Professional Documents

Culture Documents

Hydrochloric Acid Regeneration - Wikipedia, The Free Encyclopedia

Uploaded by

zamburittiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydrochloric Acid Regeneration - Wikipedia, The Free Encyclopedia

Uploaded by

zamburittiCopyright:

Available Formats

Hydrochloric acid regeneration - Wikipedia, the free encyclopedia

1 of 5

http://en.wikipedia.org/wiki/Hydrochloric_acid_regeneration

Hydrochloric acid regeneration

From Wikipedia, the free encyclopedia

Hydrochloric acid regeneration or HCl regeneration refers to a chemical process for the reclamation of bound and

unbound HCl from metal chloride solutions such as hydrochloric acid.[1]

Contents

1 Field of application

2 Known processes

2.1 Regeneration

2.2 Recovery of free HCl

2.3 Transformation of FeCl2 to FeCl3

3 Hydrothermal regeneration

3.1 Step1: Oxidation

3.2 Step2: Hydrolysis

3.3 Advantages

3.4 Known implementations

4 Pyrohydrolysis of spent pickle liquor

4.1 Main differences between different implementations of pyrohydrolytic acid regeneration

4.2 Basic process flow diagram of spray roaster hydrochloric acid regeneration plant

4.3 Process description of spray roaster hydrochloric acid regeneration plant

4.3.1 Preconcentration

4.3.2 Roasting

4.3.3 Absorption

4.3.4 Exhaust gas treatment

4.4 Environmental impact

5 Notes

6 External links

Field of application

The commercially most relevant field of application for HCl regeneration processes is the recovery of HCl from waste pickle

liquors from carbon steel pickling lines. Other applications include the production of metal oxides such as, but not limited, to

Al2O3 and MgO as well as rare earth oxides by pyrohydrolysis of aqueous metal chloride or rare earth chloride solutions.

A number of different process routes are available. The most widely used is based on pyrohydrolysis and adiabatic absorption

of hydrogen chloride in water, a process invented in the 1960s. However tightening environmental standards and stringent air

permit policies render it increasingly difficult to establish new pyrohydrolysis based acid regeneration plants.

Known processes

The following processes for the regeneration of HCl from spent pickle liquors have been adopted by the ferrous metals

processing industry:

Regeneration

Pyrohydrolysis

17.04.2015 09:53

Hydrochloric acid regeneration - Wikipedia, the free encyclopedia

2 of 5

http://en.wikipedia.org/wiki/Hydrochloric_acid_regeneration

Spray Roaster Pyrohydrolysis

Fluidised Bed Pyrohydrolysis

Hydrothermal Regeneration

Electrolytic Fe-precipitation

Recovery of free HCl

Retardation

Dialysis

Ion Exchange

Transformation of FeCl2 to FeCl3

Electrolytic Oxidation

Chemical Oxidation

Hydrothermal regeneration

Hydrothermal Hydrolysis of hydrochloric SPL from carbon steel pickling lines is a hydrometallurgical reaction which takes

place according to the following chemical formulae:

Step1: Oxidation

12 FeCl2 + 3 O2 -> 8 FeCl3 + 2 Fe2O3

Step2: Hydrolysis

2 FeCl3 + 3 H2O -> 6 HCl + Fe2O3

Today hydrothermal hydrolysis, which operates at very low temperatures, consumes only a fraction of the energy other

processes demand and produces virtually no emissions, is considered the most effective way to regenerate any given quantity

of spent pickle liquor.

Advantages

low energy consumption (approx. 1300 kJ per litre waste acid)

no gaseous emissions

wide operating range (10 to 100% of nominal capacity)

high value by product (>20m3/g BET specific surface;>2 kg/l specific weight;<0.05% water soluble Chlorides)

theoretically unlimited operating capacity

Known implementations

Known implementations of the hydrothermal HCl regeneration processes include the PORI process (1974 for J&L Steel,

dismantled) and the optimized SMS Demag wet process (2008 for ThyssenKrupp Steel, under construction).

Pyrohydrolysis of spent pickle liquor

Pyrohydrolysis of hydrochloric spent pickle liquor from carbon steel pickling lines is a hydrometallurgical reaction which

takes place according to the following chemical formulae:

4 FeCl2 + 4 H2O + O2 = 8 HCl + 2 Fe2O3

2 FeCl3 + 3 H2O = 6 HCl + Fe2O3

17.04.2015 09:53

Hydrochloric acid regeneration - Wikipedia, the free encyclopedia

3 of 5

http://en.wikipedia.org/wiki/Hydrochloric_acid_regeneration

The process is an inversion of the chemical descaling (pickling) process.

Main differences between different implementations of pyrohydrolytic acid regeneration

Furnace Type (Spray Roaster, Fluidised Bed or Combined Furnace)

Physical Properties of Iron Oxide By-Product (Ferric Oxide Powder or Pellets)

Purity and commercial value of Iron Oxide By-Product

Cl content

SiO2 content (typically 40 to 1000 ppm)

other impurities

specific weight (typically 0.3 to 4 kg per litre)

specific surface (typically 0.01 to 8 m2/g)

Energy Consumption (between 600 and 1200 kcal/l)

Fuel Type

Concentration of regenerated acid (typically approx. 18% wt/wt)

Purity of regenerated acid (remaining Fe content, Cl content)

Recovery Efficiency (typically 99%)

Rinse Water Utilization

Stack Emissions (HCl, Cl2, Dust, CO, NOx)

Liquid Effluents (composition, amount)

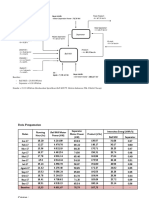

Basic process flow diagram of spray roaster hydrochloric acid regeneration plant

Process description of spray roaster hydrochloric acid regeneration plant

Preconcentration

The metal chloride solution (in the most common case waste pickle liquor from a carbon steel pickling line) is fed to the

venturi evaporator (III), where direct mass and heat exchange with the hot roast gas from the roaster (reactor/cyclone) takes

place. The separator (IV) separates the gas and liquid phase of the venturi evaporator product. The liquid phase is

re-circulated back to the venturi evaporator to increase mass and heat exchange performance.

approx. 25 to 30% of the waste acid (H2O, HCl) are evaporated

roast gas is cooled down to approx. 92 to 96 C

dust particles are removed from the roast gas

Roasting

17.04.2015 09:53

Hydrochloric acid regeneration - Wikipedia, the free encyclopedia

4 of 5

http://en.wikipedia.org/wiki/Hydrochloric_acid_regeneration

Preconcentrated waste acid from the preconcentrator (III / IV) is injected into the reactor (I) by means of one or more spray

booms (VIII) bearing one or more injection nozzles each. Injection takes place at reactor top at a pressure between 4 and 10

bar. The reactor is directly fired by tangentially mounted burners that create a hot swirl. Temperatures inside the reactor vary

between 700 C (burner level) and 370 C (roast gas exit duct). In the reactor the conversion of droplets of preconcentrated

waste acid into iron oxide powder and hydrogen chloride gas takes place. Hydrogen Chloride leaves the reactor through the

top, while iron oxide powder is removed from the reactor bottom by means of mechanical extraction devices. A cyclone (II)

in the roast gas duct ensures separation and feed back of larger oxide particles carried by the roast gas.

Absorption

In the absorption column (V) the hydrogen chloride compound of the saturated roast gas leaving the preconcentrator is

adiabatically absorbed in water (which in many cases is acid rinse water from a carbon steel pickling line). Regenerated acid

(typical strength: 18% wt/wt) is collected at absorption column bottom.

Exhaust gas treatment

The roast gas is conveyed through the system by means of an exhaust gas fan (VI). Fans in plants provide pressure increases

of approx. 200 mbar and are feedback-controlled to maintain a relative pressure of -3 mbar between reactor and atmosphere

to avoid any overpressure-related leakinge of acid gas. To rinse the impeller and cool the gas as well as to remove remaining

traces of HCl from the roast gas, the exhaust gas fan is commonly supplied with quenching water, which is separated from the

exhaust gas stream by means of a mist eliminator (VII) at the pressure side of the fan. In a final scrubber, commonly

consisting of a combination of wet scrubbers such as venturi scrubbers (IX) and scrubber columns (X), remaining traces of

HCl and dust are removed. In some plant, absorption chemicals such as NaOH and Na 2S2O3 are used to bind HCl and Cl2

(which is created under certain circumstances in several, but not all spray roasting reactors).

Environmental impact

Pyrohydrolysis based acid regeneration processes produce a considerable amount of stack emissions containing HCl, particles

and chlorine, which has led to numerous violations of the U.S. clean air act in the past.[2]

Notes

1. "Hydrochloric acid regeneration" (http://www.komalgroup.com/waste_water_treatment4.html).

2. U.S. Department of Justice (2006). "Notice of Lodging of Consent Decree Under the Clean Air Act" (http://regulations.justia.com

/view/52449/). Justia Regulation Tracker.

External links

Minimizing Fuel Cost during Regeneration of the HCl Lixiviant (by Hatch) (http://www.hatch.ca/technologies

/fluidization_technologies/articles/minimizing_fuel_costs_thermal_hydrochloric_acid.htm)

3D Animation of Spray Roaster Hydrochloric Acid Regeneration Plant (by SMS Siemag Process Technologies)

(http://www.youtube.com/watch?v=TrmCPkYF4Jg)

3D Animation of Fluidized Bed Hydrochloric Acid Regeneration Plant (by SMS Siemag Process Technologies)

(http://www.youtube.com/watch?v=wfz8N_BdzGs)

3D Animation of Hydrothermal Hydrochloric Acid Regeneration Plant (by SMS Siemag Process Technologies)

(http://www.youtube.com/watch?v=NNR-26Okvco)

Retrieved from "http://en.wikipedia.org/w/index.php?title=Hydrochloric_acid_regeneration&oldid=606344835"

Categories: Inorganic reactions Chemical processes

This page was last modified on 29 April 2014, at 15:52.

Text is available under the Creative Commons Attribution-ShareAlike License; additional terms may apply. By using

this site, you agree to the Terms of Use and Privacy Policy. Wikipedia is a registered trademark of the Wikimedia

Foundation, Inc., a non-profit organization.

17.04.2015 09:53

Hydrochloric acid regeneration - Wikipedia, the free encyclopedia

5 of 5

http://en.wikipedia.org/wiki/Hydrochloric_acid_regeneration

17.04.2015 09:53

You might also like

- Rugged Single-Shaft Hammer Crusher for 2500mm MaterialsDocument1 pageRugged Single-Shaft Hammer Crusher for 2500mm MaterialspeymanNo ratings yet

- Jaypee Cement Project ReportDocument29 pagesJaypee Cement Project ReportPurnendu MishraNo ratings yet

- 15th NCB Technical PaperDocument10 pages15th NCB Technical PaperSalah RomdaniNo ratings yet

- ESP Operation: Charging Particles & Collecting DustDocument14 pagesESP Operation: Charging Particles & Collecting DustBrayan AguileraNo ratings yet

- Fluid Scr24r PremiumDocument2 pagesFluid Scr24r Premiumvenka070% (1)

- Hms Drum PlantDocument2 pagesHms Drum Plantrichard gutierrezNo ratings yet

- Annex 16.1 & 16.2: Mill calculation plant dimensions and filling degree formulasDocument2 pagesAnnex 16.1 & 16.2: Mill calculation plant dimensions and filling degree formulasIrfan AhmedNo ratings yet

- Tumbler Screening Machines TSM / Tsi: Maximum Screening Quality For Fine and Ultra-Fine ProductsDocument8 pagesTumbler Screening Machines TSM / Tsi: Maximum Screening Quality For Fine and Ultra-Fine Productsgabriel quinteroNo ratings yet

- Gear and equipment specification summaryDocument4 pagesGear and equipment specification summaryprashant mishraNo ratings yet

- ESPDocument15 pagesESPlrpatraNo ratings yet

- FG-Spiral Classifier Operating ManualDocument5 pagesFG-Spiral Classifier Operating ManualRogelio Israel LedesmaNo ratings yet

- Sturt Air ClassifierDocument6 pagesSturt Air ClassifierHenry Vladimir VianchaNo ratings yet

- Muller Mixer Machine - Specifications and Description - SuryaDocument2 pagesMuller Mixer Machine - Specifications and Description - Suryakeshab_machineries100% (1)

- FAM Apron Feeders: WWW - Fam.de Förderanlagen MagdeburgDocument4 pagesFAM Apron Feeders: WWW - Fam.de Förderanlagen MagdeburgriteshsamantrayNo ratings yet

- Services For Bulk Material Handling Projects: Project Formulation Phase Project Engineering PhaseDocument29 pagesServices For Bulk Material Handling Projects: Project Formulation Phase Project Engineering PhasesrichmechNo ratings yet

- High-capacity natural frequency vibrating conveyorsDocument8 pagesHigh-capacity natural frequency vibrating conveyorsZiggy GregoryNo ratings yet

- Dorr-Oliver Vacuum Drum FilterDocument4 pagesDorr-Oliver Vacuum Drum FilterFrancois HamiauxNo ratings yet

- Wet Scrapper Equipment SpecificationDocument1 pageWet Scrapper Equipment Specificationprashant mishraNo ratings yet

- Electrical Documentation For Radar Level TransmitterDocument6 pagesElectrical Documentation For Radar Level TransmittersatfasNo ratings yet

- Condition monitoring of raw mill sectionDocument2 pagesCondition monitoring of raw mill sectionlaxman JoshiNo ratings yet

- Presep Air Separator VTP enDocument6 pagesPresep Air Separator VTP enBrunoNo ratings yet

- Vertical Roller Mill State of The Art Raw GrindingDocument4 pagesVertical Roller Mill State of The Art Raw GrindingzementheadNo ratings yet

- Ore Forming MineralsDocument14 pagesOre Forming MineralsRebecca FrancisNo ratings yet

- Iron Ore Dressing Plant Auditing - LectureDocument7 pagesIron Ore Dressing Plant Auditing - LectureravibelavadiNo ratings yet

- Apron Feeder Data Sheet Material Handling SystemsDocument1 pageApron Feeder Data Sheet Material Handling SystemsPat AuffretNo ratings yet

- Neraca Massa dan Energi Ball Mill dan SeparatorDocument10 pagesNeraca Massa dan Energi Ball Mill dan SeparatorLuthfanNo ratings yet

- Long Filter BagDocument1 pageLong Filter BagAlbar BudimanNo ratings yet

- Raw Mill InspectionDocument20 pagesRaw Mill InspectionAtiq Ur RehmanNo ratings yet

- Based On Leaf Test Data For Moisture, Cake and Cloth ResistanceDocument2 pagesBased On Leaf Test Data For Moisture, Cake and Cloth ResistanceMiguel OrtizNo ratings yet

- Jaw Crusher Kinematics Simulation and AnalysisDocument5 pagesJaw Crusher Kinematics Simulation and AnalysisInternational Journal of Research in Engineering and ScienceNo ratings yet

- GSI Bucket Elevator AssemblyDocument38 pagesGSI Bucket Elevator AssemblyElias ArizaNo ratings yet

- Understanding belt tracking patterns and causes of belt swayDocument29 pagesUnderstanding belt tracking patterns and causes of belt swayNishantKumarGauravNo ratings yet

- Boiler SchematicDocument1 pageBoiler SchematicChristine GriffithNo ratings yet

- Impact CrusherDocument8 pagesImpact CrusherSharath MenonNo ratings yet

- Ball Mill Machine Guide - Less than 40 CharactersDocument2 pagesBall Mill Machine Guide - Less than 40 Characterspadma26327No ratings yet

- DTS - Belt Conveyor Data SheetDocument3 pagesDTS - Belt Conveyor Data SheetBRUNA NASCIMENTONo ratings yet

- Hammer DesaignDocument21 pagesHammer DesaignZahlul AmriNo ratings yet

- Rotary Drum and Fluidized Bed Dryers Optimize Mineral ProcessingDocument12 pagesRotary Drum and Fluidized Bed Dryers Optimize Mineral ProcessingesteNo ratings yet

- Screw Conveyor and Bucket Elevator Engineering GuideDocument32 pagesScrew Conveyor and Bucket Elevator Engineering GuideJorge Cronwell Montaño VásquezNo ratings yet

- Iso 3684 1990Document8 pagesIso 3684 1990joaquin fuentealba moralesNo ratings yet

- 1.1 Design Features of Bucket Elevator: Package M10: Auxiliary Equipment - Maintenance and RepairDocument56 pages1.1 Design Features of Bucket Elevator: Package M10: Auxiliary Equipment - Maintenance and RepairDilnesa EjiguNo ratings yet

- Trojosky2019 PDFDocument21 pagesTrojosky2019 PDFHector CabezasNo ratings yet

- AUMUND Bucket Elevators 180801Document16 pagesAUMUND Bucket Elevators 180801Tino TorehNo ratings yet

- Tyre CouplingsDocument5 pagesTyre CouplingsKarthik VkNo ratings yet

- Ent Sulphuric Acid RegenerationDocument2 pagesEnt Sulphuric Acid RegenerationOmar MBnNo ratings yet

- 20 TPH Bucket ElevatorDocument4 pages20 TPH Bucket ElevatorAlok NayakNo ratings yet

- Shock Load Roller MillDocument1 pageShock Load Roller MillrecaiNo ratings yet

- MS 300 Belt Selection FactorsDocument22 pagesMS 300 Belt Selection FactorsaldoarthoNo ratings yet

- Calculations For Gear Box Selection For 7Document3 pagesCalculations For Gear Box Selection For 7Jiten Kumar BiswalNo ratings yet

- Type SDFC Sizes 290 To 1040 - EngDocument2 pagesType SDFC Sizes 290 To 1040 - EngKUNALJAYNo ratings yet

- Insert Able Jet Pulse FilterDocument4 pagesInsert Able Jet Pulse FilterM.IBRAHEEMNo ratings yet

- Filter & Size ReductionDocument20 pagesFilter & Size ReductionMuhammad Putra RamadhanNo ratings yet

- 8 Crusher Rod MillDocument4 pages8 Crusher Rod MillvvananthNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- HydrocrackingDocument33 pagesHydrocrackingNikita SeleznevNo ratings yet

- Catalytic Conversion of Methane To Hydrogen Using Nickle Catalyst in A Palladium Membrane ReactorDocument15 pagesCatalytic Conversion of Methane To Hydrogen Using Nickle Catalyst in A Palladium Membrane ReactorRakeshKumarNo ratings yet

- Hydrogen Production: P A R T 6Document34 pagesHydrogen Production: P A R T 6Bharavi K SNo ratings yet

- Hydrogen Production by Steam Reforming Chemical Engineering ProcessingDocument8 pagesHydrogen Production by Steam Reforming Chemical Engineering ProcessingviettiennguyenNo ratings yet

- HCl Regeneration Technologies ComparisonDocument5 pagesHCl Regeneration Technologies ComparisonNadia WhiteNo ratings yet

- FFormation and The Structure of Freeze-Dried MgO Nanoparticle Foams and Their Electrical Behaviour in PolyethyleneDocument18 pagesFFormation and The Structure of Freeze-Dried MgO Nanoparticle Foams and Their Electrical Behaviour in PolyethylenezamburittiNo ratings yet

- Production of Gamma-Ferric Oxide Hydrate and Gamma-Ferri'c OxideDocument2 pagesProduction of Gamma-Ferric Oxide Hydrate and Gamma-Ferri'c OxidezamburittiNo ratings yet

- Chemical Product and Company Information: Material Safety Data SheetDocument5 pagesChemical Product and Company Information: Material Safety Data Sheetkirandas_mullasseryNo ratings yet

- Advanced Wastewater Treatment Technology - Mech Vapor RecompressionDocument42 pagesAdvanced Wastewater Treatment Technology - Mech Vapor RecompressionMacarthur B. Monsanto100% (1)

- Production of Magnesia - Methods and ProcessesDocument2 pagesProduction of Magnesia - Methods and ProcesseszamburittiNo ratings yet

- Advanced Wastewater Treatment Technology - Mech Vapor RecompressionDocument42 pagesAdvanced Wastewater Treatment Technology - Mech Vapor RecompressionMacarthur B. Monsanto100% (1)

- Ques Tiona Ry For CHL OR ALK ALY Plant S End User S: Avs Technology Ag. Lange Gasse 15 - CH 4002 Basel - SwitzerlandDocument8 pagesQues Tiona Ry For CHL OR ALK ALY Plant S End User S: Avs Technology Ag. Lange Gasse 15 - CH 4002 Basel - SwitzerlandNarrak KurrekNo ratings yet

- Efficient calcium chloride production processDocument4 pagesEfficient calcium chloride production processzamburitti100% (1)

- Beam Design Formulas With Shear and MomentDocument20 pagesBeam Design Formulas With Shear and MomentMuhammad Saqib Abrar100% (8)

- Crystal IzationDocument10 pagesCrystal IzationJavier Eduardo Penagos VazquezNo ratings yet

- Crystal IzationDocument10 pagesCrystal IzationJavier Eduardo Penagos VazquezNo ratings yet

- MSDS Sodium ChlorideDocument6 pagesMSDS Sodium ChlorideNur Oktri Mulya DewiNo ratings yet

- Vibration Lectures Part 1Document71 pagesVibration Lectures Part 1AshokNo ratings yet

- The Mechanical Vapor Compression 38 Years of Experience PDFDocument10 pagesThe Mechanical Vapor Compression 38 Years of Experience PDFzamburittiNo ratings yet

- Chem3i03 PDFDocument6 pagesChem3i03 PDFkumarrajiv22No ratings yet

- Notes MechV PDFDocument21 pagesNotes MechV PDFzamburittiNo ratings yet

- Ferrous Chloride Solution PDFDocument5 pagesFerrous Chloride Solution PDFzamburittiNo ratings yet

- Chapter 1 - Introduction To Mechanical Vibrations PDFDocument13 pagesChapter 1 - Introduction To Mechanical Vibrations PDFLuchito CtNo ratings yet

- ITV Scelta enDocument15 pagesITV Scelta enRehan Mehmood ChaudhryNo ratings yet

- ITV Scelta enDocument15 pagesITV Scelta enRehan Mehmood ChaudhryNo ratings yet

- Understanding Fan Pressures and TheoryDocument52 pagesUnderstanding Fan Pressures and Theoryabhishek_bhatia2k5No ratings yet

- vVIBRAX - SIEBTECHNIK GMBH PDFDocument32 pagesvVIBRAX - SIEBTECHNIK GMBH PDFzamburittiNo ratings yet

- Plant Engineers Fan Design ReferenceDocument23 pagesPlant Engineers Fan Design ReferenceKumaran GopalNo ratings yet

- FLUID BED TECHNOLOGY FOR BIOPLASTICS DRYINGDocument16 pagesFLUID BED TECHNOLOGY FOR BIOPLASTICS DRYINGzamburitti100% (1)

- Hydraulic Fan Drive Systems Design GuidelinesDocument64 pagesHydraulic Fan Drive Systems Design Guidelineszamburitti100% (1)

- Krauss-Maffei Pusher Centrifuge SZ EDocument16 pagesKrauss-Maffei Pusher Centrifuge SZ ECesar MonteNo ratings yet

- Straight-Through Type With Double or Single Compression Fitting 3/4 To 1 1/2Document1 pageStraight-Through Type With Double or Single Compression Fitting 3/4 To 1 1/2zamburittiNo ratings yet

- CC Bin ActivatorDocument4 pagesCC Bin ActivatorzamburittiNo ratings yet

- CentrifugeDocument2 pagesCentrifugezamburittiNo ratings yet

- Liquid Nitrogen Safety TrainingDocument21 pagesLiquid Nitrogen Safety TrainingSteven James CapuanoNo ratings yet

- 3se3 100-1caDocument5 pages3se3 100-1cadainheniNo ratings yet

- Coherent Motions in The Turbulent Boundary Layer!: Stephen RobinsonDocument39 pagesCoherent Motions in The Turbulent Boundary Layer!: Stephen RobinsonUmair IsmailNo ratings yet

- Experiment 1 Solubility of Organic CompoundsDocument2 pagesExperiment 1 Solubility of Organic CompoundsJamica AmbionNo ratings yet

- Frequency, Energy, Wavelength Activity C12!2!01Document7 pagesFrequency, Energy, Wavelength Activity C12!2!01Niko BrocesNo ratings yet

- Performance Evaluation For Inerter-Based Dynamic Vibration AbsorbersDocument28 pagesPerformance Evaluation For Inerter-Based Dynamic Vibration Absorbersgakada prbNo ratings yet

- Vulkollan: The Ultimate ElastomerDocument24 pagesVulkollan: The Ultimate ElastomerMS Mechanic HSM 2No ratings yet

- Fluid Pressure Measurement TechniquesDocument52 pagesFluid Pressure Measurement Techniquesrohit sharma100% (1)

- Sunon DC Brushless Fan & Blower - (190-E)Document88 pagesSunon DC Brushless Fan & Blower - (190-E)1cisco1No ratings yet

- Sandwich Panel Anchors - Precast ConcreteDocument40 pagesSandwich Panel Anchors - Precast ConcreteCorbean AlexandruNo ratings yet

- HQD Series Meters and IntelliCAL Probes Data Sheet (Lit 2599)Document8 pagesHQD Series Meters and IntelliCAL Probes Data Sheet (Lit 2599)prannoyNo ratings yet

- TP PDFDocument1 pageTP PDFRîkèñ PâtélNo ratings yet

- Dokumen - Tips - Cotter Joint PPTX 58f9ab8d3dbc9Document19 pagesDokumen - Tips - Cotter Joint PPTX 58f9ab8d3dbc9Good YagNo ratings yet

- GEI-M1026 Installation Vertical Non-Reverse-Bolted Coupling PDFDocument9 pagesGEI-M1026 Installation Vertical Non-Reverse-Bolted Coupling PDFEric AndrésNo ratings yet

- IR sensor operation theory explainedDocument4 pagesIR sensor operation theory explainedSebastin Ashok100% (1)

- 4 - 002 Qafco Urea3 Plant High PressureDocument13 pages4 - 002 Qafco Urea3 Plant High PressureJUNAID RAFEYNo ratings yet

- How Do We Classify An Antipumping Relay?: What Will Happen If Antipumping Relay Circuit Is Not Present?Document6 pagesHow Do We Classify An Antipumping Relay?: What Will Happen If Antipumping Relay Circuit Is Not Present?joseNo ratings yet

- Preparation, Structure and Morphology of Polymer Supports: David C. SherringtonDocument12 pagesPreparation, Structure and Morphology of Polymer Supports: David C. Sherringtonkishorkumarn8212No ratings yet

- Micro Diaphragm Gas Sampling Pumps: Operating and Installation InstructionsDocument12 pagesMicro Diaphragm Gas Sampling Pumps: Operating and Installation Instructionssunilsheelavant100% (1)

- Coal Carbonization: Current and Future ApplicationsDocument9 pagesCoal Carbonization: Current and Future ApplicationsVenkata Krishnan RamanujamNo ratings yet

- MM1080 Ie 3Document3 pagesMM1080 Ie 3Paul RuckNo ratings yet

- Vts Capacity ProfileDocument18 pagesVts Capacity ProfilevudinhnambrNo ratings yet

- 13thPMO Area Ver5Document3 pages13thPMO Area Ver5Yinkci Heart Entertainment StudioNo ratings yet

- Physics Report Total Internal Reflection - EditedDocument10 pagesPhysics Report Total Internal Reflection - EditedJASMSJS SkskdjNo ratings yet

- Tehnički List Praha 9005 Epoxid-Poliester, Sitna Struktura, MatDocument2 pagesTehnički List Praha 9005 Epoxid-Poliester, Sitna Struktura, Matjoki_loNo ratings yet

- Physics QuestionsDocument25 pagesPhysics QuestionsCarlos KasambiraNo ratings yet

- PLC Simulation ReportDocument62 pagesPLC Simulation ReportAsraful Goni NirabNo ratings yet

- Stopping Sight DistanceDocument28 pagesStopping Sight DistanceEman MousaNo ratings yet

- FMDocument4 pagesFMvishalNo ratings yet