : Cast iron

6 Shaft sealing : Gland Packing

D Drive Specifications

1 Type : Vendor to Specify

2 Model : Vendor to Specify

3 Minimum Recommended Rating : Vendor to Specify

Required to be quoted with the system,

4 Control Panel For Pump & Engine : Audiovisual Annunciator in pump house when

any particular pump is switched on

Required to be provided by vendor with the

5 Pump & Engine Foundation :

system

All the necessary electrical wiring from main

utilities to the pump house and within pump

6 Wiring : house to be provided by vendor with the

system, should also consider distribution

boards, starters, circuit breakers/HRC fuses

All Material to be supplied should be new and

with necessary approval certificates along with

7 Certificate : Manufacturers Test Certificates duly signed

and stamped, no material supplied will be

acceptable without these documents.

8 Weight of Pump set (kg) : Vendor to Specify

E Ancillaries

1 Vibration pads : Vendor to Specify

2 Expansion bellow : Required (Both Suction and Delivery Side)

3 Coupling guard : Required

4 Foundation bolts : Required

3. Centrifugal Pumps - Electrical Driven Jockey Pump

Vertical Inline Multistage type Electrical Motor

A Type

Driven Jockey Pump

1 Make Grudfos, DP,WILO or equivalent Europ Make

2 Flow, Rated : 180 LPM

3 Differential Head / Pressure Rated : 100 Meter

4 Type of Suction : Positive Suction

5 Liquid : Water

6 Pump Model : Vendor to Specify

7 NPSH Available, Rated : Vendor to Specify

B Performance

1 Speed, Rated 2900/3000 rpm

2 Impeller Diameter, Rated : Vendor to Specify

3 Impeller Diameter, Max : Vendor to Specify

4 Impeller Diameter, Min : Vendor to Specify

5 Suc/Del size : Vendor to Specify

6 Efficiency : Vendor to Specify

7 Stages : Vendor to Specify

8 Pressure - Flow Curve : Vendor to Specify

9 Shutoff Head : < 140 % of rated head

1.5 times of shutoff pressure or 16bar

10 Max Allowable Working Pressure :

whichever is higher

1.5 times of working pressure or 16 kg/cm2

11 Hydrostatic Test Pressure :

whichever is higher

C Material of Construction

1 Impeller MOC : SS

2 Pump Shaft MOC AISI – 410 / Stainless Steel

3 Shaft Sleeve SS

4 Casing Wearing N/A

5 Casing Cast iron

6 Shaft sealing : Gland packing

D Drive Specifications

1 Type : Vendor to Specify

2 Enclosure : TEFC, IP-55,

3 Transmission : Directly Coupled

4 Power supply : 400 ±5%V, 3 Phase, 50 ±3% Hz.

5 Motor Rating (Kw) / Poles : Vendor to Specify

6 Motor Efficiency : Vendor to Specify

Required to be quoted with the system,

7 Control Panel For Pump & Motor : Audiovisual Annunciator in pump house when

any particular pump is switched on.

Required to be provided by vendor with the

8 Pump & Motor Foundation :

system.

All the necessary electrical wiring from main

utilities to the pump house and within pump

9 Wiring : house to be provided by vendor with the

system, should also consider distribution

boards, starters, circuit breakers/HRC fuses.

Pump Control panel should be new and with

necessary approval certificates along with

10 Certificate : Manufacturers Test Certificates duly signed

and stamped, no material supplied will be

acceptable without these documents.

11 Weight of Pump set (kg) : Vendor to Specify

E Ancillaries

1 Vibration pads : Vendor to Specify

2 Expansion bellow : Required (Both Suction and Delivery Side)

3 Coupling guard : Required

4 Foundation bolts : Required

You might also like

- Calculation Authored and Generated by CTC Design, Inc. Fan Laws and Fan HPDocument3 pagesCalculation Authored and Generated by CTC Design, Inc. Fan Laws and Fan HPavgpaulNo ratings yet

- Fire Pump Size Calculation: ProjectDocument3 pagesFire Pump Size Calculation: ProjectVaibhav SawantNo ratings yet

- Boiler SchematicDocument1 pageBoiler SchematicChristine GriffithNo ratings yet

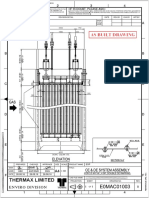

- THERMAX BAG FILTER TECHNICAL DATA SHEETDocument18 pagesTHERMAX BAG FILTER TECHNICAL DATA SHEETpavaniNo ratings yet

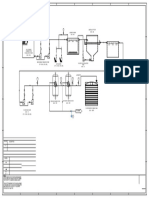

- P&id For STP PlantDocument1 pageP&id For STP PlantHardik KhetaniNo ratings yet

- Air Foam Chamber: Fire Fighting Equipment Data SheetDocument8 pagesAir Foam Chamber: Fire Fighting Equipment Data SheetMihir JhaNo ratings yet

- PG ASE-10-MEC-DWG-192 As Built Electrostatic PrecipitatorDocument69 pagesPG ASE-10-MEC-DWG-192 As Built Electrostatic PrecipitatorAgung Saputro100% (1)

- Dosing System Design DescriptionDocument4 pagesDosing System Design DescriptionHai NguyenNo ratings yet

- Process Control Philosophy 05-01-23Document8 pagesProcess Control Philosophy 05-01-23svnaik14No ratings yet

- Design and hydraulic calculation of foam systemDocument26 pagesDesign and hydraulic calculation of foam systembecpavanNo ratings yet

- Ipmg B SF DSH 1005 03Document5 pagesIpmg B SF DSH 1005 03sgh1355No ratings yet

- BoilerDocument13 pagesBoilerEDUARDONo ratings yet

- Gear Pump For Foam ApplicationDocument1 pageGear Pump For Foam ApplicationRAGHVENDRA PRATAP SINGHNo ratings yet

- Water Treatment Clarifier Data SheetDocument2 pagesWater Treatment Clarifier Data SheetgffNo ratings yet

- Sales Catalogue: Turbo-Dryer®Document31 pagesSales Catalogue: Turbo-Dryer®thomas_v501925No ratings yet

- Piping and Instrument Diagrams for Air EquipmentDocument3 pagesPiping and Instrument Diagrams for Air EquipmentAjeng OctaviaNo ratings yet

- Fire Fighting Pupms Data SheetDocument18 pagesFire Fighting Pupms Data SheetnourfarmajidNo ratings yet

- PR Minent: Plan View Piping SchematicDocument1 pagePR Minent: Plan View Piping SchematicrameshNo ratings yet

- TDS For Basket StrainerDocument2 pagesTDS For Basket StrainerRAGHVENDRA PRATAP SINGHNo ratings yet

- Chemical DosingDocument24 pagesChemical DosingIskerNo ratings yet

- BHEL ASh Handling Equp QA RequiremntDocument27 pagesBHEL ASh Handling Equp QA Requiremntamol1321100% (2)

- Monnet - Recommended Scheme and Write Up of Auto ControlsDocument34 pagesMonnet - Recommended Scheme and Write Up of Auto ControlsDipti BhanjaNo ratings yet

- SVSW 004110 G16 0001 Rev.a Datasheet For PumpDocument6 pagesSVSW 004110 G16 0001 Rev.a Datasheet For Pumpnguyenquoc1988No ratings yet

- DTS - Belt Bucket Elevator - DatasheetDocument3 pagesDTS - Belt Bucket Elevator - DatasheetBRUNA NASCIMENTONo ratings yet

- Annexure D - For Cable Cellar MVWS SystemDocument1 pageAnnexure D - For Cable Cellar MVWS Systemsujay AvatiNo ratings yet

- Perhitungan Water Balance Pg. Pesantren Baru Kapasitas 6000 TCDDocument3 pagesPerhitungan Water Balance Pg. Pesantren Baru Kapasitas 6000 TCDRahman SuyadiNo ratings yet

- Training DuctingDocument20 pagesTraining Ductingpanji uteNo ratings yet

- A Tse Spe 000 30000 0Document28 pagesA Tse Spe 000 30000 0ZaidiNo ratings yet

- Exhaust HoodsDocument4 pagesExhaust HoodsMohammed MustafaNo ratings yet

- Annexure D - For Cable Cellar MVWS SystemDocument1 pageAnnexure D - For Cable Cellar MVWS SystemVaibhav SawantNo ratings yet

- Fire Extinguisher Design Procedure General Design Criteria Floor Basis Travel BasisDocument3 pagesFire Extinguisher Design Procedure General Design Criteria Floor Basis Travel Basistribhuvan ShankarNo ratings yet

- Appendix3 25113Document189 pagesAppendix3 25113iezohreNo ratings yet

- Guide For Test Pack Eng ResponsibiliesDocument1 pageGuide For Test Pack Eng ResponsibiliesDinesh RadhakrishnanNo ratings yet

- Hydraulic Cal - Tanks Vent To FlareDocument1 pageHydraulic Cal - Tanks Vent To FlareRexx Mexx0% (1)

- Boiler SpecificationDocument62 pagesBoiler SpecificationamitjpNo ratings yet

- FW Pump Suction & Discharge Cal PDFDocument2 pagesFW Pump Suction & Discharge Cal PDFkisan singh100% (1)

- Dust Extraction Design ReportDocument13 pagesDust Extraction Design ReportKartik Mendiratta100% (1)

- TenderDocument43 pagesTenderYogeshNo ratings yet

- CFPG-Foam Bladder Technical Data SheetDocument13 pagesCFPG-Foam Bladder Technical Data SheetParveen NakwalNo ratings yet

- Basket FilterDocument1 pageBasket FilterShreya TrikhaNo ratings yet

- Extraction Flow Calculation by IterationDocument6 pagesExtraction Flow Calculation by Iterationarunrajmech09No ratings yet

- Maintaining Vung Ang Thermal Power Plant's SCR SystemDocument31 pagesMaintaining Vung Ang Thermal Power Plant's SCR SystemTNHH TM & DV KT TH NHÂT MINH CtyNo ratings yet

- Gas Pressure Reduction StationDocument2 pagesGas Pressure Reduction StationMathias OnosemuodeNo ratings yet

- G LST 001 Ab Tank Farm in ProgressDocument270 pagesG LST 001 Ab Tank Farm in ProgressPhilippe AlexandreNo ratings yet

- Cooling Water Pump Data Sheet FinalDocument8 pagesCooling Water Pump Data Sheet FinalShahzaibUsmanNo ratings yet

- PMG-EnG-O-DSH-U00-001-W Rev 3 Fire Fighting & Safety Equipment Datasheet - Part11Document1 pagePMG-EnG-O-DSH-U00-001-W Rev 3 Fire Fighting & Safety Equipment Datasheet - Part11Aditya PranotoNo ratings yet

- K TRON Loss in Weight Single Screw Feeder K ML S500 10DDocument2 pagesK TRON Loss in Weight Single Screw Feeder K ML S500 10Ddeus_7No ratings yet

- PT. WIJAYA KARYA ENGINEERING DOCUMENTDocument2 pagesPT. WIJAYA KARYA ENGINEERING DOCUMENTLucious LightNo ratings yet

- Water Sprayer Calculation For Vertical VesselDocument11 pagesWater Sprayer Calculation For Vertical VesselSdferwste Srqre0% (1)

- O&M Manual - Part 1 of 5 PDFDocument58 pagesO&M Manual - Part 1 of 5 PDFYOUTH FUTURENo ratings yet

- Dust extraction system bag filter detailsDocument6 pagesDust extraction system bag filter detailsAnonymous W9VINoTzaNo ratings yet

- Erbil Refinery Diesel Filling Pump Data SheetDocument5 pagesErbil Refinery Diesel Filling Pump Data SheetSardar PerdawoodNo ratings yet

- Tanks Thickness & Pipe Size CalculationDocument4 pagesTanks Thickness & Pipe Size CalculationANKITA BISWASNo ratings yet

- 100-T-1100 Methanol Tank SampleDocument3 pages100-T-1100 Methanol Tank SampleSachinl PatelNo ratings yet

- RideDocument8 pagesRidewahyuNo ratings yet

- Digitally signed wet dust extraction system design reportDocument17 pagesDigitally signed wet dust extraction system design reportmathan_aeNo ratings yet

- Air Blowe DatasheetDocument1 pageAir Blowe DatasheetMoein PNo ratings yet

- BASIS OF CALCULATION TITLEDocument19 pagesBASIS OF CALCULATION TITLEt_i_f_anoNo ratings yet

- ACI-10-17-2019-0001SyncroFlo 334719 - Technical SEPT 2612345PDF FINAL PDFDocument7 pagesACI-10-17-2019-0001SyncroFlo 334719 - Technical SEPT 2612345PDF FINAL PDFJoselito OlivaNo ratings yet

- Pump Specification Data SheetDocument3 pagesPump Specification Data SheetMelvin MagbanuaNo ratings yet

- RSG 303Document196 pagesRSG 303Makinde TimiNo ratings yet

- Tata Steel-MDP SessionDocument69 pagesTata Steel-MDP Sessionsasharma82No ratings yet

- AP Poetry TermsDocument8 pagesAP Poetry TermsTEACHER BARAY LLCE ANGLAISNo ratings yet

- Omega 1 Akanksha 9069664Document5 pagesOmega 1 Akanksha 9069664Akanksha SarangiNo ratings yet

- SAP ABAP Interview Questions and AnswersDocument8 pagesSAP ABAP Interview Questions and AnswersKarthi ThirumalaisamyNo ratings yet

- Rate of ChangeDocument22 pagesRate of ChangeTrisha MariehNo ratings yet

- 178 - 7 - Fun For Flyers. Progress Tests - 2017, 4th - 91p.pdf Foods NatureDocument1 page178 - 7 - Fun For Flyers. Progress Tests - 2017, 4th - 91p.pdf Foods NatureYu KoNo ratings yet

- At GN4Document1 pageAt GN4jazzvivekNo ratings yet

- San Lam Stratus FundsDocument2 pagesSan Lam Stratus FundsTiso Blackstar GroupNo ratings yet

- BITS ZG628T Dissertation (For Students of M. Tech. Software Systems)Document21 pagesBITS ZG628T Dissertation (For Students of M. Tech. Software Systems)Shiva Beduduri100% (1)

- Project Management OfficeDocument42 pagesProject Management OfficeqazqazNo ratings yet

- Large Generators WEBDocument16 pagesLarge Generators WEBMaycon MaranNo ratings yet

- A Very Rare Type of NeuralgiaDocument2 pagesA Very Rare Type of NeuralgiarosaNo ratings yet

- Analgesia SystemDocument7 pagesAnalgesia SystemMudassar Roomi100% (1)

- Solution SellingDocument18 pagesSolution Sellingvikramgulati13090% (1)

- CSE 323-Final-Summer 2021Document2 pagesCSE 323-Final-Summer 2021nahimur rahmanNo ratings yet

- Capacity Based On Shear Parameters As Per IS 6403: C C C C W Q Q Q Q F y y y yDocument5 pagesCapacity Based On Shear Parameters As Per IS 6403: C C C C W Q Q Q Q F y y y yKishore KumarNo ratings yet

- Chapter 2Document5 pagesChapter 2Ayush Hooda class 12 ANo ratings yet

- LC1D150M7: Product Data SheetDocument3 pagesLC1D150M7: Product Data SheetTrong Hung NguyenNo ratings yet

- Max-OT For Dummies - Bodybuilding - Com ForumsDocument21 pagesMax-OT For Dummies - Bodybuilding - Com ForumsPhong QuachNo ratings yet

- HTML MCQDocument22 pagesHTML MCQBuxar Students LifeNo ratings yet

- First Preliminary Music Video ScriptDocument1 pageFirst Preliminary Music Video Scriptapi-455734096No ratings yet

- Cognitive Load Theory (John Sweller) : Information ProcessingDocument2 pagesCognitive Load Theory (John Sweller) : Information ProcessingNik ZazlealizaNo ratings yet

- SRV210 - 250TC Spare PartsDocument2 pagesSRV210 - 250TC Spare PartsEnzo SovittiNo ratings yet

- Williamstown Cannabis Cultivation PlanDocument48 pagesWilliamstown Cannabis Cultivation PlanOltion JaupajNo ratings yet

- Chemists 12-2023Document7 pagesChemists 12-2023PRC BaguioNo ratings yet

- Delays in Endoscope Reprocessing and The Biofilms WithinDocument12 pagesDelays in Endoscope Reprocessing and The Biofilms WithinHAITHM MURSHEDNo ratings yet

- CUMSUM Process ControlDocument6 pagesCUMSUM Process Controljess fantonalgoNo ratings yet

- Som-Ii Uqb 2019-20Document23 pagesSom-Ii Uqb 2019-20VENKATESH METHRINo ratings yet

- Bartending and Catering: Agenda: Basics of Bartending Bar Tools and EquipmentDocument146 pagesBartending and Catering: Agenda: Basics of Bartending Bar Tools and EquipmentMars Mar100% (1)