Professional Documents

Culture Documents

Wartsila 7.085MW

Uploaded by

Senthil Kumar0 ratings0% found this document useful (0 votes)

20 views26 pagesOriginal Title

WARTSILA 7.085MW

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

20 views26 pagesWartsila 7.085MW

Uploaded by

Senthil KumarCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 26

FUJI TECHNICAL SERVICES PVT LTD-

WARTSILA W16V32 ENGINE ALONGWITH 11KV

ALTERNATOR FOR SALE

Engine Make:- Wartsila-Finland

Engine Model:- W16V32

Year of Mfg.:- 2/2006

Capacity:- 7085 KW

RPM:- 750

Fuel in use:- HFO

Fuel Type: HSD/HFO

Date of last O/H :- 4/2014

R/H of last major O/H:- 38738

Present running hour

(24/01/2017):- 39044

R/H after major O/H:- 306

With all standard tools

Description of unit Make

Governor Actuator Woodward

Lubricating oil separator Alfa laval

HFO separator Alfa laval

Feeder Unit Group power

Booster unit Aura marine

C.T pump Kirloskar

Fabricated,

Chimney Structured Height:- 75 Meters

supported.

Turbo Charger ABB

Charge Air filter AAF International

FUJI TECHNICAL SERVICES PVT LTD-

WARTSILA W16V32 ENGINE ALONGWITH 11KV

ALTERNATOR FOR SALE

Alternator Detail

Sr. No

1 Capacity 8562KVA

2 Speed 750rpm

3 Current 449Amp.

4 Voltage 11KV

5 Power Factor 0.80

6 Phase 3-phase

7 Ambin Temp. 50 deg.C

8 Exit volt 61.5 VDC

9 Exit current 8.4 Amp. DC

10 Frequency 50Hz

11 Type AMG 1120MK08

12 Connection Star

13 Insulation "F" class

Protection of

14 Enclosure IP23

15 Make ABB

SCOPE OF SUPPLY

Sr No. Description UOM Quantity Scope of supply

A Power Generation

A1 Generating Set

A1.1 Diesel Engine

Diesel Engine Nos 1 YES

A 1.2 Alternator

Alternator 11kv Nos 1 YES

A1.3 Base Frame

Base Frame for engine and alternator (independent) Nos 1 YES

shifting tools for engine and alternator set 1 NO

A 1.4 Elastic mounting

Fiexble mountings (rubber pads) set 1 YES

Shim plates, fasteners for rubber pads & foundation bolts set 1 YES

A1.5 Coupling

Flexible coupling pads (holset) set 1 YES

Flywheel guard Nos 1 YES

A1.7 Flexible connections

Flexible connections (complete set) set 1 YES

A1.8 Maint. Platform

Maint. Platform for engine Nos 1 YES

Maint. Platform between pipe modules Lot YES

Walkway platform checkered plates complete Lot 1 YES

A2 Mechanical systems

A2.1 Fuel oil system

A2.1.1 Light Fuel oil system (HSD)

Unloading system Nos 1 NO

Storage tank Nos 1 NO

Equipment for storage tank Lot 1 NO

Transfer pump unit Nos NO

Day tank Nos NO

Pipeing inside DG House Lot 1 YES

Piping outside DG house Lot 1 NO

A2.1.2 Heavy fuel oil system

Tanker fuel heating arrangment for fuel unloading Nos

Unloading unit Lot 1 NO

Storage tank Lot 1 NO

Equpement for HFO storage tank Lot 1 NO

Transfer pump unit Nos 1 YES BUT WITHOUT MOTOR

Buffer tank (settling tank) with accessories Lot 1 NO

Electro-pneumatic valve Nos 1 NO

Separator Unit for hfo set 1 YES

Day tank with accessories Lot 1 NO

Feeder unit Nos 1 YES

Booster unit Nos 1 YES

Fuel oil unit Nos 1 YES

Return fuel oil unit Nos 1 YES

Piping inside DG house Lot 1 YES

Piping outside DG house Lot 1 NO

A2.2 Lub oil system

A2.2.1 Engine lub oil system

Lub oil Separator Nos 1 YES

Pipe module Nos 1 YES

Lub oil cooler Nos 1 YES

Pre lub pump Nos 1 YES

Lub oil Filter Nos 1 YES

Water preheater Nos 1 YES

Thermostatic Valves Nos 1 YES

A2.2.2 Plant Lub oil system

Unloading/ Transfer pump unit (mobile unit) Nos 1 NO

A2.3 Compressed air system

A2.3.1 Starting Air System

Starting Air compressor unit Lot 1 YES

Starting air bottle Nos 1 YES

Piping inside DG huse Lot 1 YES

A2.3.2 Control &Instrument air system

Instrument air system (pressure regulator with moisture trap) YES WITH COMPRESSOR

Piping inside DG house

A2.4 Cooling system

A2.4.1 Engine cooling system

Expansion vessel (S) Lot 1 YES

Thermostatic valve HT Lot 1 NO( PNEUMATIC)

Piping in side DG house Lot 1 YES

Piping outside DG house Lot 1 NO

A2.4.2 Plant cooling System

Cooling tower Lot 1 NO

Maintenance water tank Nos 1 YES

Raw water tank Lot 1 NO

DM/Softening water plant for separators and Engine Lot 1 NO

Storage tank forDM water/softened water Lot 1 NO

Hydrophore unit Nos 1 NO

Chemicals for closed circuit water Lot 1 NO

Piping inside DG house Lot 1 YES

Piping Outside DG House Lot 1 NO

A2.5 Charge air system

Intake air filter (s) set 1

Intake air silencer (s) Nos 2

Intake air ducting (between engine &air filter(s)) Lot 1

Expansion bellow (s) Nos 2

A2.6 Exhaust gas System

Exhaust gas silencer (s) Nos 1 YES

Exhaust gas ducting (from engine to silencer) Lot 1 YES

Expansion bellows set 1 YES

Exhaust Gas steel stack Lot 1 YES

A2.8 Station Support System

A2.8.1 Fire Fighting System

Fire extinguishers for class " B" and "C" fires &Sand Buckts

Fire alarm &detection system

Fire hydrant &other system

Fire hydrant piping Lot 1

Fire water pumps water distribution system

Hydrants

Fire Hose Equpements NO

A2.8.2 Sludge System

Oily water collecting pits Nos 1

Equipment for collecting pit Lot 1

Oily water transfer pump unit Lot 1

Sludge storage Tank Nos 1

Equpment for Sludge storage tank Lot 1

Sludge unloading pump unit Lot 1

Sludge piping between interconnecting units Lot 1 NO

A2.9 Steel structures

Supports for Charge Air Ducting Lot

Supp. For exhaust gas duct-inside DG House Lot

Supp. For exhaust gas duct-o/s upto stack Lot

1

Supports for pipes inside DG house Lot

Supports for pipes outside DG house Lot

Supporting structure for expn. Tank Lot YES

A2.x Piping

Piping complete Lot 1 YES

A.3 Electrical Systems

Engine Junction box Lot 1 YES

A.3.1 Main Switchgear (MV)

Generator Cubicle (INCOMER) Nos 1 YES

Outgoing cubicle -A, 11kv Nos 1 YES

Station transformer cubicle Nos 1 NO

Bus PT Nos 1 NO

NGR Cubicle 1 YES

MV cable Lot 1 YES

Cable Tray Lot 1 YES

A.3.1 Station Service System

Station Service transformer Lot 1 NO

Station low voltage Switchgear Lot 1 NO

Engine local control panel No 1 YES

Aux. MCC for fuel oil pump house Lot YES

Aux. MCC for cooling tower Lot 1 YES

Aux. MCC for DG Hall ventilation Lot

Aux. MCC for lighting Lot 1 NO

Aux. MCC forLT Power Distribution Lot 1 YES

LV power & control Cables For Auxiliaries

Inside DG House Lot

Outside DG House Lot 1 YES

Cable Trays for Lvpower & control cables

Inside DG House Lot

1 YES

Outside DG House Lot 1 YES

A3.3 DC system (for 3*18v32)

Batteries

Battery Charger

DC distribution board

Cables Lot 1 YES

A3.4 Earthing & lightning protection system

Earthing inside DG House Lot NO

Earthing outside DG House Lot NO

Lighting protection including chimney Lot 1 YES

A3.5 Outdoor Switchyard

Step-up /step-down transformer NO

Sub station Switchgear NO

Outdoor Switchyard NO

Cables 1 NO

A3.6 Emergency DG set (Black Start)

Required power maximum-----KW Lot 1 NO

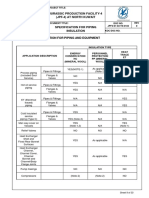

A3.7 Insulation

Insulation of all tanks (Buffer &Day tank ) Lot 1 NA

Heat tracing and Insulation of all hfo piping Lot 1 NA

Insulation of exhaust pipes Lot 1 YES

A.4 Automation , Monitoring & Supervision

A4.4 Control and Supervision System (Basic)

DG Control panels Lot 1 YES

Synchronizing panel No 1 NO

A4.9.1 Cables/Accessories

Set of control and instrumentation cables Lot 1 YES

A.6 Emission control system

A.7 Tool

Maintenance tool Set

Maintenance tool for turbocharger Set

Maintenance tool lube-oil separator Set

Maintenance tool for Hfo separator Set 1 YES

A.8 Spares

Commissioning spares Lot 1 NO

Running in filter cartridge & accessories Lot 1 NO

Housing for running in filter Lot 1 YES

A.9 Boiler & its auxiliaries

Boiler & its associated Auxiliaries complete Lot NA

B.0 Power plant Building & Utility

B.1 Power House

B.1.1 Power Plant - civil construction

Input details for EQUIPMENTS

DG Building

Tank farm -tank fdns, dyke wall etc

Exhaust gas stack foundation

Radiator foundation

Pipe Pedestals

Transformer Foundation

Fuel oil pump House

Roads around power plant buildings

Gates/Fencing Lot 1 NOT APPLICABLE

Security office

B1.2 Sewage and Drainage

B1.3 Ventilation & Air Conditioning

DG Hall ventilation (pressurised) Lot 1 NO

Ventillation filters Lot 1 NO

Exhaust fans mounted on Roof top and wall mounted Lot 1 NO

B1.3.4 Air conditioning system

Window air conditioners Lot 1 NO

B1.4 Building Electricals NO

B1.4.1 Lighting System NO

Lighting DG Hall NO

Lighting HT switchgear & control room NO

Lighting storage area & outside DG house NO

Lightning protection NO

Earth Mat NO

Lighting cables Lot 1 NO

B1.6 Lifting System

DG House overhead crane-EOT Lot 1 NO

Girders for overhead crane movement Lot 1 NO

C. Services

C.1 Engnieering

Preliminary Engnieering

Basic Engnieering

Detailed Engnieering Set 1 NOT APPLICABLE

C.2 Supervision

Supervision of removal Lot

Supervision of installation Lot

Supervision of testing & commissioing Lot 1 NOT APPLICABLE

C.3 Erecation & Installation

Erecation-client supply eqpt.

Flushing Oil & other consumables

First fill of lubricants, fuel oil & grease Lot 1 NOT APPLICABLE

C.4 Testing and Commissioning

Tests on completion at site Lot 1 NOT APPLICABLE

C.6 Documents

Preliminary Engnieering

Basic Engnieering

Detailed Engnieering Set 1 NOT APPLICABLE

C.7 Other

Fuel quality & composition tests 1

Water Quality analysis 1

Ambient air Quality analysis 1

Soil Investigation 1

Statutory clearance- Explosives Lot 1

Statutory clearance- Electrical 1

Statutory clearance- Pollution 1

Statutory clearance- Factory Inspector 1

Statutory clearance- All other clearances 1 NOT APPLICABLE

Loading & Unloading 1

Transportation of equipments 1

Packing 1

Port Clearance

Lot

Transit insurance 1

Lodging, Boarding & local Conveyance for Wartsila Engineers 1

Painting 1

Erection & commissioning insurance 1 NOT APPLICABLE

Refurbishment work on electrical & mechanical Lot 1

DG Overhauling spares + T/C Lot 1

All Auxiliary Spares/overhauling if required Lot 1 NOT APPLICABLE

You might also like

- 50 MVA Trfo-2Document6 pages50 MVA Trfo-2p m yadavNo ratings yet

- MOTOR SERVICING WORK RECORD SUMMARYDocument9 pagesMOTOR SERVICING WORK RECORD SUMMARYKholis JaimonNo ratings yet

- Technical Manual EPMDocument53 pagesTechnical Manual EPMJoel TimajoNo ratings yet

- JMS 416 GS - 1451 KWDocument6 pagesJMS 416 GS - 1451 KWemamul613No ratings yet

- BOQ For GensetDocument6 pagesBOQ For GensetPritam MitraNo ratings yet

- 1 Trent 1000 - Pocket GuideDocument57 pages1 Trent 1000 - Pocket GuideJuan Lozano100% (3)

- Lrs Resistencia Liquid StarterDocument45 pagesLrs Resistencia Liquid StarterQ Llanos HenryNo ratings yet

- 06.PS135 AC Brochure MinDocument2 pages06.PS135 AC Brochure Mindanny nugrohoNo ratings yet

- Alternador AVK - DSG DIG Instalacion Servicio y MantenimientoDocument595 pagesAlternador AVK - DSG DIG Instalacion Servicio y MantenimientoMartin FloresNo ratings yet

- 630 Kva Emmvee GTPDocument3 pages630 Kva Emmvee GTPGurudas SwainNo ratings yet

- Technical Data Ig ArgoniteDocument2 pagesTechnical Data Ig ArgoniteTun JebatNo ratings yet

- 1600 Kva GTPDocument3 pages1600 Kva GTPBADRI VENKATESHNo ratings yet

- Board - Load DetailsDocument6 pagesBoard - Load DetailsvikasmikkuNo ratings yet

- Motor (Leeson) Cooler Acite Bombas HidracellDocument5 pagesMotor (Leeson) Cooler Acite Bombas HidracellycuncanchonNo ratings yet

- Offer For 150 KVA SubstationDocument6 pagesOffer For 150 KVA SubstationSajib BhowmikNo ratings yet

- CHECK LIST FOR FIRE PUMP NFPA 20 SYSTEMSDocument2 pagesCHECK LIST FOR FIRE PUMP NFPA 20 SYSTEMSsaus sambalNo ratings yet

- Inv - Comments 14 56Document43 pagesInv - Comments 14 56sridhar_gandra1253No ratings yet

- Farady Spec 3.75MVADocument2 pagesFarady Spec 3.75MVAJoel Alevxandr OsorttoNo ratings yet

- 1600KVA GTP & DrawingsDocument8 pages1600KVA GTP & DrawingsDarshit VyasNo ratings yet

- 4000kVA Technical Submittal IEC76Document7 pages4000kVA Technical Submittal IEC76Bilal KhalidNo ratings yet

- Comprehensive guide to air-cooled diesel generatorsDocument31 pagesComprehensive guide to air-cooled diesel generatorslliu yunNo ratings yet

- High-quality generator sets with comprehensive testing and protection featuresDocument4 pagesHigh-quality generator sets with comprehensive testing and protection featuresfirman harianjaNo ratings yet

- 100 KvaDocument4 pages100 KvaAndi AnchaNo ratings yet

- Schedule No 1 Plant Including MandatoryDocument33 pagesSchedule No 1 Plant Including MandatoryHossam AlzubairyNo ratings yet

- Reliable 100kVA Generating Set Features Comprehensive ProtectionDocument4 pagesReliable 100kVA Generating Set Features Comprehensive Protectiongirindra yudhaNo ratings yet

- Lovol 100 KVADocument4 pagesLovol 100 KVAgirindra yudhaNo ratings yet

- 1LIT480005T0012 - R00 - Data SheetDocument2 pages1LIT480005T0012 - R00 - Data SheetflofikNo ratings yet

- fiches techniquesDocument30 pagesfiches techniquesnajib elhakymNo ratings yet

- Technical Sche 1500T ModifiedDocument21 pagesTechnical Sche 1500T Modifiedkbl11794No ratings yet

- 20 Kva Perkins Meccalte Acoustic Diesel Generator: DimensionsDocument2 pages20 Kva Perkins Meccalte Acoustic Diesel Generator: DimensionsihsanjuNo ratings yet

- 011 Chapter 9Document10 pages011 Chapter 9xiaomiNo ratings yet

- Pulsar Generator Information ChecklistDocument3 pagesPulsar Generator Information ChecklistDaniel Alejandro Hernandez ToldoNo ratings yet

- PR01115Document1 pagePR01115DILNo ratings yet

- Sr. No. Item Description MakeDocument10 pagesSr. No. Item Description MakePritam SinghNo ratings yet

- Troubleshoot turbocharger issuesDocument20 pagesTroubleshoot turbocharger issuesKomatsu Perkins HitachiNo ratings yet

- 500 Kva Perkins Newage Diesel Generator: DimensionsDocument2 pages500 Kva Perkins Newage Diesel Generator: DimensionsRifky ZuliansyahNo ratings yet

- 1 TransformerDocument3 pages1 TransformerSyed Noman AhmedNo ratings yet

- TK20 Series Tank Controller Provides Realistic Sound and MovementDocument55 pagesTK20 Series Tank Controller Provides Realistic Sound and MovementherrysugarNo ratings yet

- E-380kVA KOEL DG Set drg.-R1 15.09.2022Document2 pagesE-380kVA KOEL DG Set drg.-R1 15.09.2022Electrical RadicalNo ratings yet

- BOQ For GensetDocument2 pagesBOQ For GensetPritam MitraNo ratings yet

- Water Cooled Unit and Electronics - TranspoDocument18 pagesWater Cooled Unit and Electronics - TranspoHenriqueNo ratings yet

- Mooney Maintenance Inspection GuideDocument7 pagesMooney Maintenance Inspection Guidesandy0% (1)

- DG SetDocument4 pagesDG SetabhishitewariNo ratings yet

- 07 Catalog Krisbow9 GensetDocument14 pages07 Catalog Krisbow9 GensetEnrique da Matta100% (1)

- 1500 Kva Technical SubmittalDocument7 pages1500 Kva Technical SubmittalFaheem RoyNo ratings yet

- Ge - PK.1380.1250.SS 0 10 11 12 13Document8 pagesGe - PK.1380.1250.SS 0 10 11 12 13Callany AnycallNo ratings yet

- Sos (5G 4M C) - ZK77Document90 pagesSos (5G 4M C) - ZK77ariyakkannaaNo ratings yet

- Mitsubish Engine 6D34 PDFDocument292 pagesMitsubish Engine 6D34 PDFkyaw89% (9)

- Generator Guide: Home and Portable Open Frame ModelsDocument15 pagesGenerator Guide: Home and Portable Open Frame ModelsharisNo ratings yet

- InsulationDocument5 pagesInsulationjaleelNo ratings yet

- Trouble Shooting Dewatering PumpDocument136 pagesTrouble Shooting Dewatering PumpMuhammad NoorNo ratings yet

- (A8TR1) گیربکس اتومات هیوندا سنتنیالDocument43 pages(A8TR1) گیربکس اتومات هیوندا سنتنیالمحمد قراگوزلو100% (1)

- Perkins 150 KVADocument4 pagesPerkins 150 KVAsigit aryantoNo ratings yet

- FK4220 Electrical Alternator 91Document3 pagesFK4220 Electrical Alternator 91Wagner GuimarãesNo ratings yet

- Reliable 15kVA Generator Set FeaturesDocument4 pagesReliable 15kVA Generator Set FeaturestritiluNo ratings yet

- L123277491-POR Att B-0Document5 pagesL123277491-POR Att B-0Anonymous AyDvqgNo ratings yet

- C7 Engine 950H Wheel Loader PM DocumentationDocument1 pageC7 Engine 950H Wheel Loader PM DocumentationjogremaurNo ratings yet

- 1683587578BHEL India 2Document18 pages1683587578BHEL India 2Senthil KumarNo ratings yet

- 12 MSG Anti-Corruption - enDocument64 pages12 MSG Anti-Corruption - enSenthil KumarNo ratings yet

- 14 Model 231 of Eni SpA - EngDocument21 pages14 Model 231 of Eni SpA - EngSenthil KumarNo ratings yet

- Wartsila GTC 2022 GeDocument6 pagesWartsila GTC 2022 GeSenthil KumarNo ratings yet

- Cea - Standard Technical Specification For Main Plant Package (2 500 MW)Document1,011 pagesCea - Standard Technical Specification For Main Plant Package (2 500 MW)vasudevapavanNo ratings yet

- Solar Energy Corporation of India Limited: TenderDocument528 pagesSolar Energy Corporation of India Limited: TenderSenthil KumarNo ratings yet

- PVS980-MWS Megawatt Station Flyer 3AXD50000042986 RevC EN LowresDocument4 pagesPVS980-MWS Megawatt Station Flyer 3AXD50000042986 RevC EN LowresSenthil KumarNo ratings yet

- SECI000097 609956 TechnicalDocumentDocument309 pagesSECI000097 609956 TechnicalDocumentSenthil KumarNo ratings yet

- Solar PV Grid Interactive Guidelines-TANGEDCO-2021Document33 pagesSolar PV Grid Interactive Guidelines-TANGEDCO-2021SRINIVASAN TNo ratings yet

- Contribute To The Safe Operation of A Ship Subject To The IGF CodeDocument60 pagesContribute To The Safe Operation of A Ship Subject To The IGF CodeSenthil KumarNo ratings yet

- 20200820-C3750 LeafletDocument4 pages20200820-C3750 LeafletSenthil KumarNo ratings yet

- Tiger Neo N-Type 78HL4-BDV: 605-625 WattDocument2 pagesTiger Neo N-Type 78HL4-BDV: 605-625 WattJosé Manuel Vargas HerreraNo ratings yet

- Siggberg WartsilaDocument27 pagesSiggberg WartsilaSenthil KumarNo ratings yet

- Kaj Portin - Wartsila FinlandDocument11 pagesKaj Portin - Wartsila FinlandSenthil KumarNo ratings yet

- BioLNG. Liquefied Biogas As A Viable Step Towards Emission ReductionDocument14 pagesBioLNG. Liquefied Biogas As A Viable Step Towards Emission ReductionSenthil KumarNo ratings yet

- ARES CE ARES Standard Comparison 2019Document2 pagesARES CE ARES Standard Comparison 2019Senthil KumarNo ratings yet

- TSS Eig ProformaDocument21 pagesTSS Eig ProformaAman AgrawalNo ratings yet

- Vigilohm in Healthcare PresentationDocument64 pagesVigilohm in Healthcare PresentationnooruddinkhanNo ratings yet

- I-Gard C-429em - Dsp-Ohmni - 2 - 12Document44 pagesI-Gard C-429em - Dsp-Ohmni - 2 - 12alvaro Lorca MoyaNo ratings yet

- EMCDocument10 pagesEMCTaner ErtürkNo ratings yet

- FS08 - ELEC - SCH HDocument34 pagesFS08 - ELEC - SCH Hlkt_pestechNo ratings yet

- Vigilohm Insulation MonitorDocument95 pagesVigilohm Insulation MonitorAsanka Niroshan SamaranayakeNo ratings yet

- 9-3 SANS10292 - dss-2Document36 pages9-3 SANS10292 - dss-2dvanheerden2194100% (4)

- Melfa Handleiding ENG PDFDocument484 pagesMelfa Handleiding ENG PDFtmanNo ratings yet

- Frequently Asked Questions: Wiring RulesDocument21 pagesFrequently Asked Questions: Wiring RulesRashdan HarunNo ratings yet

- Design and Built Needs StatementDocument175 pagesDesign and Built Needs StatementKNS CSBNo ratings yet

- Electricity ReportDocument42 pagesElectricity ReportNik TahNo ratings yet

- Lightning CalculationsDocument48 pagesLightning Calculationsbuntysurat83% (6)

- Earthing SystemDocument14 pagesEarthing SystemNelson A. García RodríguezNo ratings yet

- H 046 006153 00 iPM Service Manual 1.0 PDFDocument130 pagesH 046 006153 00 iPM Service Manual 1.0 PDFSardhara TrusharNo ratings yet

- Earthing and Lightning Protection Product CatalogueDocument64 pagesEarthing and Lightning Protection Product CatalogueZzzdddNo ratings yet

- Design of Earthing System For A Substation: A Case StudyDocument6 pagesDesign of Earthing System For A Substation: A Case StudyHimanshu RanjanNo ratings yet

- Chapter 2. Earthing Systems-Rev1 PDFDocument54 pagesChapter 2. Earthing Systems-Rev1 PDFHasan JomaaNo ratings yet

- 0109 Specification For Earthing FINALDocument15 pages0109 Specification For Earthing FINALhardeepsingh_08No ratings yet

- Buyers Guide HV Live Tank Circuit Breakers Ed5 en PDFDocument126 pagesBuyers Guide HV Live Tank Circuit Breakers Ed5 en PDFaalisafaNo ratings yet

- Mxd-K+an Ahu+Kit Installatin+Manual Db68-03711a-04 English 160706Document40 pagesMxd-K+an Ahu+Kit Installatin+Manual Db68-03711a-04 English 160706El Ajiaco BikeNo ratings yet

- Grounding - 3 PhaseDocument4 pagesGrounding - 3 PhaseMrNo ratings yet

- Operation Manual: Smart-UPS On-Line SRT Uninterruptible Power SupplyDocument37 pagesOperation Manual: Smart-UPS On-Line SRT Uninterruptible Power SupplyKudzaishe MutambaneshiriNo ratings yet

- Electrical Drawing Checklist GuideDocument13 pagesElectrical Drawing Checklist GuideMehboob Alam100% (1)

- HPE - NonStop I NS2300 and NS2400 Site Planning GuideDocument72 pagesHPE - NonStop I NS2300 and NS2400 Site Planning GuideAdminNo ratings yet

- 1009 00 PP Ten 2020 - d1 (Vol III) Technical Part9 E&i SpecificationDocument300 pages1009 00 PP Ten 2020 - d1 (Vol III) Technical Part9 E&i SpecificationRashmi Ranjan MohantyNo ratings yet

- Lighting Circuits Guide: Selection, Dimensioning and Management With Simple SolutionsDocument76 pagesLighting Circuits Guide: Selection, Dimensioning and Management With Simple Solutionsjiwani87100% (1)

- 6-P-173 - 220 KV IsolatorsDocument23 pages6-P-173 - 220 KV IsolatorsSarmad HussainNo ratings yet

- Earthing Systems ExplainedDocument14 pagesEarthing Systems ExplainedShaista MalikNo ratings yet

- 22kV Kiosk Distribution Substation - Scope of WorksDocument82 pages22kV Kiosk Distribution Substation - Scope of WorksMauricio SaulNo ratings yet

- Schneider Electric Seminar on LV Power Concepts and DevicesDocument51 pagesSchneider Electric Seminar on LV Power Concepts and DevicesSihamaSihamNo ratings yet