Professional Documents

Culture Documents

Cpi Gtr50 Service Manual

Uploaded by

Klara PataiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cpi Gtr50 Service Manual

Uploaded by

Klara PataiCopyright:

Available Formats

Collaboration

Professional

Innovation

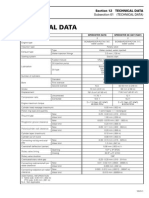

CONTENTS

PREFACE.....................................................................................1-1

TROUBLE SHOOTING..................................2-1 2-6

ENGINE REMOVALE INSPECTION......................................3-1 3-2

LUBRICATION SYSTEM..............................4-1 4-2

FUEL SYSTEM............................5-1 5-4

CYLINDEER HEAD-CYLINDER PISTON.....................6-1 6-5

TRANSMISSION SYSTEM...........................................7-1 7-6

CRANKSHAFT-CRANKCASE.............................................8-1 8-4

A.C.GENERATOR.........................................9-19-2

ELECTRIC SYSTEM.10-110-4

CPI MOTOR

PREFACE GTR50

1-1

THE CONTENTS OF THIS MANUAL PROVIDE THE SERVICE

INFORMATION FOR CPI \GTR50.

MOST CHAPTERS START WITH A SYSTEM OR ASSEMBLY

ILLUSTRATION AND SPECIFICATIONS THE FOLLOWING

PAGES GIVE DETAIL PROCEDURES.

IF YOU DO NOT KNOW WHAT THE SOURCE OF THE

TROUBLE IS, PLEASE GO TO THE TROUBLESHOOTERS FOR

ADDITIONAL HELP.

ALL THE CONTENTS OF THIS MANUAL ARE BASED ON

THE LATEST MODEL INFORMATION CPI RESERVES THE

RIGHT TO MAKE CHANGE AT ANY TIME WITHOUT NOTICE

AND WITHOUT ANY RESPONSIBILITY OR ENGAGEMENT ON

OUR PART.

CPI MOTOR

TROUBLE SHOOTING GTR50

2-1

ENGINE WILL NOT START OR IS HARD TO START

PROBABLE CAUSE

1

CHECK IF FUEL REACHES

CARBURETOR

FUEL REACHES

CARBURETOR

FUEL DOES NOT REACH

CARBURETOR

(1) NO FUEL IN TANK

(2) CLOGGED FUEL LINE BETWEEN

FUEL TANK AND CARBURETOR

(3) CLOGGED FUEL VALVE

(4) CLOGGED FUEL TANK CAP

BREATHER HOLE

2

REMOVE SPARK PLUG AND

TEST SPARK

GOOD SPARK

WEAK OR NO SPARK (1) FAULTY OR FOULED PLUG

(2) FAULTY C.D.I.

(3) BROKEN OR SHORTED HIGH

TENSION CORD

(4) FAULTY IGNITION SWITCH

(5) INCORRECT IGNITION TIMING

3

TEST CYLINDER

COMPRESSION

NORMAL COMPRESSION

LOW COMPRESSION (1) ENGINE NOT CRANKED

(2) NO VALVE CLEARANCE

(3) VALVE STUCK OPEN

(4) WORN CYLINDER AND PISTON

RINGS

(5) BLOWN CYLINDER HEAD GASKET

(6) FLAW IN CYLINDER HEAD

(7) INCORRECT VALVE TIMING

(8) BURNED VALVE

4

START ENGINE

ENGINE FIRES

ENGINE FIRES, BUT

DOES NOT START

(1) CHOKE VALVE OPEN

(2) CARBURETOR PILOT SCREW OPEN

(3) AIR LEAKING THROUGH IN TAKE

PIPE

(4) INCORRECT IGNITION TIMING

5

REMOVE SPARK PLUG

DRY PLUG

WET PLUG (1) FLOODED CARBURETOR

(2) CHOKE VALVE CLOSED

6

START ENGINE WITH

CHOKE CLOSED

CPI MOTOR

TROUBLE SHOOTING GTR50

2-2

ENGINE LACKS POWER

FLOW PATH BAD SITUATION PROBABLE CAUSE

1

RAISE WHEELS OFF

GROUND AND SPIN

WHEELS SPIN FREELY

WHEELS DO NOT SPIN

FREELY

(1) DRAGGING BRAKE

(2) FAULTY WHEEL BEARING

(3) OVERTIGHTENED DRIVE CHAIN

(4) WHEEL BEARING NOT

LUBRICATED PROPERLY

2

CHECK TIRE

PRESSURE

NORMAL PRESSURE

INCORRECT TIRE

PRESSURE

(1) PUNCTURED TIRE

(2) FAULTY TIRE VALVE

3

RAPIDLY

ACCELERATE FROM

LOW TO SECOND

ACCELERATES

DOES NOT ACCELERATE

WITH ENGINE SPEED

RAISED

(1) SLIPPING CLUTCH

(2) WORN OR UNEVEN CLUTCH

FACINGS

(3) CLUTCH PLATE WARPED

4

REV UP GRADUALLY

ENGINE SPEED

INCREASES

ENGINE SPEED DOES

NOT INCREASE

(1) CARBURETOR CHOKE CLOSED

(2) CLOGGED AIR CLEANER

(3) CLOGGED FUEL LINE

(4) CLOGGED FUEL TANK CAP

BREATHER HOLE

(5) CLOGGED MUFFLER

5

CHECK IGNITION

TIMING

CORRECT TIMING

INCORRECT TIMING

INCORRECT TIMING ADJ USTMENT

6

CHECK VALVE

CLEARANCE

CORRECT VALVE

CLEARANCE

INCORRECT VALVE

(1) INCORRECT VALVE CLEARANCE

(2) WORN VALVE SEAT

CPI MOTOR

TROUBLE SHOOTING GTR50

2-3

7

TEST CYLINDER

COMPRESSION

NORMAL

COMPRESSION

LOSS OF COMPRESSION (1)VALVE STUCK OPEN

(2) WORN CYLINDER AND PISTON RINGS

(3) BLOWN CYLINDER HEAD GASKET

(4) INCORRECT VALVE TIMING

(5) FLAWS IN CYLINDER HEAD OR

CYLINDER

8

CHECK CARBURETOR

FOR CLOGGING

CARBURETOR NOT

CLOGGED

CARBURETOR CLOGGED(1) CARBURETOR J ETS CLOGGED

9

REMOVE SPARK PLUG PLUG FOULED OR

DISCOLORED COLORED

(1) FOULED PLUG

(2) INCORRECT HEAT RANGE PLUG

10

CHECK OIL LEVEL

AND CONDITION

CORRECT ENGINE OIL

LEVEL

OIL DIRTY OR LEVEL

INCORRECT

(1) LEVEL TOO LOW OR HIGH

(2) CONTAMINATED OIL

11

REMOVE CYLINDER

HEAD COVER AND

CHECK

SUFFICIENTLY

LUBRICATION

INSUFFICIENTLY

LUBRICATED

(1) CLOGGED OIL PASSAGE

(2) POOR OIL PUMP DELIVERY

12

CHECK IF ENGINE

OVERHEATS

ENGINE DOES NOT

OVERHEAT

ENGINE OVERHEATS

(1) EXCESSIVE CARBON IN

COMBUSTION CHAMBER

(2) INCORRECT FUEL

(3) SLIPPING CLUTCH

13

RAPIDLY

ACCELERATE OR URN

AT HIGH SPEEDS

ENGINE DOES NOT

KNOCK

ENGINE KNOCKS

(1) WORN PISTON OR CYLINDER

(2) MIXTURE TOO LEAN

(3) INCORRECT FUEL

(4) EXCESSIVE CARBON IN

COMBUSTION CHAMBER

(5) LGNITION TIMING TOO EARLY

CPI MOTOR

TROUBLE SHOOTING GTR50

2-4

POOR PERFORMANCE AT IDLE AND LOW SPEEDS

FLOW PATH BAD SITUATION PROBABLE CAUSE

1

CHECK IGNITION

TMING AND VALVE

CLEARANCE

CORRECT TIMING AND

CLEARANCE

INCORRECT TIMING

AND CLEARANCE

(1) INCORRECT TIMING

ADJ USTMENT

(2) INCORRECT VALVE CLEARANCE

2

CHECK CARBURETOR

PILOT SCREW

ADJ USTMENT

CORRECTLY ADJUSTED

INCORRECTLY

ADJ USTED

(1) MIXTURE TOO LEAN

(2) MIXTURE TOO RICH

3

CHECK FOR AIR

LEAKS

NO AIR LEAKS

AIR LEAKS

(1) FAULTY CARBURETOR PACKING

(2) CARBURETOR NOT SECURELY

TIGHTENED

(3) FAULTY INTAKE PIPE GASKET

4

REMOVE SPARK PLUG

AND TEST SPARK

WEAK OR

INTERMITTENT SPARK

(1) FAULTY OR FOULED PLUG

(2) FAULTY C.D.I.

(3) MAGNET AT FAULT

CPI MOTOR

TROUBLE SHOOTING GTR50

2-5

POOR PERFORMANCE AT HIGH SPEED

FLOW PATH BAD SITUATION PROBABLE CAUSE

1

CHECK IGNITION

TIMING AND VALVE

CLEARANCE

CORRECT TIMING AND

CLEARANCE

INCORRECT TIMING

AND CLEARANCE

(1) INCORRECT TIMING ADJ USTMENT

(2) INCORRECT VALVE CLEARANCE

2

DISCONNECT FUEL

LINE AT CARBURETOR

AND CHECK FOR

CLOGGING

UNRESTRICTED FUEL

FLOW

RESTRICTED FUEL

FLOW

(1) EMPTY FUEL TANK

(2) CLOGGED FUEL LINE

(3) CLOGGED FUEL TANK CAP

BREATHER HOLE

(4) CLOGGED FUEL PETCOCK

3

CHECK FUEL FILTER,

FUEL VALVE AND

CARBURETOR J ET FOR

CLOGGING

NOT CLOGGED

CLOGGED

(1) CLOGGED J ET

(2) CLOGGED FUEL FILTER

(3) CLOGGED FUEL VALVE

4

REPLACE

CARBURETOR MAIN

J ET

CONDITION IMPROVED

CONDITION

AGGRAVATED

(1) J ET SIZE TOO SMALL

(2) IF CONDITION IS IMPROVED WITH

SMALL J ET:

A) CLOGGED AIR CLEANER

B) CHOKE NOT OPENED FULLY

5

CHECK VALVE TIMING

CORRECT

INCORRECT

INCORRECT VALVE TIMING

ADJ USTMENT

6

CHECK VALVE SPRING

TENSION

SPRING TENSION

CORRECT

WORN OR BROKEN

SPRING

FAULTY VALVE SPRING

CPI MOTOR

TROUBLE SHOOTING GTR50

2-6

SMOKY EXHAUST

FLOW PATH BAD SITUATION PROBABLE CAUSE

1

RUN MOTORCYCLE A

LONG DISTANCE AT

HIGH SPEED

THIN EXHAUST

EMITTED

BLACK SMOKE EMITTED

(1) WORN CYLINDER AND PISTON

RINGS

(2) OIL LEVEL TOO HIGH

(3) PISTON RINGS INCORRECTLY

INSTALLED

(4) FAULTY PISTON OR CYLINDER

(5) FLAWS IN CYLINDER HEAD

2

RETURN THROTTLE

GRIP QUICKLY

WHITE SMOKE EMITTED

(1) WORN INTAKE VALVE GUIDE OR

STEM

(2) EXCESSIVE VALVE-TO-GUIDE

CLEARANCE

POOR HANDLING

FLOW PATH BAD SITUATION PROBABLE CAUSE

1

IF STEELING IS HEAVY

CHECK TIRE PRESSURE

(1) STEERING HEAD ADJ USTER TOO

TIGHT

(2) DAMAGED STEERING CONES OR

STEEL BALLS

2

IF EITHER WHEEL IS

WOBBLING

(1) EXCESSIVE WHEEL BEARING

PLAY

(2) DISTORTED RIM

(3) IMPROPERLY INSTALLED WHEEL

HUB

(4) SWING ARM PIVOT BUSHING

EXCESSIVELY WORN

(5) DISTORTED FRAME

(6) IMPROPER DRIVE CHAIN TENSION

OR ADJ USTMENT

3

IF THE MOTORCYCLE

PULLS TO ONE SIDE

(1) MISAPPLIED SHOCK ABSORBER

(2) FRONT AND REAR WHEELS NOT

ALIGNED

(3) BENT FRONT FORK

(4) BENT SWING ARM

CPI MOTOR

ENGINE REMOVAL/INSTALLATION GTR50

3-1

ENGINE REMOVAL

1. Open and remove the seat.

2. Remove the rear luggage case.

Remove the side cover.

Remove the throttle valve from the carburetor.

Disconnect the earth wire of engine.

Disconnect the coil wire.

Disconnect the A.C.G. wire.

Disconnect the start motor wire.

Disconnect the starter plunger wire.

CPI MOTOR

ENGINE REMOVAL/INSTALLATION GTR50

3-2

Disconnect the fuel & the vacuum tube.

Disconnect the spark plug cap.

Disconnect the rear brake cable.

Remove the setting bolt of rear cushion.

Remove the setting bolt of engine.

Remove the engine.

ENGINE INSTALLATION

The installation sequence is essentially the reverse

of removal.

NOTE:

Route all the wire and cable properly.

Adjust the throttle cable free play.

clearance.

Adjust the rear brake free play.

CPI MOTOR

ENGINE REMOVAL/INSTALLATION GTR50

3-3

TORQUE

TORQUE STANDARD

SORTS TORQUE(kg-m)

5mm screw, nut 0.5

6mm screw, nut 1.2

8mm screw, nut 2.7

10mm screw, nut 4.0

12mm screw, nut 5.5

INNER OF ENGING

ITEM AMOUNT DIAMETER(mm) TORUQUE(kg-m) REMARKS

Cylinder head bolt, A 2 8 3.0 Stud bolt side

Cylinder head bolt, B 2 8 3.0 Stud bolt side

EXH. pipe joint bolt 2 8 0.9 Spread on thread

Drive face nut 1 17 3.5~4.0

A.C.G. nut 1 17 3.5~4.0

Oil pump bolt 2 6 0.8

Cylinder head cover bolt 2 10 1.5

Spark plug 1 12 1.8

FRAME

ITEM AMOUT DIAMETER(mm) TORQUE(kg-m)

Shaft steering nut 1 10 4.5

FR. Wheel axle nut 1 12 6.0

RR. Wheel axle nut 1 16 9.0

RR. shock absorber bolt (up) 1 10 3.0

RR. shock absorber bolt (down) 1 8 3.0

ENG. Hanger BRKT. Bolt 1 10 5.5

CPI MOTOR

LUBRICATION SYSTEM GTR50

4-1

OIL PUMP REMOVAL

Remove luggage box & side covers.

Disconnect the oil tube of oil pump (intake &

output).

Remove the oil pump control cable.

Remove the setting bolt of oil pump.

Remove the oil pump.

OIL PUMP INSPECTION

Check the O-ring, gear & seal for wear or any

damage.

NOTE:

Do not disassembly the oil pump body

to prevent any damage.

OIL PUMP INSTALLATION

Coating some oil on the O-ring.

Install the oil pump onto the crankcase.

Connect the oil tube.

Connect the oil pump control cable and adjust

the clearance.

CPI MOTOR

LUBRICATION SYSTEM GTR50

4-2

RELEASE THE AIR OF OIL PUMP

Loosen the drain screw.

Let the oil drain out in smoothly then tight the

screw.

NOTE:

If the oil can not drain out in smoothly,

it is mean some air still in the oil pump.

CPI MOTOR

FUEL SYSTEM GTR50

5-1

THROTTLE VALVE REMOVAL

Remove the seat.

Remove the luggage box.

Loose the carburetor cap of throttle valve.

Remove the throttle valve from the carburetor.

Remove the throttle valve from the throttle cable.

THROTTLE VALVE DISASSEMBLY

Remove the retainer and take out the jet needle clip

from the throttle valve.

INSPECTION

Check the throttle valve and the jet needle surface of

dirt, scratches or wear.

CARBURETOR REMOVAL

Remove the side cover

Remove the luggage box ASSY.

Remove the starter plunger wire.

Remove the throttle cable.

Remove the fuel tube from the carburetor.

Loose the screw of the air cleaner band.

Loose the bolts between the intake pipe & the

carburetor.

Remove the carburetor.

CPI MOTOR

FUEL SYSTEM GTR50

5-2

Remove the carburetor and let it cool down by

nature for thirty minutes.

Check the current of air route as show.

GOOD : PASSABLE

NG :IMPASSABLE

BLOW

Connect a full charged battery to the starter plunger

wore for five minutes.

Check the current of route as show.

GOOD : IMPASSABLE

NG : PASSABLE

BLOW

FLOAT CHAMBER DISASSEMBLY

Remove the setting screws.

Remove the chamber cap.

Remove the float setting bolt.

Remove the float pin.

Remove the float.

Remove the float valve.

CPI MOTOR

FUEL SYSTEM GTR50

5-3

Remove the main jet, slow jet, needle seat & air

screw.

Clean all the jet & all the hole by using high

pressure air.

FUEL HEIGHT INSPECTION

Measure the height by using a gauge.

STANDARD: 18.5

CARBURETOR INSTALLATION

The installation sequence is essentially the reverse

of remove.

Adjust the clearance of the throttle valve cable.

Adjust the air screw.

STANDARD : 1+1/2round

Adjust the idle speed.

STANDSRD: 1800100 rpm

CPI MOTOR

FUEL SYSTEM GTR50

5-4

REED VALVE REMOVAL

Remove the carburetor.

Remove the intake pipe.

Remove the reed valve.

REED VALVE INSPECTION

Measure the height of reed valve stopper.

STANDARD: 6.0-6.4

Check the flatness of reed valve.

SERVOCE LIMIT : 7.0

REED VALVE INSTALLATION

The installation sequence is essentially the reverse

of removal.

CPI MOTOR

CYLINDER HEAD/CYLINDER/PISTON GTR50

6-1

CYLINDER HEAD REMOVAL

Put the right side of vehicle on the ground.

Attention! Please have a protected pad on the proper

location of the ground to avoid crash or damage of

plastic parts.

Remove the spark plug cap.

Remove the exhaust muffler.

Remove the cylinder air shrouds.

Remove the spark plug.

Remove the setting bolts of cylinder head.

Remove the cylinder head.

Cylinder head flatness inspection.

SERVICE LIMIT: 0.05

CYLINDER REMOVAL

Remove the cylinder head.

Remove the cylinder.

Remove the cylinder gasket.

NOTE:

Clean all the material of cylinder gasket with

a scraper.

CPI MOTOR

CYLINDER HEAD/CYLINDER/PISTON GTR50

6-2

PISTON REMOVAL

Remove the piston pin clip.

NOTE:

Do not let the clip fall into the crankcase.

Remove the piston pin.

Remove the piston.

PISTON / PISTON RING INSPECTION

Remove the piston rings.

Clean the grooves for carbon deposit completely.

NOTE:

Do not damage the piston ring during

removal.

Cylinder block flatness inspections:

SERVICE LIMITS: 0.05

CYLINDER INSPECTION

Inspect the cylinder bore for wear or damage.

Measure the cylinder I. D. at three places; top,

middle and bottom of piston travel and in two

directions at right angle to each other.

STANDARD:39.993-40.013mm

SERVICE LIMITS: 40.2

CPI MOTOR

CYLINDER HEAD/CYLINDER/PISTON GTR50

6-3

Calculate the piston-to-cylinder clearance.

SERVICE LIMITS : 0.1

Calculate the taper and out of round.

SERVICE LIMITS:

Out of round: 0.05

Taper: 0.05

Measure piston pin bore O. D. at a point 10 from the

bottom.

STANDARD:39.95

Measure piston pin bore I. D. in two directions at right

angle to each other.

STANDARD: 12.05

Measure the piston pin O. D. at the front, center and rear

and in two directions across from each other.

STANDARD: 12.05

Insert each piston ring into cylinder with the piston and

measure the ring end gap in the cylinder to a point 10

(0.04 in) from the bottom.

STANDARD:

Top / Second: 0.15~0.35

CPI MOTOR

CYLINDER HEAD/CYLINDER/PISTON GTR50

6-4

Connecting rod small end inspections:

SERVICE LIMITS: 14.06 .

PISTON RING INSTALLATION

Clean the piston ring grooves thoroughly.

Install the piston ring.

NOTE:

Avoid piston and piston ring damage

during installation.

All ring should be installed with the

mark facing up.

PISTON INSTALLATION

Install the piston, piston pin and new piston pin

clips.

NOTE:

Piston the EX mark on the exhaust

side.

Do not let the piston pin clip fall into

the crankcase.

CPI MOTOR

CYLINDER HEAD/CYLINDER/PISTON GTR50

6-5

CYLINDER INSTALLATION

Install the cylinder gasket.

Coat the cylinder and piston ring with the engine oil.

Install the cylinder.

COMPRESSION PREASURE TEST

NOTE:

Worm up the engine before test.

Remove the seat & luggage box.

Remove the spark plug cap & spark plug.

Turn the throttle grip with the throttle valve on the

upset position.

Start the motor for 7-8 seconds for test the pressure

CPI MOTOR

TRANSMISSION SYSTEM GTR50

7-1

LEFT CRANKCASE COVER REMOVAL

Remove the start kick.

Remove the crankcase cover.

Remove the dowel pin.

Remove the kick pinion with the kick friction

spring.

Disconnect the kick start spring.

Remove the cir-clip & plate washer.

Remove the kick spindle bush.

Remove the spindle & the spring.

Remove the O-ring.

Remove the setting nut of clutch outer.

CPI MOTOR

TRANSMISSION SYSTEM GTR50

7-2

Remove the clutch outer & driven pulley.

Remove the drive belt.

Remove the setting nut of driver face.

Remove the conical spring washer & the one way

clutch.

Remove the claw washer, driver face & plat washer.

Remove the movable drive face & collar.

CPI MOTOR

TRANSMISSION SYSTEM GTR50

7-3

START CLUTCH REMOVAL

Remove the starter clutch & starter wheel.

Remove the gear boss.

Remove the plat washer.

Remove the idle gear plate.

Remove the idle gear.

DRIVEN BELT INSPECTION

Inspect the belt for crack wear or any damage

measure the width of belt.

SERVICE LIMIT : 14.60

WEIGHT ROLLER INSPECTION

Measure the weight roller O. D.

SERVICE LIMIT : 14.5

14.60mm

CPI MOTOR

TRANSMISSION SYSTEM GTR50

7-4

MOVABLE DRIVEN FACE INSPECTION

Measure the movable driven face I. D.

STANDARD: 20.5

BOSS OF DRIVEN FACE INSPECTION

Measure the boss I. D.

SERVICE LIMIT :17.90

CLUTCH OUTER INSPECTION

Measure clutch outer I. D.

STANDARD : 109.5

CLUTCH LINING INSPECTION

Measure the lining thickness.

STANDARD : 1.0

CPI MOTOR

TRANSMISSION SYSTEM GTR50

7-5

DRVIEN PULLEY DISASSEMBLY

Fix the driven pulley in a compressor.

Remove the special nut (28).

Release the compressor.

Remove the driven plat assy.

DRIVEN FACE SPRING INSPECTION

Measure the spring free leant.

STANDARD : 89.5

DRIVEN FACE INSPECTION

Measure the drive face O. D.

STANDARD : 33.94

MOVABLE DRIVEN FACE INSPECTION

Measure the movable driven face I. D.

STANDARD : 34.06

CPI MOTOR

TRANSMISSION SYSTEM GTR50

7-6

Final transmission gear removal.

Drain the gear oil

Remove the mission cover.

Remove mission cover gasket & dowel pin.

Remove final shaft & final gear.

Remove counter shaft.

FINAL GEAR TRANSMISSION GEAR

INSPECTION

Inspect the gears & shafts for wear or damage.

CPI MOTOR

CRANKSHAFT/CRANKCASE GTR50

8-1

CRANKCASE REMOVAL

Remove the crankcase setting bolts.

Remove the right crankcase from the left crankcase

by using a pulley.

Remove the crankcase from the left crankcase by

using a pulley.

Remove the bearing of crankcase by using a bearing

pulley.

CPI MOTOR

CRANKSHAFT/CRANKCASE GTR50

8-2

CRANKSHAFT INSPECTION

Measure the connecting rod big end side clearance with a

feeler gauge.

STANDARD: 0.55

Measure the connecting rod big end radial clearance at

two different point across from each other.

STANDARD:0.05

Place the crankshaft on a stand or V-blocks and measure

the run out using a dial gauge.

Actual bend is 1/2 of total indicator reading.

STANDARD: 0.1

Check the crankshaft bearing play.

If they are noisy or have recessive play, replace a new

one.

CPI MOTOR

CRANKSHAFT/CRANKCASE GTR50

8-3

CRANKCASE INSTALLATION

Install the crankshaft bearing into the left crankcase.

Install the crankshaft bearing into the right crankcase.

Install the crankshaft into the left crankcase.

Install the oil seal into the left crankcase.

CPI MOTOR

CRANKSHAFT/CRANKCASE GTR50

8-4

Install the dowel pins.

Install the right crankcase.

Install the oil seal into the right crankcase.

Install the setting bolts of crankcase.

TORQUE : 1.0 -m.

CPI MOTOR

A.C.GENERATOR GTR50

9-1

A. C. GENERATOR REMOVAL

Remove the seat & luggage box.

Remove the side covers.

Remove the cylinder air should.

Remove the fly wheel setting nut by using a Y

fixer.

Remove the fly wheel by using a pulley.

Disconnect the wires of A. C. G.

CPI MOTOR

A.C.GENERATOR GTR50

9-2

Remove the A. C. G. setting bolts.

Remove the A. C. G.

A.C. G. INSTALLATION

The installation sequence is essentially the reverse of

removal.

CPI MOTOR

ELECTRIC SYSTEM GTR50

10-1

BATTERY INSPECTION

Check the voltage of the battery.

FULL CHARGE : 13.013.2 v

UNDER CHARGE : 12.3 v

BATTERY CHARGING

Connect charge position (+) cable to the battery

positive termini.

Connect the charge negative (-) cable to the battery

negative (-) terminal.

CHARGING CURRENT : STANDARD : 0.4A

SWIFTNESS : 4A

CHARGING TIME : STANDARD :5 hrs

SWIFTNESS : 30 min

RESISTER INSPECTION

Check the continuity between the wire of resister and

earth.

C.D. I. INSPECTION

AC110V

GOOD NG

1. OFF

2. P

3. EXT

4. ON.1

5. ON.2

NO SPARK

SPARK

SPARK

NO SPARK

CPI MOTOR

ELECTRIC SYSTEM GTR50

10-2

IGNITION COIL INSPECTION

Check the primary coil for continuity.

Mark connections with an ohmmeter as shown.

The coil is normal if there is continuity.

STANDARD: 0.11.0 ( 20)

Check the secondary coil for continuity.

The ignite coil is correct if there is continuity.

STANDSRD:

With plug cap: 712 k

No plug cap : 35 k

Check the coil output on a ignition coil tester.

Set the tester to ignition test, dial out the electrodes

and observe the spark gap.

GOOD: Continuous spark.

NG: Discontinuous spark

NOTE:

Follow the instructions supplied with the

tester.

CPI MOTOR

ELECTRIC SYSTEM GTR50

10-3

IGNITION TIMING INSPECTION

Check the ignition timing by using a timing light

after warm up the engine.

STANDARD:

BTDC :171

(1800100rpm)

START MOROTR

START MORTOR INSPECTION

Connect a battery (12 V) to the motor.

Check the performance of the motor.

NOTE :

Use a fully charged battery.

:

CPI MOTOR

ELECTRIC SYSTEM GTR50

10-4

CPI MOTOR

ADDENDUM GTR50

11-1

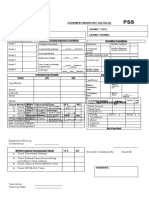

REGULAR INSPECTION

The chart below lists the recommended intervals for all the

returned periodic service work necessarily to keep the motorcycle

operating at peak performance and utmost efficiency. Mileages are

expressed in terms of kilometers and months.

These intervals judged by odometer reading or month whichever

comes first.

Km

300

Km

1000

Km

2000

Km

3000

Km

4000

Km

5000

Km

6000

Km

7000

Km

8000

Km

9000

Km

10000

Km

11000

Km

12000

Km

Months

Item

new

scooter

period

1

month

2

months

3

months

4

months

5

months

6

months

7

months

8

months

9

months

10

months

11

months

12

months

Battery I I I I I I I I I I I I I

Tire I I I I I I I I I I I I I

Brake I I I I I I I I I I I I I

Brake fluid I I R I R

Bolts and nuts I I I I I I I I I I I I I

Spark plug I I I I I

Air cleaner I I I I

Final gear oil R R R

Cylinder head nut

exhaust pipe bolts

I I I I I

Steering system I I I

Engine idle rpm I I I I I I I I I I I I I

Muffler I I I

Oil pump I I I I I

Fuel filter I R R

I=Inspect and clean, adjust, lubricate or replace, if necessary.

R=Replace

T=Tighten

CPI MOTOR

ADDENDUM GTR50

11-2

SPECIAL TOOLS

1. FOR FRAME ASSEMBLY

i. For the front fork

ii. For the brake sensor

2. FOR ENGINE ASSEMBLY

i. For A.C.G.

CPI MOTOR

ADDENDUM GTR50

11-3

COOLING SYSTEM DRAWING

PLIERS

clamp 2

You might also like

- Single Cylinder L-Head Repair ManualDocument338 pagesSingle Cylinder L-Head Repair ManualKlara Patai100% (2)

- Clutch: SectionDocument22 pagesClutch: SectionMatea Virgil SorinNo ratings yet

- Radiator Grille Removal and InstallationDocument2 pagesRadiator Grille Removal and InstallationMichael HernandezNo ratings yet

- Engine Mechanical PDFDocument115 pagesEngine Mechanical PDFAndrey GladyshevNo ratings yet

- Footing Tie Beam Details: Left MID RightDocument1 pageFooting Tie Beam Details: Left MID RightLong Live TauNo ratings yet

- Tillotson Exchange Catalog PDFDocument47 pagesTillotson Exchange Catalog PDFKlara Patai100% (1)

- Zundapp 50 125 Manual de Reparatie 1 WWW - Manualedereparatie.infoDocument45 pagesZundapp 50 125 Manual de Reparatie 1 WWW - Manualedereparatie.infoKlara PataiNo ratings yet

- BYD-ED400 User Manual (English) 2010-05-04Document25 pagesBYD-ED400 User Manual (English) 2010-05-04Jacobo Antonio Camacho ZarateNo ratings yet

- GPZ1100 1983 Kawasaki Service ManualDocument80 pagesGPZ1100 1983 Kawasaki Service ManualKlara Patai33% (3)

- WARN Industrial Winch: Part Number Model Series 15-A-1D Electric Winch Manual Clutch Motor TypeDocument2 pagesWARN Industrial Winch: Part Number Model Series 15-A-1D Electric Winch Manual Clutch Motor Typejolupeco44No ratings yet

- Ax1006675-Stamford Alternator Parts CatalogDocument54 pagesAx1006675-Stamford Alternator Parts CatalogLuis Carlos Santos Sobrinho67% (3)

- Class IV-Model Question paper-MEK (General)Document2 pagesClass IV-Model Question paper-MEK (General)ritheshNo ratings yet

- Engine Mechanical : Group 11CDocument36 pagesEngine Mechanical : Group 11CRomaNo ratings yet

- Yamaha JogDocument204 pagesYamaha Joganxony100% (3)

- Inventory of New California WarehouseDocument164 pagesInventory of New California Warehouseluis felipe rojas huamaniNo ratings yet

- Manual de Partes de 21ac PDFDocument52 pagesManual de Partes de 21ac PDFAbelCuevasHuamaniNo ratings yet

- Commutation in DC Machines PDFDocument2 pagesCommutation in DC Machines PDFTom0% (1)

- JAKجيبDocument344 pagesJAKجيبملك الشيريNo ratings yet

- Tra 41a Servo Drive Mitsubishi ManualDocument28 pagesTra 41a Servo Drive Mitsubishi Manualsasa mitic100% (1)

- Webasto Thermotop C InstallationDocument44 pagesWebasto Thermotop C InstallationLucian100% (1)

- The AutotransformerDocument7 pagesThe AutotransformerJohn Brix BalisterosNo ratings yet

- Gilera Runner 125 - 200 (EN)Document335 pagesGilera Runner 125 - 200 (EN)Manualles81% (16)

- 90cc (LT-Z90K7 AD41A 2007)Document43 pages90cc (LT-Z90K7 AD41A 2007)Klara PataiNo ratings yet

- Foundation Notes:-: G.A. Drawing For 6 Mtrs. Octagonal Pole With 1M Single ArmDocument1 pageFoundation Notes:-: G.A. Drawing For 6 Mtrs. Octagonal Pole With 1M Single ArmP.MannaNo ratings yet

- RENR2200 04 SpecificationDocument203 pagesRENR2200 04 SpecificationGerman GuaglianoneNo ratings yet

- Sodime 1 Norme SmsDocument49 pagesSodime 1 Norme Smsnqh2009100% (2)

- ATRO Field Manual 061214Document68 pagesATRO Field Manual 061214Raja Sekaran Sajja100% (1)

- Owner S ManualDocument68 pagesOwner S Manualfadrique54No ratings yet

- Mojito Workshop ManualDocument105 pagesMojito Workshop Manualmapgwarez75% (4)

- CPI GTR150 Frame T74-40000-00-00Document47 pagesCPI GTR150 Frame T74-40000-00-00Kurniawan AdeNo ratings yet

- CPI GTR150-81J Engine PDFDocument43 pagesCPI GTR150-81J Engine PDFKurniawan Ade100% (1)

- UntitledDocument156 pagesUntitledЕвгений БычкоNo ratings yet

- Pares de Apriete Del Corolla 2002 Al 2004 1.8LDocument10 pagesPares de Apriete Del Corolla 2002 Al 2004 1.8LGuillén CarsNo ratings yet

- Prices EuroDocument36 pagesPrices EuroRi ChardNo ratings yet

- PGO PMX Naked - Workshop Manual 1of 2Document58 pagesPGO PMX Naked - Workshop Manual 1of 2Jan Johansson50% (2)

- G25M R TransmissionDocument29 pagesG25M R TransmissionMaksym VovkNo ratings yet

- Omega 980 Info CatalogDocument8 pagesOmega 980 Info CatalogIAN CUMMING CARRERENo ratings yet

- 5维修手册 Chapter 6Document28 pages5维修手册 Chapter 6Frank Ch Ccaico100% (1)

- GA15 Engine DisassemblyDocument79 pagesGA15 Engine DisassemblyJohn CoxxNo ratings yet

- Service Manual Picanto Ion G3HGDocument12 pagesService Manual Picanto Ion G3HGrectificamosNo ratings yet

- Saturn Brake BleedingDocument4 pagesSaturn Brake Bleedinglamping_ap100% (1)

- 03 DR-Z125-03-EngineDocument60 pages03 DR-Z125-03-EngineVincent RoyNo ratings yet

- 2003 Yamaha WR450F Partscatalog PDFDocument62 pages2003 Yamaha WR450F Partscatalog PDFPACHYYNNo ratings yet

- ToyotaDocument12 pagesToyotaZarate CruzNo ratings yet

- Diesel Engine and Components: Series Paragraphs 51-53Document9 pagesDiesel Engine and Components: Series Paragraphs 51-53Branko MikulinjakNo ratings yet

- 2GR FE ChargingDocument25 pages2GR FE Chargingmink4uNo ratings yet

- Foton 1039v4jd3-0aza11Document189 pagesFoton 1039v4jd3-0aza11Abderrahim Boutabba100% (1)

- 1E48F-E EngineDocument31 pages1E48F-E EnginePatrik ArvhultNo ratings yet

- Goulds Pumps Spare Parts PDFDocument32 pagesGoulds Pumps Spare Parts PDFjhonny barrantesNo ratings yet

- Front Fender Explorer Removal and InstallationDocument2 pagesFront Fender Explorer Removal and InstallationMichael HernandezNo ratings yet

- Airtester HP-3-GB D3188001 03Document7 pagesAirtester HP-3-GB D3188001 03federalulNo ratings yet

- c1 1Document301 pagesc1 1Liza Cabalquinto LorejoNo ratings yet

- Jonsered 49SP ManualDocument8 pagesJonsered 49SP ManualBlackbenellieSBE1No ratings yet

- Uputstvo - Sprint ExactlyDocument24 pagesUputstvo - Sprint ExactlyvladomiljNo ratings yet

- SoloVac III Spray VaccinatorDocument2 pagesSoloVac III Spray VaccinatorAmer Adas100% (1)

- Fuel NozzlesDocument25 pagesFuel NozzlesMarcos Daniel Pérez AriasNo ratings yet

- Trim Panel Removal and InstallationDocument3 pagesTrim Panel Removal and InstallationMichael HernandezNo ratings yet

- 2GR-FSE - Engine Mechanical - Recommended ToolsDocument1 page2GR-FSE - Engine Mechanical - Recommended ToolsJohn LockeNo ratings yet

- Breakdown in LiquidsDocument17 pagesBreakdown in LiquidsMuhd Nur RidzwanNo ratings yet

- Heated Oxygen Sensor Ho2s and Catalyst Monitor Sensor 8212 Exploded View 4 6l 3v Removal and Installation PDFDocument1 pageHeated Oxygen Sensor Ho2s and Catalyst Monitor Sensor 8212 Exploded View 4 6l 3v Removal and Installation PDFMichael HernandezNo ratings yet

- v2c 650s - T Parts Book CrusierDocument66 pagesv2c 650s - T Parts Book CrusierSebastian RodriguezNo ratings yet

- Caterpillar Engine Service Manual CT S Eng 3208Document9 pagesCaterpillar Engine Service Manual CT S Eng 3208Kyaw SoeNo ratings yet

- Duratech 2.5L Engine V6Document112 pagesDuratech 2.5L Engine V6jbakert100% (2)

- Adp ReportDocument92 pagesAdp ReportNILASRI R S100% (1)

- Montara H1 ST1 Well ReleaseDocument62 pagesMontara H1 ST1 Well Releasemack_eausNo ratings yet

- Intake Venturi System (LN 2L-T: Only)Document11 pagesIntake Venturi System (LN 2L-T: Only)David QuispeNo ratings yet

- PDFDocument4 pagesPDFalx56No ratings yet

- VOITH DIWA - Servisni IntervaliDocument4 pagesVOITH DIWA - Servisni IntervaliElmin SkuljNo ratings yet

- 99 Speedster SpecsDocument6 pages99 Speedster SpecsLee PrineNo ratings yet

- Endress KatalogDocument72 pagesEndress KatalogpnsanatNo ratings yet

- Sezione 2 PDFDocument8 pagesSezione 2 PDFMAZZI1978100% (1)

- Soosan Crane Training: (Principles)Document119 pagesSoosan Crane Training: (Principles)Boumediene CHIKHAOUINo ratings yet

- Chapter 4Document10 pagesChapter 4igorNo ratings yet

- 3541RL 3541RL: Service Manual Service ManualDocument18 pages3541RL 3541RL: Service Manual Service Manualyousef ALadwanNo ratings yet

- Clutch: Description and Operation Clutch ComponentsDocument8 pagesClutch: Description and Operation Clutch ComponentsawemetalNo ratings yet

- Kymco Super 8 50cc 2 Stroke Parts Catalog 2009 PDFDocument95 pagesKymco Super 8 50cc 2 Stroke Parts Catalog 2009 PDFKlara Patai0% (1)

- Dink50 SH10BADocument85 pagesDink50 SH10BAKlara PataiNo ratings yet

- Illustrated Parts Manual: Transmatic Lawn Tractor Models 760, 770 761, 771 762, 772 769, 779Document28 pagesIllustrated Parts Manual: Transmatic Lawn Tractor Models 760, 770 761, 771 762, 772 769, 779Klara PataiNo ratings yet

- Cpi JW 50-90-100 ServicemanualDocument81 pagesCpi JW 50-90-100 ServicemanualKlara Patai50% (2)

- CPI Cheetah XS Service Manual 2tDocument46 pagesCPI Cheetah XS Service Manual 2tKlara PataiNo ratings yet

- Aprilia RS 50 1Document11 pagesAprilia RS 50 1Klara PataiNo ratings yet

- For Noncommercial Use Only! For Noncommercial Use Only!: PDF Created With Fineprint Pdffactory Trial VersionDocument1 pageFor Noncommercial Use Only! For Noncommercial Use Only!: PDF Created With Fineprint Pdffactory Trial VersionKlara PataiNo ratings yet

- Oliver 50cc Scooter Owners ManualDocument37 pagesOliver 50cc Scooter Owners ManualKlara PataiNo ratings yet

- Aprilia MX 50Document6 pagesAprilia MX 50Klara PataiNo ratings yet

- Cpi JW 50-90-100 ServicemanualDocument81 pagesCpi JW 50-90-100 ServicemanualKlara Patai50% (2)

- Peugeot - Ha1 - 50cc 2t EngineDocument28 pagesPeugeot - Ha1 - 50cc 2t EngineKlara PataiNo ratings yet

- PLDT PSS: Node 1 Node 2 Node 3 Node 4 Node 5 Node 6 Outside Dimension Locking Mechanism Key Type/brand Base Pad HeightDocument2 pagesPLDT PSS: Node 1 Node 2 Node 3 Node 4 Node 5 Node 6 Outside Dimension Locking Mechanism Key Type/brand Base Pad HeightGerald CorneliaNo ratings yet

- ULMCOM Specifiers Sheet - 1 PDFDocument2 pagesULMCOM Specifiers Sheet - 1 PDFmjay90No ratings yet

- Cayenne Turbo Driver's Manual (0307) PDFDocument367 pagesCayenne Turbo Driver's Manual (0307) PDFRA SOTHEANo ratings yet

- Gewiss 70 RT HP - Rotary IsolatorDocument2 pagesGewiss 70 RT HP - Rotary IsolatorEman AdhamNo ratings yet

- PBC 6200Document53 pagesPBC 6200YousufaLi Moiz HussainNo ratings yet

- Fire ChecklistDocument2 pagesFire ChecklistMichael D. CroweNo ratings yet

- CSPDocument6 pagesCSPBADRI VENKATESHNo ratings yet

- PA Footwear GA Tank AssemblyDocument1 pagePA Footwear GA Tank AssemblyMahidhar TalapaneniNo ratings yet

- Atwater Kent 40-42-52-56-57 SchematicsDocument1 pageAtwater Kent 40-42-52-56-57 SchematicsEdd WhatleyNo ratings yet

- 2006-2008-Cbf1000-A-19 Ignition SystemDocument8 pages2006-2008-Cbf1000-A-19 Ignition Systemdrkrassas100% (1)

- Vernacular Words Construction Architecture 2019 Yas PDFDocument3 pagesVernacular Words Construction Architecture 2019 Yas PDFCyril Joy NagrampaNo ratings yet

- Dictionar Scolar Englez-Roman Si Roman-EnglezDocument4 pagesDictionar Scolar Englez-Roman Si Roman-EnglezcDraghia0% (1)

- ELEG 310L Prelab 3Document3 pagesELEG 310L Prelab 3ghaliaNo ratings yet

- Fig.1350 Accelerator LinkageDocument1 pageFig.1350 Accelerator LinkageДмитрий ЗесковNo ratings yet

- Ols XXX - XXXNX: OLS Optical Level SwitchDocument4 pagesOls XXX - XXXNX: OLS Optical Level SwitchAhmad YogaNo ratings yet

- 968 Headlight CUDocument1 page968 Headlight CUNehmaizNo ratings yet

- YLI LightingDocument28 pagesYLI Lightingyun yen wongNo ratings yet

- Elastimold Underground Cable Accessories MV HV CatalogueDocument60 pagesElastimold Underground Cable Accessories MV HV Cataloguejmrs7322No ratings yet

- Amaya School of Home Industries Sahud-Ulan Tanza, CaviteDocument83 pagesAmaya School of Home Industries Sahud-Ulan Tanza, CaviteEdz CabrigaNo ratings yet

- Syncrosnap® Centrifugal Switches For Single-Phase Electric MotorsDocument4 pagesSyncrosnap® Centrifugal Switches For Single-Phase Electric MotorsMohit GargNo ratings yet

- Protections in NODocument4 pagesProtections in NOsantoshkumarNo ratings yet

- ICU800-67LC Incoming Units (+C108/+C109) : Hardware ManualDocument108 pagesICU800-67LC Incoming Units (+C108/+C109) : Hardware ManualIvan Fook TkdNo ratings yet

- ABB - Util. Categories For ContactorsDocument1 pageABB - Util. Categories For ContactorskoustasdNo ratings yet

- HFD2Document4 pagesHFD2Miguel PerniaNo ratings yet