Professional Documents

Culture Documents

Bucket Elevator Presentation

Uploaded by

Salman0 ratings0% found this document useful (0 votes)

24 views8 pagesBucket elevators are designed for vertical conveying of large quantities of material and work by attaching buckets to an endless rotating chain or belt with pulleys on both sides. They are primarily categorized as either belt bucket elevators or chain bucket elevators, with subtypes including centrifugal bucket elevators ideal for free-flowing bulk materials, positive discharge buckets suitable for sticky materials, and continuous bucket elevators for handling fragile cargo at low speeds. Proper maintenance involves weekly cleaning, monthly lubrication, and weekly tensioning to keep bucket elevators functioning optimally.

Original Description:

Original Title

bucket elevator presentation

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentBucket elevators are designed for vertical conveying of large quantities of material and work by attaching buckets to an endless rotating chain or belt with pulleys on both sides. They are primarily categorized as either belt bucket elevators or chain bucket elevators, with subtypes including centrifugal bucket elevators ideal for free-flowing bulk materials, positive discharge buckets suitable for sticky materials, and continuous bucket elevators for handling fragile cargo at low speeds. Proper maintenance involves weekly cleaning, monthly lubrication, and weekly tensioning to keep bucket elevators functioning optimally.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

24 views8 pagesBucket Elevator Presentation

Uploaded by

SalmanBucket elevators are designed for vertical conveying of large quantities of material and work by attaching buckets to an endless rotating chain or belt with pulleys on both sides. They are primarily categorized as either belt bucket elevators or chain bucket elevators, with subtypes including centrifugal bucket elevators ideal for free-flowing bulk materials, positive discharge buckets suitable for sticky materials, and continuous bucket elevators for handling fragile cargo at low speeds. Proper maintenance involves weekly cleaning, monthly lubrication, and weekly tensioning to keep bucket elevators functioning optimally.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 8

Function

• Designed for vertical (preferably) and high lift conveying of large

quantities of material

• Buckets attached to a rotating chain or belt with pulleys on both

sides

Major categorization

1. Bucket elevators mounted on belts

2. Chain bucket elevators

Sub types

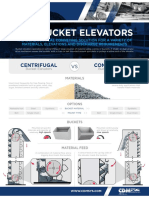

1. Centrifugal Bucket Elevator

– Ideal for conveying free flow bulk material

– Work great with materials such as grains clay gravel finished

cement and dry chemicals as well as woodchips

– High speed

– Buckets are attached at distance

Types

2. Positive discharge buckets

– Similar to centrifugal

– Suitable for sticky material

Types

3. Continuous Bucket Elevator

– Handles fragile material that must be

prevented from aeration

– Work well with hard and sluggish material

– Low speed

– Buckets closely attached

Maintenance

• Periodic cleaning (weekly)

• Component lubrication (monthly)

• Tensioning (weekly)

Q&A

Ask away!

You might also like

- DTS AS Aeroslide - V3.3 - 2009 11Document3 pagesDTS AS Aeroslide - V3.3 - 2009 11BRUNA NASCIMENTONo ratings yet

- Bucket ElevatorDocument9 pagesBucket Elevatorkoripella_prasadNo ratings yet

- CDM Bucket Elevators: Centrifugal ContinuousDocument2 pagesCDM Bucket Elevators: Centrifugal ContinuousOcta IrawanNo ratings yet

- DTS-BE-Bucket Elevator - 10-04-2007Document3 pagesDTS-BE-Bucket Elevator - 10-04-2007BRUNA NASCIMENTONo ratings yet

- 3-Bucket Elev. & 4-Chain ConvDocument24 pages3-Bucket Elev. & 4-Chain ConvYhaneNo ratings yet

- Pan Conveyors PDFDocument24 pagesPan Conveyors PDFcachorrexNo ratings yet

- 09.30 Cemengal Tanger BK6 FDDocument18 pages09.30 Cemengal Tanger BK6 FDMohd AliNo ratings yet

- Drag Conveyors: Learner GuideDocument21 pagesDrag Conveyors: Learner GuidehgNo ratings yet

- Ido Tank CilDocument40 pagesIdo Tank CilSafrin SangiaNo ratings yet

- Failure Analysis of Belt Conveyor Damage Caused by The Falling Material. Part 1 PDFDocument9 pagesFailure Analysis of Belt Conveyor Damage Caused by The Falling Material. Part 1 PDFCezar PajaresNo ratings yet

- Manual Hornos KHDDocument309 pagesManual Hornos KHDjkanclaNo ratings yet

- Scales and Weighing Systems ExplainedDocument41 pagesScales and Weighing Systems ExplainedmkpqNo ratings yet

- AUMUND Chain Conveyors 2Document12 pagesAUMUND Chain Conveyors 2NavidJalalianNo ratings yet

- (Esteban, Perez Bernal) Spring Stiffness and Grinding ForceDocument31 pages(Esteban, Perez Bernal) Spring Stiffness and Grinding ForceRaúl Marcelo VelozNo ratings yet

- BEUMER Bucket ElevatorsDocument12 pagesBEUMER Bucket ElevatorsIsmailNo ratings yet

- Pipe Conveyor Conveyors Pm-Check ListDocument5 pagesPipe Conveyor Conveyors Pm-Check Listgullipalli srinivasa raoNo ratings yet

- 1.1 Design Features of Bucket Elevator: Package M10: Auxiliary Equipment - Maintenance and RepairDocument56 pages1.1 Design Features of Bucket Elevator: Package M10: Auxiliary Equipment - Maintenance and RepairDilnesa EjiguNo ratings yet

- Neraca Massa dan Energi Ball Mill dan SeparatorDocument10 pagesNeraca Massa dan Energi Ball Mill dan SeparatorLuthfanNo ratings yet

- Entrenamiento de Bandas MTCDocument67 pagesEntrenamiento de Bandas MTCFabio BringaNo ratings yet

- Shutdown Maintenance Activites at Mechanical Clinker (Line-1)Document4 pagesShutdown Maintenance Activites at Mechanical Clinker (Line-1)salman saleemNo ratings yet

- Christian Pfeiffer Grinding Media Sorting MachineDocument1 pageChristian Pfeiffer Grinding Media Sorting MachineMohamedNo ratings yet

- 23 HaverDocument36 pages23 HaverkonstantasNo ratings yet

- Polycom High-Pressure Grinding Roll: Our New Name IsDocument7 pagesPolycom High-Pressure Grinding Roll: Our New Name Isrmano22No ratings yet

- Visual inspection of HPGR rollers manualDocument1 pageVisual inspection of HPGR rollers manualRAVINo ratings yet

- Up Wear ResistantDocument14 pagesUp Wear ResistantIrshad HussainNo ratings yet

- MULTIDOS MTD-E® Conveyor Belt Scraper Operating Manual Supplement - bvh2350gbDocument20 pagesMULTIDOS MTD-E® Conveyor Belt Scraper Operating Manual Supplement - bvh2350gbSoehartono HsNo ratings yet

- Seperator Efficiency CM1 May 2015Document9 pagesSeperator Efficiency CM1 May 2015Junaid MazharNo ratings yet

- 03 Wear Phenomena Vietnam Seminar HK 2011Document51 pages03 Wear Phenomena Vietnam Seminar HK 2011quỳnh lêNo ratings yet

- Gravity ConveyorsDocument49 pagesGravity ConveyorsAdriel Aron DiazNo ratings yet

- Services For Bulk Material Handling Projects: Project Formulation Phase Project Engineering PhaseDocument29 pagesServices For Bulk Material Handling Projects: Project Formulation Phase Project Engineering PhasesrichmechNo ratings yet

- Packer Machine (Ia)Document34 pagesPacker Machine (Ia)Safi'i AchmadNo ratings yet

- Pan ConveyorsDocument24 pagesPan ConveyorswereerNo ratings yet

- Installation Handbook - Multiply Conveyor Belts - Rev.4Document36 pagesInstallation Handbook - Multiply Conveyor Belts - Rev.4Guru Raja Ragavendran NagarajanNo ratings yet

- 5,000,000 Kilowatts of Installed ExpertiseDocument16 pages5,000,000 Kilowatts of Installed ExpertiseRahul RoyNo ratings yet

- PROK Product CatalogueDocument32 pagesPROK Product CatalogueDiego AndradeNo ratings yet

- Bucket ElevatorsDocument30 pagesBucket ElevatorsarhescobarNo ratings yet

- The Circle of Refractory Maintenance: Brokk and Bricking SolutionsDocument36 pagesThe Circle of Refractory Maintenance: Brokk and Bricking SolutionsManh PhamNo ratings yet

- 15th NCB Technical PaperDocument10 pages15th NCB Technical PaperSalah RomdaniNo ratings yet

- Polytrack Clinker Cooler.: PolysiusDocument3 pagesPolytrack Clinker Cooler.: PolysiushathamphanNo ratings yet

- Learning More About Roller Press: Transporation, Storage & Bearing AssemblyDocument27 pagesLearning More About Roller Press: Transporation, Storage & Bearing AssemblyHari Prathap ReddyNo ratings yet

- BANDAS (Housekeeping Manual) PDFDocument93 pagesBANDAS (Housekeeping Manual) PDFFabio BringaNo ratings yet

- GSI Bucket Elevator AssemblyDocument38 pagesGSI Bucket Elevator AssemblyElias ArizaNo ratings yet

- 1) Flender StandardsDocument16 pages1) Flender Standardsoner erdeveNo ratings yet

- Shree Project FinalDocument20 pagesShree Project FinalMostafa KordyNo ratings yet

- Overview of The Cement Manufacturing ProcessDocument26 pagesOverview of The Cement Manufacturing ProcessMahmoud RashadNo ratings yet

- 24 00 RP and BM Operation EDocument9 pages24 00 RP and BM Operation EDiego AlejandroNo ratings yet

- FEM Analysis of A Conveyor Belt On The Driving Drum of A Pipe Conveyor PDFDocument9 pagesFEM Analysis of A Conveyor Belt On The Driving Drum of A Pipe Conveyor PDFWilfredo BullonNo ratings yet

- 06 Mill Body Upper HousingDocument15 pages06 Mill Body Upper HousingDavid Vilca MamaniNo ratings yet

- Belt Conveyor Idler: Read These Instructions Carefully Before Starting InstallationDocument8 pagesBelt Conveyor Idler: Read These Instructions Carefully Before Starting InstallationKenji LacambraNo ratings yet

- Compaction With Roller PressesDocument4 pagesCompaction With Roller PressesRollerJonnyNo ratings yet

- 03 RP - Maintenance Practices For RPDocument50 pages03 RP - Maintenance Practices For RPaff bearNo ratings yet

- 2016 PreCut PowerLine FineCut EnglishDocument16 pages2016 PreCut PowerLine FineCut Englishrcaleta0% (1)

- CPB LIners PresentationDocument40 pagesCPB LIners Presentationkakonauta1No ratings yet

- Maintenance of Crushers: R S BaislaDocument52 pagesMaintenance of Crushers: R S BaislaRavindranath BheemisettyNo ratings yet

- Feed Material Guide For POLYCOM: Machine Manual en-PM - MFU.001.BDocument39 pagesFeed Material Guide For POLYCOM: Machine Manual en-PM - MFU.001.BYinder Vega OsorioNo ratings yet

- Chapter 3 1 ConveyorsDocument49 pagesChapter 3 1 ConveyorsMatthew MhlongoNo ratings yet

- Power Plant AnalysisDocument19 pagesPower Plant AnalysisRandyl ManayagaNo ratings yet

- Solids Storage and TransportationDocument51 pagesSolids Storage and Transportationebuy100% (1)

- Vibratory ConveyorsDocument8 pagesVibratory Conveyorsadrian ejemNo ratings yet

- BeltsDocument58 pagesBeltsSalmanNo ratings yet

- Prevent Equipment Failure with Condition Monitoring and MaintenanceDocument29 pagesPrevent Equipment Failure with Condition Monitoring and MaintenanceSalman100% (1)

- Screw Conveyor Applications, Types, Design and FailuresDocument8 pagesScrew Conveyor Applications, Types, Design and FailuresSalmanNo ratings yet

- AirsidesDocument9 pagesAirsidesSalmanNo ratings yet