Professional Documents

Culture Documents

ENGINE Starting - Service Information - Ram Pickup PDF

Uploaded by

charlesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ENGINE Starting - Service Information - Ram Pickup PDF

Uploaded by

charlesCopyright:

Available Formats

2014 RAM 3500 HD Laramie

2014 ENGINE Starting - Service Information - Ram Pickup

2014 ENGINE

Starting - Service Information - Ram Pickup

OPERATION

REMOTE STARTING SYSTEM

The remote starting system will allow the vehicle to be started from distances of up to approximately 300 feet

away from the vehicle. It operates using the remote keyless entry key fob which is part of your ignition key.

In order to remote start your vehicle, the hood and all the doors must be closed.

To remote start your vehicle, press the REMOTE START button on the key fob twice within three seconds. To

indicate that the vehicle is about to start, the parking lights will flash and the horn will sound briefly.

Once the vehicle has started, the engine will run for 15 minutes. To cancel remote start, press the REMOTE

START button once.

The parking lamps will remain illuminated to indicate that the vehicle has remote started and the engine is

running. The lamps will turn off when the ignition is turned to RUN or the remote start is cancelled.

To enter the vehicle while the engine is running during a remote start, you must first unlock the vehicle using

the UNLOCK button on the key fob. After the vehicle is unlocked, you have 60 seconds to enter the vehicle,

insert the key in the Ignition and move it to the RUN position, otherwise the engine will cancel remote start and

automatically turn off.

Remote start will cancel if any of the following occur:

If the engine stalls or RPM exceeds 2500

Any engine warning lamps come on

The hood is opened

The hazard switch is pressed

The transmission is moved out of park

Low fuel indicator is on. Low fuel levels.

The brake pedal is pressed before the vehicle door has been unlocked. If you remote start the vehicle

while inside the vehicle and press the brake pedal, the vehicle remote start will cancel.

The vehicle can be started remotely up to a maximum of two times. The vehicle is also allowed a maximum of

one failed start. This is where the remote start sequence was initiated but the engine stopped cranking without

starting. After either of these conditions, or if the Vehicle Theft Alarm is alarming, or if the PANIC button was

pressed, the vehicle must be reset by inserting a valid key into the ignition and moving it to the RUN position,

then back to LOCK.

DIAGNOSIS AND TESTING

Thursday, November 16, 2017 19:34:41

19:34:39 Page 1

2014 RAM 3500 HD Laramie

2014 ENGINE Starting - Service Information - Ram Pickup

REMOTE START SYSTEM

Before attempting to diagnose a problem with the remote starting system, first be sure the starter motor and

starter solenoid are working properly. The starter should operate with the use of the standard ignition key in the

ignition switch. Any starter or solenoid problems must be repaired first.

Also be sure the engine will easily start and run with the use of the standard ignition key in the ignition switch.

Any engine running, idling or driveability problems must be repaired first.

Also note that the remote start system will automatically be cancelled if any of the following occur:

IF THE ENGINE STALLS OR RPM EXCEEDS 2500

NORMAL TIME OUT RUN MODE (15 MINUTES)

CUSTOMER MOVES IGNITION INTO RUN/START

ANY VEHICLE DOOR AJAR

TRUNK/LIFTGATE AJAR

HOOD AJAR

START COUNTER REACHED

LOW RPM SHUTDOWN

KEY IN IGNITION

BRAKE APPLIED. IF THE VEHICLE IS REMOTE STARTED AND THE CUSTOMER THEN

UNLOCKS AND ENTERS THE VEHICLE, THE BRAKE APPLICATION WILL NOT STALL THE

VEHICLE. IF THE VEHICLE IS REMOTE STARTED AND NO ENTRY IS DETECTED, BRAKE

APPLICATION WILL SHUT DOWN THE ENGINE.

LOW FUEL LEVELS. FUEL INDICATOR ACTIVE.

THE HAZARD SWITCH IS PRESSED

NOT IN PARK OR NEUTRAL

VEHICLE SPEED HIGH

VTA ALARM TRIGGERED

PANIC MODE ACTIVATED

BATTERY VOLTAGE HIGH

BATTERY VOLTAGE LOW

LOSS OF BATTERY VOLTAGE

MIL ON

LOW OIL PRESSURE

COOLANT TEMPERATURE HIGH

CRANK NO START

RKE OFF MESSAGE

VEHICLE NOT CONFIGURED

HOOD SWITCH NOT INSTALLED OR INOPERATIVE

Thursday, November 16, 2017 19:34:39 Page 2

2014 RAM 3500 HD Laramie

2014 ENGINE Starting - Service Information - Ram Pickup

NO AUTOMATIC TRANSMISSION

INVALID KEY

IGNITION SNA

IGNITION NOT IN LOCK

VEHICLE IN SHIPPING MODE

VEHICLE NOT PROGRAMMED

If all of the previous items checked OK, and the remote starting system will not operate, refer to DIAGNOSIS

AND TESTING .

STARTING SYSTEM

The battery, starting, and charging systems operate in conjunction with one another, and must be tested as a

complete system. For correct starting/charging system operation, all of the components involved in these three

systems must perform within specifications.

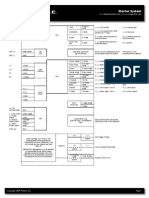

STARTING SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSE CORRECTION

STARTER FAILS TO 1. Battery discharged or 1. Charge and test battery. Refer to BATTERY,

OPERATE inoperative DIAGNOSIS AND TESTING . Replace battery,

if required.

2. Test the starter motor and solenoid. Refer to

2. Starter motor or

STARTER, DIAGNOSIS AND TESTING.

solenoid inoperative

Replace starter motor, if required.

3. Starter relay 3. See Wiring Information. Test and replace the

inoperative starter relay, if required

4. Clutch pedal position 4. See Clutch Pedal Position Switch. Test and

switch inoperative (if adjust or replace switch, if required.

equipped with manual

transmission)

5. Park/Neutral position 5. See Park/Neutral Position Switch. Test and

switch inoperative (if adjust or replace switch, if required.

equipped with automatic

transmission)

6. Ignition switch 6. Test the Ignition Switch and Key Lock

inoperative Cylinder. Replace ignition switch if required.

7. Starting circuit wiring 7. See Wiring Information. Test and repair starter

inoperative feed and/or control circuits, if required.

STARTER ENGAGES, 1. Battery discharged or 1. Charge and test battery. Refer to BATTERY,

BUT FAILS TO TURN inoperative DIAGNOSIS AND TESTING . Replace battery

ENGINE if required.

2. Test the starter motor and solenoid. Refer to

2. Starter motor or

STARTER, DIAGNOSIS AND TESTING.

solenoid inoperative

Replace starter motor if required.

Thursday, November 16, 2017 19:34:39 Page 3

2014 RAM 3500 HD Laramie

2014 ENGINE Starting - Service Information - Ram Pickup

3. Starting circuit wiring 3. See Wiring Information. Test and repair starter

inoperative feed and/or control circuits, if required.

4. Engine seized 4. See 9 - Engine. Test and repair engine as

required.

STARTER ENGAGES, 1. Test the starter motor and solenoid. Refer to

1. Starter motor or

BUT THEN STARTER, DIAGNOSIS AND TESTING.

solenoid inoperative

DISENGAGES BEFORE Replace starter motor, if required.

ENGINE STARTS 2. Remove starter motor and inspect starter ring

2. Starter ring gear

gear. Refer to STARTER, DIAGNOSIS AND

damaged

TESTING. Replace starter ring gear, if required.

STARTER DOES NOT 1. Starter motor 1. Inspect and test the starter motor and solenoid.

DISENGAGE incorrectly installed or Refer to STARTER, DIAGNOSIS AND

solenoid inoperative TESTING. Replace starter motor, if required.

2. Starter relay 2. See Wiring Information. Test and replace the

inoperative starter relay, if required.

3. Ignition switch 3. Test the Ignition Switch and Key Lock

inoperative Cylinder. Replace ignition switch, if required.

STARTING SYSTEM TESTING

COLD CRANKING TEST

NOTE: See Wiring Information for complete starter wiring circuit diagrams.

Fig. 1: Connecting Volt-Ampere Tester To Battery Terminals - Typical

Courtesy of CHRYSLER GROUP, LLC

1. Fully charge and load-test the battery. Refer to DIAGNOSIS AND TESTING .

2. Connect volt-ampere tester leads (1 and 2 to the battery terminals. Connect volt-ampere tester lead (3)

around the positive battery cable. See instructions provided by manufacturer of volt-ampere tester being

used.

Thursday, November 16, 2017 19:34:39 Page 4

2014 RAM 3500 HD Laramie

2014 ENGINE Starting - Service Information - Ram Pickup

3. Place transmission in Park or Neutral with the parking brake set (depending on transmission application).

4. If equipped with manual transmission, block clutch pedal in fully depressed position.

5. Verify that all lamps and accessories are turned off.

6. To prevent a gasoline engine from starting, remove Automatic Shut Down (ASD) relay. To prevent a

diesel engine from starting, remove Fuel Pump Relay. See Wiring Information for relay locations.

WARNING: Attempt to start engine a few times before proceeding with following

step.

NOTE: A cold engine will increase starter current (amperage) draw reading, and

reduce battery voltage reading.

7. Rotate and hold ignition switch in Start position. Note cranking voltage and current (amperage) draw

readings shown on volt-ampere tester.

a. If voltage reads below 9.6 volts, see starter motor diagnosis and testing. Refer to STARTER,

DIAGNOSIS AND TESTING. If starter motor is OK, see appropriate diagnosis and testing in

appropriate ENGINE mechanical article for further diagnosis and testing of the engine. If starter

motor is not OK, replace the starter motor. Refer to STARTER, REMOVAL.

b. See Feed Circuit Test if voltage reads above 9.6 volts and current (amperage) draw reads below

specifications.

c. See Feed Circuit Test if voltage reads 12.5 volts or greater and starter motor does not turn or turns

very slowly.

FEED CIRCUIT TEST

NOTE: See Wiring Information for complete starter wiring circuit diagrams.

The starter feed circuit test (voltage drop method) will determine if there is excessive resistance in high-

amperage feed circuit.

When performing these tests, it is important to remember that voltage drop is giving an indication of resistance

between two points at which voltmeter probes are attached.

Example: When testing resistance of positive battery cable, touch voltmeter leads to positive battery cable

clamp and cable connector at starter solenoid. If you probe positive battery terminal post and cable connector at

starter solenoid, you are reading combined voltage drop in positive battery cable clamp-to-terminal post

connection and positive battery cable.

The following procedure requires a voltmeter accurate to 1/10 (0.10) volt. Before proceeding, be certain that the

following are accomplished:

Fully charge and load-test the battery. Refer to DIAGNOSIS AND TESTING .

Place transmission in Park or Neutral with the parking brake set (depending on transmission application).

Thursday, November 16, 2017 19:34:39 Page 5

2014 RAM 3500 HD Laramie

2014 ENGINE Starting - Service Information - Ram Pickup

If equipped with manual transmission, block clutch pedal in fully depressed position.

Verify that all lamps and accessories are turned off.

To prevent a gasoline engine from starting, remove Automatic Shut Down (ASD) relay. See Wiring

Information for relay locations.

Fig. 2: Testing Battery Negative Connection Resistance - Typical

Courtesy of CHRYSLER GROUP, LLC

1 - VOLTMETER

2 - BATTERY

1. Connect positive lead of voltmeter (1) to negative battery cable terminal post. Connect negative lead of

voltmeter to negative battery cable clamp. Rotate and hold ignition switch in Start position. Observe

voltmeter. If voltage is detected, correct poor contact between cable clamp and terminal post.

Fig. 3: Testing Battery Positive Connection Resistance - Typical

Courtesy of CHRYSLER GROUP, LLC

Thursday, November 16, 2017 19:34:39 Page 6

2014 RAM 3500 HD Laramie

2014 ENGINE Starting - Service Information - Ram Pickup

1 - VOLTMETER

2 - BATTERY

2. Connect positive lead of voltmeter to positive battery terminal post. Connect negative lead of voltmeter to

battery positive cable clamp. Rotate and hold ignition switch in Start position. Observe voltmeter. If

voltage is detected, correct poor contact between cable clamp and terminal post.

Fig. 4: Testing Battery Positive Cable Resistance - Typical

Courtesy of CHRYSLER GROUP, LLC

1 - BATTERY

2 - VOLTMETER

3 - STARTER MOTOR

3. Connect voltmeter (2) to measure between positive terminal post on battery (1) and the battery terminal

stud on the starter solenoid (3). Rotate and hold ignition switch in Start position. Observe voltmeter. If

reading is above 0.2 volt, clean and tighten battery cable connection at solenoid and repeat test. If reading

is still above 0.2 volt, replace the positive battery cable.

Thursday, November 16, 2017 19:34:39 Page 7

2014 RAM 3500 HD Laramie

2014 ENGINE Starting - Service Information - Ram Pickup

Fig. 5: Testing Ground Circuit Resistance - Typical

Courtesy of CHRYSLER GROUP, LLC

1 - VOLTMETER

2 - BATTERY

3 - ENGINE GROUND

4. Connect voltmeter (1) to measure between negative terminal post on battery (2) and a good clean ground

on engine block (3). Rotate and hold ignition switch in Start position. Observe voltmeter. If reading is

above 0.2 volt, clean and tighten negative battery cable attachment on engine block and repeat test. If

reading is still above 0.2 volt, replace the negative battery cable.

Fig. 6: Testing Starter Ground - Typical

Courtesy of CHRYSLER GROUP, LLC

1 - STARTER MOTOR

2 - BATTERY

3 - VOLTMETER

Thursday, November 16, 2017 19:34:39 Page 8

2014 RAM 3500 HD Laramie

2014 ENGINE Starting - Service Information - Ram Pickup

NOTE: Certain diesel equipped models use dual batteries. If equipped with dual

battery system, this procedure must be performed twice, once for each

battery.

5. Connect positive lead of voltmeter (3) to starter housing (1). Connect negative lead of voltmeter to

negative terminal post on battery (2). Rotate and hold ignition switch in Start position. Observe voltmeter.

If reading is above 0.2 volt, correct poor starter to engine block ground contact.

6. If equipped with dual battery system (certain diesel equipped models), connect positive lead of voltmeter

to positive battery cable clamp on battery located on left side of vehicle. Connect negative lead of

voltmeter to positive battery terminal post on battery located on right side of vehicle. Rotate and hold

ignition switch in Start position. Observe voltmeter. If reading is above 0.2 volt, clean and tighten battery

cables at both batteries and repeat test. If reading is still above 0.2 volt, replace positive battery cable.

7. If resistance tests detect no feed circuit problems, inspect and test the starter motor and solenoid. Refer to

STARTER, DIAGNOSIS AND TESTING.

SPECIFICATIONS

STARTING SYSTEM

STARTING SYSTEM SPECIFICATIONS

Starter Motor

Engine Application 3.7L / 4.7L Gas Powered 5.7L Gas Powered 6.7L Diesel Powered

1.4 Kilowatt / 1.9

Power Rating 1.2 Kilowatt 2.7 Kilowatt

Horsepower

* Cranking Amperage

100 - 200 Amperes 125 - 250 Amperes 200 Amperes

Draw Test

* Test at operating temperature. Cold engine, tight (new) engine, or heavy oil will increase starter

amperage draw.

TORQUE

TORQUE SPECIFICATIONS

DESCRIPTION N.m Ft. Lbs. In. Lbs.

Battery Cable Eyelet Nut at 14 10 124

Solenoid

Starter Mounting Bolts - Gas 68 50 -

Engines

Starter Mounting Nut - Gas 68 50 -

Engines

Starter B+ Cable Nut - Diesel

24 18 -

Engine

Starter Motor Bolts - Diesel

43 32 -

Engine

Thursday, November 16, 2017 19:34:39 Page 9

2014 RAM 3500 HD Laramie

2014 ENGINE Starting - Service Information - Ram Pickup

STARTER

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - STARTER MOTOR

NOTE: This test can only be performed with starter motor removed from vehicle.

Correct starter motor operation can be confirmed by performing the following free running bench test. Refer to

SPECIFICATIONS for starter motor specifications.

1. Remove starter motor from vehicle. Refer to REMOVAL.

2. Mount starter motor securely in a soft-jawed bench vise. The vise jaws should be clamped on the

mounting flange of starter motor. Never clamp on starter motor by field frame.

3. Connect a suitable volt-ampere tester and a 12-volt battery to starter motor in series, and set ammeter to

100 ampere scale. See instructions provided by manufacturer of volt-ampere tester being used.

4. Install jumper wire from solenoid terminal to solenoid battery terminal. The starter motor should operate.

If starter motor fails to operate, replace faulty starter motor assembly.

5. Adjust carbon pile load of tester to obtain free running test voltage. Refer to SPECIFICATIONS for

starter motor free running test voltage specifications.

6. Note reading on ammeter and compare reading to free running test maximum amperage draw. Refer to

SPECIFICATIONS for starter motor free running test maximum amperage draw specifications.

7. If ammeter reading exceeds maximum amperage draw specification, replace faulty starter motor

assembly.

STARTER SOLENOID

NOTE: Certain vehicles with certain engines may require starter motor removal for the

following test.

Thursday, November 16, 2017 19:34:39 Page 10

2014 RAM 3500 HD Laramie

2014 ENGINE Starting - Service Information - Ram Pickup

Fig. 7: Solenoid Continuity Test

Courtesy of CHRYSLER GROUP, LLC

1. If necessary, remove starter motor from vehicle. Refer to REMOVAL.

2. Disconnect solenoid connector wiring from starter motor.

3. Check for continuity between solenoid terminal (2) and solenoid case (3). There should be continuity. If

not OK, replace faulty starter motor assembly.

REMOVAL

5.7L/6.4L

Thursday, November 16, 2017 19:34:39 Page 11

2014 RAM 3500 HD Laramie

2014 ENGINE Starting - Service Information - Ram Pickup

Fig. 8: Starter Mounting Bolts

Courtesy of CHRYSLER GROUP, LLC

1. Disconnect and isolate the negative battery cable.

2. Raise and support the vehicle.

3. Remove the starter heat shield.

4. Note: If equipped with 4WD and certain transmissions, a support bracket is used between front axle and

side of transmission. Remove 2 support bracket bolts at transmission. Pry support bracket slightly to gain

access to lower starter mounting bolt.

5. Remove the two mounting bolts (2).

6. Move the starter motor towards front of vehicle far enough for the nose of the starter pinion housing to

clear the housing. Always support the starter motor during this process, do not let the starter motor hang

from wire harness.

7. Tilt nose the downwards and lower starter motor far enough to access and remove the nut that secures the

battery positive cable wire harness connector to the solenoid battery terminal stud. Do not let the starter

motor hang from the wire harness.

Fig. 9: Starter Electrical Connectors

Courtesy of CHRYSLER GROUP, LLC

8. Remove the battery positive cable wire harness connector eyelet (3) from the solenoid battery terminal

stud.

9. Disconnect the battery positive cable wire harness connector from the solenoid terminal connector

receptacle.

10. Remove the starter motor.

6.7L DIESEL

Thursday, November 16, 2017 19:34:39 Page 12

2014 RAM 3500 HD Laramie

2014 ENGINE Starting - Service Information - Ram Pickup

Fig. 10: Left Engine Block Stiffener & Bolts

Courtesy of CHRYSLER GROUP, LLC

1. Disconnect and isolate both negative battery cables.

2. Raise and support vehicle. Refer to HOISTING, STANDARD PROCEDURE .

3. If equipped, remove bolts (2) and the left engine block stiffener (1).

Fig. 11: Starter 6.7L Diesel

Courtesy of CHRYSLER GROUP, LLC

4. Disconnect solenoid wire harness connector (3).

5. Remove the B+ cable (1) dust cover.

6. Remove nut (2) and the B+ cable (1) from stud.

Thursday, November 16, 2017 19:34:39 Page 13

2014 RAM 3500 HD Laramie

2014 ENGINE Starting - Service Information - Ram Pickup

7. Remove three bolts (4) and starter motor from engine.

INSTALLATION

5.7L/6.4L

Fig. 12: Starter Electrical Connectors

Courtesy of CHRYSLER GROUP, LLC

1. Connect the solenoid wire to starter motor (snaps on).

2. Position the battery cable to the solenoid stud. Install and tighten the battery cable eyelet nut to 13 N.m

(10 ft. lbs.). Do not allow the starter motor to hang from the wire harness.

Thursday, November 16, 2017 19:34:39 Page 14

2014 RAM 3500 HD Laramie

2014 ENGINE Starting - Service Information - Ram Pickup

Fig. 13: Starter Mounting Bolts

Courtesy of CHRYSLER GROUP, LLC

3. Position the starter motor to engine.

4. If equipped with automatic transmission, slide the cooler tube bracket into position.

5. Install and tighten both mounting bolts. Tighten to 68 N.m (50 ft. lbs.).

6. Install the starter heat shield.

7. Lower the vehicle.

8. Connect the negative battery cable.

6.7L DIESEL

Fig. 14: Starter 6.7L Diesel

Courtesy of CHRYSLER GROUP, LLC

1. Install the starter motor. Tighten the three bolts (4) to 43 N.m (32 ft. lbs.).

2. Connect solenoid wire harness connector (3).

3. Install the B+ cable (1) onto stud. Tighten nut (2) to 24 N.m (18 ft. lbs.).

4. Install the B+ cable (1) dust cover.

Thursday, November 16, 2017 19:34:39 Page 15

2014 RAM 3500 HD Laramie

2014 ENGINE Starting - Service Information - Ram Pickup

Fig. 15: Left Engine Block Stiffener & Bolts

Courtesy of CHRYSLER GROUP, LLC

5. If equipped, install the engine block stiffener (1). Tighten bolts (2) to 89 N.m (66 ft. lbs.).

6. Lower the vehicle.

7. Connect both negative battery cables.

ANTENNA, REMOTE START

DESCRIPTION

DESCRIPTION

Thursday, November 16, 2017 19:34:39 Page 16

2014 RAM 3500 HD Laramie

2014 ENGINE Starting - Service Information - Ram Pickup

Fig. 16: Remote Start Antenna Module Assembly

Courtesy of CHRYSLER GROUP, LLC

The Remote Start Antenna Module Assembly consists of an electrical connection to the Radio Frequency (RF

Hub), a length of coaxial cable and two mounting clips. The antenna is located in the drivers rear cab above the

headliner.

The antenna which is printed on a circuit board in an enclosed plastic housing that is fed regulated 5v DC (+/-

5%) via the attached coaxial cable pigtail. The Remote Start Antenna captures radiated RF signals that are

transmitted from the Key FOB transmitter throughout the intended broadcast bands. The RF signal captured is

then amplified and sent to the desired receiver/tuner.

OPERATION

OPERATION

The Remote Start Antenna is used to receive the signal from the remote key. The antenna captures radiated RF

signals that are transmitted from the Key FOB transmitter throughout the intended broadcast bands. The RF

signal captured is then amplified and sent to the Remote Frequency Hub Module (RFHUB).

REMOVAL

REMOVAL

Fig. 17: Remove/Install Remote Start Antenna (RSA)

Courtesy of CHRYSLER GROUP, LLC

1. Disconnect and isolate negative battery cable.

2. Lower the headliner assembly. Refer to HEADLINER, REMOVAL .

3. Remove the two fasteners (1) securing the Remote Start Antenna (RSA) (2) to the roof cover rear section

Thursday, November 16, 2017 19:34:39 Page 17

2014 RAM 3500 HD Laramie

2014 ENGINE Starting - Service Information - Ram Pickup

header.

Fig. 18: RSA Wiring Harness Connector

Courtesy of CHRYSLER GROUP, LLC

4. Disconnect the RSA wiring harness connector (1) and remove remote module assembly.

INSTALLATION

INSTALLATION

Fig. 19: Remove/Install Remote Start Antenna (RSA)

Courtesy of CHRYSLER GROUP, LLC

Thursday, November 16, 2017 19:34:39 Page 18

2014 RAM 3500 HD Laramie

2014 ENGINE Starting - Service Information - Ram Pickup

1. Disconnect and isolate negative battery cable.

2. Install remote module assembly (2) and connect the wiring harness connector (3).

3. Install the headliner. Refer to HEADLINER, INSTALLATION .

4. Connect the negative battery cable.

RELAY, STARTER

DESCRIPTION

DESCRIPTION

The starter relay is integrated within the Power Distribution Center and is not serviceable separately.

SYSTEM, START STOP

DESCRIPTION

STOP/START OPTION

STOP/START feature. This feature will allow the engine to automatically start and stop when certain conditions

are meet.

The STOP/START starting system consists of:

Starter relay

Starter motor (including an integral starter solenoid)

STOP/START switch

Other components to be considered as part of starting system are:

An advanced AGM battery and intelligent battery sensor. The AGM (Advanced Glass Mat) type battery

is capable of withstanding the increased cycling that a stop/start vehicle will experience

High durability battery cables.

A 220a generator that is up-sized specifically for use with the stop/start system. This is true for both 3.6L

Pentastar and 5.7L Hemi applications.

A larger, higher durability starter is equipped on all stop/start vehicles.

A Voltage Stabilization Module (VSM) which will allow power accessories to remain functional between

the stop/start event.

PCM (monitors conditions for STOP/START)

The Battery, Starting, and Charging systems operate in conjunction with one another, and must be tested as a

complete system. For correct operation of starting/charging systems, all components used in these 3 systems

must perform within specifications. When attempting to diagnose any of these systems, it is important that you

keep their interdependency in mind.

Thursday, November 16, 2017 19:34:39 Page 19

2014 RAM 3500 HD Laramie

2014 ENGINE Starting - Service Information - Ram Pickup

The diagnostic procedures used in each of these groups include the most basic conventional diagnostic methods,

to the more sophisticated On-Board Diagnostics (OBD) built into the Powertrain Control Module (PCM). Use

of an induction-type milliampere ammeter, volt/ohmmeter, battery charger, carbon pile rheostat (load tester),

and 12-volt test lamp may be required.

Certain starting system components are monitored by the PCM and may produce a Diagnostic Trouble Code

(DTC).

OPERATION

STOP/START

The START/STOP feature operation works in part like a non-STOP/START system.

To Start The Engine While In The STOP/START AUTO STOP ACTIVE Mode -

When the shift lever is in NEUTRAL, the engine will start when the accelerator pedal is pressed. The vehicle

will go into STOP/START SYSTEM NOT READY mode until the vehicle speed is greater than 3 mph (5

km/h).

Conditions that force a manual key cycle start while in STOP/START AUTO STOP ACTIVE mode:

The engine will not start automatically if:

The driver's seatbelt was unbuckled.

The engine hood has been opened.

A STOP/START system error occurs.

The engine may then only be restarted with an ignition key cycle. The STOP/START KEY START

REQUIRED message will appear in the Electronic Vehicle Information Center (EVIC) under these conditions.

To Manually Turn Off The Start Stop System:

Press the STOP/START Off switch (located on the Integrated Center Stack Switch Bank otherwise

known as the ICS)

The STOP/START OFF message will appear in the EVIC.

At the next vehicle stop (after turning off the STOP/START system) the engine will not be stopped.

If the STOP/START system is manually turned off, the engine can only be started and stopped by cycling

the ignition switch.

The STOP/START system will reset itself back to an ON condition every time the ignition is turned off

and back on.

To manually turn on the STOP/START system:

1. Press the STOP/START off switch (located on the ICS.

Thursday, November 16, 2017 19:34:39 Page 20

2014 RAM 3500 HD Laramie

2014 ENGINE Starting - Service Information - Ram Pickup

2. The light on the switch will turn off.

For the engine to "AUTO-STOP" the vehicle must meet the following conditions:

Vehicle speed < 4.5KPH (2.8 MPH)

Engine coolant temperature between 20?C (68?F) and 115?C (239?F)

Battery state acceptable

Brake vacuum acceptable

Ambient temperature and pressure acceptable

HVAC high demand not present

Hood not open

T-case not low-range

DPF regeneration not active

Stop/start functionality not turned off

Driver seat belt latched

Starter overheat protection not active

System fault not present (critical or non-critical)

For the engine to "AUTO-START" the vehicle must meet the following conditions :

Vehicle speed > 5 KPH (3 MPH)

Engine coolant temperature between 20?C (68?F) and 115?C (239?F)

Accelerator pedal not pressed

Battery state acceptable

HVAC high demand not present

Hood not open

T-case not low-range

DPF regeneration not active

Driver seat belt latched

Starter overheat protection not active

System fault not present (critical or non-critical)

DIAGNOSIS AND TESTING

STOP START SYSTEM DIAGNOSIS

For diagnostics of the starting system, please refer to DIAGNOSIS AND TESTING.

For diagnostics of the Stop Start system, the scan tool can be used to review the inhibitor menu to help root

cause a potential Stop Start concern.

Thursday, November 16, 2017 19:34:39 Page 21

2014 RAM 3500 HD Laramie

2014 ENGINE Starting - Service Information - Ram Pickup

Possible Reasons The Engine Does Not AUTO STOP

Prior to engine shut down, the system will check many safety and comfort conditions to see if they are fulfilled.

In following situations the engine will not stop:

Driver's seat belt is not buckled.

Outside temperature is less than 1°F (-17°C) or greater than 104°F (40°C).

Actual cabin temperature is significantly different than temperature set on Auto HVAC.

HVAC is set to full defrost mode.

Engine has not reached normal operating temperature.

Battery discharged.

When driving in REVERSE.

Hood is open. for further information on the Hood Ajar Switch operation and diagnostics. Refer to

SWITCH, HOOD AJAR, DESCRIPTION .

Vehicle is in 4LO transfer case mode.

It may be possible for the vehicle to be driven several times without the STOP/START system going into a

STOP/START READY state under more extreme conditions of the items listed above.

For a more technical and detailed explanation of AutoStop, review the following inhibitors.

When it comes to Stop Start, we allow AutoStop event if:

Accelerator pedal is in the rest position.

HVAC Control allows an auto stop event. The AC load can not be in a high demand mode of operation.

Battery state (charge 65%, function 8 volts, health 40 ampere hour) is within an acceptable range.

Current master cylinder brake pressure exceeds the required Hill Speed Assist (HSA) brake pressure and

is sufficient to hold the vehicle on a grade.

Electronic Stability Control (ECS) is not requesting control.

Fuel level is greater than the minimum fuel level threshold.

Both hood switches indicate the hood is closed.

Predefined OBD faults are not present.

Vehicle occupants are not attempting a vehicle exit maneuver.

Absolute Barometric Pressure is within range. Barometric pressure is greater then a minimum of 605KPa.

Brake Booster is sufficient to maintain master cylinder pressure with current applied pedal force.

Minimum 205Ka.

Starter motor engagement has not exceeded prescribed frequency use.

Vehicle speed is 0.

Steering angle has not exceeded the prescribed range.

Steering torque is less than the prescribed value.

Ambient Air Temperature is within the prescribed range (-10F - 110F).

Thursday, November 16, 2017 19:34:39 Page 22

2014 RAM 3500 HD Laramie

2014 ENGINE Starting - Service Information - Ram Pickup

Catalyst temperature is within the prescribed range (150F - 950F).

Coolant temperature is within the prescribed range.

Engine oil temperature is within the prescribed range (40C - 110C).

Anti-lock brake system is not active.

Transfer case is not in 4WDLO.

Vehicle is not in tow haul mode.

Vehicle is in valid target gear and brake switch combination.

Threshold vehicle speed exceeded or timeout since last shift out of reverse.

Transmission ready.

Battery temperature is within the prescribed range (-256F - 256F).

Engine speed is below a set threshold of 1000 RPM.

Engine run time is greater then threshold of 3 seconds.

Start Stop disable switch is not active.

Flex fuel learn mode is not active.

Vehicle is not on a grade.

Threshold vehicle speed exceeded since last engine start is 8mph.

Conditions that will cause the engine to start automatically while in STOP/START AUTO STOP

ACTIVE mode:

Actual cabin temperature is significantly different than temperature set in Auto HVAC.

HVAC is set to full defrost mode.

STOP/START AUTO STOP TIME ACTIVE exceeds 5 minutes.

Battery Voltage drops too low.

Low brake vacuum e.g. after several brake pedal applications.

Vehicle is moving faster then 3 mph (5 km/h).

STOP/START OFF switch is pressed.

4WD is put into 4LO mode.

We allow Stop Start AutoStarts to occur when any of the conditions are made active:

Accelerator pedal is in the "rest" position.

HVAC Control is allows an Auto Stop event.

Battery State (charge, function, health) is within acceptable range.

Current master cylinder brake pressure exceeds the required HSA brake pressure and is sufficient to hold

the vehicle on a grade.

Electronic Stability Control system is not requesting control.

Fuel Level is greater than the minimum fuel level threshold.

Both hood switches indicate hood is closed.

Thursday, November 16, 2017 19:34:39 Page 23

2014 RAM 3500 HD Laramie

2014 ENGINE Starting - Service Information - Ram Pickup

Predefined OBD faults are not present.

Vehicle occupants are not attempting a vehicle exit maneuver.

Absolute Barometric Pressure is within range.

Brake Booster Pressure is sufficient to maintain master cylinder pressure with current applied pedal force.

Starter motor engagement has not exceeded prescribed frequency of use.

Vehicle speed is 0.

Steering Angle has not exceeded the prescribed range.

Steering Torque is less than the prescribed value.

Ambient Air Temperature is within the prescribed range.

Catalyst Temperature is within the prescribed range.

Coolant Temperature is within the prescribed range.

Engine Oil Temperature is within the prescribed range.

Anti-Lock Brake System is not active.

Transfer Case Mode is not in 4WDLO.

Vehicle is not in TOW-HAUL mode.

Vehicle is in valid target gear and brake switch state combination.

Threshold vehicle speed exceeded or timeout since last shift out of reverse.

Transmission ready.

Battery temperature is within the prescribed range.

Engine speed is below a set threshold.

Threshold vehicle speed exceeded since last engine start.

Engine run time greater than threshold.

Stop-Start disable switch is not active.

Flex fuel learn mode not active.

Vehicle is not on a grade.

We allow Stop Start AutoStarts to occur when any of the conditions are made active:

Accelerator pedal is not in the "rest" position.

HVAC Control is active.

Battery State (charge, function, health) is out of range.

Current master cylinder brake pressure does not have enough HSA brake pressure.

Electronic Stability Control system is requesting control.

Fuel Level is lower than the minimum fuel level threshold.

One or both hood switches indicate hood is open.

Predefined OBD faults are present.

Absolute Barometric Pressure is out of range.

Brake Booster Pressure is insufficient to maintain master cylinder pressure with current applied pedal

Thursday, November 16, 2017 19:34:39 Page 24

2014 RAM 3500 HD Laramie

2014 ENGINE Starting - Service Information - Ram Pickup

force.

Starter motor engagement has exceeded prescribed frequency of use.

Vehicle speed is above 0.

Steering Angle has exceeded the prescribed range.

Steering Torque is more than the prescribed value.

Ambient Air Temperature is outside the prescribed range.

Catalyst Temperature is outside the prescribed range.

Coolant Temperature is outside the prescribed range.

Engine Oil Temperature is outside the prescribed range.

Anti-Lock Brake System is active.

Transfer Case Mode is in 4WDLO.

Vehicle is in TOW-HAUL mode.

Transmission not ready.

Battery temperature is out of the prescribed range.

Stop-Start disable switch is active.

Flex fuel learn mode is active.

The above conditions can restart the vehicle as long as:

1. Completed initial engine key start.

2. Occupant sensing allow engine start condition met.

3. OBD allow engine start condition met.

4. Vehicle hood closed.

System Malfunction:

If there is a malfunction in the STOP/START system, the system will not shut down the engine. A SERVICE

STOP/START SYSTEM message will appear in the EVIC.

RELAY, IN-RUSH CURRENT REDUCTION

DESCRIPTION

DESCRIPTION

In-rush Current Reduction Relay

Thursday, November 16, 2017 19:34:39 Page 25

2014 RAM 3500 HD Laramie

2014 ENGINE Starting - Service Information - Ram Pickup

Fig. 20: In-Rush Current Reduction Relay Components

Courtesy of CHRYSLER GROUP, LLC

In-Rush Current Reduction Relay

1 To Battery B+ Stud

2 ICR Control

3 Starter Control

4 Starter Drive

5 Starter Solenoid

6 Ring Gear

7 Case Ground

8 Shorting Bar

9 Resistor Bar

10 ICR Relay. Case Ground is at this location.

The In-Rush Current Reduction Relay (ICR) is to reduce the electrical system's voltage drop, induced by the

starter motor's large current draw, during the first few milliseconds of the cranking cycle. The ICR has the

appearance of a solenoid assembly. On the V6 engine the relay is normally mounted towards the bottom end of

the engine where the power steering pump used to be located. On the V8 engines the ICR is mounted towards

the front cover of the engine towards the top. The relay is serviceable and is shipped along with a bracket that

Thursday, November 16, 2017 19:34:39 Page 26

2014 RAM 3500 HD Laramie

2014 ENGINE Starting - Service Information - Ram Pickup

secures the ICR.

OPERATION

OPERATION

In-Rush Current Reduction Relay.

Within the ICR relay, prior to the starter motor solenoid's contact closure, the shorting bar opens contacts, thus

routing the starter motor current through a resistor bar (10 mOhm for V6 Pentastar). The increase in series

resistance reduces/eliminates the initial current spike (or, inrush current) and reduces the consequent voltage

drop. After a set time (185 msec), the power to the ICR relay is cut, the shorting bar closes the contacts,

removing the resistor bar from the circuit and restoring full power to the starter motor. At this point, there is a

rebound of the current surge and subsequent drop in voltage; however, neither is as intense as they would be

would be without initial jump in resistance.

Thursday, November 16, 2017 19:34:39 Page 27

You might also like

- ENGINE Fuel System - Ram Pickup PDFDocument391 pagesENGINE Fuel System - Ram Pickup PDFcharlesNo ratings yet

- Diesel PowertrainDocument284 pagesDiesel PowertrainCOSTIN NESTIANNo ratings yet

- 2000 Buick Regal Prueba de Sistema y ComponentesDocument158 pages2000 Buick Regal Prueba de Sistema y ComponentesRubenNo ratings yet

- 2005 Ram Intro PDFDocument14 pages2005 Ram Intro PDFRonaldNo ratings yet

- ACCESSORIES and EQUIPMENT ChimeBuzzerDriver Assist - Service Information - Ram PickupDocument22 pagesACCESSORIES and EQUIPMENT ChimeBuzzerDriver Assist - Service Information - Ram PickupcharlesNo ratings yet

- TRANSFER CASE Final Drive Control Module (FDCM) - Electrical Diagnostics - Ram Pickup PDFDocument139 pagesTRANSFER CASE Final Drive Control Module (FDCM) - Electrical Diagnostics - Ram Pickup PDFcharlesNo ratings yet

- p1811-p0748 Impala PDFDocument5 pagesp1811-p0748 Impala PDFUlloaEliasNo ratings yet

- Start No ClickDocument4 pagesStart No Clicklamping_apNo ratings yet

- ZG Chime/Buzzer Warning Systems 8U - 1Document4 pagesZG Chime/Buzzer Warning Systems 8U - 1ensmartisNo ratings yet

- 2010 Chrysler SebringDocument444 pages2010 Chrysler SebringHELEN QUIROGANo ratings yet

- FordDocument5 pagesFordmiguelNo ratings yet

- Model Indentifiction For Cars TestsDocument454 pagesModel Indentifiction For Cars TestsRichard Thodé JrNo ratings yet

- System Wiring Diagrams: Air ConditioningDocument67 pagesSystem Wiring Diagrams: Air ConditioningJose Luis Orozco RobledoNo ratings yet

- Rs Wiring DiagramDocument594 pagesRs Wiring DiagramRuben Castro100% (1)

- ACCESSORIES and EQUIPMENT AudioVideoEntertainmentConnectivity - Service Information - Ram PickupDocument59 pagesACCESSORIES and EQUIPMENT AudioVideoEntertainmentConnectivity - Service Information - Ram PickupcharlesNo ratings yet

- ENGINEDocument2,790 pagesENGINEAdan Flores CorreaNo ratings yet

- Ford CrownVic 1998 ManualDocument160 pagesFord CrownVic 1998 ManualNasir AyubNo ratings yet

- BRAKES Antilock Brake System (ABS) - Electrical Diagnostics - Ram Pickup PDFDocument179 pagesBRAKES Antilock Brake System (ABS) - Electrical Diagnostics - Ram Pickup PDFcharlesNo ratings yet

- GR00005100 23a PDFDocument152 pagesGR00005100 23a PDFNicu PascalutaNo ratings yet

- P0117 ECT Sensor LowDocument6 pagesP0117 ECT Sensor Lowflash_24014910No ratings yet

- 3500 HD 2013 6.7LDocument303 pages3500 HD 2013 6.7LLuis Ramon Arguello RealNo ratings yet

- Chrysler Neon 99 - Instrument Panel and SystemsDocument4 pagesChrysler Neon 99 - Instrument Panel and SystemseephantomNo ratings yet

- TSB 18-020-10 PCM Software Sensor & DTC ImprovementsDocument7 pagesTSB 18-020-10 PCM Software Sensor & DTC ImprovementsJose ivan delgado Ugalde100% (1)

- Passsive Restraint Systems GuideDocument12 pagesPasssive Restraint Systems GuideDane WallaceNo ratings yet

- SUSPENSION Front Suspension & Wheel Alignment - Ram Pickup PDFDocument86 pagesSUSPENSION Front Suspension & Wheel Alignment - Ram Pickup PDFcharlesNo ratings yet

- Antilock BrakesDocument117 pagesAntilock BrakesNoel Alejandro Cordova Rangel100% (1)

- JourneyDocument194 pagesJourneyjuan carlos garciaNo ratings yet

- Avenger 2.4 2013Document263 pagesAvenger 2.4 2013Saul HernándezNo ratings yet

- ACCESSORIES AND EQUIPMENT External AudioVideo Module - Electrical Diagnostics - Ram Pickup PDFDocument38 pagesACCESSORIES AND EQUIPMENT External AudioVideo Module - Electrical Diagnostics - Ram Pickup PDFcharlesNo ratings yet

- 04-13-012 Engine Controls Emissions - OBDII Drive Cycle ReviDocument29 pages04-13-012 Engine Controls Emissions - OBDII Drive Cycle Reviapi-3855859100% (2)

- Chrysler Specific Diagnostic Trouble CodesDocument8 pagesChrysler Specific Diagnostic Trouble CodesVadim UrupaNo ratings yet

- At Service E40dDocument5 pagesAt Service E40ds.e. e.p.No ratings yet

- Ram 2500 2010 5.7LDocument198 pagesRam 2500 2010 5.7LMario SánchezNo ratings yet

- Jtec PDFDocument9 pagesJtec PDFcesar Miranda100% (1)

- ACCESSORIES and EQUIPMENT Communication - Non-DTC Based Diagnostics - Ram PickupDocument97 pagesACCESSORIES and EQUIPMENT Communication - Non-DTC Based Diagnostics - Ram PickupcharlesNo ratings yet

- 2013 Genesis Coupe Automatic Transaxle Specs and Repair GuideDocument75 pages2013 Genesis Coupe Automatic Transaxle Specs and Repair GuideNacho MowjiNo ratings yet

- 13OBDG09 Engine DiagnosticsDocument562 pages13OBDG09 Engine DiagnosticsEric Joseph GoldenNo ratings yet

- GM 4L60E/4L65E/4L70E transmission solenoid testDocument2 pagesGM 4L60E/4L65E/4L70E transmission solenoid testtwinturbo2No ratings yet

- Brake SystemDocument151 pagesBrake SystemHassan ZAFFA CISNEROSNo ratings yet

- CompuStar CM5200Document7 pagesCompuStar CM5200JamesParadisoNo ratings yet

- Vehicle Specifications: ContentsDocument146 pagesVehicle Specifications: ContentsnanaNo ratings yet

- Headlamp Adjustments 2007 Nissan VersaDocument2 pagesHeadlamp Adjustments 2007 Nissan Versachrisban35No ratings yet

- 2017 Chevrolet Express Owners Manual PDFDocument346 pages2017 Chevrolet Express Owners Manual PDFmfruge7No ratings yet

- T-Rex Installation ManualDocument2 pagesT-Rex Installation ManualVictor Bitar100% (2)

- Direct Injection (Current) PDFDocument7 pagesDirect Injection (Current) PDFToni JuanNo ratings yet

- Dodge Avenger camshaft solenoid testDocument7 pagesDodge Avenger camshaft solenoid testflash_24014910No ratings yet

- Accessories: Chrysler Town & CountryDocument8 pagesAccessories: Chrysler Town & CountryswiftNo ratings yet

- Problems Before: and After RebuildDocument6 pagesProblems Before: and After RebuildMarco Antonio Ortiz RomeroNo ratings yet

- 2009 Mazda6 Mazdaspeed6 Service ManualDocument8 pages2009 Mazda6 Mazdaspeed6 Service ManualErikNo ratings yet

- Chrysler Scan Tool Flash Availability - 06 - May - 2018Document1,027 pagesChrysler Scan Tool Flash Availability - 06 - May - 2018compukarsalNo ratings yet

- Jeep 8W+WIRING+DIAGRAMSDocument426 pagesJeep 8W+WIRING+DIAGRAMSFarhani ZaghouanNo ratings yet

- ACCESSORIES AND EQUIPMENT Heated Glass - Service Information - Ram Pickup PDFDocument5 pagesACCESSORIES AND EQUIPMENT Heated Glass - Service Information - Ram Pickup PDFcharlesNo ratings yet

- Eti 4M09 4 09 04 29 GM TacDocument8 pagesEti 4M09 4 09 04 29 GM TaclaurianNo ratings yet

- 5R55W S VacTestLocationsDocument2 pages5R55W S VacTestLocationsPedroMecanico100% (1)

- Diagnosis and TestingDocument12 pagesDiagnosis and TestingRepuesto GeneralNo ratings yet

- Zongshen User ManualDocument7 pagesZongshen User ManualScribdTranslationsNo ratings yet

- Wiper and Washer Systems: Symptom Related Diagnostic Procedures Windshield Wiper Washer System MalfunctionDocument5 pagesWiper and Washer Systems: Symptom Related Diagnostic Procedures Windshield Wiper Washer System MalfunctionJose GarciaNo ratings yet

- Description & Operation: Ignition Switch Continuity TestDocument69 pagesDescription & Operation: Ignition Switch Continuity Testomar menciasNo ratings yet

- 5-vmax_owner_operationDocument2 pages5-vmax_owner_operationzuntoy000No ratings yet

- Starting SystemDocument21 pagesStarting Systemmkisa70No ratings yet

- Approach May June12Document36 pagesApproach May June12charlesNo ratings yet

- TRANSFER CASE Final Drive Control Module (FDCM) - Electrical Diagnostics - Ram Pickup PDFDocument139 pagesTRANSFER CASE Final Drive Control Module (FDCM) - Electrical Diagnostics - Ram Pickup PDFcharlesNo ratings yet

- SYSTEM WIRING DIAGRAMS RAM - 3500 HD 2 of 2 PDFDocument97 pagesSYSTEM WIRING DIAGRAMS RAM - 3500 HD 2 of 2 PDFcharlesNo ratings yet

- UTV - Off.road - Magazine March - April.2020Document69 pagesUTV - Off.road - Magazine March - April.2020charlesNo ratings yet

- Azure Transit Vnet Deployment GuideDocument178 pagesAzure Transit Vnet Deployment GuidecharlesNo ratings yet

- TRANSFER CASE BW44-46 - Service Information - Ram Pickup PDFDocument42 pagesTRANSFER CASE BW44-46 - Service Information - Ram Pickup PDFcharles100% (1)

- TRANSFER CASE BW44-47 - Service Information - Ram Pickup PDFDocument60 pagesTRANSFER CASE BW44-47 - Service Information - Ram Pickup PDFcharles100% (1)

- SUSPENSION Tires & Wheels - Service Information - Ram Pickup PDFDocument49 pagesSUSPENSION Tires & Wheels - Service Information - Ram Pickup PDFcharlesNo ratings yet

- STEERING Steering System - Ram Pickup PDFDocument96 pagesSTEERING Steering System - Ram Pickup PDFcharlesNo ratings yet

- Suspension Ram Wheel Alignment Specifications PDFDocument22 pagesSuspension Ram Wheel Alignment Specifications PDFcharlesNo ratings yet

- RESTRAINTS Service Information - Ram Pickup PDFDocument146 pagesRESTRAINTS Service Information - Ram Pickup PDFcharlesNo ratings yet

- SUSPENSION Front Air Suspension Control Module (ASCM) - Electrical Diagnostics - Ram Pickup PDFDocument236 pagesSUSPENSION Front Air Suspension Control Module (ASCM) - Electrical Diagnostics - Ram Pickup PDFcharles100% (1)

- System Wiring Diagrams Ram - 3500 HD 1 of 2Document167 pagesSystem Wiring Diagrams Ram - 3500 HD 1 of 2charlesNo ratings yet

- SUSPENSION Rear Suspension - Ram Pickup PDFDocument67 pagesSUSPENSION Rear Suspension - Ram Pickup PDFcharlesNo ratings yet

- HVAC Heating & Air Conditioning - Service Information - Ram Pickup PDFDocument200 pagesHVAC Heating & Air Conditioning - Service Information - Ram Pickup PDFcharlesNo ratings yet

- STEERING Steering Control Module (SCM) - Electrical Diagnostics - Ram Pickup PDFDocument59 pagesSTEERING Steering Control Module (SCM) - Electrical Diagnostics - Ram Pickup PDFcharlesNo ratings yet

- SUSPENSION Front Suspension & Wheel Alignment - Ram Pickup PDFDocument86 pagesSUSPENSION Front Suspension & Wheel Alignment - Ram Pickup PDFcharlesNo ratings yet

- MANUAL TRANSMISSION G56 - Service Information - Ram Pickup PDFDocument101 pagesMANUAL TRANSMISSION G56 - Service Information - Ram Pickup PDFcharlesNo ratings yet

- GENERAL INFORMATION Circuit Testing Procedures - Non-DTC-Based Diagnostics - Ram Pickup PDFDocument51 pagesGENERAL INFORMATION Circuit Testing Procedures - Non-DTC-Based Diagnostics - Ram Pickup PDFcharlesNo ratings yet

- REMINDER INDICATOR RESET PROCEDURES Chrysler Dodge Plymouth RAM - 1978-14 PDFDocument22 pagesREMINDER INDICATOR RESET PROCEDURES Chrysler Dodge Plymouth RAM - 1978-14 PDFcharlesNo ratings yet

- HVAC Heating & Air Conditioning - Electrical Diagnostics - Ram Pickup PDFDocument213 pagesHVAC Heating & Air Conditioning - Electrical Diagnostics - Ram Pickup PDFcharlesNo ratings yet

- GENERAL INFORMATION Vehicle Quick Reference - Ram Pickup PDFDocument57 pagesGENERAL INFORMATION Vehicle Quick Reference - Ram Pickup PDFcharlesNo ratings yet

- ENGINE Starting - Non-DTC Based Diagnostics - Ram Pickup PDFDocument13 pagesENGINE Starting - Non-DTC Based Diagnostics - Ram Pickup PDFcharlesNo ratings yet

- ENGINE Starting - Service Information - Ram Pickup PDFDocument27 pagesENGINE Starting - Service Information - Ram Pickup PDFcharlesNo ratings yet

- ENGINE PERFORMANCE Driveability - Diesel - Non-DTC Based Diagnostics, 6.7L Diesel - Ram Pickup PDFDocument73 pagesENGINE PERFORMANCE Driveability - Diesel - Non-DTC Based Diagnostics, 6.7L Diesel - Ram Pickup PDFcharlesNo ratings yet

- ENGINE PERFORMANCE Emissions Control - Ram Pickup PDFDocument138 pagesENGINE PERFORMANCE Emissions Control - Ram Pickup PDFcharlesNo ratings yet

- GENERAL INFORMATION Vehicle Data - Ram Pickup PDFDocument14 pagesGENERAL INFORMATION Vehicle Data - Ram Pickup PDFcharlesNo ratings yet

- ENGINE Ignition System - Service Information - Ram Pickup PDFDocument20 pagesENGINE Ignition System - Service Information - Ram Pickup PDFcharlesNo ratings yet

- ENGINE Exhaust System - Ram Pickup PDFDocument58 pagesENGINE Exhaust System - Ram Pickup PDFcharlesNo ratings yet

- Security Indicator: Immobilizer System Symptom Troubleshooting InformationDocument34 pagesSecurity Indicator: Immobilizer System Symptom Troubleshooting InformationrankiadNo ratings yet

- 2015 Jeep Patriot 38596Document572 pages2015 Jeep Patriot 38596kossovi kossovoNo ratings yet

- hcs301.. EncodingDocument30 pageshcs301.. Encodingmhamid101No ratings yet

- Ncs 409Document17 pagesNcs 409vjayk73No ratings yet

- Mircom MUS3140K Data SheetDocument2 pagesMircom MUS3140K Data SheetJMAC SupplyNo ratings yet

- SecuriKey Common ManualDocument12 pagesSecuriKey Common ManualBrandoNo ratings yet

- 2000 Mercedes Benz ML 320 Vehicle Wiring Chart and DiagramDocument2 pages2000 Mercedes Benz ML 320 Vehicle Wiring Chart and DiagramDiamondNo ratings yet

- HFM4C01 - Technical Spec & Operational DescriptionDocument6 pagesHFM4C01 - Technical Spec & Operational DescriptionOscar castroNo ratings yet

- How To Disable The Alarm On A 2000 Ford Expedition: InstructionsDocument4 pagesHow To Disable The Alarm On A 2000 Ford Expedition: Instructionsedin1234No ratings yet

- RX 400h Personalized SettingsDocument8 pagesRX 400h Personalized SettingsSavin CristiNo ratings yet

- 2012 Chevrolet Sonic OwnersDocument354 pages2012 Chevrolet Sonic OwnersHelimenes De JesúsNo ratings yet

- 2023 Jeep RenegadeDocument316 pages2023 Jeep Renegadecarpiofloria8642No ratings yet

- 2002 Volvo S40 & V40Document88 pages2002 Volvo S40 & V40Mrashdi OmarNo ratings yet

- Door Locks ServiceDocument12 pagesDoor Locks ServiceRepuesto GeneralNo ratings yet

- AES Security Protocol Implementation For Automobile Remote Keyless SystemDocument4 pagesAES Security Protocol Implementation For Automobile Remote Keyless Systempaney93346No ratings yet

- Evoque Owners Club Manual PDFDocument258 pagesEvoque Owners Club Manual PDFishanNo ratings yet

- Woot17 Paper BenadjilaDocument13 pagesWoot17 Paper BenadjilaKaci AmaoucheNo ratings yet

- Musso Service Manual PDFDocument216 pagesMusso Service Manual PDFfitNo ratings yet

- Al 1510 Edp PDFDocument18 pagesAl 1510 Edp PDFChuz HerreraNo ratings yet

- Owner's Handbook: Downloaded From Manuals Search EngineDocument16 pagesOwner's Handbook: Downloaded From Manuals Search EnginethugsdeiNo ratings yet

- CX-5 - Personalized Features PDFDocument8 pagesCX-5 - Personalized Features PDFNuttapong SukganNo ratings yet

- W211 SBC Brake Disable - Enable Without Star DiagnosisDocument3 pagesW211 SBC Brake Disable - Enable Without Star DiagnosisDreambear80% (5)

- 2013 Volkswagen Touareg 88279Document440 pages2013 Volkswagen Touareg 88279Zoltan MarosanNo ratings yet

- 2014 Volkswagen Tiguan 88297Document418 pages2014 Volkswagen Tiguan 88297Mab294No ratings yet

- User'S Guide: MODEL 7511WDocument32 pagesUser'S Guide: MODEL 7511WMartin CerdaNo ratings yet

- 2012 A7 Convenience System and Active Lane Change AssistDocument40 pages2012 A7 Convenience System and Active Lane Change AssistAbo AnasNo ratings yet

- CarManual SAIL Petrol 24sep13Document204 pagesCarManual SAIL Petrol 24sep13basantkumar83No ratings yet

- Ford Fiesta ManualDocument210 pagesFord Fiesta ManualDishara Madushan ThilakarathneNo ratings yet

- F o R D 4.0L 2000 2001 Bronco Expedition Ranger Diag Electric.Document96 pagesF o R D 4.0L 2000 2001 Bronco Expedition Ranger Diag Electric.William Belasco0% (1)

- Owner's Manual: Vehicle Security SystemDocument8 pagesOwner's Manual: Vehicle Security SystemrifhmercNo ratings yet