Professional Documents

Culture Documents

Bucket Elevator: Mechanical Engineering Department Carlos III University

Uploaded by

Ravikanth AluriOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bucket Elevator: Mechanical Engineering Department Carlos III University

Uploaded by

Ravikanth AluriCopyright:

Available Formats

1

BUCKET ELEVATOR

Mechanical Engineering Department

Carlos III University

BUCKET ELEVATOR

TRANSPORTATION

BUCKET ELEVATOR

BUCKET ELEVATORS

Bucket elevators are the most used systems for vertical

transport of bulk, dry, wet and even liquid materials.

Designed with various options of height,

speed and constructive details depending on

the type of material to be transported.

Are constructed by pieces or units to allow to

define efficiently the needed height.

2

BUCKET ELEVATOR

COMPONENTS

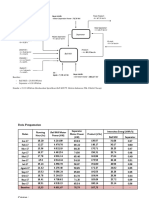

Head hood

Discharge

spout

Boot inlet hopper

Engine

Tensioning

device

Bucket

Clean

outdoors

Drive and pulley

Casing

Belt

Boot

BUCKET ELEVATOR

DEPENDING ON THE LOAD

Directly to the input hopper

By digging

Used for transport of materials that offer no resistance

to extraction, like fine grain and dusty materials.

Used for transport of abrasive and big size materials.

Chain/belt travelling speed is low.

3

BUCKET ELEVATOR

DEPENDING ON THE TYPE OF DISCHARGE

Centrifugal

It is the most common.

Great travelling speeds (1.2 and 1.4 m/s).

Loading is carried out by dredging the material at the

bottom of the elevator.

The separation distance between the buckets is 2 to 3

times the bucket height.

BUCKET ELEVATOR

DEPENDING ON THE TYPE OF DISCHARGE

Gravity or continuous

Lower travelling speeds (0.5 and 1.0 m/s).

It is taken advantage of self weight.

Classification:

Free gravity. It is necessary to change the free branch

line or incline the bucket.

Forced. The buckets are situated one after the other

without separation between them. The discharge takes

place due to gravity by means of the lower part of the

preceding bucket that acts as a discharge spout.

4

BUCKET ELEVATOR

DEPENDING ON THE TYPE OF DISCHARGE

Positive

Similar to the gravity elevator safe that

buckets are fitted at the edges with two

cords.

Bucket speed is low are appropriate for

light, aired, sticky materials.

Cords

BUCKET ELEVATOR

MATERIAL TRANSPORTED FLUX

c

P i j =

Material weight

(kg)

Bucket volume (l)

Density (kg/l)

Fill in bucket coefficient

(0,6 0,9)

3.6

c

P v

Q

t

=

Transported

material flux (t/h)

Pitch:

Standard buckets:

Flake bucket:

[ ] h h t 3 , 2

h t =

chain

t cte t =

For chains:

Bucket height

Travelling

speed (m/s)

5

BUCKET ELEVATOR

POWER

0

( )

3.6

a

Q

F H H

v

= +

The force the drive pulley needs to move the belt (kg):

Elevating height

(m)

Fictitious height

(m)

15.3 Big

11.4 Medium

7.6 Little

By digging

3.8 From the inlet hopper

Value of H

0

(m) Material size Load system

Power of the engine (CV):

75

a

a

F v

N

Engine efficiency

BUCKET ELEVATOR

MAXIMUM TENSION OF THE BELT

a a

T F k =

Maximumtension of the belt (kg):

Coefficient that

depends on the pulley

1.49 Dry layer

1.73 Humid layer

1.64 Dry smooth

3.20 Humid smooth

K Pulley conditions

6

BUCKET ELEVATOR

m

MATERIAL DISCHARGING

A

m g

m g

cos m g

m g sin

2

m v

R

2

cos

R

m v

F m g

R

=

2

cos

R

F v

m g g R

=

<

=

>

0

BUCKET ELEVATOR

O

MATERIAL DISCHARGING

2

cos

R

F v

m g g R

=

O

2

v

g R

cos

0

90

+ -

1

0

2

1

v

g R

<

2

1

cos

v

g R

Predominance of

the centrifugal

forces

2

2

cos

v

g R

Predominance of

gravity forces

7

BUCKET ELEVATOR

MATERIAL DISCHARGING

2

cos

R

F v

m g g R

=

O

2

v

g R

cos

O

0

90

+ -

2

1

v

g R

<

A

C

2

1

v

g R

=

B

BUCKET ELEVATOR

h

s

MATERIAL DISCHARGING

Pulley diameter

c g

F F =

2

V

m m g

R

=

2

V

R

g

=

Material path

2

1

2

s v t a t = +

v

s

780 480 0.4

1220 600 0.5

440 360 0.3

195 240 0.2

50 120 0.1

S

v

(m) S

h

(m) TIME (s)

v = 0.5 m/s

8

BUCKET ELEVATOR

Design the features of a belt conveyor that has

to transport dry clay of density 1700 kg/m

3

with an approximate capacity of 15t/h:

Size of the bucket

Spacing

Belt speed

Pulley diameter

EXAMPLE

BUCKET ELEVATOR

EXAMPLE

9

BUCKET ELEVATOR

EXAMPLE

Load weight=(2/3)bucket volumedensity=

(2/3)0,741700=0,84 kg per bucket

To move 15t/h we need:

(15000/0,84)=17857 buckets/h=5 buckets/s

Spacing

Pitch=[2h,3h] if bucket height is 105mm Pitch=300 mm

Belt speed=5 bucket/s 300 mm=1,5 m/s

Pulley diameter: D=2R=2(v

2

/g)=460 mm

You might also like

- Circular MotionDocument45 pagesCircular MotionJames Young100% (1)

- 04 General Frames Pedestals Lower HousingDocument13 pages04 General Frames Pedestals Lower HousingDavid Vilca MamaniNo ratings yet

- Bucket ElevatorsDocument30 pagesBucket ElevatorsarhescobarNo ratings yet

- Belt Conveyors: Mechanical Engineering Department Carlos III UniversityDocument19 pagesBelt Conveyors: Mechanical Engineering Department Carlos III UniversityAlfredo VelasquezNo ratings yet

- Chassis Design Report PDFDocument8 pagesChassis Design Report PDFPrakhar YadavNo ratings yet

- Design and Analysis of Screw ConveyorDocument21 pagesDesign and Analysis of Screw Conveyoravinash1987No ratings yet

- Special Tools: CatalogueDocument160 pagesSpecial Tools: CatalogueKot8780% (1)

- Owner's Manual For Porsgrunn Rotary Vane Steering Gear S-1995Document124 pagesOwner's Manual For Porsgrunn Rotary Vane Steering Gear S-1995O olezhaod100% (4)

- Sae J500 EstriadosDocument2 pagesSae J500 EstriadosMarcel Dandaro100% (1)

- Belt Bucket Elevator DesignDocument14 pagesBelt Bucket Elevator Designking100% (1)

- 09 - C - Belt Conveyor SelectionDocument22 pages09 - C - Belt Conveyor SelectionaldoarthoNo ratings yet

- Screw ConveyorDocument7 pagesScrew ConveyorTots HolaresNo ratings yet

- Ball MillDocument23 pagesBall MillSajjad Rasool ChaudhryNo ratings yet

- Igcse/O Level Add Maths Vectors (Constant Velocity) Past PapersDocument13 pagesIgcse/O Level Add Maths Vectors (Constant Velocity) Past PapersKiefer Ansel OBBOHNo ratings yet

- Comminution 2Document159 pagesComminution 2Kumar RajeshNo ratings yet

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshFrom EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNo ratings yet

- Pipe Conveyor: Sheet 1 of 3Document3 pagesPipe Conveyor: Sheet 1 of 3Ravi KumarNo ratings yet

- 5,000,000 Kilowatts of Installed ExpertiseDocument16 pages5,000,000 Kilowatts of Installed ExpertiseRahul RoyNo ratings yet

- FLSPfister IB05000 I GBTRWSD0216 MailDocument26 pagesFLSPfister IB05000 I GBTRWSD0216 MailLuis Angel BusturiaNo ratings yet

- IPCC ConceptDocument24 pagesIPCC ConceptTapadev DasNo ratings yet

- Services For Bulk Material Handling Projects: Project Formulation Phase Project Engineering PhaseDocument29 pagesServices For Bulk Material Handling Projects: Project Formulation Phase Project Engineering PhasesrichmechNo ratings yet

- SinomaDocument52 pagesSinomansprasad88No ratings yet

- 1.1 Design Features of Bucket Elevator: Package M10: Auxiliary Equipment - Maintenance and RepairDocument56 pages1.1 Design Features of Bucket Elevator: Package M10: Auxiliary Equipment - Maintenance and RepairDilnesa EjiguNo ratings yet

- Partlist SF Series PDFDocument36 pagesPartlist SF Series PDFsofyan100% (1)

- Packer Machine (Ia)Document34 pagesPacker Machine (Ia)Safi'i AchmadNo ratings yet

- Bixby MaxFire HighlightsDocument6 pagesBixby MaxFire HighlightsAl Malley100% (2)

- Rex High Performance Chain Bucket Elevator - Manual PDFDocument170 pagesRex High Performance Chain Bucket Elevator - Manual PDFJohnNo ratings yet

- Bucket ElevatorsDocument11 pagesBucket ElevatorsMehmet CNo ratings yet

- Multitrans UkDocument4 pagesMultitrans UknmaafonsoNo ratings yet

- Strida Folding Bike - Personal Tips and Facts From The CreatorDocument8 pagesStrida Folding Bike - Personal Tips and Facts From The CreatorGeorg100% (2)

- VSK SeparatorDocument3 pagesVSK Separatorm_verma21No ratings yet

- Bucket Elevator: Instruction Manual MaintenanceDocument26 pagesBucket Elevator: Instruction Manual MaintenanceJ Dany T. Delgado100% (1)

- "Design and Model of Bucket Elevator": Under The Guidance ofDocument92 pages"Design and Model of Bucket Elevator": Under The Guidance ofSekson JunsukplukNo ratings yet

- Ventomatic Packing MachineDocument85 pagesVentomatic Packing MachineMudassir RafiqNo ratings yet

- Bucket Elevator PresentationDocument8 pagesBucket Elevator PresentationSalmanNo ratings yet

- DTS AS Aeroslide - V3.3 - 2009 11Document3 pagesDTS AS Aeroslide - V3.3 - 2009 11BRUNA NASCIMENTONo ratings yet

- Iso 3684 1990Document8 pagesIso 3684 1990joaquin fuentealba moralesNo ratings yet

- MAMMUT Single-Shaft Hammer Crusher: HilfsvorrichtungenDocument1 pageMAMMUT Single-Shaft Hammer Crusher: HilfsvorrichtungenpeymanNo ratings yet

- Dura FlexDocument16 pagesDura FlexJohn ChivNo ratings yet

- Sturt Air ClassifierDocument6 pagesSturt Air ClassifierHenry Vladimir VianchaNo ratings yet

- Failure Analysis of Belt Conveyor Damage Caused by The Falling Material. Part 1 PDFDocument9 pagesFailure Analysis of Belt Conveyor Damage Caused by The Falling Material. Part 1 PDFCezar PajaresNo ratings yet

- Hydrochloric Acid Regeneration - Wikipedia, The Free EncyclopediaDocument5 pagesHydrochloric Acid Regeneration - Wikipedia, The Free EncyclopediazamburittiNo ratings yet

- (Esteban, Perez Bernal) Spring Stiffness and Grinding ForceDocument31 pages(Esteban, Perez Bernal) Spring Stiffness and Grinding ForceRaúl Marcelo VelozNo ratings yet

- Baghouse Filter Modular Pulse Jet Type: Operation and ApplicationDocument5 pagesBaghouse Filter Modular Pulse Jet Type: Operation and ApplicationBudy AndikaNo ratings yet

- AUMUND Bucket Elevators 180801Document16 pagesAUMUND Bucket Elevators 180801Tino TorehNo ratings yet

- NM3Document1 pageNM3Venkatesan RamalingamNo ratings yet

- DTS-BE-Bucket Elevator - 10-04-2007Document3 pagesDTS-BE-Bucket Elevator - 10-04-2007BRUNA NASCIMENTONo ratings yet

- Ball MillDocument10 pagesBall MillLuthfanNo ratings yet

- Long Filter BagDocument1 pageLong Filter BagAlbar BudimanNo ratings yet

- Basic Hydraulics and Pneumatics Training1Document74 pagesBasic Hydraulics and Pneumatics Training1birhanu sintayehuNo ratings yet

- 09.30 Cemengal Tanger BK6 FDDocument18 pages09.30 Cemengal Tanger BK6 FDMohd AliNo ratings yet

- RABH-sugest by SatputeDocument1 pageRABH-sugest by Satputegvrr1954No ratings yet

- BEUMER Bucket ElevatorsDocument12 pagesBEUMER Bucket ElevatorsIsmailNo ratings yet

- Conveyor Speed Calculation: ResultsDocument2 pagesConveyor Speed Calculation: ResultsyusefriNo ratings yet

- Raw Mill Check ListDocument2 pagesRaw Mill Check Listlaxman JoshiNo ratings yet

- Shutdown Maintenance Activites at Mechanical Clinker (Line-1)Document4 pagesShutdown Maintenance Activites at Mechanical Clinker (Line-1)salman saleemNo ratings yet

- Technical Manual Sample PagesDocument4 pagesTechnical Manual Sample PagesmkpqNo ratings yet

- Jaypee Cement Project ReportDocument29 pagesJaypee Cement Project ReportPurnendu MishraNo ratings yet

- 90 Belt Transfer Unit or Steerable Diverter Latest Product Shorting Technology For ConveyorDocument7 pages90 Belt Transfer Unit or Steerable Diverter Latest Product Shorting Technology For ConveyorImpel IntralogisticsNo ratings yet

- S3 Product Range - EnglishDocument35 pagesS3 Product Range - EnglishJuan Esteban Luque ZegarraNo ratings yet

- Successful Applications Using Alternative Fuels in The Philippines - Luc ReibelDocument25 pagesSuccessful Applications Using Alternative Fuels in The Philippines - Luc Reibelnathaniel villanuevaNo ratings yet

- Department:Production: Cement Mill Process Control and OperationDocument6 pagesDepartment:Production: Cement Mill Process Control and OperationZegera MgendiNo ratings yet

- 01 Basic Principle and TerminologyDocument4 pages01 Basic Principle and TerminologyNatsuko KayamaNo ratings yet

- Bucket - elevator-ME Carlos III UDocument9 pagesBucket - elevator-ME Carlos III Ujack-bcNo ratings yet

- Chapter 9Document37 pagesChapter 9Nebiyou KorraNo ratings yet

- Material Handling SC 3.3.2019Document43 pagesMaterial Handling SC 3.3.2019Manoy BermeoNo ratings yet

- ConveyDocument6 pagesConveyAbnetastroNo ratings yet

- Copia de Bucket and Screw ConveyorDocument37 pagesCopia de Bucket and Screw ConveyorjuandchiNo ratings yet

- Tractor: Workshop ManualDocument292 pagesTractor: Workshop Manualyosy prastiyoNo ratings yet

- Air Cleaner and Air Intake Parts Models With Turbocharged EngineDocument2 pagesAir Cleaner and Air Intake Parts Models With Turbocharged EngineNeftali FuentesNo ratings yet

- Material FormatsDocument2 pagesMaterial FormatsSultan RomiNo ratings yet

- Angular GripperDocument12 pagesAngular GripperAman RajNo ratings yet

- Catalogo de Partes Blue BirdDocument112 pagesCatalogo de Partes Blue Birdjhongua7No ratings yet

- Parts Manual Yanmar VIO82Document187 pagesParts Manual Yanmar VIO82Stephen Rivett100% (1)

- Instruction Manual ControltromikDocument10 pagesInstruction Manual ControltromikVoştinar IoanNo ratings yet

- 1B) Manicooler & Outlet BoxDocument2 pages1B) Manicooler & Outlet BoxSonthi MooljindaNo ratings yet

- Well Rounded.: 360 CassetteDocument12 pagesWell Rounded.: 360 Cassettetafadzwa simbiNo ratings yet

- Computational Fluid Dynamics (CFD) Modeling of Grain-Water Suspensions in TubeDocument15 pagesComputational Fluid Dynamics (CFD) Modeling of Grain-Water Suspensions in TubebhuniakanishkaNo ratings yet

- Mi 9664 TDocument5 pagesMi 9664 Tamir barekatiNo ratings yet

- Compressed Air MonitoringDocument4 pagesCompressed Air MonitoringRonak JoshiNo ratings yet

- F885-84 (2011) Standard Specification for Envelope Dimensions for Bronze Globe Valves NPS 1ظ - - 4 to 2Document3 pagesF885-84 (2011) Standard Specification for Envelope Dimensions for Bronze Globe Valves NPS 1ظ - - 4 to 2islamakthamNo ratings yet

- Cuptor Coven - 6emd UslDocument22 pagesCuptor Coven - 6emd UslPaul MocanuNo ratings yet

- Valves: Oscar Mauricio Cala Camacho - 2152815 Iván Darío Nova Uribe - 2142795 Facilidades de Superficie Grupo H1 2020-1Document34 pagesValves: Oscar Mauricio Cala Camacho - 2152815 Iván Darío Nova Uribe - 2142795 Facilidades de Superficie Grupo H1 2020-1Oscar CalaNo ratings yet

- Ipc 9521Document4 pagesIpc 9521ashu0470No ratings yet

- PrimeRoyal HPD LE IOMDocument82 pagesPrimeRoyal HPD LE IOMTadeo FajardoNo ratings yet

- Technical Specifications For ValvesDocument32 pagesTechnical Specifications For ValvesEr Hussain GhadialiNo ratings yet

- RTA-59 Procedures and Relevant Information For RTA Engines To Comply With The Annex VI NOx LimitDocument7 pagesRTA-59 Procedures and Relevant Information For RTA Engines To Comply With The Annex VI NOx LimitCatalin CataNo ratings yet

- ZL-7901A en V2.6b PDFDocument8 pagesZL-7901A en V2.6b PDFElio Jose Burgos Brieva100% (1)

- Electrical Systems Console (S - N 512911001 - 512911999) - 331Document3 pagesElectrical Systems Console (S - N 512911001 - 512911999) - 331Ronaldo Javier Vergara AnayaNo ratings yet