Professional Documents

Culture Documents

L123277491-POR Att B-0

Uploaded by

Anonymous AyDvqgCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

L123277491-POR Att B-0

Uploaded by

Anonymous AyDvqgCopyright:

Available Formats

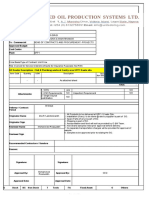

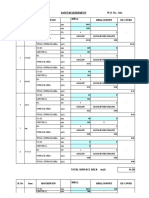

Customer COVANTA ENERGY

Station Pasco County Solid Waste Resource Facility

Site Address Pasco County, Florida

Proposal No. 22447S

Project Status "A" - Firm

Job No. T12327

General

Complete Condenser Yes

Modules No

Full Fab or Flat Pack Full Fab

Partial component supply Full Fab

General

No. of Units 1

Single Pressure or Multi-Pressure Single Pressure

Condenser Type Downward Exhaust

Shell Type Cylindrical

No. of Shells per Unit 1 This is a single shell, single pressure design.

No. of Bundles per Shell 1

Flow Type Non-Divided Flow

No. of Passes 2

General

Duplicate No

Foreign Material Allowed Yes Material Origin to be informed to TEi

Field Service Required - TEi No

# of Days / Roundtrips Days Trips

Field Service Required - Vendor No

# of Days / Roundtrips Days Trips

Shipping

INCO Terms FOB- Free On Board

Shipping Address Port of Export

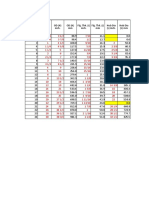

Site/Port Date Manufacturer Destination Qty (Per Shell) Delivery Date

Hotwell Port of Export Whole Complete Condenser to be shipped in single piece.

Transition Additional Trasition pieace to be supplied loose per GA

Extended Neck Port of Export Whole

Shells (Bundles)

Waterboxes

Ship Loose

Accessories

Shipping Weight (includes 5%) - Unitary Weight Lbs Kgs

Complete Condenser shop assembled 94,500 42,865 Complete condenser weight including shell, bundle, hotwell, transition,

Transition waterboxes. Complete assembled condenser to be shipped in signle piece.

Extended Neck Half

Shell

Waterboxes (In-Out & Reversing)

Ship Loose - Transition piece 3,800 1,724 Transition piece to be shipped loose as per GA

Method Truck / Barge

Job Site Rail Spur Available No

Shipping Protection Seaworthy

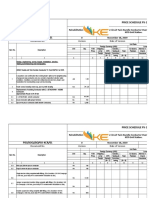

Codes and Standards

HEI Yes

PED No

Additional Design Standards N/A

Sub

By Tei By Sub Comment

Confirm

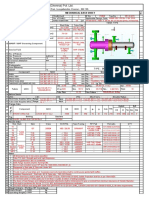

Tubes Main Bundle Air Drawoff Impingement

Tube Material Cu-Ni 90-10 Cu-Ni 90-10 Cu-Ni 70-30

Tube Additional Specification Included Yes

Tube OD 0.75"

Tube Gauge (BWG) 20 20 18

Wall Thickness (Avg. or Min.) Avg. Avg. Avg.

Tube Quanity per Zone 2,512 118 160 X Tubes to be procured by fabricator

Tube Quantity (without Spares) 2,790

Indicative only, fabricator to decide spares

No. of Spare Tubes 0 tubes Qty.

Tubes to be procured by fabricator. Refer

Total Tube Quantity (without Spares) per SHELL 2,790 X BOM for mock-up tubes qty.

The tubes quantity mentioned are without

Total Tube Quantity (without Spares) per UNIT 2790 X any spares, fabricator to decide the spares

tube per their experience.

Actual required length, fabricator to decide if

Total Tube Length 311" extra length to be required.

Tube to Tubesheet Joint Rolled Only X

Impingement Rods Yes X

No. of Impingement Rod Rows 3

Impingement Rod Pattern Top Row / Upper Sides

Shop or Field Installed Tubes Shop X

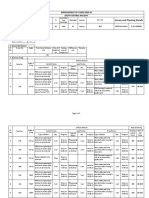

Tubesheet

Material Cu-Ni 90-10 X

Refer BOM, Tubesheet to be consider

Base Material (in) 1.25

single piece

Clad Material Thickness (in) 0

Total Thickness (in) 1.25

No. of Grooves N/A

Mock up to be done at shop before starting

Tubesheet Mockup Yes X of expansion on actual job

Tubesheet Additional Specification No

Tubesheet to Shell Frame Joint Bolted X

Tubesheet to Waterbox Joint Bolted X

Tubesheet to Shell Frame Gasket Yes X

Tubesheet to Waterbox Gasket Yes X

Support Plates Qty Thickness

Main Support Plates (per Bundle) 11 0.5" X Refer BOM

Intermediate Support Plates (per Bundle)

Total No. of Support Plates per Shell 11 X Per Condenser; 1 Condenser Required

Total No. of Support Plates per Unit 11 X Total

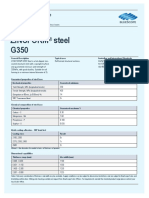

Material SA 516-70 Carbon Steel X

Support Plate Spacing - Center Span 26"

Support Plate Spacing - End Span 24.25"

Shell

Material SA 516-70 Carbon Steel X

Thickness 0.5" Refer BOM

Transition

Material SA 516-70 Carbon Steel X

# of Manways / Size 1 24" X Per Condenser; 1 Condenser Required

Manway Gaskets Yes X Refer BOM

Transition to Expansion Joint/Turbine Connection Landing Bar X

Extended Neck Yes X Shall be supplied in loose condition

Extraction Piping No

Extraction Piping Lagging No

Heater in Condenser Neck No

Heater Supports No

Heater Lagging No

BFPT Exhaust Connection No

Bypass Lines Installed No

Reinforcements Pads Included Yes X Where ever required

Hotwell

Material SA 516-70 Carbon Steel X Refer BOM

# of Manways / Size 1 24" X Per Condenser; 1 Condenser Required

Manway Gaskets Yes X Refer BOM

Hotwell Splitter Plate No

Retention Plate No

False Bottom Plate / Reheat Trays No

Condensate Outlet Type Individual Sumps X

Foundation Supports

Springs No

Solid Foundation Yes X Refer BOM (Included in Hotwell BOM)

Teflon Pads Yes X Refer BOM (Included in Hotwell BOM)

Sole Plates / Shear Keys No

Anchor Bolts No

Waterboxes

Material SA 516-70 Carbon Steel X Refer BOM

# of Manways / Size 3 24" X Per Condenser; 1 Condenser Required

Manway Gaskets Yes X Refer BOM

Refer BOM. Per Condenser; 1 set required

Waterbox Gaskets Yes X

for installation

Manway Screens No

Personnel Screens No

Cross-over Piping No

Cross-over Nuts and Bolts No Qty

Tube Bundle

Tube Leak Detection Trays Yes X

Tube Leak Detection Analyzers and Sensors No

Materials - Internal

Vent Duct and Air Draw off piping Carbon Steel X Refer BOM

Bypass Lines NA

Spargers and Baffles NA

Major Nozzle Connections (per Shell) Qty Size

Circulating Water Inlet 1 24" X Per Condenser; 1 Condenser Required

Circulating Water Outlet 1 24" X Per Condenser; 1 Condenser Required

Condensate Outlet 2 6" X Total

HP / HRH Bypass

IP Bypass

LP / CRH Bypass

Air Drawoff 1 5" X Per Condenser; 1 Condenser Required

Additional Nozzles Qty Size

Misc. #1 X

Misc. #2 Refer Condenser Outline Drawing (2327-D01)/ X

Misc. #3 X

Misc. #4 Connection List (2327-D02) X

Misc. #5 X

Coatings

Shell / Waterbox Exterior Inorganic Zinc X

Specific Brand Cust. Spec: No X Vendor to inform

Shell Interior - Rust Preventative Yes Cust. Spec: No X Dubois Rust Inhibitor

Waterbox - Interior Coal Tar Epoxy X

Specific Brand Coal Tar Epoxy Cust. Spec: No X Vendor to inform

NDE's

Tube to Tubesheet Joint - 100% Liquid Dye Penetrant Test No

Tube to Tubesheet Joint - 100% Vacuum Leak Test Yes X

Tube to Tubesheet Joint - 100% Visual Inspection Yes X

Waterbox Hydrotest - Back to Back No

To be performed after successful Shell side

Tube Side Hydrotest Yes X waterfill test including bolted waterbox

To be performed at shop for complete

Shell Side Waterfill Test Yes X

condenser before tubeside hydrotest

Waterfill test for Transition loose piece Yes X

Accessories

Main Steam Expansion Joint Yes Stainless Steel X By TEi

Expansion

Proposed Vendor

Joints

Pass-Through Piping Expansion Joints No

Extraction Piping Expansion Joints No

Cross-over Piping Expansion Joints No

Vacuum Equipment Yes Steam Jet Air Ejectors X By TEi

Vacuum

Equip.

Proposed Vendor

Waterbox Priming System No

Proposed Vendor

Vacuum Deaerator No

Other Major

Proposed Vendor

Buyouts

Tube Cleaning System No

Proposed Vendor

Debris Filters No

Proposed Vendor

Vacuum Breaker Valves No Size

Valves

Circulating Water Nozzle Butterfly Valves No Qty / Size

Air Release Valves No Qty / Size

Atmospheric Relief Valves No Qty / Size

pressuri

zation

Over-

Rupture Disks No Qty / Size

Vent Stack(s) No

Free issue by TEI to vendor, Installation

Cathodic Protection Yes Type Sacrificial Anodes X inside WB to be in vendor scope after

successful hydrotest

No

Nuts / Bolts

Circulating Water Cross-Over Piping Qty / Size N/A

Circulating Water Nozzles No Qty / Size

Main Steam Inlet Expansion Joint to Transition No Qty / Size

Main Steam Inlet Expansion Joint to Steam Turbine No Qty / Size

Basket Tips Yes X

Instrumentation

Gauge Glass No No

Thermocouples No No

Thermowells No No

Temperature Gauge No No

Pressure Gauge No No

Leak Detection Conductivity Cells No No

Root Valves No

Tubes (to site) No Qty

Spares

Tube Details: 3/4" OD, Cu/Ni 20 BWG

54 Nos Type 1 (Type 1) / 18 BWG (Type 2) tubes.

Tube Plugs Yes Qty X

4 Nos Type 2 Plug Material: Silicon (Double Plug)

Spares

Make: HEPCO

Tube Expander, Mandrells, Tube Collapsing Tool, Tube puller Yes Qty Yes X 1 Set to be provided

Manway Gaskets Yes Qty / Size 1 Set X

Waterbox Gaskets No Qty

Rupture Disks No Qty / Size

Anodes No Qty

Nuts & Bolts Yes Qty X 10% of Water Box bolts quantity

Miscellaneous

Earthing terminal lug & pad No

Name plate and labeling Yes X

Reinforced Blanking Plate No

Misc

Impingement Angles No

Impingement Shields No

Gasket - Expansion Joint to Condenser No

Gasket - Expansion Joint to Steam Turbine No

Transition Flange instead of Landing Bar No

Additional Project Scope

Classroom Training No Days / Trips

1. Refer Condenser BOM & Drawings for more details. Condenser Shell side to be 1st waterfill tested and finally tubeside to be Hydro- tested

as per the test pressure mentioned in GAD.

Remarks 2. Compete condenser (including shell, hotwell, waterbox, transition) shall be transported as a single piece.

3. Transition Piece (Shaded yellow in transition BOM), shall be shipped as a loose items along with other miscellaneous item

4. 100% Tube to tubesheet joint to be tested by Vacuum Leak Test at shop.

NOTE: ALL OF THE ABOVE DIMENSIONS ARE IN ENGLISH UNITS

You might also like

- Well Completion or Recompletion Report and Well LogDocument2 pagesWell Completion or Recompletion Report and Well LogJati LionNo ratings yet

- Page 1 of 3Document3 pagesPage 1 of 3DILNo ratings yet

- Item Code Quantity UOM Description Stock / Non Stock Item Estimated Unit Cost N Total Cost NDocument42 pagesItem Code Quantity UOM Description Stock / Non Stock Item Estimated Unit Cost N Total Cost NDILNo ratings yet

- Hoja de Datos - Válvula Modelo WDCLDocument9 pagesHoja de Datos - Válvula Modelo WDCLEnriqueAzuaraNo ratings yet

- Well Completion or Re-Completion ReportDocument2 pagesWell Completion or Re-Completion ReportTheophile IZERENo ratings yet

- 50 MVA Trfo-2Document6 pages50 MVA Trfo-2p m yadavNo ratings yet

- Item Code Quantity UOM Description Stock / Non Stock Item Estimated Unit Cost ($) Total Cost ($)Document2 pagesItem Code Quantity UOM Description Stock / Non Stock Item Estimated Unit Cost ($) Total Cost ($)DILNo ratings yet

- Reem Takrouri PDF - Results PDFDocument5 pagesReem Takrouri PDF - Results PDFريم تكروريNo ratings yet

- Schedule of Prices For 220 KV Double CKT Twin Bundle BQPS - KCR (OH & UGTL) & Grid WorksDocument143 pagesSchedule of Prices For 220 KV Double CKT Twin Bundle BQPS - KCR (OH & UGTL) & Grid WorksShan UL Haq RehmaniNo ratings yet

- Item Code Quantity UOM Description Stock / Non Stock Item Estimated Unit Cost ($) Total Cost ($)Document2 pagesItem Code Quantity UOM Description Stock / Non Stock Item Estimated Unit Cost ($) Total Cost ($)DILNo ratings yet

- Weekly Status 131222Document3 pagesWeekly Status 131222Vedatma BhoyrooNo ratings yet

- Rig Vessel Approach CertificationDocument3 pagesRig Vessel Approach Certificationeng7mohamed7hashimNo ratings yet

- WesTech Clarifier QuestionnaireDocument1 pageWesTech Clarifier QuestionnaireCarlos TovarNo ratings yet

- Item Code Quantity UOM Description Stock / Non Stock Item Estimated Unit Cost ($) Total Cost ($)Document2 pagesItem Code Quantity UOM Description Stock / Non Stock Item Estimated Unit Cost ($) Total Cost ($)DILNo ratings yet

- WellPlan ReportDocument10 pagesWellPlan ReportManuel Osorio ReginoNo ratings yet

- Wartsila 7.085MWDocument26 pagesWartsila 7.085MWSenthil KumarNo ratings yet

- Data Requirement SheetDocument1 pageData Requirement SheetganeshkumarbemechNo ratings yet

- Hrol - 19DVG41G43 700RTDocument5 pagesHrol - 19DVG41G43 700RTGohds100% (1)

- C150197 - Section 4B Part II - ...Document37 pagesC150197 - Section 4B Part II - ...Iswanto STNo ratings yet

- FM-087 Plant Pre Acceptance Checklist - APS042 Skid SteerDocument2 pagesFM-087 Plant Pre Acceptance Checklist - APS042 Skid SteerWenceslao JaimesNo ratings yet

- N2 Package - Post Bid Clarifications - Round 1 (Atlas Copco)Document5 pagesN2 Package - Post Bid Clarifications - Round 1 (Atlas Copco)Naveedullah AwanNo ratings yet

- Lifting Plan For 62.07 RepairDocument6 pagesLifting Plan For 62.07 RepairLaith Salman100% (1)

- PR01115Document1 pagePR01115DILNo ratings yet

- BOQ - Hopper Countainer - R0Document2 pagesBOQ - Hopper Countainer - R0Ekky RiksawanNo ratings yet

- Village Sanitation Profile-1Document5 pagesVillage Sanitation Profile-1sureshNo ratings yet

- LESER High Efficiency Catalog enDocument68 pagesLESER High Efficiency Catalog enandy131078No ratings yet

- Rigless, A Misnomer?: Applications To Late Well LifecyclesDocument32 pagesRigless, A Misnomer?: Applications To Late Well LifecyclesRizwan FaridNo ratings yet

- BOQ - SL TC - 682 Turbina Tower Corrective BOQ SIDocument4 pagesBOQ - SL TC - 682 Turbina Tower Corrective BOQ SIJohn Kenedy Hernandez CasapaoNo ratings yet

- Purchase Order (PR) 27-Mar-21 UOPSL-GPP1-OP-PUR-213 Operations & MaintenanceDocument6 pagesPurchase Order (PR) 27-Mar-21 UOPSL-GPP1-OP-PUR-213 Operations & MaintenanceDILNo ratings yet

- Api - Standard PardDocument116 pagesApi - Standard Pardঅর্ফিয়াস ইকারাসNo ratings yet

- TE-OS Y-FinalDocument10 pagesTE-OS Y-FinalShem Kirby TrayvillaNo ratings yet

- Philippine Merchant Marine School 1571 Lope de Vega Street, Sta. Cruz, Manila, PhilippinesDocument21 pagesPhilippine Merchant Marine School 1571 Lope de Vega Street, Sta. Cruz, Manila, PhilippinesRelvin VallesteroNo ratings yet

- Cargo Ship-Shore Additional Agreements LoadingDocument6 pagesCargo Ship-Shore Additional Agreements Loading898n6fxsrwNo ratings yet

- High Efficiency Catalog US PDFDocument68 pagesHigh Efficiency Catalog US PDFvelmuruganNo ratings yet

- Cost Drilling 2 FDPDocument3 pagesCost Drilling 2 FDPZuhairi ZakariaNo ratings yet

- Plant 1S2E Section 4.1 - TL Herat To Shindand BOQ - July 22Document11 pagesPlant 1S2E Section 4.1 - TL Herat To Shindand BOQ - July 22Rakshit KumarNo ratings yet

- Project Name: Myanmar Aquarium Project: 1 Year 150Document3 pagesProject Name: Myanmar Aquarium Project: 1 Year 150mcgNo ratings yet

- RFP Screening TemplateDocument1 pageRFP Screening TemplateGbengaNo ratings yet

- Item Code Quantity UOM Description Stock / Non Stock Item Estimated Unit Cost ($) Total Cost ($)Document6 pagesItem Code Quantity UOM Description Stock / Non Stock Item Estimated Unit Cost ($) Total Cost ($)DILNo ratings yet

- BDN 29.11.2021Document1 pageBDN 29.11.2021Fahrul Ajie ImansyahNo ratings yet

- AG25 5 Sea Trial Review FormDocument4 pagesAG25 5 Sea Trial Review FormLin LinNo ratings yet

- Pipe Description: Line Pipe Coating Recommendation FormDocument1 pagePipe Description: Line Pipe Coating Recommendation FormkalaiNo ratings yet

- Project Name: Myanmar Aquarium Project: 1 Year 106Document3 pagesProject Name: Myanmar Aquarium Project: 1 Year 106Yati ChanNo ratings yet

- JKO Yard Improvements Survey DSCDocument3 pagesJKO Yard Improvements Survey DSCraju aketiNo ratings yet

- LRF-3 Transformer Comparision (SMS-1)Document2 pagesLRF-3 Transformer Comparision (SMS-1)SOUMENNo ratings yet

- Towing Operations (Appendix)Document3 pagesTowing Operations (Appendix)evrim korıNo ratings yet

- Bill of Quantity Electrical WorksDocument1 pageBill of Quantity Electrical WorksXtra BabeNo ratings yet

- Well Information Data Sheet - Swellable: Application Overview Input: CommentsDocument1 pageWell Information Data Sheet - Swellable: Application Overview Input: CommentshafeezNo ratings yet

- Data Sheet Ejector PDFDocument1 pageData Sheet Ejector PDFdonyaNo ratings yet

- Checklist For Preliminary Bridge DesignDocument2 pagesChecklist For Preliminary Bridge DesignbkgossNo ratings yet

- Final Revised Check List For Investigation of Uncoupling CasesDocument31 pagesFinal Revised Check List For Investigation of Uncoupling CasesSantosh KumarNo ratings yet

- BB Local ChargesDocument1 pageBB Local ChargesCarolina GuerreroNo ratings yet

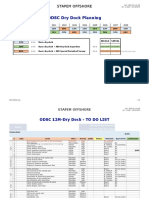

- MAR-FO-141-EN-1 ODSC - Dry Dock - ToDoListDocument6 pagesMAR-FO-141-EN-1 ODSC - Dry Dock - ToDoListNarvalNo ratings yet

- BOQ For GensetDocument6 pagesBOQ For GensetPritam MitraNo ratings yet

- Standard Is at Ion of Tugs - VesselsDocument3 pagesStandard Is at Ion of Tugs - VesselsejasmudarNo ratings yet

- Plant 1S2E Section 4.1 - TL Shindand To Farah BOQ - July 22Document12 pagesPlant 1S2E Section 4.1 - TL Shindand To Farah BOQ - July 22Rakshit KumarNo ratings yet

- Item Code Quantity UOM Description Stock / Non Stock Item Estimated Unit Cost ($) Total Cost ($)Document2 pagesItem Code Quantity UOM Description Stock / Non Stock Item Estimated Unit Cost ($) Total Cost ($)DILNo ratings yet

- Handbook of Heating, Ventilating and Air ConditioningFrom EverandHandbook of Heating, Ventilating and Air ConditioningRating: 4 out of 5 stars4/5 (6)

- The Instant Handbook of Boat Handling, Navigation, and Seamanship: A Quick-Reference Guide for Sail and PowerFrom EverandThe Instant Handbook of Boat Handling, Navigation, and Seamanship: A Quick-Reference Guide for Sail and PowerRating: 5 out of 5 stars5/5 (1)

- H2065FAD2017SH03OF04Document1 pageH2065FAD2017SH03OF04Anonymous AyDvqgNo ratings yet

- Gin Numbegin Descrigin Date (Dproject Co Vendor Deitem Code Item Nameitem Descritem Type LocationDocument4 pagesGin Numbegin Descrigin Date (Dproject Co Vendor Deitem Code Item Nameitem Descritem Type LocationAnonymous AyDvqgNo ratings yet

- H2065FAD2017SH01OF04Document1 pageH2065FAD2017SH01OF04Anonymous AyDvqgNo ratings yet

- Absolute PressureDocument2 pagesAbsolute PressureAnonymous AyDvqgNo ratings yet

- MFG - Patch Release - Version - 17.59Document4 pagesMFG - Patch Release - Version - 17.59Anonymous AyDvqgNo ratings yet

- L123277491-POR Att C-0Document5 pagesL123277491-POR Att C-0Anonymous AyDvqgNo ratings yet

- FnA - Patch Release - Version - 17.59Document2 pagesFnA - Patch Release - Version - 17.59Anonymous AyDvqgNo ratings yet

- Code InterpretationDocument1 pageCode InterpretationAnonymous AyDvqgNo ratings yet

- 30 Surface Area CalculationDocument8 pages30 Surface Area CalculationAnonymous AyDvqgNo ratings yet

- Design Tentative Week PlanDocument10 pagesDesign Tentative Week PlanAnonymous AyDvqgNo ratings yet

- Precision Equipments (Chennai) Pvt. LTD.: Design Data Tema TypeDocument2 pagesPrecision Equipments (Chennai) Pvt. LTD.: Design Data Tema TypeAnonymous AyDvqgNo ratings yet

- 0 1 2 Sl. No. 4 Page No. Latest Page Revision 3Document1 page0 1 2 Sl. No. 4 Page No. Latest Page Revision 3Anonymous AyDvqgNo ratings yet

- Torispherical Dish Height CalculationDocument3 pagesTorispherical Dish Height CalculationAnonymous AyDvqgNo ratings yet

- Weight CalculationDocument24 pagesWeight CalculationAnonymous AyDvqgNo ratings yet

- CG of Equipments Item No. 16-XS 101ABDocument3 pagesCG of Equipments Item No. 16-XS 101ABAnonymous AyDvqgNo ratings yet

- Precision Equipments (Chennai) Pvt. Ltd. Plot No.B-70/1, Sipcot Industrial Park, Irrungattukottai, Chennai - 602105. Mechanical Data SheetDocument1 pagePrecision Equipments (Chennai) Pvt. Ltd. Plot No.B-70/1, Sipcot Industrial Park, Irrungattukottai, Chennai - 602105. Mechanical Data SheetAnonymous AyDvqgNo ratings yet

- 44.lifting Lug With Collar CalculationDocument44 pages44.lifting Lug With Collar CalculationAnonymous AyDvqg100% (1)

- 35.weight Full Fo Water CalculatorDocument6 pages35.weight Full Fo Water CalculatorAnonymous AyDvqgNo ratings yet

- LWNRF WeightDocument24 pagesLWNRF WeightAnonymous AyDvqgNo ratings yet

- 37.SRN Nozzle ProjectionDocument1 page37.SRN Nozzle ProjectionAnonymous AyDvqgNo ratings yet

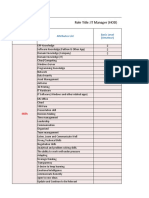

- Role Title: IT Manager (HOD) : Iceberg Elements Attributes List Basic Level (Amateur)Document6 pagesRole Title: IT Manager (HOD) : Iceberg Elements Attributes List Basic Level (Amateur)Anonymous AyDvqgNo ratings yet

- Meeting Attendence RecordDocument4 pagesMeeting Attendence RecordAnonymous AyDvqgNo ratings yet

- Flange Input Data Values Description: FLGDocument4 pagesFlange Input Data Values Description: FLGAnonymous AyDvqgNo ratings yet

- 1 WeightDocument4 pages1 Weightmiteshpatel191No ratings yet

- Mechanical Standards Tema Class R C B Section 5: ®tubular Exchanger Manufacturers Association, IncDocument1 pageMechanical Standards Tema Class R C B Section 5: ®tubular Exchanger Manufacturers Association, IncAnonymous AyDvqgNo ratings yet

- Calculation Template Status SL - No. Document No. Description Revision NoDocument15 pagesCalculation Template Status SL - No. Document No. Description Revision NoAnonymous AyDvqgNo ratings yet

- Certification of Manufacturer Design Report - RegDocument1 pageCertification of Manufacturer Design Report - RegAnonymous AyDvqgNo ratings yet

- Certificate of Authorization: Precision Equipments (Chennai) Private LimitedDocument1 pageCertificate of Authorization: Precision Equipments (Chennai) Private LimitedAnonymous AyDvqgNo ratings yet

- Certificate of Authorization: Precision Equipments (Chennai) Private LimitedDocument1 pageCertificate of Authorization: Precision Equipments (Chennai) Private LimitedAnonymous AyDvqgNo ratings yet

- 20b GT PART2 PDFDocument178 pages20b GT PART2 PDFHANIF AKBARNo ratings yet

- 3m Adhesive Sealant BrochureDocument6 pages3m Adhesive Sealant BrochureJP anonymousNo ratings yet

- Paper Cutting MachineDocument10 pagesPaper Cutting MachineApoorv BansalNo ratings yet

- Knife Making ProcessDocument18 pagesKnife Making ProcessPinjaman Peribadi67% (3)

- Friction Stir Welding ReportDocument35 pagesFriction Stir Welding ReportTelvinNo ratings yet

- Welder ListDocument2 pagesWelder ListYulian AdhriansyahNo ratings yet

- Shielded Metal Arc WeldingDocument33 pagesShielded Metal Arc WeldingAit Biñan100% (3)

- New Microsoft Office Excel WorksheetDocument2 pagesNew Microsoft Office Excel Worksheetg_sanchetiNo ratings yet

- BgasslideshowDocument55 pagesBgasslideshowAdil Hasanov100% (1)

- Dies-3-130918074155-Phpapp02 Die3 - Design Process PDFDocument24 pagesDies-3-130918074155-Phpapp02 Die3 - Design Process PDFBong ThoNo ratings yet

- Device and Method For Adaptive Control of Blanks MachiningDocument4 pagesDevice and Method For Adaptive Control of Blanks MachiningspriditisNo ratings yet

- Shrinkage DefectsDocument11 pagesShrinkage DefectsMohsin Abbas100% (1)

- Project DescriptionDocument2 pagesProject DescriptionArgha PaulNo ratings yet

- Tankguard Plus Jotun PaintDocument5 pagesTankguard Plus Jotun PaintGurdeep Sungh AroraNo ratings yet

- Bulk Deformation Process Wire Rod Tube Drawing Ch6Document51 pagesBulk Deformation Process Wire Rod Tube Drawing Ch6gereNo ratings yet

- Aws d1.1 2010 Table 6.1 VT PT MTDocument1 pageAws d1.1 2010 Table 6.1 VT PT MTRonel John Rodriguez Custodio0% (1)

- EI ServicesDocument2 pagesEI ServicesAnonymous P8Bt46mk5INo ratings yet

- ZILAN-Stainless Steel Non Pressurized Solar Water Heaters Price ListDocument1 pageZILAN-Stainless Steel Non Pressurized Solar Water Heaters Price ListferkobNo ratings yet

- Causes (Curling, Buckling and Fractured)Document5 pagesCauses (Curling, Buckling and Fractured)Nur Fatin EmiliaNo ratings yet

- ME8793 Process Planning and Cost EStimation UNIT 5 NotesDocument26 pagesME8793 Process Planning and Cost EStimation UNIT 5 NotesLEO PRAVIN PNo ratings yet

- Kammprofile Gasket Grooving Machine SUNWELL E500KGM-B1574489497Document2 pagesKammprofile Gasket Grooving Machine SUNWELL E500KGM-B1574489497rinaldo KurniawanNo ratings yet

- Dry Electrodes SystemDocument8 pagesDry Electrodes SystemhamoudabiNo ratings yet

- Ornamental Sealer: Product InformationDocument4 pagesOrnamental Sealer: Product InformationGuruNo ratings yet

- Used Water SES 5 Construction of Tunnels Ancillaries 2012Document28 pagesUsed Water SES 5 Construction of Tunnels Ancillaries 2012Mark BenjieNo ratings yet

- What Weld Rod To UseDocument2 pagesWhat Weld Rod To Usesatgk0% (1)

- Intro To LPEDocument10 pagesIntro To LPEBalasahebNo ratings yet

- Steel - Continuous CastingDocument11 pagesSteel - Continuous CastingAli AzharNo ratings yet

- Cryogenic MachiningDocument16 pagesCryogenic MachiningSagar MoreNo ratings yet

- Hydraulic and Non Hydraulic CementDocument25 pagesHydraulic and Non Hydraulic CementKristan JayNo ratings yet

- 02 Cokemaking Process (54 Slides)Document54 pages02 Cokemaking Process (54 Slides)karinzzinhaNo ratings yet