Professional Documents

Culture Documents

Impact Crusher

Uploaded by

Sharath MenonOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Impact Crusher

Uploaded by

Sharath MenonCopyright:

Available Formats

IMPACT CRUSHER

PRESENTED BY SHARATH SUDHAKARAN MENON S5 ME VAST

Impact crushers involve the use of impact rather than pressure to crush material. There are two types of impact crushers: horizontal shaft impactor and vertical shaft impactor.

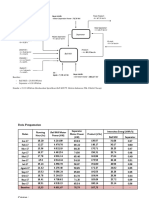

HORIZONTAL SHAFT IMPACTOR

Horizontal Shaft Impact (HSI) crushers are best used for primary or secondary crushing operations. It consists of a horizontal rotating shaft to which a rotor is attached. Breaks rock by impacting the rock with hammers that are fixed upon the outer edge of a spinning rotor.

ADVANTAGES OF HSI

Offers high throughput primary and secondary crushing with good control of product size. High reduction ratios are available by this. Capital cost per ton of capacity is low It works well with ore that is sticky or have high clay content.

VERTICAL SHAFT IMPACTOR

VSI crushers utilize velocity rather than surface force as the predominant force to break rock. By utilising velocity, the breaking force can be evenly applied both across the surface of the rock and the mass of the rock The final particle size can be controlled by 1) the velocity at which the rock is thrown against the anvil 2) the distance between the end of the rotor and the impact point on the anvil.

THANK YOU

You might also like

- Machinary For Crushing & GrindingDocument75 pagesMachinary For Crushing & GrindingAsad Imran MunawwarNo ratings yet

- VibrofeederDocument32 pagesVibrofeederNaveen LingamkuntaNo ratings yet

- Rugged Single-Shaft Hammer Crusher for 2500mm MaterialsDocument1 pageRugged Single-Shaft Hammer Crusher for 2500mm MaterialspeymanNo ratings yet

- Neraca Massa dan Energi Ball Mill dan SeparatorDocument10 pagesNeraca Massa dan Energi Ball Mill dan SeparatorLuthfanNo ratings yet

- Classify spiral classifiers with SEO-optimized titleDocument4 pagesClassify spiral classifiers with SEO-optimized titlerajeevup2004No ratings yet

- Industrial Screening Equipment TypesDocument25 pagesIndustrial Screening Equipment TypesDikshithaNo ratings yet

- FG-Spiral Classifier Operating ManualDocument5 pagesFG-Spiral Classifier Operating ManualRogelio Israel LedesmaNo ratings yet

- Electrical Documentation For Radar Level TransmitterDocument6 pagesElectrical Documentation For Radar Level TransmittersatfasNo ratings yet

- Polysiushpgr (HPGR)Document20 pagesPolysiushpgr (HPGR)Alexis GodoyNo ratings yet

- Filter & Size ReductionDocument20 pagesFilter & Size ReductionMuhammad Putra RamadhanNo ratings yet

- Roll Crusher BrochureDocument4 pagesRoll Crusher BrochureWaris La Joi Wakatobi100% (1)

- Pipe Conveyor Conveyors Pm-Check ListDocument5 pagesPipe Conveyor Conveyors Pm-Check Listgullipalli srinivasa raoNo ratings yet

- Conveyor Systems Guide: Types, Working Principles & ApplicationsDocument49 pagesConveyor Systems Guide: Types, Working Principles & ApplicationsGowthaman MaruthamuthuNo ratings yet

- Pneumatic Conveying: Technology You Can TrustDocument16 pagesPneumatic Conveying: Technology You Can TrustSyed Rameez MohiuddinNo ratings yet

- F Class Tech SpecsDocument8 pagesF Class Tech SpecskosmcNo ratings yet

- PallaDocument16 pagesPallaJuan Alberto Giglio FernándezNo ratings yet

- Screen Media FL SmithDocument24 pagesScreen Media FL SmithDAVID VENEGASNo ratings yet

- Mechanical Centrifugal Air ClassifiersDocument3 pagesMechanical Centrifugal Air ClassifiersBramJanssen76No ratings yet

- fm60c 0Document8 pagesfm60c 0Srinivas NandikantiNo ratings yet

- Polycom High-Pressure Grinding Roll: Our New Name IsDocument7 pagesPolycom High-Pressure Grinding Roll: Our New Name Isrmano22No ratings yet

- Sturt Air ClassifierDocument6 pagesSturt Air ClassifierHenry Vladimir VianchaNo ratings yet

- Ball Mill ManualDocument7 pagesBall Mill ManualAnonymous EBReO8vNo ratings yet

- 2016 PreCut PowerLine FineCut EnglishDocument16 pages2016 PreCut PowerLine FineCut Englishrcaleta0% (1)

- MS 300 Belt Selection FactorsDocument22 pagesMS 300 Belt Selection FactorsaldoarthoNo ratings yet

- Vertical Roller Mill State of The Art Raw GrindingDocument4 pagesVertical Roller Mill State of The Art Raw GrindingzementheadNo ratings yet

- Maintenance of Crushers: R S BaislaDocument52 pagesMaintenance of Crushers: R S BaislaRavindranath BheemisettyNo ratings yet

- Gear and equipment specification summaryDocument4 pagesGear and equipment specification summaryprashant mishraNo ratings yet

- Shanghai Horizons Technology Limited Stone Crusher and Grinding Mill GuideDocument24 pagesShanghai Horizons Technology Limited Stone Crusher and Grinding Mill Guidesaleem2412100% (1)

- GSI Bucket Elevator AssemblyDocument38 pagesGSI Bucket Elevator AssemblyElias ArizaNo ratings yet

- Hms Drum PlantDocument2 pagesHms Drum Plantrichard gutierrezNo ratings yet

- Hydrochloric Acid Regeneration - Wikipedia, The Free EncyclopediaDocument5 pagesHydrochloric Acid Regeneration - Wikipedia, The Free EncyclopediazamburittiNo ratings yet

- DTS-BE-Bucket Elevator - 10-04-2007Document3 pagesDTS-BE-Bucket Elevator - 10-04-2007BRUNA NASCIMENTONo ratings yet

- Apron Feeder DScrusherDocument7 pagesApron Feeder DScrusherRyan R CunninghamNo ratings yet

- PEF500X750 Jaw CrusherDocument21 pagesPEF500X750 Jaw CrushersanjeevarorahsrNo ratings yet

- Modification HPGR 18 Synchronous Piston Accumulator InstallationDocument28 pagesModification HPGR 18 Synchronous Piston Accumulator InstallationAnonymous gcMAj2IXlNo ratings yet

- Calculating Power Draw When Sizing Ball Mills: Arabinda Bandyopadhyay (Bandyo)Document11 pagesCalculating Power Draw When Sizing Ball Mills: Arabinda Bandyopadhyay (Bandyo)RAVI1972No ratings yet

- Why Skewing Is Not Beneficial For Your HPGRDocument8 pagesWhy Skewing Is Not Beneficial For Your HPGRAbe ArdiNo ratings yet

- Turbo Air Classifier DesignDocument21 pagesTurbo Air Classifier Designnayan patelNo ratings yet

- Roll CrusherDocument7 pagesRoll CrusherSudarshan Devarapalli100% (1)

- Influence of Quartz Particles On Wear in Vertical Roller Mills.Document9 pagesInfluence of Quartz Particles On Wear in Vertical Roller Mills.chienhamthepNo ratings yet

- WO 2014/075722 Al: International BureauDocument17 pagesWO 2014/075722 Al: International BureauneusonNo ratings yet

- Raw Mill InspectionDocument20 pagesRaw Mill InspectionAtiq Ur RehmanNo ratings yet

- Cast Central Pipe - EN - SmidthDocument4 pagesCast Central Pipe - EN - SmidthLuis Orlando Villarroel TorrezNo ratings yet

- Uranium Corporation of India Limited P.O: Jaduguda Mines, Jharkhand - 832102Document4 pagesUranium Corporation of India Limited P.O: Jaduguda Mines, Jharkhand - 832102arsanioseNo ratings yet

- Hammer DesaignDocument21 pagesHammer DesaignZahlul AmriNo ratings yet

- Kinds of Conveyor Belts Pipe Conveyor Belt Conveyo 5ad270867f8b9acc4a8b4583Document19 pagesKinds of Conveyor Belts Pipe Conveyor Belt Conveyo 5ad270867f8b9acc4a8b4583nicolasNo ratings yet

- Christian Pfeiffer Grinding Media Sorting MachineDocument1 pageChristian Pfeiffer Grinding Media Sorting MachineMohamedNo ratings yet

- CrusherDocument16 pagesCrusherRomi FadliNo ratings yet

- Bucket Elevator SanweiDocument1 pageBucket Elevator SanweiTriết Lãm NgôNo ratings yet

- VibratingEquipmentBrochure PDFDocument10 pagesVibratingEquipmentBrochure PDFWilliam VillamizarNo ratings yet

- Particle TechnologyDocument40 pagesParticle Technologyasharab70No ratings yet

- Double Roll CrusherDocument3 pagesDouble Roll CrusherjtpmlNo ratings yet

- SelectionDocument87 pagesSelectionRAVI ANANTHAKRISHNANNo ratings yet

- 2022-04-08 - HPGR Adantages in Ore GrindingDocument24 pages2022-04-08 - HPGR Adantages in Ore Grindingpanchada.srinivasuNo ratings yet

- Jaw Crusher: Cam Pitman Lever NutcrackerDocument13 pagesJaw Crusher: Cam Pitman Lever NutcrackerVickram JainNo ratings yet

- Crushers: Jaw and Gyratory TypesDocument2 pagesCrushers: Jaw and Gyratory Typesanosh khanNo ratings yet

- Crusher WikipediaDocument8 pagesCrusher WikipediaJaya ChandranNo ratings yet

- FINAL PPT-Aggregate ProductionDocument77 pagesFINAL PPT-Aggregate ProductionLeilani Manalaysay100% (1)

- Surface Mining Bench PreparationDocument9 pagesSurface Mining Bench PreparationKunal Kishor100% (1)

- Rock Excavation SystemsDocument16 pagesRock Excavation SystemsKerim AydinerNo ratings yet

- PET Resin Properties, Grades, and ApplicationsDocument4 pagesPET Resin Properties, Grades, and ApplicationsSharath MenonNo ratings yet

- IRCTC Case Study FinalDocument19 pagesIRCTC Case Study FinalSharath Menon0% (1)

- Project Furniture ShopDocument18 pagesProject Furniture ShopSharath Menon0% (1)

- Macro Economics - Class 9 - Chapter 10 - Self-Adjustment or InstabilityDocument43 pagesMacro Economics - Class 9 - Chapter 10 - Self-Adjustment or InstabilitySharath MenonNo ratings yet

- Every Day Amul Collects 447Document2 pagesEvery Day Amul Collects 447Sharath MenonNo ratings yet

- Liquidity and Cash ManagementDocument9 pagesLiquidity and Cash ManagementSharath MenonNo ratings yet

- Module 2 CAMDocument29 pagesModule 2 CAMSharath MenonNo ratings yet

- Design Scrap Compressing MachineDocument46 pagesDesign Scrap Compressing MachineSharath MenonNo ratings yet

- We've All Heard It:: - One, - One, - OneDocument31 pagesWe've All Heard It:: - One, - One, - OneSharath MenonNo ratings yet

- Introduction To Material JoiningDocument45 pagesIntroduction To Material JoiningSharath MenonNo ratings yet

- TS68Document52 pagesTS68finandariefNo ratings yet

- Your Guide To BricklayingDocument6 pagesYour Guide To BricklayingChristopher GeorgeNo ratings yet

- Dresser 1900Document104 pagesDresser 1900Ildefonso FloresNo ratings yet

- MTC MasterFlow 718Document1 pageMTC MasterFlow 718Vikram DhabaleNo ratings yet

- Increasing Profits in Jet Fighter Manufacturing - BCG CaseDocument3 pagesIncreasing Profits in Jet Fighter Manufacturing - BCG CaseAkhilGovindNo ratings yet

- Guide For Conducting Marine Fire Investigations Chapter 5Document13 pagesGuide For Conducting Marine Fire Investigations Chapter 5Anthony tim CastNo ratings yet

- Hempcrete Study 2023 Morrocco 1-S2.0-S0195925523000513-MainDocument15 pagesHempcrete Study 2023 Morrocco 1-S2.0-S0195925523000513-MainJeanPierrervillNo ratings yet

- Tensile Properties of Ground Coffee Waste Reinforced Polyethylene CompositeDocument4 pagesTensile Properties of Ground Coffee Waste Reinforced Polyethylene CompositemhmmdzulvaNo ratings yet

- Rheinzink Standing Seam TechnologyDocument106 pagesRheinzink Standing Seam TechnologyAndrei TeacăNo ratings yet

- MORTALEX ZSz0Document1 pageMORTALEX ZSz0Muhammad TayyabNo ratings yet

- Magnetic Pulse FormingDocument13 pagesMagnetic Pulse FormingUmesh KsNo ratings yet

- Gyta53 PDFDocument5 pagesGyta53 PDFcarlosvicunavNo ratings yet

- Phoenix Contact DATA SHEETDocument16 pagesPhoenix Contact DATA SHEETShivaniNo ratings yet

- 2006 Kawasaki ZZR600 Service Repair Manual PDFDocument35 pages2006 Kawasaki ZZR600 Service Repair Manual PDFjksmmmdd50% (2)

- Pt. Estu Artha LancarDocument9 pagesPt. Estu Artha Lancarhelmi_69No ratings yet

- Paint Master Plaster Primer - TDSDocument2 pagesPaint Master Plaster Primer - TDSMichael JoudalNo ratings yet

- Hot TappingDocument22 pagesHot Tappingfalista anggiNo ratings yet

- Alhambra Foundry CatalogDocument119 pagesAlhambra Foundry CatalogMikeNo ratings yet

- Thistle Grove E-Brochure PDFDocument17 pagesThistle Grove E-Brochure PDFougueway100% (1)

- Microplan Ward 192 Block Data SheetsDocument20 pagesMicroplan Ward 192 Block Data SheetsDashami AnandNo ratings yet

- Tribhuvan University Institute of Engineering Pulchowk CampusDocument23 pagesTribhuvan University Institute of Engineering Pulchowk CampusSujan BaralNo ratings yet

- Mems and NemsDocument25 pagesMems and Nemssvasanth007No ratings yet

- WCM2012F2S Series Wire Wound Common Mode Filter Supresses NoiseDocument4 pagesWCM2012F2S Series Wire Wound Common Mode Filter Supresses Noisegoogi7No ratings yet

- 2010 HSC Exam ChemistryDocument38 pages2010 HSC Exam ChemistryFiras AhmadNo ratings yet

- 02 - WORLDBRIDGE - Aluminum Dome RoofDocument50 pages02 - WORLDBRIDGE - Aluminum Dome RoofALONSO GOMEZNo ratings yet

- Module 06. Materials and HardwareDocument277 pagesModule 06. Materials and HardwarePart-66 Free86% (21)

- Sakthi Auto Components LimitedDocument6 pagesSakthi Auto Components Limitedpgn.exlNo ratings yet

- API 1104 Acceptance CriteriaDocument2 pagesAPI 1104 Acceptance CriteriaEngr Arfan Ali Dhamraho79% (14)

- CS Steel Pipe Selection GuideDocument40 pagesCS Steel Pipe Selection GuideImran HussainNo ratings yet