Professional Documents

Culture Documents

Excessive Fuel Consumption: Downloaded From Manuals Search Engine

Uploaded by

David QuispeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Excessive Fuel Consumption: Downloaded From Manuals Search Engine

Uploaded by

David QuispeCopyright:

Available Formats

ENGINE MECHANICAL - Troubleshooting (Diesel Engine Diagnosis) EM-11

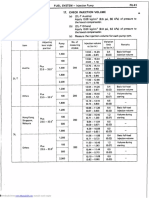

EXCESSIVE FUEL CONSUMPTION

HINT: Check whether clutch slipping, brakes grabbing, tires wrong size or air filter clogged.

(Possible Cause) (Check Procedure and Correction Method)

Refer to step 3 of ROUGH l DLE WITH WARM

ENGINE.

After sufficiently warming up engine, check idle

speed. (See page EM-27)

Idle speed: 2L-T 700 - 800 rpm

3L 650 - 750 rpm

If not as above, adjust with idle speed adjusting

screw.

1 3. MAXIMUM SPEED TOO HIGH -1 Check maximum speed. (See page EM-27)

Maximum speed:

2 L-T -

4,700 4,900 rpm

3L (Hong Kong, Singapore and Malaysia)

4,300 - 4,500 rpm

3L (Others) 4,500 - 4,700 rpm

If not as above, adjust bivith maximum speed adjust-

ing screw.

4. IMPROPER INJECTION TIMING 1 Refer to step 7 of ENGINE CRANKS NORMALLY

BUT WILL NOT START.

Refer to step 9 of ENGINE CRANKS NORMALLY

BUT WILL NOT START.

Downloaded from www.Manualslib.com manuals search engine

EM-12 ENGINE MECHANICAL - Troubleshooting (Diesel Engine Diagnosis)

ENGINE NOISE WHEN W A R M

(Cranking Noise with Excessive Vibration)

(Possible Cause) (Check Procedure and Correction Method)

1. ENGINE COOLANT Check coolant temperature with water temperature

TEMPERATURE TOO LOW gauge.

I f not sufficiently warm, thermostat is faulty and

should be replaced.

2. IMPROPER IN Refer to step 7 of ENGINE CRANKS NORMALLY

BUT WI L L NOT START.

3. FAULTY INJ Refer to step 9 of ENGINE CRANKS NORMALLY

BUT WILL NOT START.

ENGINE WlLL NOT RETURN TO IDLE

(Possible Cause) (Check Procedure and Correction Method)

Operate adjusting lever on top of injection pump.

and check if engine returns to idle. (See page

EM-27)

I f so, accelerator cable is binding or improperly ad-

justed and should be repaired accordingly.

I f engine does not return to idle, injection pump is

faulty and should be replaced.

ENGINE WlLL NOT SHUT OFF WITH KEY

(Possible Cause) (Check Procedure and Correction Method)

IMPROPER FUEL CUT SOLENOID Disconnect connector of fuel cut solenoid, and

OPERATION check if engine stops.

I f so, starter switch is faulty and should be repaired

as necessary or replaced.

I f engine does not stop, either fuel cut solenoid is

faulty or there is interference by foreign particles.

Repair as necessary.

Downloaded from www.Manualslib.com manuals search engine

I roub1esnootlng

ENGINE MECHANICAL -(Diesel Electrical System Diagnosis [2L-T Austria]) EM-13

Diesel Electrical System Diagnosis [2L-T Austria1 +

ENGINE DOES NOT START COLD

HINT:

---

Battery voltage a t least 12 V - starter switch OFF.

Engine cranks normally.

Fusible link okay.

Check the voltage marked with an asterisk ( * ) just as the starter switch is placed a t ON because the voltage

will change.

1. Pre-Heating System (Super Glow Type)

I isc connect the water temperature I

sensor.

I

Check if indicator light lights up Check f u v A Check for short circuit I

with starter switch ON. No I (See page ST-2) I Fuse I

and repair if necessary. I

Light on: 5 - 6 seconds I I

Blown I I

1 Fuse OK

Yes Check indicator 1- Replace bulb.

light bulb. Bulb

No Good

1 Bulb OK

Check for battery voltage to terminal 825 ( W ) or A4

(LN) of pre-heatingtimer connector (on wire harness

side).

Check for battery voltage to terminal A6 ( W ) or A3

(LN) of pre-heating timer connector (on wire harness

side).

1 Yes

Are terminals 81 5, 822 and B24(LJ) or B11 and B14(LN)

of the timer grounded?

Replace timer. Open circuit or ground faulty in

wire harness between terminals

of the timer and body ground.

Pre-Heating Timer (Emission Control ECU)

I Starter switch OFF.

I

CONTINUED ON PAGE EM-14

Downloaded from www.Manualslib.com manuals search engine

Troubleshooting

EM-14 ENGINE MECHANICAL - (Diesel Electrical System Diagnosis [2L-T Austria])

CONTINUED FROM PAGE EM-13

1

"Place starter switch a t ON and

check i f current flow to terminal

B23( W ) or A5(LN) of timer is in Pre-heating duration differs from the specified

accordance. duration.

Current flow: 120 seconds

Timer is faulty and should be replaced.

No 1

Voltage

I * ~ f t ecompletion

r of pre-heating, I

check for voltage a t terminal

B23 ( LJ) or A5 ( LN) again when

No

starter switch i s placed a t START.

Voltage

I

1 Starter switch OFF. 1

"Place starter switch a t ON and "Check for battery voltage a t negative (-1 side of

check for voltage to glow plug a glow plug resistor.

few seconds later. Thereafter, I f no voltage, No. 1 glow plug relay is faulty and

No

voltage should drop about 112. should be replaced.

Voltage

"Check for battery voltage to positive (+I side of

- glow plug resistor.

I f okay, replace the resistor.

Voltage I f no voltage, No. 2 glow plug relay is faulty and

Remains should be replaced.

a t Battery

Voltage,

or Falls to

0v

i

Check glow plug for resistance. -4

Infinity

Glow plug i s faulty and should be replaced.

t

I Glow plug okay.

Connect water temperature sensor.

Downloaded from www.Manualslib.com manuals search engine

m==--

Troubleshooting

ENGINE MECHANICAL - (Diesel Electrical System Diagnosis [2L-T Austria]) EM-15

2. Fuel Cut Solenoid Valve a

With starter switch turned ON, 1 Fuel cut solenoid valve okay.

check for fuel cut solenoid valve Noise

operation noise (clicking sound)

while repeatedly connecting and

disconnecting fuel cut solenoid

valve.

No Noise

iI

Check fuse. Check for short circuit, and repair as necessary.

I

Blown

Fuse OK

I ---

Apply battery voltage directly to Check wire harness from fuse to fuel cut solenoid.

solenoid, and check for noise. Noise

I No Noise

I

I Replace fuel cut solenoid valve.

Downloaded from www.Manualslib.com manuals search engine

Troubleshootins

EM-16 ENGINE MECHANICAL - (Diesel ~lectricalSystem Diagnosis I2L-T Others])

Diesel Electrical System Diagnosis [2L-T Others]

ENGINE DOES NOT START COLD

HINT:

Battery voltage at least 12 V - starter switch OFF.

Engine cranks normally.

Fusible link okay.

Check the voltage marked with an asterisk ( * ) just as the starter switch is placed at ON because the voltage

will change.

1. Pre-Heating System (Super Glow Type)

I Disconnect the water temperature /

sensor.

t

-

P P

Check if indicator light lights up Check fuse. I Check for short circuit

with starter switch ON. No (See page ST-2) Fuse and repair i f necessary.

Light on: 6 - 7 seconds Blown

1 Yes

Check indicator Replace bulb.

No Good

I I Bulb OK

i

Starter switch OFF

timer connector (on wire harness side).

I f okay, pre-heating timer is faulty and should be

replaced.

"Check for battery voltage t o - "Check that there is 1 V or less t o terminal 9. I

terminal 1 of pre-heating timer No I f okay, timer is faulty and should be replaced.

with starter switch ON. Voltage

t

"Check if voltage t o terminal 1 of

pre-heating timer is terminated No

- Start engine and check if there is voltage at terminal

9 of pre-heating timer.

,

i

I after engine is started. I f faulty, repair charging system as necessary. i

I f okay, timer is faulty and should be replaced.

Starter switch OFF. Pre-Heating Timer

I CONTINUED ON PAGE EM-17 6 5 4 3 1

Downloaded from www.Manualslib.com manuals search engine

Troubleshooting

ENGINE MECHANICAL - (Diesel Electrical System Diagnosis [2L-T Others] ) EM-17

I

1 CONTINUED FROM PAGE EM-16

"Place starter switch a t ON and - 1

check if current flow to terminal I

5 of timer is in accordance. I Pre-heating duration differs from the specified

Current flow : 15-29 seconds I duration.

I

Timer is faulty and should be replaced.

Voltage

"After completion of pre-heating,

check for voltage a t terminal 5

again when starter switch is

Voltage

( Starter switch OFF.

/*place starter switch a t ON and 1 "Check for battery voltage a t negative (-) side of

check for voltage to glow plug a

few seconds later. Thereafter,

- glow plug resistor.

I f no voltage, No.1 glow plug relay is faulty and

No

voltage should drop about 112. should be replaced.

Voltage -

a t All

'Check for battery voltage to positive (+) side of

glow plug resistor.

- I

I f okay, replace the resistor.

Voltage I f no voltage, No.2 glow plug relay is faulty and

Remains should be replaced.

a t Battery

Voltage,

of Falls to

0v

Glow plug is faulty and should be replaced.

I Glow plug okay. I

I Connect water temperature sensor. I

Downloaded from www.Manualslib.com manuals search engine

EM-18 ENGINE MECHANICAL - Engine Tune-up

ENGINE TUNE-UP

INSPECTION OF ENGINE COOLANT

(See steps 1 and 2 on page CO-4)

INSPECTION OF ENGINE OIL

(See steps 1 and 2 on page LU-4)

INSPECTION OF BATTERY

(See pages 1 and 2 on page CH-3)

Standard specific gravity:

When fully charged at 20°C (68" F)

1.27 - 1.29 (80D26R)

1.25 - 1.27 (Others)

INSPECTION OF AIR FILTER

(Paper Filter Type)

1. INSPECT AIR FILTER

Visually check that the filter element is not excessively

dirty, damaged or oily.

2. CLEAN AIR FILTER

Clean the filter element with compressed air.

First blow from the inside thoroughly. Then blow off the

outside of the filter element.

(Washable Type)

1. INSPECT AIR FILTER

Visually check that the filter element is not excessively

dirty, damaged or oily.

/

1 2. CLEAN AIR FILTER

Downloaded from www.Manualslib.com manuals search engine

ENGINE MECHANICAL - Engine Tune-up EM-19

(b) Submerge the filter element in the water and agitate 3

it up and down more than ten times.

(c) Repeat rinsing in clean water until rinse water is clear.

(d) Remove excess water by shaking the filter element or

blowing with compressed air.

NOTICE: Do not beat or drop filter element.

(e) Wipe off dust on the air cleaner case interior.

INSPECTION OF ALTERNATOR DRIVE BELTS

(See step 3 on page CH-3)

Drive belt deflection:

New belt -

7 10 mm (0.28 - 0.39 in.)

-

Used belt 10 15 mm (0.39 - 0.59 in.)

Drive belt tension (Reference) :

-

New belt 4 0 6 0 kg

Used belt 20 - 35 kg

INSPECTION OF GLOW PLUGS

(See page ST-6)

Downloaded from www.Manualslib.com manuals search engine

EM-20 ENGINE MECHANICAL - Engine Tune-up

ADJUSTMENT OF VALVE CLEARANCE

HINT: Adjust the valve clearance while the engine is cold.

(2L-T)

REMOVE AIR CLEANER

(w/ Intake Pipe)

REMOVE INTAKE PIPE

REMOVE CYLINDER HEAD COVER

(See step 16 on page EM-38)

SET NO. 1 CYLINDER TO TDCICOMPRESSION

(a) Turn the crankshaft pulley clockwise, and align its

groove with the timing pointer.

(b) Check that the valve lifters on the No. 1 cylinder are

loose and valve lifters on the No. 4 cylinder are tight.

If not, turn the crankshaft one revolution (360") and align

the mark as above.

ADJUST VALVE CLEARANCE

No. 1 No. 3

EX EX (a) Check only the valves indicated in the illustration.

Using a feeler gauge, measure the clearance be-

tween the valve lifter and camshaft.

Record the valve clearance measurements which

are out of specification. They will be used later to

determine the required replacement adjusting shim.

Valve clearance (Cold):

Intake 0.20 - 0.30 mm (0.008 - 0.012 in.)

Exhaust 0.40 - 0.50 mm (0.016 - 0.020 in.)

(b) Turn the crankshaft one revolution (360°), and align

No. 2 No. 4 the mark as above (See procedure step 4).

EX EX

(c) Check only the valves indicated in the illustration.

Measure the valve clearance.

(See procedure step (a))

(d) Remove the adjusting shim.

Turn the crankshaft to position the cam lobe of

the camshaft on the adjusting valve upward.

Using SST, press down the valve lifter.

SST 09248-64010

HINT: Before pressing down the valve lifter, position the

notch on the exhaust manifold side.

Downloaded from www.Manualslib.com manuals search engine

You might also like

- Pratt & Whitney R-1340 Engine Operating SupplementDocument7 pagesPratt & Whitney R-1340 Engine Operating Supplementarizonaflyer1_732976100% (1)

- (KIA) Manual de Taller Kia Rio 2001 PDFDocument69 pages(KIA) Manual de Taller Kia Rio 2001 PDFJenny Mora Leon100% (1)

- Engine Jeep Patriot 2.0Document296 pagesEngine Jeep Patriot 2.0Yoga Ariant100% (1)

- ENGINE 5.7L - Service Information - Ram Pickup PDFDocument291 pagesENGINE 5.7L - Service Information - Ram Pickup PDFcharlesNo ratings yet

- Installation of Cylinder Head: Downloaded From Manuals Search EngineDocument6 pagesInstallation of Cylinder Head: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Excessive Exhaust S M O K E: Downloaded From Manuals Search EngineDocument11 pagesExcessive Exhaust S M O K E: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Troubleshooting: Insufficient Acceleration, Lack of Power or Excessive Fuel ConsumptionDocument6 pagesTroubleshooting: Insufficient Acceleration, Lack of Power or Excessive Fuel ConsumptionDavid QuispeNo ratings yet

- Panda AGT-DC 4000 Trouble ShootingDocument4 pagesPanda AGT-DC 4000 Trouble Shootingjerrywen08No ratings yet

- Optimize 5.7L Engine DiagnosisDocument50 pagesOptimize 5.7L Engine DiagnosisJay AndrewsNo ratings yet

- 4 Tec Troubleshooting ChartDocument11 pages4 Tec Troubleshooting ChartnelsoncoNo ratings yet

- ENGINE Starting - Service Information - Ram Pickup PDFDocument27 pagesENGINE Starting - Service Information - Ram Pickup PDFcharlesNo ratings yet

- Group 2 operational checks and troubleshootingDocument8 pagesGroup 2 operational checks and troubleshootingMarco OlivettoNo ratings yet

- Locomotive Troubleshooting PrintableDocument14 pagesLocomotive Troubleshooting PrintableMuhammathali JNo ratings yet

- SUN Dwell / TachDocument8 pagesSUN Dwell / TachWongstorn DamrongmaneeNo ratings yet

- Troubleshooting: LiningDocument48 pagesTroubleshooting: Liningplanner samulosNo ratings yet

- Inline S3.8 TroubleshootingDocument32 pagesInline S3.8 TroubleshootingKrishna PardeshiNo ratings yet

- Group 2 Operational Checks and TroubleshootingDocument7 pagesGroup 2 Operational Checks and TroubleshootingREMZONANo ratings yet

- Dart RT 2013Document541 pagesDart RT 2013nataly1993No ratings yet

- Section 13 Propeller and GovernolDocument6 pagesSection 13 Propeller and GovernolMario VolpattiNo ratings yet

- IDA Low Speed CalibrationDocument3 pagesIDA Low Speed Calibrationirony2No ratings yet

- Test Motor Transmisie Volvo Ec140Document4 pagesTest Motor Transmisie Volvo Ec140Michael DavenportNo ratings yet

- Grúa Tadano Faun ATF 130 G5Document171 pagesGrúa Tadano Faun ATF 130 G5Reinaldo Zorrilla100% (1)

- 5-vmax_owner_operationDocument2 pages5-vmax_owner_operationzuntoy000No ratings yet

- Group 2 operational checks and troubleshootingDocument8 pagesGroup 2 operational checks and troubleshootingaimerNo ratings yet

- Maintaining and Operating the DV11 EngineDocument10 pagesMaintaining and Operating the DV11 EngineООО "СК "СМП-708"No ratings yet

- Mining Wide-Body Dump Truck Operators TrainingDocument36 pagesMining Wide-Body Dump Truck Operators Trainingpebi live100% (1)

- HSR Tuning Manual 050102Document16 pagesHSR Tuning Manual 050102tomektomek6347No ratings yet

- Magneto Check BasicsDocument3 pagesMagneto Check BasicsNico Molfino100% (2)

- 1500 2014 5.7LDocument285 pages1500 2014 5.7LLuis Ramon Arguello RealNo ratings yet

- Izuzu Motor x22 SeDocument102 pagesIzuzu Motor x22 SeGerardo FloresNo ratings yet

- Pentastar Jeep 3.6 v6 Rubicon 4gDocument524 pagesPentastar Jeep 3.6 v6 Rubicon 4glambdaNo ratings yet

- MF MX Graduar Tiempo y Relenti Vol1Document6 pagesMF MX Graduar Tiempo y Relenti Vol1Manuel RosuNo ratings yet

- 1kz-Te Turbocharger PDFDocument18 pages1kz-Te Turbocharger PDFwill meridithNo ratings yet

- 2500 HD 2014 5.7LDocument287 pages2500 HD 2014 5.7LJuan PerezNo ratings yet

- ESP-Operation & Trouble ShootingDocument11 pagesESP-Operation & Trouble ShootingnawarsNo ratings yet

- 4-2 Operational Checks and TroubleshotingDocument8 pages4-2 Operational Checks and TroubleshotingManuel PomahualiNo ratings yet

- Adjust carburetor settings and check float levelDocument4 pagesAdjust carburetor settings and check float levelelnyniosNo ratings yet

- Carburetor Setup and Best Idle (Ajustar Carburador)Document2 pagesCarburetor Setup and Best Idle (Ajustar Carburador)Lex RadilloNo ratings yet

- Instructions Carb Type 7LDocument2 pagesInstructions Carb Type 7LEdgar Alexander Grisales VallejoNo ratings yet

- Hphd40 Post Hole DiggerDocument20 pagesHphd40 Post Hole DiggerGlenn FarrellNo ratings yet

- 2JZ-GTE Turbocharger GuideDocument25 pages2JZ-GTE Turbocharger Guideyogapost100% (1)

- Auburn Tune Up 14pagesDocument14 pagesAuburn Tune Up 14pagesjorge Angel LopeNo ratings yet

- Mikuni Tuningmanual - 021003Document20 pagesMikuni Tuningmanual - 021003Faqih GoetiaNo ratings yet

- 7 StepimpcosystemDocument2 pages7 StepimpcosystemGuillermo Rueda Quevedo100% (2)

- B2301 B2601 Operator's ManualDocument95 pagesB2301 B2601 Operator's ManualspncbusinessNo ratings yet

- Cat 950GDocument10 pagesCat 950GManuel BarahonaNo ratings yet

- Group 2 Operational Checks and Troubleshooting Group 2 Operational Checks and TroubleshootingDocument8 pagesGroup 2 Operational Checks and Troubleshooting Group 2 Operational Checks and Troubleshootingmãi bên emNo ratings yet

- Breakdown Analysis Motor Inching Z2M13PMDocument6 pagesBreakdown Analysis Motor Inching Z2M13PMmaherianto 29No ratings yet

- 7B5B4BK4D4E26781008manual 2077287029Document2 pages7B5B4BK4D4E26781008manual 2077287029FedePereiroBeyerNo ratings yet

- TROUBLESHOOTINGDocument7 pagesTROUBLESHOOTINGSteven LincolnNo ratings yet

- e-QD Series Generator Set Models Mdkau, Mdkav, MDKBG, Mdkaw, Mdkaz, MDKBD, Mdkbe, MDKBFDocument2 pagese-QD Series Generator Set Models Mdkau, Mdkav, MDKBG, Mdkaw, Mdkaz, MDKBD, Mdkbe, MDKBFDimas PrasetyoNo ratings yet

- 5 Engine ArrangementDocument98 pages5 Engine Arrangementhendra hardyNo ratings yet

- Group 2 Operational Checks and TroubleshootingDocument8 pagesGroup 2 Operational Checks and TroubleshootingDenNo ratings yet

- 650.01 DieselGenerator Operating 2013.08.12Document18 pages650.01 DieselGenerator Operating 2013.08.12Tuan Linh VoNo ratings yet

- Engine FuelDocument24 pagesEngine FuelЮра Петренко100% (1)

- SM 1Document262 pagesSM 1Miguel Martinez100% (1)

- Figure 21-3. Troubleshooting Turboprop Engines.: Module 15 - Gas Turbine EngineDocument1 pageFigure 21-3. Troubleshooting Turboprop Engines.: Module 15 - Gas Turbine EngineLovejeet GujratiNo ratings yet

- Rav1 Feseau MoteurDocument3 pagesRav1 Feseau MoteurHirwa Jules KlutchNo ratings yet

- Diesel Engine Care and Repair: A Captain's Quick GuideFrom EverandDiesel Engine Care and Repair: A Captain's Quick GuideRating: 5 out of 5 stars5/5 (1)

- 4Y Engine: TOYOTA Material Handling CompanyDocument5 pages4Y Engine: TOYOTA Material Handling CompanyDavid QuispeNo ratings yet

- Datasheet (3) (254-284) - 1-5Document5 pagesDatasheet (3) (254-284) - 1-5David QuispeNo ratings yet

- Troubleshooting: Downloaded From Manuals Search EngineDocument6 pagesTroubleshooting: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Atmega16 (L) : Table 106. Pin Name Mapping (Continued)Document6 pagesAtmega16 (L) : Table 106. Pin Name Mapping (Continued)David QuispeNo ratings yet

- Atmega16 (L) : Programming The EepromDocument6 pagesAtmega16 (L) : Programming The EepromDavid QuispeNo ratings yet

- !3imzy: Oil Cooler and Relief ValvesDocument6 pages!3imzy: Oil Cooler and Relief ValvesDavid QuispeNo ratings yet

- Starting System: Differ From The Above Listed ManualDocument6 pagesStarting System: Differ From The Above Listed ManualDavid QuispeNo ratings yet

- Downloaded From Manuals Search EngineDocument6 pagesDownloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Downloaded From Manuals Search EngineDocument6 pagesDownloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Fuel System FU-31 2. Pre-Set Full Load Injection VolumeDocument6 pagesFuel System FU-31 2. Pre-Set Full Load Injection VolumeDavid QuispeNo ratings yet

- Fuel injection pump assemblyDocument6 pagesFuel injection pump assemblyDavid QuispeNo ratings yet

- 2L-T W/ Hac: Downloaded From Manuals Search EngineDocument6 pages2L-T W/ Hac: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Description: Valve LiftersDocument6 pagesDescription: Valve LiftersDavid QuispeNo ratings yet

- Installation of Injection Pump: Downloaded From Manuals Search EngineDocument6 pagesInstallation of Injection Pump: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- I Removal of TurbochargerDocument6 pagesI Removal of TurbochargerDavid QuispeNo ratings yet

- INJECTION PUMP DISASSEMBLYDocument6 pagesINJECTION PUMP DISASSEMBLYDavid QuispeNo ratings yet

- Is As: &sleeve PlugDocument6 pagesIs As: &sleeve PlugDavid QuispeNo ratings yet

- System: Differ From The Above Listed ManualDocument6 pagesSystem: Differ From The Above Listed ManualDavid QuispeNo ratings yet

- Inspection and Repair of Crankshaft: Crank Journal DiameterDocument6 pagesInspection and Repair of Crankshaft: Crank Journal DiameterDavid QuispeNo ratings yet

- Fuel Pump ComponentsDocument6 pagesFuel Pump ComponentsDavid QuispeNo ratings yet

- Intake Venturi System (LN 2L-T: Only)Document11 pagesIntake Venturi System (LN 2L-T: Only)David QuispeNo ratings yet

- Adjustment of Valve Clearance: No. 1 No. 3 EX EXDocument11 pagesAdjustment of Valve Clearance: No. 1 No. 3 EX EXDavid QuispeNo ratings yet

- Introduction to Diesel Engine Abbreviations and ComponentsDocument11 pagesIntroduction to Diesel Engine Abbreviations and ComponentsDavid QuispeNo ratings yet

- Downloaded From Manuals Search EngineDocument10 pagesDownloaded From Manuals Search EngineDavid Quispe100% (1)

- 4Y Engine Service ManualDocument10 pages4Y Engine Service ManualDavid QuispeNo ratings yet

- (Others) : Downloaded From Manuals Search EngineDocument10 pages(Others) : Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Cutout: Downloaded From Manuals Search EngineDocument10 pagesCutout: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Renault Triber - Official Review - Team-BHPDocument17 pagesRenault Triber - Official Review - Team-BHPramkumar31No ratings yet

- RC BW 24RH-27RHDocument2 pagesRC BW 24RH-27RHCopemaq CopemaqNo ratings yet

- Lifeboat Engine Operation GuideDocument19 pagesLifeboat Engine Operation GuideMico YogoreNo ratings yet

- Solar Water Pumps: Addressing Reliability IssuesDocument6 pagesSolar Water Pumps: Addressing Reliability Issuessandeepbabu28No ratings yet

- Mori Seiki MV-65 ParametrosDocument258 pagesMori Seiki MV-65 Parametrosfrancisco sandovalNo ratings yet

- Sim300 An Handset Design v1.02Document10 pagesSim300 An Handset Design v1.02ankush_laxmanNo ratings yet

- Fire sensor detects flameDocument33 pagesFire sensor detects flamePrabu BalaNo ratings yet

- Scott Alert S101 PMDocument29 pagesScott Alert S101 PMMarcelo AlegreNo ratings yet

- ES-50X Manual PDFDocument164 pagesES-50X Manual PDFLord Vampyr JuanNo ratings yet

- Medições BateriaDocument4 pagesMedições BateriaFrancisco José da Costa GomesNo ratings yet

- Staubsaugen Erfrischend Anders.: Der Beutellose SaugerDocument20 pagesStaubsaugen Erfrischend Anders.: Der Beutellose SaugerlubeckuNo ratings yet

- CB-534D CB-534DXW Vibratory Compactor FGH00001-UP (MACHINE) POWERED BY 3054C Engine (KEBP0242 - 83) - DocumentaDocument3 pagesCB-534D CB-534DXW Vibratory Compactor FGH00001-UP (MACHINE) POWERED BY 3054C Engine (KEBP0242 - 83) - DocumentaIvan PalominoNo ratings yet

- Systems & Components For The Bus and CoachDocument8 pagesSystems & Components For The Bus and CoachAlessandra NoeliaNo ratings yet

- Light Vehicle Brake Systems: Technical Standards Document No. 135, Revision 3Document39 pagesLight Vehicle Brake Systems: Technical Standards Document No. 135, Revision 3acairalexNo ratings yet

- Vdocument - in Presentation On Spur GearDocument31 pagesVdocument - in Presentation On Spur GearShokeen SinghNo ratings yet

- 6042 Parts 8990467 02-22-12 ANSI EnglishDocument462 pages6042 Parts 8990467 02-22-12 ANSI EnglishwalmadasanNo ratings yet

- FlowDocument16 pagesFlowDiego Fernando AVENDA¥O RODRIGUEZNo ratings yet

- Catalog Modicon ABLP Power SupplyDocument11 pagesCatalog Modicon ABLP Power Supplyaditya agasiNo ratings yet

- Hardware Maintenance Manual: Thinkpad X240SDocument100 pagesHardware Maintenance Manual: Thinkpad X240SADAMO PATRICIO O'BYRNE RIVERANo ratings yet

- QEC - Atr - 42 - Rev15 Motor PW ATR 72Document203 pagesQEC - Atr - 42 - Rev15 Motor PW ATR 72Dorival Venâncio100% (3)

- Climmy-Comfort 3 cc3 en PDFDocument47 pagesClimmy-Comfort 3 cc3 en PDFVeljko MilicevicNo ratings yet

- Car Inspection Report - 2014 Toyota CorollaDocument9 pagesCar Inspection Report - 2014 Toyota CorollaAham AhamNo ratings yet

- Takeoff p1Document2 pagesTakeoff p1Guilherme KaiserNo ratings yet

- Launch x431 Padii Manual Part4Document6 pagesLaunch x431 Padii Manual Part4Mohammed EssamNo ratings yet

- EC206 CO Modelqn2 Ktustudents - inDocument3 pagesEC206 CO Modelqn2 Ktustudents - ingpuonlineNo ratings yet

- Compact Thermoelectric Cooling SystemDocument25 pagesCompact Thermoelectric Cooling SystemHP ghnNo ratings yet

- Parts Catalog - Option Detail: Option Group Graphic Film Card DateDocument2 pagesParts Catalog - Option Detail: Option Group Graphic Film Card DateagvassNo ratings yet

- Honeywell Price List Jan 2022 PDFDocument76 pagesHoneywell Price List Jan 2022 PDFSergey BashtoviyNo ratings yet

- SR ShipsDocument1 pageSR ShipsolegNo ratings yet

- Serta MotionPerfect Owner Manual V001 10.16.18 V2Document36 pagesSerta MotionPerfect Owner Manual V001 10.16.18 V2i800621No ratings yet