CONSORTIUM OF PT.

WIJAYA KARYA &

PT. WIJAYA KARYA REKAYASA KONSTRUKSI

ENGINEERING DOCUMENT

PLTMG BIAK

KKS NUMBERING Page 4 of 4

ENG-DED-BIK-PR-03-MJ-002

KKS NUMBERING

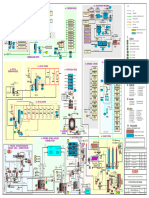

No Area Area No Sub System Sub System KKS Code Function Sub function

1 Pump House 1 Fuel Oil Unloading EGC Supply of liquid fuels Pump system

2 Fuel Oil Purifier + Transfer EGC Supply of liquid fuels Pump system

3 Fuel Oil Forwarding EGC Supply of liquid fuels Pump system

4 Lube Oil Unloading LV Lubricating Supply system -

5 Lube Oil Transfer LV Lubricating Supply system -

2 Tank Area 1 Main Storage EGB Supply of liquid fuels Tank farm

2 Daily Tank EGB Supply of liquid fuels Tank farm

3 Lube Oil Storage LV Lubricating Supply system -

3 Gas Supply 1 Coalescer EKE Supply of gaseous fuels Mechanical Cleaning, scrubbing

2 Metering EKU Supply of gaseous fuels Billing Meter Station

4 Powerhouse (TM Module) 1 Fuel Oil Duplex+Flow Meter+Drain Tank Engine 1 MJN Diesel Engine Plant Fuel System

2 Fuel Oil Duplex+Flow Meter+Drain Tank Engine 2 MJN Diesel Engine Plant Fuel System

3 Pilot Oil Tank+Forwarding+Cooler Engine 1 MJN Diesel Engine Plant Fuel System

4 Pilot Oil Tank+Forwarding+Cooler Engine 2 MJN Diesel Engine Plant Fuel System

5 Lube Oil Prelube+Cooler+Purifier Engine 1 MJV Diesel Engine Plant Lubricant Supply System

6 Lube Oil Prelube+Cooler+Purifier Engine 2 MJV Diesel Engine Plant Lubricant Supply System

7 HT LT System Engine 1 MJG Diesel Engine Plant Liquid Cooling System

8 HT LT System Engine 2 MJG Diesel Engine Plant Liquid Cooling System

5 Powerhouse 1 HT LT Expansion Tank MJG Diesel Engine Plant Liquid Cooling System

2 Lube Oil Drain Tank MJV Diesel Engine Plant Lubricant Supply System

3 Unloading Lube Oil Portable MJV Diesel Engine Plant Lubricant Supply System

4 Used Lube Oil Portable MJV Diesel Engine Plant Lubricant Supply System

5 Starting Air MJP Diesel Engine Plant Start-up unit

6 Instrument Air MJX Diesel Engine Plant Fluid supply system for control and protection equipment

7 Intake MJQ Diesel Engine Plant Air intake system

8 Exhaust MJR Diesel Engine Plant Exhaust gas system

9 Gas Valve Unit MR Gas Engine Plant -

10 Radiator Engine 1 MJG Diesel Engine Plant Liquid Cooling System

11 Radiator Engine 2 MJG Diesel Engine Plant Liquid Cooling System

6 WTP 1 Deep Well GAF Raw Water treatment Pump System

2 Water Pond GAD Raw Water treatment Storage System

3 Water Treatment GC Treatment System -

4 Water Storage GAD Raw Water treatment Storage System

7 WWTP 1 Drain Pit GNK Process Drains Treatment system Temporary storage system

2 Corrugated Plate Interceptor GNB Process Drains Treatment system Filtering, mechanical cleaning system

3 Electric Coagulant GNF Process Drains Treatment system Ion exchange system

4 Sludge Tank GNL Process Drains Treatment system Storage system outside fluid treatment

8 Fire Water 1 System SGA Stationary fire protection system Fire water system

2 Foam SGF Stationary fire protection system Foam fire fighting system

3 Spray Nozzle SGC Stationary fire protection system Spray deluge system

4 Sprinkle SGE Stationary fire protection system Sprinkle system

9 Powerhouse Vent 1 Vent UMX Structure for main machine sets Special structure (powerhouse vent)

� 1 2 3 4 5 6

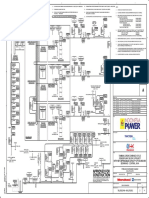

LINE IDENTIFICATION NUMBER INSTRUMENT IDENTIFICATION NUMBER

A A

- - - - -

INSTRUMENT TYPE

NOMINAL PIPE SIZE (INCH)

KKS NUMBERING

SERVICE CODE

KKS SYSTEM CODE

LINE NUMBER

PIPING MATERIAL CLASS

PRESSURE CLASS

AS PER ASTM STANDARD

INSTRUMENT TYPE

SERVICE CODE PRESSURE CLASSIFICATION

B SERVICE CODE SERVICE DESCRIPTION CODE PIPE SPECIFICATION B

AB AIR, BREATHING A CLASS 125/150

B CLASS 300

AC AIR, COMBUSTION

AIR

D CLASS 600

Al AIR, INSTRUMENT

E CLASS 900

AU AIR, UTILITY

F CLASS 1500

CA CHEMICAL, ANTIFOAM

G CLASS 2500

CB CHEMICAL, BARITE

CC CHEMICAL, GENERAL

CD CHEMICAL, DEMULSIFIERS

CE CHEMICAL, GLYCOL

CG CHEMICAL,BIOCIDE

CH CHEMICAL, CORROSION INHIBITOR

CHEMICAL CI CHEMICAL, METHANOL

CM CARBON DIOXIDE

CO CHEMICAL, OXYGEN SCAVANGER

C

C CP CHEMICAL, PPD

CS CHEMICAL, OXYGEN SCAVANGER

CW CHEMICAL, WATER CLARIFIERS

CX CHEMICAL, CAUSTIC

CZ CHEMICAL, ACIDS

DC DRAIN, CLOSED

DG DRAIN, GLYCOL

DRAIN DO DRAIN, OPEN

DA DRAIN, OPEN

DAE CHEMICAL, ACIDS

REFERENCE DOCUMENT

FA FUEL, AUTOMOTIVE / AVIATION GASO LINE

DOCUMENT / DRAWING NO. REV TITLE

FD FUEL, DIESEL

FUEL

FG FUEL,GAS

FH FUEL, HEAVY OIL

GE GAS, EXHAUST / WASTE / FLUE

GI INERT / INSTRUMENT GAS (DRY) D

D

GN PROCESS/ PRODUCED NON- CORROSIVE GAS

GAS CIVIL

GS STARTING GAS

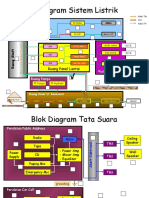

MECHANICAL

GU

MOBILE POWER PLANT AND R

UTILITY ELECTRICAL

FIXED TYPE GAS ENGINE POWER PLANT E

GX PROCESS/ PRODUCED CORROSIVE GAS I&C

PACKAGE III (FIXED POWER PLANT) V

SUPPORT

GZ PROCESS / PRODUCED,TOXIC PLTMG BIAK 15 MW I

CONTRACTOR DOCUMENT REVIEW E

OH OIL, HYDRAULIC W

OIL OL OIL, LUBE/ SEAL LOG DATE

OQ IN COMM.NO.

HEAT TRANSFER OIL

A APPROVED

SC STEAM CONDENSATE B APPROVED ASNOTED D CONTRACTOR

C NOT APPROVED I RECORD

HEAT TRANSFER SM STEAM MP

I INFORMATION S WORKING DOCUMENT

SL STEAM LP T

VENT TO ATMSOPHERE APPROVAL DOES NOT RELIEVE R

VA

CONTRACTOR FROM RESPONSIBILITY FOR I

VC FLARE AND VENT, CORROSIVE ERROS OR DEVIATIONS FROM CONTRACT B

REQUIREMENTS U

VN NON-CORROSIVE,VENT

T

VZ TOXIC VENT BY : DATE : I

E WC WATER, COOLING LOG DATE : O E

VENT N

OUT COMM.NO :

WD WATER, DOMESTIC PLUMBING

OWNER

PT. PERUSAHAAN LISTRIK NEGARA ( PERSERO )

WF WATER, FIRE

UNIT INDUK PEMBANGUNAN PAPUA

WG WATER,GRAY (WASTE)

ENGINERING

WI DEOXYGENATED WATER PT. PLN ( PERSERO ) PUSAT ENJINIRING KETENAGALISTRIKAN

WJ WATER, JACKET

CONTRACT . NO : 0177.PJ/DAN.02.01/DIR/2017

WM DEOXYGENATED / MEMBRANE FEED WATER

PLN DOC. NO.

WN PROCESS/ PRODUCED NON-CORROSIVE WATER 1 1 0 2 6 B 3 . 5 - 0 0 - M - 5 2 - Z - 0 0 1 1 - 0 1 - 0

WO WATER, OILY

WP WATER, POTABLE

TITLE : P&ID SYMBOLS AND LEGENDS

(SHEET 2 OF 3)

WATER WZ WATER, CHLORIDE

WATER, HEAT TRANSFER MEDIUM PURPOSE :

WQ ISSUED FOR APPROVAL

WS WATER, SEA OR SALYY

REV DESCRIPTION PREPARED CHECKED APPROVED DATE

WT WATER, THEATED (DE-IONIZED)

WU UTILTY / RAW / WASH, NON CORROSIVE WATER

F WW WASTE WATER

F

XE EXHAUST, RECIPROCATING ENGINE

EXHAUST

XT EXHAUST, GAS TURBINE ENGINE 0 ISSUED FOR APPROVAL AL RA DE 14-08-17

CONTRACTOR DOC. NO :

REKAYASA

K NSTRUKSI

PT WIJAYA KARYA(Persero)Tbk

ENG-DED-BIK-PR-52-MJ-001-02

CONSULTANT

PT PUSTEK E&T

1 2 3 4 5 6