Professional Documents

Culture Documents

Intake Venturi System (LN 2L-T: Only)

Uploaded by

David QuispeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Intake Venturi System (LN 2L-T: Only)

Uploaded by

David QuispeCopyright:

Available Formats

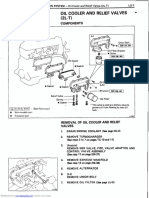

EM-30 ENGINE MECHANICAL - Intake Venturi System (LN 2L-T only)

INTAKE VENTURI SYSTEM

(LN 2L-T only)

ON-VEHICLE INSPECTION

NOTICE: Always stop the engine when installing or re-

moving the vacuum gauges, or removing the vacuum hoses.

(Austria)

PREPARATION

Using two 3-way connectors, connect two vacuum gauges

to hoses between the actuator and VSV.

CHECK THROTTLE VALVE (LOW ALTITUDE AREA)

HINT: Perform this check a t an altitude below 800 m

(2,600 ft) and a t an atmospheric pressure above 700

mm Hg (94.5 kg/cm2).

Start the engine and check that vacuum operates on

diaphragm chamber B so that the rods are pulled up.

Check that when the accelerator pedal is depressed,

atmospheric air operates on both diaphragm cham-

bers so that the rods return.

Check that when the starter switch is turned OFF

(engine stopped) from idling condition, vacuum

operates on both diaphragm chambers so that the

rods are pulled up.

Check that after the starter switch i s turned OFF, the

rods gradually return.

CHECK THROTTLE VALVE (HIGH ALTITUDE AREA)

HINT: Perform this check a t an altitude above 800 m

(2,600 ft) and a t an atmospheric pressure below 690

mm Hg (93.2 kg/cm2).

Check that during idling or with the starter switch OFF

(engine stopped), vacuum i s not operating on either

diaphragm chamber.

Downloaded from www.Manualslib.com manuals search engine

ENGINE MECHANICAL - Intake Venturi Svstem (LN 2L-T only) EM-31

(Others) d

PREPARATION

Using a 3-way connector, connect a vacuum gauge to hose

between the actuator and VSV.

CHECK THROTTLE VALVE

(a) Start the engine and check that the vacuum gauge

indicates zero vacuum.

(b) Check. that when the starter switch is turned OFF

(engine stopped) from idling condition, vacuum

operates on the diaphragm chamber so that the rods

return.

(c) Check that after the starter switch is turned OFF, the

rods gradually return.

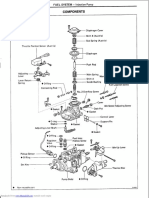

INSPECTION OF INTAKE VENTURI SYSTEM

COMPONENTS

1. INSPECT VENTURI

(a) Fully close the throttle valve, and check that it re-

turns smoothly.

(b) (Austria)

Using the hand-help vacuum pump, check that when

vacuum is gradually applied to diaphragm chamber B

of the actuator, the throttle valve opens half-way.

(c) (Austria)

Using the hand-help vacuum pump check that when

vacuum is gradually applied to diaphragm chambers A

and B of the actuator, the throttle valve fully opens.

Downloaded from www.Manualslib.com manuals search engine

EM-32 ENGINE MECHANICAL - Intake Venturi System (LN 2L-T only)

(d) (Others)

Using the hand-help vacuum pump, check that when

vacuum is gradually applied to the diaphragm cham-

ber of the actuator, the throttle valve opens half-way.

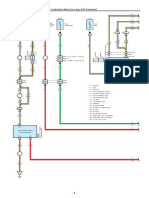

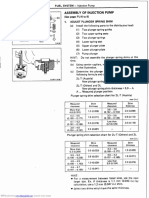

INSPECT VSV

Ohmmeter

lnspect VSV for open circuit

Using an ohmmeter, check that there is continuity be-

tween the terminals.

Resistance (Cold): 37 - 44 !2

I f there is no continuity, replace the VSV.

Inspect VSV for ground

Using an ohmmeter, check that there is no continuity b e

tween each terminal and the body.

I f there is continuity, replace the VSV.

C. lnspect VSV operation

Air (a) Check that air flows from pipes E to G.

(b) Apply battery voltage across the terminals.

(c) Check that air flows from port E to the filter

I f operation is not as specified, replace the VSV.

Downloaded from www.Manualslib.com manuals search engine

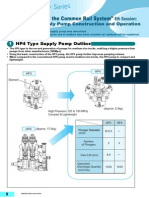

ENGlNE MECHANICAL - Com~ressionCheck

COMPRESSION CHECK

HINT: I f there is lack of power, excessive oil consump-

tion or poor fuel economy, measure the compression pres-

sure.

WARM UP AND STOP ENGINE

Allow the engine to reach normal operating temperature.

DISCONNECT INJECTION PUMP (FUEL CUT

SOLENOID) CONNECTOR

REMOVE AIR CLEANER

(w/ Intake Pipe)

REMOVE INTAKE PIPE

REMOVE GLOW PLUGS

CHECK CYLINDER COMPRESSION PRESSURE

(a) Install SST (attachment) to the glow plug hole.

SST 09992-00024 (09992-0012 1)

(b) Connect SST (compression gauge) to SST (attach-

ment).

SST 09992-00024 (09992-0012 1,09992-002 11)

(c) Fully open the throttle valve.

(d) While cranking the engine, measure the compression

pressure.

HINT: Always use a fully charged battery to obtain

engine revolution of 250 rpm or more.

(e) Repeat steps (a) through (d) for each cylinder.

NOTICE: This measurement must be done in as short a

time as possible.

Compression pressure:

2L-T 31.0 kg/cm2 (441 psi, 3,040 kPa) or more

3L 32.0 kg/cm2 (455 psi, 3,138 kPa) or more

Minimum pressure:

20.0 kg/cm2 (284 psi, 1,961 kPa)

Difference between each cylinder:

5.0 kg/cm2 (71 psi, 490 kPa) or less

Downloaded from www.Manualslib.com manuals search engine

(f) I f the cylinder compression in one or more cylinders

is low, pour a small amount of engine oil into the

cylinder through the glow plug hole and repeat steps

(a) through (d) for the cylinder with lowcompression.

I f adding oil helps the compression, chances are

that the piston rings and/or cylinder bore are worn

or damaged.

I f pressure stays low, a valve may be sticking or

seating improperly, or there may be leakage past

the gasket.

REINSTALL GLOW PLUGS

(w/ Intake Pipe)

REINSTALL INTAKE PIPE

REINSTALL AIR CLEANER

RECONNECT INJECTION PUMP (FUEL CUT

SOLENOID) CONNECTOR

Downloaded from www.Manualslib.com manuals search engine

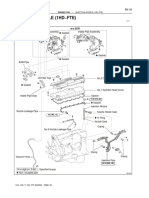

ENGINE MECHANICAL - Cylinder Head (2L-T) EM-35

CYLINDER HEAD (2L-T)

COMPONENTS

Cylinder Heat Cover

No. 2 Heat Insulator

do.

Camshaft Bearing Cap

e

,- Valve Lifter

Keeper

@- Spring Retainer

Camshaft Bearing

@-valve Spring

8-+ Oil Seal

-Spring Seat

EGR Valve and Pipe

Combustion Chamber

Belt Cover

EGR Valve Adaptor

Engine Hanger 4 Venturi Assembly

Air Pipe (Austria)

I kg-cm (ft-lb, ~ m ) :] Specified torque

+ Non-reusable part -

EM92:11

Downloaded from www.Manualslib.com manuals search engine

EM-36 ENGINE MECHANICAL - Cylinder Head (2L-T)

REMOVAL OF CYLINDER HEAD

(See page EM-35)

DRAIN ENGINE COOLANT (See page CO-4)

REMOVETURBOCHARGER

(See steps 2 to 7 on pages TC- 10 and 11)

REMOVE TIMING BELT

(See steps 2 to 7 on page FU-4)

REMOVE INJECTION PUMP

(See steps 8 to 16 on pages FU-4 and 5)

REMOVE INJECTION NOZZLES

REMOVE CAMSHAFT TIMING PULLEY

REMOVE NO. 2 TIMING BELT COVER

Remove the four bolts and belt cover.

REMOVE WATER OUTLET AND OUTLET HOUSING

ASSEMBLY

(a) Disconnect the water temperature switch connector.

(b) Disconnect the by-pass hose from the thermo wax of

the injection pump.

(c) Remove the three bolts, water outlet, outlet housing

assembly and gasket.

REMOVE LH ENGINE HANGER

(LN)

REMOVE VENTURI ASSEMBLY

(a) Disconnect the connector and vacuum hoses from the

VSV.

(b) Remove the venturi assembly and gasket.

(c) Remove the two bolts and wire support.

Downloaded from www.Manualslib.com manuals search engine

ENGINE MECHANICAL - Cylinder Head (2L-T) EM-37

11. (Austria)

)r

REMOVE EGR VALVE, PIPE, VALVE ADAPTOR AND

CONTROL VALVE ASSEMBLY

(a) Remove the four nuts, air pipe (LN only), EGR valve

adaptor and two gaskets.

(b) Disconnect the connectors from the VSV and EVRV.

(c) Remove the three bolts and EGR control valve

assembly.

(d) Remove the two nuts, EGR valve with the pipe and

gasket.

REMOVE INTAKE MAN1FOLD

(a) Remove the nut and insulator of the glow plug re-

sistor.

(b) Remove the six bolts, two nuts, intake manifold and

gasket.

REMOVE EXHAUST MANIFOLD

(a) Remove the four bolts, nut and two heat insulators.

Downloaded from www.Manualslib.com manuals search engine

EM-38 ENGINE MECHANICAL - Cylinder Head (2L-T)

(b) Remove the four bolts, four nuts, exhaust manifold

and gasket.

14. REMOVE RH ENGINE HANGER

15. REMOVE CYLINDER HEAD COVER

~ e m o v ethe eight bolts, two nuts, cylinder head cover and

gasket.

16. REMOVE CYLINDER HEAD

(a) Uniformly loosen and remove the eighteen cylinder

head bolts in several passes in the sequence shown.

NOTICE: Head warpage or cracking could result from

removing bolts in incorrect order.

(b) Lift the cylinder head from the dowels on the cy-

linder block and place the head on wooden blocks on

a bench.

HINT: I f the cylinder head is difficult to lift off, pry

with a screwdriver between the cylinder head and block.

NOTICE: Be careful not to damage the cylinder head

and cylinder block surfaces of cylinder head gasket side.

Downloaded from www.Manualslib.com manuals search engine

ENGINE MECHANICAL - Cylinder Head (2L-T) EM-39

DISASSEMBLY OF CYLINDER HEAD a

(See page EM-35)

INSPECTION, CLEANING AND REPAIR OF

CYLINDER HEAD COMPONENTS

INSPECT CAMSHAFTS AND BEARINGS

B. Inspect cam lobes

Using a micrometer, measure the cam lobe height.

Standard cam lobe height:

lntake 2L-T 53.450 - 53.470 mm

(2.1043 - 2.1051 in.)

3L 54.290 - 54.310 mm

(2.1374 - 2.1382 in.)

Exhaust 54.990 - 55.010 mm

(2.1650 - 2.1657 in.)

Minimum cam lobe height:

lntake 2L-T 52.95 mm (2.0846 in.)

3L 53.79 mm (2.1177 in.)

Exhaust 54.49 mm (2.1453 in.)

If the cam lobe height is smaller than the minimum,

replace the camshaft.

ASSEMBLY OF CYLINDER HEAD

(See page EM-35)

INSTALL HALF CIRCULAR PLUG

(a) Remove any old packing (FIPG) material.

(b) Apply seal packing to the half circular plug as shown.

Seal packing: Part No. 08826-00080 or equivalent

(c) Install the half circular plug to the cylinder head.

Downloaded from www.Manualslib.com manuals search engine

EM-40 ENGINE MECHANICAL - Cylinder Head (2L-T)

INSTALLATION OF CYLINDER HEAD

(See page EM-35)

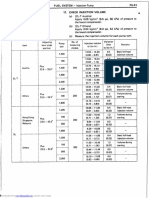

CHECK PISTON PROTRUSION AND SELECT

CYLINDER HEAD GASKET

Check protrusions of No. 1 and No. 4 pistons

(a) Align the timing marks of the crankshaft timing

pulley and timing belt case.

(b) Place a dial indicator on the cylinder block, and set

the dial indicator needle on the piston measuring

point.

(c) Find where the piston head protrudes most by slowly

turning the crankshaft clockwise and counterclock-

wise.

(d) Set the dial indicator a t 0 mm (0in.).

(e) Measure the piston protrusion from the cylinder

block by sliding the dial indicator.

Protrusion: 0.68 - 0.97 rnrn

(0.0268 - 0.0382 in.)

HINT: For each piston, measure the piston protrusion a t

two measuring points.

(When removing piston and connecting rod assembly)

I f the protrusion is not as specified, remove the piston and

connecting rod assembly and reinstall it.

Downloaded from www.Manualslib.com manuals search engine

You might also like

- Adjustment of Valve Clearance: No. 1 No. 3 EX EXDocument11 pagesAdjustment of Valve Clearance: No. 1 No. 3 EX EXDavid QuispeNo ratings yet

- Avensis Intake System PDFDocument19 pagesAvensis Intake System PDFMladen VidovićNo ratings yet

- Diesel Engine and Components: Series Paragraphs 51-53Document9 pagesDiesel Engine and Components: Series Paragraphs 51-53Branko MikulinjakNo ratings yet

- 08erm Injector 1HD FTEDocument15 pages08erm Injector 1HD FTEbrettNo ratings yet

- Removal: Automatic Transmission (A750F)Document5 pagesRemoval: Automatic Transmission (A750F)joe nathanNo ratings yet

- Service Bulletin: Fuel Injection PumpDocument15 pagesService Bulletin: Fuel Injection PumpKrunoslavNo ratings yet

- 4M4 Gr13E PDFDocument36 pages4M4 Gr13E PDFcristian garciaNo ratings yet

- Toyota Land Cruiser 1998-2007 - Air+ConditioningDocument113 pagesToyota Land Cruiser 1998-2007 - Air+ConditioningseowshengNo ratings yet

- Fundamental of Diesel EngineDocument23 pagesFundamental of Diesel EngineRita MandariNo ratings yet

- Manual Transaxle Assy (E357) : To Model IndexDocument1 pageManual Transaxle Assy (E357) : To Model IndexHenrry MendezNo ratings yet

- MAN Diesel Engines (Leisure Ships)Document28 pagesMAN Diesel Engines (Leisure Ships)Damian Cid MoralesNo ratings yet

- Emission Control PDFDocument63 pagesEmission Control PDFoz23100% (1)

- A51 A43 A34 A23 A22 A26 A24 A25 A32 A45: Position of Parts in Engine CompartmentDocument4 pagesA51 A43 A34 A23 A22 A26 A24 A25 A32 A45: Position of Parts in Engine CompartmentApril MckeeNo ratings yet

- Def 90 110 WSM Book4Document102 pagesDef 90 110 WSM Book4gourahari100% (1)

- 08 Engine MechanicalDocument80 pages08 Engine MechanicalmadcostaNo ratings yet

- 13C PDFDocument81 pages13C PDFKyaw Kyaw LinnNo ratings yet

- Mx5 95 1 of 3 EngineDocument90 pagesMx5 95 1 of 3 EngineJennifer Faith EvansNo ratings yet

- Valve Clearance (1Hd Fte) : InspectionDocument2 pagesValve Clearance (1Hd Fte) : InspectionArief SoehartoNo ratings yet

- Dyna Specs EngDocument2 pagesDyna Specs EngdionymackNo ratings yet

- Toyota 5l Valve ClearanceDocument5 pagesToyota 5l Valve ClearancedennoNo ratings yet

- Ec QG16Document320 pagesEc QG16Mahmoud El-MeghenyNo ratings yet

- 1zr-Fae Engine Mechanical Service DataDocument10 pages1zr-Fae Engine Mechanical Service DataMarzena SynoradzkaNo ratings yet

- Captiva Manual MY13Document380 pagesCaptiva Manual MY13David PomaNo ratings yet

- Diesel Injector Coding and Pilot LearningDocument3 pagesDiesel Injector Coding and Pilot LearningddaanniieellssaaNo ratings yet

- CRP D 200 Manual EngDocument16 pagesCRP D 200 Manual EngAbbode Horani100% (2)

- CRS (ECD-U2P) For Land CruiserDocument45 pagesCRS (ECD-U2P) For Land CruiserВячеслав ГлушакNo ratings yet

- Body Wiring System: Section: 9ADocument12 pagesBody Wiring System: Section: 9AsvedexNo ratings yet

- Relay Loc LCR 200Document40 pagesRelay Loc LCR 200Yannick de WalqueNo ratings yet

- Em PDFDocument148 pagesEm PDFvadim vadimNo ratings yet

- 2007 Civic Hybrid About SafetyDocument3 pages2007 Civic Hybrid About SafetyAngel ValladaresNo ratings yet

- Clutch PDFDocument25 pagesClutch PDFNinoReneNiñoRojasNo ratings yet

- Automatic Transmission PDFDocument334 pagesAutomatic Transmission PDFAriel MercochaNo ratings yet

- Installation of Cylinder Head: Downloaded From Manuals Search EngineDocument6 pagesInstallation of Cylinder Head: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Instruction Manual: For 12Psb Test BenchDocument18 pagesInstruction Manual: For 12Psb Test BenchMr CupuNo ratings yet

- CM F PDFDocument30 pagesCM F PDFJerroldLYIGNo ratings yet

- Product Knowledge 1 Training 4JA1 EngineDocument88 pagesProduct Knowledge 1 Training 4JA1 Enginefernando aritonangNo ratings yet

- Landcruiser70 SpecDocument2 pagesLandcruiser70 SpecJoao CarlosNo ratings yet

- Sds Toyota vx100Document8 pagesSds Toyota vx100Ferry DarmawanNo ratings yet

- x431 Isuzu Thailanda - Progra. Injector DieselDocument2 pagesx431 Isuzu Thailanda - Progra. Injector Dieselwilliam_senati20057051No ratings yet

- Guide To NSK Automotive Bearings For Replacement: June 2017 Page 1 of 7Document7 pagesGuide To NSK Automotive Bearings For Replacement: June 2017 Page 1 of 7Andrés UguñaNo ratings yet

- Bomba de Alta Predion Denso Hp4Document4 pagesBomba de Alta Predion Denso Hp4pepeladazoNo ratings yet

- Fortuner PMGDocument151 pagesFortuner PMGHenrique MolinaNo ratings yet

- Repair Guide For Denso Common Rail Injector RepairDocument22 pagesRepair Guide For Denso Common Rail Injector RepairJuan David Cepeda GonzalesNo ratings yet

- Live You : Technical Data: Fluids & CapacitiesDocument3 pagesLive You : Technical Data: Fluids & CapacitiesАндрей УгляницаNo ratings yet

- Engine Specifications: February 2001 ES-TOY07R1Document2 pagesEngine Specifications: February 2001 ES-TOY07R1Pencil neck100% (1)

- Service Manual: Common Rail System For NISSAN YD1-K2 Type EngineDocument40 pagesService Manual: Common Rail System For NISSAN YD1-K2 Type EngineBryan Edu Curay ZavalaNo ratings yet

- Aygo MMT ResetDocument3 pagesAygo MMT ResetAlan Ghon100% (2)

- VI - O55 - 6b - MotorDocument26 pagesVI - O55 - 6b - MotorDJJ ManutençãoNo ratings yet

- Nissan Navara D40 Automatic Gearbox Oil Change - PaperblogDocument6 pagesNissan Navara D40 Automatic Gearbox Oil Change - PaperblogMary Ann UsaragaNo ratings yet

- 17 Engine and Emission ControlDocument38 pages17 Engine and Emission ControlJoaoBorgesNo ratings yet

- 3G63 TurboDocument108 pages3G63 TurboLuis Felipe Dominguez del CastilloNo ratings yet

- Goulds Pumps Jet Pump Repair PartsDocument12 pagesGoulds Pumps Jet Pump Repair PartsMarissa Bryce50% (2)

- T SB 0274 09Document5 pagesT SB 0274 09goombaNo ratings yet

- Despiece HDJ 80Document80 pagesDespiece HDJ 80Orlando ParraNo ratings yet

- P0012 - Bomba de Injecciòn MAMDocument4 pagesP0012 - Bomba de Injecciòn MAMMIGUEL PEÑANo ratings yet

- (Others) : Downloaded From Manuals Search EngineDocument10 pages(Others) : Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- 98 Dodge Ram Truck SM SCSDocument1 page98 Dodge Ram Truck SM SCSEduardo MacMasterNo ratings yet

- 1gr-Fe SfiDocument68 pages1gr-Fe SfiByron GómezNo ratings yet

- 22 - Hybrid TransaxleDocument75 pages22 - Hybrid Transaxlepejopo100% (1)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Atmega16 (L) : Programming The EepromDocument6 pagesAtmega16 (L) : Programming The EepromDavid QuispeNo ratings yet

- Datasheet (3) (254-284) - 1-5Document5 pagesDatasheet (3) (254-284) - 1-5David QuispeNo ratings yet

- Fuel System FU-31 2. Pre-Set Full Load Injection VolumeDocument6 pagesFuel System FU-31 2. Pre-Set Full Load Injection VolumeDavid QuispeNo ratings yet

- Troubleshooting: Downloaded From Manuals Search EngineDocument6 pagesTroubleshooting: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Downloaded From Manuals Search EngineDocument6 pagesDownloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Starting System: Differ From The Above Listed ManualDocument6 pagesStarting System: Differ From The Above Listed ManualDavid QuispeNo ratings yet

- Atmega16 (L) : Table 106. Pin Name Mapping (Continued)Document6 pagesAtmega16 (L) : Table 106. Pin Name Mapping (Continued)David QuispeNo ratings yet

- Installation of Injection Pump: Downloaded From Manuals Search EngineDocument6 pagesInstallation of Injection Pump: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- !3imzy: Oil Cooler and Relief ValvesDocument6 pages!3imzy: Oil Cooler and Relief ValvesDavid QuispeNo ratings yet

- Is As: &sleeve PlugDocument6 pagesIs As: &sleeve PlugDavid QuispeNo ratings yet

- Assembly of Injection Pump: FU-16 Fuel SystemDocument6 pagesAssembly of Injection Pump: FU-16 Fuel SystemDavid QuispeNo ratings yet

- Components: Downloaded From Manuals Search EngineDocument6 pagesComponents: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Downloaded From Manuals Search EngineDocument6 pagesDownloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Fuel System FU-11 11. Remove Governor Cover: Downloaded From Manuals Search EngineDocument6 pagesFuel System FU-11 11. Remove Governor Cover: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- 2L-T W/ Hac: Downloaded From Manuals Search EngineDocument6 pages2L-T W/ Hac: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- System: Differ From The Above Listed ManualDocument6 pagesSystem: Differ From The Above Listed ManualDavid QuispeNo ratings yet

- Inspection and Repair of Crankshaft: Crank Journal DiameterDocument6 pagesInspection and Repair of Crankshaft: Crank Journal DiameterDavid QuispeNo ratings yet

- Installation of Cylinder Head: Downloaded From Manuals Search EngineDocument6 pagesInstallation of Cylinder Head: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Troubleshooting: Insufficient Acceleration, Lack of Power or Excessive Fuel ConsumptionDocument6 pagesTroubleshooting: Insufficient Acceleration, Lack of Power or Excessive Fuel ConsumptionDavid QuispeNo ratings yet

- I Removal of TurbochargerDocument6 pagesI Removal of TurbochargerDavid QuispeNo ratings yet

- Excessive Exhaust S M O K E: Downloaded From Manuals Search EngineDocument11 pagesExcessive Exhaust S M O K E: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- (Others) : Downloaded From Manuals Search EngineDocument10 pages(Others) : Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- 4Y Engine: TOYOTA Material Handling CompanyDocument10 pages4Y Engine: TOYOTA Material Handling CompanyDavid QuispeNo ratings yet

- Excessive Fuel Consumption: Downloaded From Manuals Search EngineDocument10 pagesExcessive Fuel Consumption: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Cutout: Downloaded From Manuals Search EngineDocument10 pagesCutout: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Trouble Diagnosis Trouble Diagnosis Trouble Diagnosis IntroductionDocument66 pagesTrouble Diagnosis Trouble Diagnosis Trouble Diagnosis IntroductionDavid QuispeNo ratings yet

- Abbreviations Used in Manual,: Downloaded From Manuals Search EngineDocument11 pagesAbbreviations Used in Manual,: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Ascd Brake Switch Ascd Brake Switch Component Description: Ec-29, "Automatic Speed Control Device (Ascd) "Document12 pagesAscd Brake Switch Ascd Brake Switch Component Description: Ec-29, "Automatic Speed Control Device (Ascd) "David QuispeNo ratings yet

- Downloaded From Manuals Search EngineDocument10 pagesDownloaded From Manuals Search EngineDavid Quispe100% (1)

- TTR50 2018 2CJ-F8197-10Document212 pagesTTR50 2018 2CJ-F8197-10camilomarentesNo ratings yet

- Dixon ZTR Transaxle Adjustment Manual _ Lawnmower Pros (1)Document22 pagesDixon ZTR Transaxle Adjustment Manual _ Lawnmower Pros (1)BRNo ratings yet

- Matiz - Engine Wiring Diagram PDFDocument2 pagesMatiz - Engine Wiring Diagram PDFadrian89% (19)

- Marine Genset-CCFJ120J-W : Gen-Set SpecificationsDocument2 pagesMarine Genset-CCFJ120J-W : Gen-Set Specificationsdimas alamsyahNo ratings yet

- Catalogo Planta Electrica 750kvaDocument6 pagesCatalogo Planta Electrica 750kvaJose Martin ChaconNo ratings yet

- 67Z7B-Engine Part1Document100 pages67Z7B-Engine Part119alejandrodamian2015No ratings yet

- 335D PIN 1T0335DX C184061 and 437D PIN 1T0437DX C254106 Uptime Maintenance PlannerDocument2 pages335D PIN 1T0335DX C184061 and 437D PIN 1T0437DX C254106 Uptime Maintenance PlannerNelson Andrade VelasquezNo ratings yet

- Data Sheet: Diesel Generator 1760Kw 50HZ/1500RPM Cummins Model: Qsk60-G4Document6 pagesData Sheet: Diesel Generator 1760Kw 50HZ/1500RPM Cummins Model: Qsk60-G4Phung LuctieuNo ratings yet

- Caterpillar Filtros y Aceites PDFDocument851 pagesCaterpillar Filtros y Aceites PDFtaller100% (2)

- Drain Fill With Hydraulic Oil 2Document2 pagesDrain Fill With Hydraulic Oil 2Kiril AngelovNo ratings yet

- Mini-Striker Hoja de DatosDocument4 pagesMini-Striker Hoja de DatosAlvaro Neisa LopezNo ratings yet

- Wartsila 18V46 Operations and Maintenance ManualDocument384 pagesWartsila 18V46 Operations and Maintenance ManualMechanical DeptNo ratings yet

- Component Codes: Electrical/Electronic System HD9 Euro3 Section 17Document9 pagesComponent Codes: Electrical/Electronic System HD9 Euro3 Section 17Mohamed MohamedNo ratings yet

- Pneumatic Tyre Roller Maintenance ManualDocument65 pagesPneumatic Tyre Roller Maintenance ManualFabio100% (1)

- Giantrey 2021 CatalogueDocument13 pagesGiantrey 2021 CatalogueBaytolgaNo ratings yet

- Setavap2 81000-2: Automatic Mini Vapour Pressure TesterDocument4 pagesSetavap2 81000-2: Automatic Mini Vapour Pressure TesterBakumanNo ratings yet

- 20-1 Fuel Supply System Components Remove and Install PDFDocument24 pages20-1 Fuel Supply System Components Remove and Install PDFmefisto06cNo ratings yet

- MSA15 Tuning GuideDocument32 pagesMSA15 Tuning GuidePero Peric100% (12)

- Tiffin 2004 Allegro Bay Motorhome Owners Manual ENDocument127 pagesTiffin 2004 Allegro Bay Motorhome Owners Manual ENTerrence JonesNo ratings yet

- CAT MD6 Technical TrainingDocument269 pagesCAT MD6 Technical TrainingMatthias100% (1)

- OMVL Dream On DiagramaDocument12 pagesOMVL Dream On DiagramaMoisei LucianNo ratings yet

- Backhoe Loader 426f2Document20 pagesBackhoe Loader 426f2Julius MuhimboNo ratings yet

- 1410D 0475 XXX ENG Ver1 PDFDocument304 pages1410D 0475 XXX ENG Ver1 PDFgiapy0000100% (1)

- John Deere 624K 4WD Loader With Engine 6068HDW79, 6068HDW83 Service Repair Manual TM10691 - PDF DownloadDocument31 pagesJohn Deere 624K 4WD Loader With Engine 6068HDW79, 6068HDW83 Service Repair Manual TM10691 - PDF DownloadEquipment ManualsNo ratings yet

- Presentation R5 C6.6Document103 pagesPresentation R5 C6.6Hicham El Malless100% (1)

- HT 740 - HT 747 1Document4 pagesHT 740 - HT 747 1zzkerNo ratings yet

- Snorkel Maintenimiento TB80 TB 86JDocument22 pagesSnorkel Maintenimiento TB80 TB 86Jcesar alejandro scavoNo ratings yet

- 89Document1 page89Armando MartinNo ratings yet

- An Intro To Subaru TuningDocument46 pagesAn Intro To Subaru Tuningkai_isman100% (6)