Professional Documents

Culture Documents

SUSPENSION Tires & Wheels - Service Information - Ram Pickup PDF

Uploaded by

charlesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SUSPENSION Tires & Wheels - Service Information - Ram Pickup PDF

Uploaded by

charlesCopyright:

Available Formats

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

2014 SUSPENSION

Tires & Wheels - Service Information - Ram Pickup

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - TIRE AND WHEEL VIBRATION

Tire and wheel imbalance, runout and tire road force variation can cause vehicles to exhibit steering wheel

vibration and/or seat vibration.

VEHICLES WITH A VIBRATION OR SHAKE

The following procedure is to identify, prevent and correct tire flat spotting.

Description

Immediately following delivery, some vehicles may exhibit a vibration or shake due to temporary tire flat-

spotting. The vibration may be felt in the steering wheel or seat and will be most noticeable at highway speeds

(60 mph (96 kph). This could be misinterpreted as an out of balance tire. Flat Spotting can occur if the vehicle

has not been moved for a few days or for a longer period of time. In most cases it is temporary condition. In

extreme cases it can be permanent.

Tire pressure is often inflated to the maximum sidewall pressure at the vehicle assembly plant to prevent "flat

spots" on tires during new vehicle shipping and vehicle storage. Inflating tires to the maximum sidewall tire

pressure helps to preserve the integrity of the tire and reduces potential technical issues.

It is important to remove temporary flat spotting before performing tire balance, tire run-out or tire road force

checks. If the flat spotting is not removed it can result in incorrect measurements.

Flat Spotting Removal

NOTE: If the vehicle has been sitting for an extended period of time it is recommended

to drive the vehicle to warm the tires. This process could eliminate flat spots

that can cause vibration.

1. Drive the vehicle at highway speeds until the vibration (flat spotting) is eliminated.

NOTE: In most cases, flat spot vibrations will be eliminated within 20

minutes (about 20 miles) of driving at highway speeds. If the vehicle

has been stored without moving for an extended time, it may be

necessary to drive the vehicle longer at highway speeds. If the

vibration is not completely eliminated during the test drive, go to 2 .

2. Within 10 minutes after driving the vehicle, raise the vehicle so there is no load on the tires.

Thursday, November 16, 2017 19:57:10

19:57:07 Page 1

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

3. Check the tire and wheel assemblies for balance, run-out, and road force variation. Refer to STANDARD

PROCEDURE.

4. Only install new tires after the vehicle has been driven as directed and all appropriate wheel and tire

diagnostics have been completed.

VISUAL INSPECTION

Visual inspection of the vehicle is recommended prior to road testing or performing any other procedure. Raise

and support the vehicle. Refer to HOISTING, STANDARD PROCEDURE .

Inspect for the following:

Verify correct (OEM) wheel and tire, as well as presence of wheel weights.

Inspect tires and wheels for damage, mud packing and unusual wear; correct as necessary.

Check and adjust tire air pressure to the pressure listed on the label attached to the driver's door opening.

ROAD TEST

NOTE: If a Noise & Vibration Analyzer is available, use it to diagnosis the issue during

the road test.

NOTE: If the vehicle has been sitting for an extended period of time it is recommended

to drive to warm the tires. This process could eliminate flat spots that can cause

vibration.

Road test vehicle on a smooth road at and near the designated speed where legal speed limits allow. Lightly

place hands on steering wheel at the 10:00 and 2:00 positions and observe for:

Steering wheel oscillation: clockwise/counterclockwise

Steering wheel high frequency movement: rapid vibration up and down

Seat high frequency movement: rapid vibration up and down

To rule out vibrations due to brakes or powertrain:

Lightly apply brakes at the designated speed; if vibration occurs or is enhanced, vibration is likely due to

a brake concern.

Shift transmission into neutral while vibration is occurring; if vibration is eliminated, vibration is likely

due to a powertrain concern. Refer to the appropriate Service Information .

TIRE/WHEEL BALANCE AND ROAD FORCE VARIATION

NOTE: If wheel balance equipment is capable of testing tire road force variation and

the tire/wheel assemblies are within specification, place the tires with the

greater road force variation on the rear of the vehicle.

Thursday, November 16, 2017 19:57:07 Page 2

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

Balance the tire and wheel assemblies as necessary, and if wheel balance equipment is capable, also test for tire

and wheel runout and road force variation following the wheel balancer manufacturer's instructions and using

the information listed in Tire And Wheel Balance. Refer to STANDARD PROCEDURE. Repeat the road test

above to verify the vibration is repaired.

STANDARD PROCEDURE

TIRE AND WHEEL BALANCE

BACK CONE MOUNTING

A multimedia supplement to the instructions contained in this article is

available.

To view the multimedia example of the condition described go to;

http://www.youtube.com/user/

then type "A00619574.vid1" into the "Search Channel" box.

FLANGE PLATE MOUNTING

A multimedia supplement to the instructions contained in this article is

available.

To view the multimedia example of the condition described go to;

http://www.youtube.com/user/

then type "A00619574.vid2" into the "Search Channel" box.

CHROME/PLASTIC CLAD WHEEL SERVICE

A multimedia supplement to the instructions contained in this article is

available.

To view the multimedia example of the condition described go to;

http://www.youtube.com/user/

then type "A00619574.vid3" into the "Search Channel" box.

FORCE MATCHING

A multimedia supplement to the instructions contained in this article is

available.

To view the multimedia example of the condition described go to;

http://www.youtube.com/user/

then type "A00619574.vid4" into the "Search Channel" box.

NOTE: Always verify the wheel and tire balance before removing any wheel weights. If

assembly is within specification and weights are not corroded or loose, do not

remove weights. The process of removing and adding weight could damage

wheel protective coating.

Thursday, November 16, 2017 19:57:07 Page 3

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

NOTE: Balance and road force variation equipment must be calibrated and maintained

per equipment manufacturer's specifications.

NOTE: If a tire sealant & inflator kit was used to temporarily repair small punctures

then the tire must be removed from wheel and all the sealant must be removed

with a water damped cloth before repairing & balancing the assembly.

NOTE: Some wheels may not have an outer flange. Apply adhesive weights on

midplane surface to balance.

Fig. 1: Balancing Wheels Using Cone/Collet

Courtesy of CHRYSLER GROUP, LLC

NOTE: Use of the proper collet will prevent potential damage to the Chrome Clad

wheels.

NOTE: Balance equipment could read an incorrect balance result when measuring

Chrome Clad wheels. This is caused by the equipments mounting cone/collet

contacting the cladding or the cone/collet is not balanced. A dual-taper collet (1)

type wheel centering tool is recommended as opposed to a high-taper cone (2)

type wheel centering tool. Always use the manufacturer's recommended

balance equipment.

Dual-taper collet type (1)

High-taper cone type (2)

Possible obstruction (3)

May not seat properly (4)

No obstruction (5)

Thursday, November 16, 2017 19:57:07 Page 4

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

Properly seated (6)

NOTE: If wheel balance equipment is capable of testing tire road force variation and

the tire/wheel assemblies are within specification, place the tires with the

greater road force variation on the rear of the vehicle.

Fig. 2: Dynamic Balancing

Courtesy of CHRYSLER GROUP, LLC

For dynamic balancing (recommended ), the balance equipment is designed to indicate the location and amount

of weight to be applied to both the inner and outer rim flanges (2).

Fig. 3: Static Balancing

Courtesy of CHRYSLER GROUP, LLC

For static balancing (not recommended ), find the location of the heavy spot causing the imbalance (1).

Counter balance the wheel directly opposite the heavy spot. Determine weight required to counterbalance the

area of imbalance. Place half of this weight on the inner rim flange and the other half on the outer rim flange

Thursday, November 16, 2017 19:57:07 Page 5

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

(3) at the predetermined spots.

Aluminum wheels use a different type wheel weight than steel wheels. Be sure to use the correct wheel weight

for the wheel type.

Always verify the balance. When using off-vehicle equipment, remount the tire and wheel assembly 180

degrees on the balancer spindle and recheck balance. Balance variation from one spot to the other should not be

more than 0.125 (?) ounce. If variation is more than 0.125 ounce, balancing equipment could be malfunctioning,

or the wrong collet/cone may have been used.

If difficult to balance, break down the tire and wheel assembly and check for loose debris inside the tire. Prior to

disassembly, mark (index) the tire at the valve stem. Use this mark in order to remount the tire in its original

orientation with respect to the wheel.

TIRE ROTATION

Tires on the front and rear axles operate at different loads and perform different steering, driving, and braking

functions. For these reasons, the tires wear at unequal rates. They may also develop irregular wear patterns.

These effects can be reduced by rotating the tires according to the maintenance schedule in the Owners Manual.

This will improve tread life, traction and maintain a smooth quiet ride.

Fig. 4: Tire Rotation Pattern - Single Rear Wheel (SRW)

Courtesy of CHRYSLER GROUP, LLC

The recommended method of tire rotation for a single rear wheel vehicle is to cross the front wheels to the rear,

and to move the rear wheels straight forward to the front. Other methods can be used, but may not provide the

same tire longevity benefits.

NOTE: The TPM system uses unique sensors in the inner rear wheels to help identify

them from the outer rear wheels, because of this, the inner and outer wheel

locations can't be switched.

NOTE: After a tire rotation is completed, as followed below, the system can auto learn

the locations of each sensor ID. Auto learning/localization occurs when the

vehicle ignition status is changed from Off to On and speeds of greater than 5

Thursday, November 16, 2017 19:57:07 Page 6

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

mph (8km/h) are obtained and remain over 5mph for at about a 15 minute

period. You may need to drive for 20 minutes to account slower speeds and

stops .

NOTE: If the tires are rotated incorrectly, The Auto localization of the TPM sensors will

fail to locate correctly resulting in incorrect locations for the pressure values

displayed in the Instrument Cluster.

Tires on the front and rear axles operate at different loads and perform different steering, driving, and braking

functions. For these reasons, the tires wear at unequal rates. They may also develop irregular wear patterns.

These effects can be reduced by rotating the tires according to the maintenance schedule in the Owners Manual.

This will improve tread life, traction and maintain a smooth quiet ride.

Fig. 5: Dual Rear Aluminum Wheel Rotation Pattern - 3500

Courtesy of CHRYSLER GROUP, LLC

The recommended method of tire rotation for dual wheel vehicles is to switch the 2 front wheels, switch the

inside left rear with the inside right rear, and to switch the outside right rear with the outside left rear.

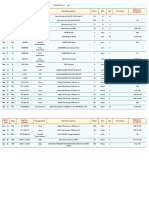

SPECIFICATIONS

SPECIFICATIONS

DESCRIPTION N.m Ft. Lbs. In. Lbs.

Lug Nut M14 (1500) 183 135 -

Lug Nut M14 (2500, 3500 -

203 150 -

SRW)

Lug Nut M14 with Flat Washer

196 145 -

(3500, 4500, 5500 - DRW)

Spare Tire Winch (1500) 20 15 177

Spare Tire Winch (2500, 3500

52 38 -

Pickup)

SPECIAL TOOLS

SPECIAL TOOLS

Thursday, November 16, 2017 19:57:07 Page 7

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

C-4150A - Press, Ball Joint

(Originally Shipped In Kit Number(s)

6672, 6745.)

TIRES

DESCRIPTION

TIRES

Tires are designed and engineered for each specific vehicle. They provide the best overall performance for

normal operation. The ride and handling characteristics match the vehicle's requirements. With proper care they

will give excellent reliability, traction, skid resistance, and tread life.

Driving habits have more effect on tire life than any other factor. Careful drivers will obtain in most cases,

much greater mileage than severe use or careless drivers. A few of the driving habits which will shorten the life

of any tire are:

Rapid acceleration

Severe brake applications

High speed driving

Excessive speeds on turns

Striking curbs and other obstacles

Radial-ply tires are more prone to irregular tread wear. It is important to follow the tire rotation interval. Refer

to STANDARD PROCEDURE. This will help to achieve a greater tread life.

TIRE IDENTIFICATION

Thursday, November 16, 2017 19:57:07 Page 8

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

Fig. 6: Identifying Tire Identification Information

Courtesy of CHRYSLER GROUP, LLC

Tire type, size, aspect ratio and speed rating are encoded in the letters and numbers imprinted on the side wall of

the tire. Refer to Fig. 6 to decipher the tire identification code.

Performance tires have a speed rating letter after the aspect ratio number. The speed rating is not always printed

on the tire sidewall. These ratings are:

Q up to 99 mph

S up to 112 mph

T up to 118 mph

U up to 124 mph

H up to 130 mph

V up to 149 mph

W (consult the tire manufacturer for the specific speed rating)

Z more than 149 mph (consult the tire manufacturer for the specific speed rating)

An All Season type tire will have either M + S, M AND S or M-S (indicating mud and snow traction)

imprinted on the side wall.

TIRE CHAINS

Tire snow chains may be used on certain models. Refer to the Owner's Manual for more information.

SPARE / TEMPORARY TIRE

The temporary spare tire is designed for emergency use only. The original tire should be repaired or replaced at

the first opportunity, then reinstalled. Do not exceed speeds of 80 KMH (50 MPH) when using the temporary

spare tire. Refer to Owner's Manual for complete details.

Thursday, November 16, 2017 19:57:07 Page 9

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

SPARE / FULL SIZE WITH MATCHING TIRE

The spare is a full usage wheel with a matching tire, It can be used within the (posted legal) speed limits or

distance limitations as of the rest of the vehicles four tires. Refer to Owner's Manual for complete details.

RADIAL - PLY TIRES

Radial-ply tires improve handling, tread life and ride quality, and decrease rolling resistance.

Radial-ply tires must always be used in sets of four. Under no circumstances should they be used on the front

only. They may be mixed with temporary spare tires when necessary. A maximum speed of 80 KMH (50 MPH)

is recommended while a temporary spare is in use.

Radial-ply tires have the same load-carrying capacity as other types of tires of the same size. They also use the

same recommended inflation pressures.

The use of oversized tires, either in the front or rear of the vehicle, can cause vehicle drive train failure. This

could also cause inaccurate wheel speed signals when the vehicle is equipped with Anti-Lock Brakes.

The use of tires from different manufactures on the same vehicle is NOT recommended. The proper tire

pressure should be maintained on all four tires.

REPLACEMENT TIRES

The original equipment tires provide a proper balance of many characteristics such as:

Ride

Noise

Handling

Durability

Tread life

Traction

Rolling resistance

Speed capability

It is recommended that tires equivalent to the original equipment tires be used when replacement is needed.

Failure to use equivalent replacement tires may adversely affect the safety and handling of the vehicle.

The use of oversize tires may cause interference with vehicle components. Under extremes of suspension and

steering travel, interference with vehicle components may cause tire damage.

WARNING: Failure to equip the vehicle with tires having adequate speed capability

can result in sudden tire failure.

Thursday, November 16, 2017 19:57:07 Page 10

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

TIRE INFLATION PRESSURES

Fig. 7: Under Inflation

Courtesy of CHRYSLER GROUP, LLC

WARNING: Over or under inflated tires can affect vehicle handling and tread wear.

This may cause the tire to fail suddenly, resulting in loss of vehicle

control.

Under inflation will cause rapid shoulder wear (1), tire flexing, and possible tire failure.

Fig. 8: Identifying Over Inflated Tire

Courtesy of CHRYSLER GROUP, LLC

Over inflation will cause rapid center wear (1) reduction in the tire's ability to cushion shocks.

Improper inflation can cause:

Uneven wear patterns

Thursday, November 16, 2017 19:57:07 Page 11

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

Reduced tread life

Reduced fuel economy

Unsatisfactory ride

Vehicle drift

For proper tire pressure specification, refer to the tire label placard usually located on the drivers door latch

pillar.

DIAGNOSIS AND TESTING

PRESSURE GAUGES

A quality air pressure gauge is recommended to check tire pressure. After checking the air pressure, replace

valve cap finger tight.

TIRE NOISE OR VIBRATION

Radial-ply tires are sensitive to force impulses caused by improper mounting, vibration, wheel defects, or

possibly tire imbalance.

To find out if tires are causing the noise or vibration, drive the vehicle over a smooth road at varying speeds.

Note the noise level during acceleration and deceleration. The engine, differential and exhaust noises will

change as speed varies, while the tire noise will usually remain constant.

TREAD WEAR INDICATORS

Fig. 9: Identifying Tread Wear Indicators

Courtesy of CHRYSLER GROUP, LLC

Tread wear indicators (3) are molded into the bottom of the tread grooves. When tread depth is 1.6 mm (1/16

in.), the tread wear indicators (3) will appear as a 13 mm (1/2 in.) band.

Thursday, November 16, 2017 19:57:07 Page 12

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

Tire replacement is necessary when indicators appear in two or more grooves or if localized balding occurs.

TIRE WEAR PATTERNS

Fig. 10: Identifying Tire Wear Patterns

Courtesy of CHRYSLER GROUP, LLC

Under inflation will cause wear on the shoulders of tire. Over inflation will cause wear at the center of tire.

Excessive camber causes the tire to run at an angle to the road. One side of tread is then worn more than the

other.

Excessive toe-in or toe-out causes wear on the tread edges and a feathered effect across the tread.

TIRE/VEHICLE LEAD

Use the following Vehicle Lead Diagnosis And Correction Chart to diagnose and correct a vehicle lead or drift

problem.

Thursday, November 16, 2017 19:57:07 Page 13

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

Fig. 11: Vehicle Lead Diagnosis & Correction Chart

Courtesy of CHRYSLER GROUP, LLC

STANDARD PROCEDURE

STANDARD PROCEDURE - TIRE REPAIR AREA

Thursday, November 16, 2017 19:57:07 Page 14

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

Fig. 12: Identifying Tire Repair Area

Courtesy of CHRYSLER GROUP, LLC

For proper repairing, a radial tire must be removed from the wheel. Repairs should only be made if the defect,

or puncture, is in the tread area (1). The tire should be replaced if the puncture is located in the sidewall.

Deflate tire completely before removing the tire from the wheel. Use lubrication such as a mild soap solution

when dismounting or mounting tire. Use tools free of burrs or sharp edges which could damage the tire or wheel

rim.

Before mounting tire on wheel, make sure all rust is removed from the rim bead and repaint if necessary.

Install wheel on vehicle, and tighten to proper torque specification.

SPECIFICATIONS

TIRE REVOLUTIONS PER MILE

TIRE SIZE REVOLUTIONS PER MILE

P245/70R17 685

LT245/70R17 675

LT265/70R17 657

LT245/70R17 684

LT265/70R17 658

LT285/70R17 632

P265/70R17 657

P265/70R17 661

LT275/70R17 649

LT275/70R17 649

P275/55R20 655

P275/60R20 636

Thursday, November 16, 2017 19:57:07 Page 15

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

P235/85R17 636

LT235/80R17 649

LT235/80R17 649

LT235/80R17 649

LT235/80R17 648

WINCH, SPARE TIRE CARRIER

REMOVAL

REMOVAL

Fig. 13: Spare Tire Carrier Winch

Courtesy of CHRYSLER GROUP, LLC

NOTE: "Do NOT use impact tools on the Spare Tire Winch assembly to raise or lower

the Spare Tire".

1. Remove the spare tire.

2. Raise and support the vehicle. Refer to HOISTING, STANDARD PROCEDURE .

3. Remove the spare tire winch bolts (2) and then remove the winch (1).

INSTALLATION

INSTALLATION

Thursday, November 16, 2017 19:57:07 Page 16

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

Fig. 14: Spare Tire Carrier Winch

Courtesy of CHRYSLER GROUP, LLC

1. Position the winch (1) on the crossmember. Install the bolts (2) and tighten to 52 N.m (38 ft. lbs.).

2. Remove the supports and lower the vehicle.

NOTE: "Do NOT use impact tools on the Spare Tire Winch assembly to raise or

lower the Spare Tire".

3. Install the spare tire back into position.

WHEELS

DESCRIPTION

GENERAL INFORMATION

Thursday, November 16, 2017 19:57:07 Page 17

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

Fig. 15: Identifying Wheel/Rim Design

Courtesy of CHRYSLER GROUP, LLC

The rim size is on the vehicle safety certification label located on the drivers door shut face. Original equipment

wheels/rims are designed for operation up to the specified maximum vehicle capacity.

All models use stamped steel, cast aluminum or forged aluminum wheels. Every wheel has raised sections

between the rim flanges (1) and rim drop well (3) called safety humps.

Initial inflation of the tire forces the bead over these raised sections. In case of rapid loss of air pressure, the

raised sections help hold the tire on the wheel.

The wheel studs and nuts are designed for specific applications. All aluminum and some steel wheels have

wheel stud nuts with an enlarged nose. This enlarged nose is necessary to ensure proper retention of the wheels.

Do not use replacement studs or nuts with a different design or lesser quality.

HD - WHEELS

Original equipment wheels are designed for the specified Maximum Vehicle Capacity.

All models use steel or aluminum drop center wheels.

Aluminum wheels require special balance weights and alignment equipment.

Thursday, November 16, 2017 19:57:07 Page 18

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

Fig. 16: Flat Face Wheel

Courtesy of CHRYSLER GROUP, LLC

1 - FLAT FACE

2 - VALVE STEM

1. On vehicles equipped with dual rear wheels, the rim is an eight stud hole pattern wheel. The wheels have

a flat mounting surface (1).

Fig. 17: Dual Rear Wheels

Courtesy of CHRYSLER GROUP, LLC

1 - WINDOW OPENINGS (5)

2 - INBOARD VALVE STEM

3 - OUTBOARD VALVE STEM

2. The slots (1) in the wheel must be aligned to provide access to the valve stem.

Thursday, November 16, 2017 19:57:07 Page 19

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - WHEEL INSPECTION

Inspect wheels for:

Excessive run out

Dents or cracks

Damaged wheel lug nut holes

Air Leaks from any area or surface of the rim

NOTE: Do not attempt to repair a wheel by hammering, heating or welding.

If a wheel is damaged an original equipment replacement wheel should be used. When obtaining replacement

wheels, they should be equivalent in load carrying capacity. The diameter, width, offset, pilot hole and bolt

circle of the wheel should be the same as the original wheel.

WARNING: Failure to use equivalent replacement wheels may adversely affect the

safety and handling of the vehicle. Used wheels are not recommended.

The service history of the wheel may have included severe treatment or

very high mileage. The rim could fail without warning.

WARNING: Chrysler LLC does not recommend that customers use "reconditioned"

wheels (wheels that have been damaged and repaired) because they can

result in a sudden catastrophic wheel failure which could cause loss of

control and result in injury or death.

For Clarification:

Cosmetic refinishing for the purpose of repairing a superficial flaw is

an acceptable procedure providing it is limited to paint or clear coat

only, the wheel is not modified in any way, and there is no exposure

to paint curing heat over 200 degrees Fahrenheit.

Damaged wheels are those which have been bent, broken, cracked

or sustained some other physical damage which may have

compromised the wheel structure

Repaired indicates that the wheel has been modified through

bending, welding, heating, straightening, or material removal to

rectify damage.

Re-plating of chrome plated wheels is not an acceptable procedure

nor is chrome plating of original equipment painted or polished

wheels, as this may alter mechanical properties and affect fatigue

life.

Thursday, November 16, 2017 19:57:07 Page 20

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

STANDARD PROCEDURE

DUAL REAR WHEEL INSTALLATION

Dual rear wheels use a special heavy duty lug nut wrench. It is recommended to remove and install dual rear

wheels only when the proper wrench is available. The wrench is also used to remove wheel center caps. For

more information, refer to Owner's Manual.

The tires on both wheels must be completely raised off the ground when tightening the lug nuts. This will

ensure correct wheel centering and maximum wheel clamping.

Fig. 18: Oil Location

Courtesy of CHRYSLER GROUP, LLC

1 - PLACE TWO DROPS OF OIL HERE

A two piece flat face lug nut with right-hand threads is used for retaining the wheels on the hubs .

The dual rear wheel lug nuts should be tightened according to the following procedure:

NOTE: Do not use more then two drops of oil on the nut/washer (1), since the center

caps attach in this area.

Place two drops of oil to the interface of the nut/washer (1) before installing on the wheel stud.

Tighten the wheel lug nuts in the numbered sequential pattern until they are snug tight. Then tighten lug

nut to specified torque following same number sequence. Refer to SPECIFICATIONS.

Tighten lug nuts in same numbered sequence a second time to the specified torque. This will ensure that

the wheels are thoroughly mated.

Check lug nut specified torque after 100 miles (160 kilometers). Also after 500 miles (800 kilometers) of

vehicle operation.

NOTE: Wheel lug nuts should be tightened to specified torque at every maintenance

Thursday, November 16, 2017 19:57:07 Page 21

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

interval thereafter.

WHEEL REPLACEMENT

The wheel studs and nuts are designed for specific applications. They must be replaced with equivalent parts.

Do not use replacement parts of lesser quality or a substitute design. All aluminum and some steel wheels have

wheel stud nuts which feature an enlarged nose. This enlarged nose is necessary to ensure proper retention of

the aluminum wheels.

Fig. 19: Removing/Installing Wheel (8-Lug Shown)

Courtesy of CHRYSLER GROUP, LLC

1 - CENTER CAP

2 - LUG NUT

3 - TIRE/WHEEL ASSEMBLY

4 - WHEEL STUDS

NOTE: Do not use chrome plated lug nuts with chrome plated wheels.

NOTE: All wheel nuts should then be tightened just snug. Gradually tighten them in

sequence to the proper torque specification.

NOTE: Never use oil or grease on studs or nuts.

Before installing the wheel, be sure to remove any build up of corrosion on the wheel mounting surfaces.

Ensure wheels are installed with good metal-to-metal contact. Improper installation could cause loosening of

wheel nuts . This could affect the safety and handling of your vehicle.

To install the wheel (3), first position it properly on the mounting surface .

Thursday, November 16, 2017 19:57:07 Page 22

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

Fig. 20: 8-Lug Tightening Pattern

Courtesy of CHRYSLER GROUP, LLC

8-lug pattern.

Fig. 21: Installing Wheel

Courtesy of CHRYSLER GROUP, LLC

5-lug pattern.

Thursday, November 16, 2017 19:57:07 Page 23

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

Fig. 22: Typical 6 - Lug Nut Tightening Pattern

Courtesy of CHRYSLER GROUP, LLC

6- bolt pattern.

Wheels must be replaced if they have:

Excessive runout

Bent or dented

Leak air through welds

Have damaged bolt holes

Wheel repairs employing hammering, heating, or welding are not allowed.

Original equipment wheels are available through your dealer. Replacement wheels from any other source

should be equivalent in:

Load carrying capacity

Diameter

Width

Offset

Mounting configuration

Failure to use equivalent replacement wheels may affect the safety and handling of your vehicle. Replacement

with used wheels is not recommended. Their service history may have included severe treatment.

COVER, WHEEL

REMOVAL

REMOVAL

Thursday, November 16, 2017 19:57:07 Page 24

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

NOTE: The hub caps must be removed before raising the vehicle off the ground.

NOTE: You must use the flat end of the hub/cap remover/installer combination tool to

pry off the wheel skins. Insert the flat tip completely and using a back and forth

motion, loosen the wheel skin. Repeat this procedure around the tire until the

wheel skin pops off.

1. On 2500/3500 single rear wheel (SRW) models, insert a hub/cap remover/installer combination tool using

the blade on the end of the tool to pry the cap off in a back and forth motion.

2. On 3500 models with dual rear wheels (DRW), you must first remove the hub caps. The hub/cap

remover/installer combination tool must be inserted in the pry off notch of the rear hub caps.

3. Position the hub/cap remover/installer combination tool and pull out on the tool firmly. The cap should

come off.

NOTE: Failure to use a back and forth motion could damage the wheel skin

chrome finish.

4. The wheel skins can now be removed from the wheel. Use the flat end of the lug nut wrench to pry off the

wheel skins. Make sure that the flat end is inserted and use a back and forth motion to remove the wheel

skin.

5. On 3500 models front hub caps use the hub/cap remover/installer combination tool to pry off the cap in a

back and forth motion. The wheel skins can now be removed.

INSTALLATION

INSTALLATION

FRONT

1. Align the valve stem with the notch in the wheel skin.

2. Seat on side of the wheel skin's wire retainer on to the wheel.

3. Using a rubber mallet, strike the opposite side of the wheel skin until the skin is properly seated.

NOTE: The wheel skin and the hub cap are fully seated when there is a consistent

gap between the skin/ cap and the wheel.

4. Tug on the hub cap/wheel skin to ensure that they are properly installed.

REAR

1. Install one 1 1/2 inch valve stem extension on each rear inner wheel.

NOTE: A 3/8 in. drive 10mm deep wheel socket with a 10 in. or greater extension

can be used to remove the existing valve stem cap and install the

extension.

Thursday, November 16, 2017 19:57:07 Page 25

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

2. Install one 1 in. valve stem extension on each outer wheel.

3. Align the cooling windows of the wheel skin with the cooling windows of the wheel. Seat one side of the

wheel skin's retainer onto the wheel. Using a rubber mallet, strike thew wheel skin on the outer

circumference. Strike at several locations around the circumference until the skin is fully seated.

NOTE: The wheel skin and the hub cap are fully seated when there is a consistent

gap between the skin/cap and the wheel.

4. Tug on the hub/cap wheel skin to ensure that they are properly installed.

STUD, WHEEL

REMOVAL

FRONT

Fig. 23: Removing Stud Using Special Tool

Courtesy of CHRYSLER GROUP, LLC

1. Raise and support the vehicle.

2. Remove the wheel and tire assembly.

3. Remove the brake caliper, caliper adapter and rotor. Refer to ROTOR, BRAKE, REMOVAL .

4. Remove the wheel speed sensor from the hub.

NOTE: After the wheel stud is pressed from the flange, the axle shaft will not turn

past the hub/bearing retaining bolt end. Before pressing the wheel stud

from the flange, rotate the axle shaft so the stud that needs replacement is

aligned with the wheel speed sensor opening.

5. Press the stud from the hub using remover (special tool #C-4150A, Press, Ball Joint) (1).

Thursday, November 16, 2017 19:57:07 Page 26

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

Fig. 24: Locating Stud AT Hub

Courtesy of CHRYSLER GROUP, LLC

6. Remove the stud (2) from the hub (1) through the backing plate access hole (3).

REAR - 1500 ONLY

Fig. 25: C-4150a Positioned For Stud Removal

Courtesy of CHRYSLER GROUP, LLC

CAUTION: Move axle shaft carefully to prevent damage to the shaft bearing and seal

in the axle tube.

1. Pull the axle shaft out of the axle approximately 25mm (1 in.) for clearance to remove the wheel stud.

Refer to the appropriate Service Information .

Thursday, November 16, 2017 19:57:07 Page 27

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

2. Press the stud (1) from the hub using Ball Joint Press (special tool #C-4150A, Press, Ball Joint) (3).

3. Remove the stud (1) from the rear of the hub flange.

REAR

Fig. 26: Removing/Installing Parking Brake Shoes

Courtesy of CHRYSLER GROUP, LLC

1. Raise and support the vehicle. Refer to HOISTING, STANDARD PROCEDURE .

2. Remove the wheel and tire assembly.

3. Remove the brake caliper, caliper adapter and rotor. Refer to ROTOR, BRAKE, REMOVAL .

4. Using appropriate tools, remove the spring (3) at parking brake adjuster (2).

5. Spread the parking brake shoes (1) apart enough to remove the adjuster (may need to back off

adjustment), then remove the adjuster (2).

Thursday, November 16, 2017 19:57:07 Page 28

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

Fig. 27: C-4150a Positioned For Stud Removal

Courtesy of CHRYSLER GROUP, LLC

6. Rotate the axle around until the wheel stud (1) lines up with the opening where the adjuster was removed.

7. Press the stud (1) from the hub using Ball Joint Press (special tool #C-4150A, Press, Ball Joint) (3).

8. Remove the stud (1) from the rear of the hub flange. It may be necessary to work the hub flange back and

forth to ease stud removal.

INSTALLATION

FRONT

Fig. 28: Locating Stud AT Hub

Courtesy of CHRYSLER GROUP, LLC

1. Install the new stud (2) into the hub flange (1).

2. Install three proper sized washers onto the stud, then install lug nut with the flat side of the nut against the

washers.

3. Tighten the lug nut until the stud is pulled into the hub flange. Verify that the stud is properly seated into

the flange.

4. Remove the lug nut and washers.

5. Install the brake rotor, caliper adapter, and caliper. Refer to ROTOR, BRAKE, INSTALLATION .

6. Install the wheel speed sensor.

7. Install the wheel and tire assembly, use new lug nut on the stud or studs that were replaced.

8. Remove the support and lower the vehicle.

REAR - 1500 ONLY

Thursday, November 16, 2017 19:57:07 Page 29

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

Fig. 29: View Of Wheel Mounting Stud Installation

Courtesy of CHRYSLER GROUP, LLC

CAUTION: Move axle shaft carefully to prevent damage to the shaft bearing and seal

in the axle tube.

1. Install the new stud (4) into the back of the hub flange (2) and seat as follows:

a. Install three proper sized washers (1) onto the new stud (4), then install a lug nut (3) with the flat

side of the nut against the washers.

b. Tighten the lug nut (3) until the stud (4) is pulled into the hub flange (2). Verify that the stud is

properly seated into the flange.

c. Remove the lug nut (3) and washers (1).

2. Install the axle shaft, refer to the appropriate Service Information .

3. Using a new lug nut on the new stud, install the wheel and tire assembly. Refer to WHEELS,

STANDARD PROCEDURE.

4. Remove the supports and lower the vehicle.

REAR

Thursday, November 16, 2017 19:57:07 Page 30

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

Fig. 30: View Of Wheel Mounting Stud Installation

Courtesy of CHRYSLER GROUP, LLC

1. Install the new stud (4) into the hub flange (2) at the opening where the adjuster was removed.

2. Install three proper sized washers (1) onto the new stud (4), then install a lug nut (3) with the flat side of

the nut against the washers.

3. Tighten the lug nut (3) until the stud (4) is pulled into the hub flange (2). Verify that the stud is properly

seated into the flange.

4. Remove the lug nut (3) and washers (1).

Fig. 31: Removing/Installing Parking Brake Shoes

Courtesy of CHRYSLER GROUP, LLC

5. Install the parking brake adjuster (2) between the parking brake shoes (1) with the adjuster star wheel near

the adjustment window in the brake shield.

Thursday, November 16, 2017 19:57:07 Page 31

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

6. Using appropriate tools, install the spring (3) at the adjuster (2).

7. Adjust parking brake shoes as necessary. Refer to SHOES, PARKING BRAKE, ADJUSTMENTS .

8. Install the brake rotor, caliper adapter and caliper. Refer to ROTOR, BRAKE, INSTALLATION .

9. Using a new lug nut on the new stud, install the wheel and tire assembly. Refer to WHEELS,

STANDARD PROCEDURE.

10. Remove the supports and lower the vehicle.

TIRE PRESSURE MONITORING

DESCRIPTION

DESCRIPTION

The Tire Pressure Monitoring (TPM) system monitors air pressure in the four road tires (excludes spare).

Pressure in the spare tire is monitored in case of a matching spare with sensor. Sensor transmissions occur if

there is significant change in pressure. RFHM has to be awake when sensor transmits to monitor spare pressure.

NOTE: Vehicles over 10, 000 lbs GVWR will not have a warning lamp.

The TPM system consists of tire pressure monitoring sensors attached to each road wheel through the valve

stem mounting hole, an electronic display, and an indicator lamp. The system communicates through the RF

Hub Module.

The receiver circuit for the TPM system is integrated into the RF Hub. The RF Hub decodes the RF signals

transmitted by each of the vehicle's tire pressure sensors. The decoded information is used to determine if

"warning" or "fault" conditions exist within the TPM system.

Upon detection of a warning or fault condition, the RF Hub will send a request to the module that controls the

indicator lamp and the text display via the vehicle bus system to illuminate or flash the indicator lamp. Also,

upon detection of a warning or fault condition, the electronic display will send a request to sound the "chime".

The RF Hub will store all warning and fault conditions, placard pressure values and low-pressure threshold

values (lamp ON and OFF) in memory that can be accessed through diagnostic communication. If new sensors

are introduced to the vehicle, the data stored for the sensor being replaced will be deleted.

The RF Hub will store all wheel sensor IDs and locations and faults in memory that can be accessed through

diagnostic communication. All other data values transmitted from each active wheel sensor shall be stored in

the RF Hub memory.

The RF Hub automatically learns and stores the sensor IDs while driving "within 20 minutes continuously

above 20 mph (32 km/h)" after a sensor has been replaced. The learning sequence will initiate when the vehicle

has been stopped for more than 20 minutes.

NOTE: A new sensor ID can also be programmed directly into the RF Hub by using a

RKE-TPM Analyzer in conjunction with a Scan Tool. Once the new sensor ID

Thursday, November 16, 2017 19:57:07 Page 32

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

has been programmed, the RKE-TPM Analyzer can be used to update the TPMS

by activating the sensor.

OPERATION

OPERATION

TIRE PRESSURE MONITORING

The tire pressure monitoring system (TPMS) is designed to operate without loss of function for all OEM tire

construction for this vehicle. Sensors, mounted to each road wheel as part of the valve stem, transmit an RF

signal indicating their individual pressure to a receiver located in the Radio Frequency (RF) Hub. Refer to

SENSOR, TIRE PRESSURE MONITORING (TPM), OPERATION.

If the TPM system detects that the tire pressure in any road tire is low, beyond the Low Pressure (lamp) ON

threshold (see placard table below), the TPM system will continuously illuminate an indicator lamp. If a system

fault is detected, the indicator lamp will flash on/off for 75 seconds, then remain on solid.

If the RF Hub detects a warning or fault condition at ignition key "on", the display module will request a chime

once per ignition cycle for the first "warning" or "fault" condition detected. A "warning" or "fault" condition

will remain enabled until the problem causing the condition is corrected and removed/reset.

The RF Hub shall continuously monitor for the receipt of tire pressure RF message transmissions from the

wheel sensors during both the ignition key "on" and key "off" cycles. The wheel sensor ID's and the location of

each sensor (e.g. Tire 1, Tire 2 etc.) are stored in the RF Hub non-volatile memory during the initial

Manufacturing Plant Process, or during a service procedure, as required.

The TPM System will continue to warn the driver of low tire pressure as long as the condition exists, and will

not turn off the indicator lamp until the tire pressure is at or above the placard. The system will automatically

update and the TPM indicator lamp will extinguish once the updated tire pressures have been received.

Tire pressure will vary with temperature by about 1 psi (6.9 kPa) for every 12°F (6.5°C). This means that when

the outside temperature decreases, the tire pressure will decrease. Tire pressure should always be set based on

cold inflation tire pressure (placard pressure). This is defined as the tire pressure after a vehicle has not been

driven for more than 3 hours (and in outside ambient temperature). The tire pressure will also increase as the

vehicle is driven; this is normal and there should be no adjustment for this increased pressure. For a system

fault, the system will return to normal once the RF Hub receives a valid transmission from that sensor location.

TPM THRESHOLD PRESSURES

The recommended "Placard Pressure" for the tires installed on the vehicle, are stored in the RF Hub non-volatile

memory during the initial Manufacturing Plant Process, or during a service procedure, as required. To

determine the pressure thresholds for a vehicle, refer to the Tire Inflation Pressure (Placard) Label, and then

apply the placard pressure to the following table.

For further information, refer to the Owners Manual or the Appropriate Diagnostic Information.

Thursday, November 16, 2017 19:57:07 Page 33

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

Placard Pressure (Cold) (PSI) Low Pressure ON Threshold (PSI)

28 22

29 23

30 24

31 25

32 25

33 26

34 27

35 28

36 29

37 29

38 30

39 31

40 32

41 33

42 34

43 35

44 36

45 36

46 37

47 38

48 38

49 39

50 40

51 41

55 44

60 48

65 52

70 56

75 60

80 64

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - TIRE PRESSURE MONITORING

NOTE: A false low pressure warning can take place if the Tire Pressure Monitoring

system fails localization. This will result in the system defaulting to the value of

80 psi for all TPM sensor locations. Perform the TPM Diagnostic Verification

Test standard procedure to correct for this condition.

When diagnosing a tire pressure issue, first check the Tire Pressure Monitoring (TPM) indicator lamp in the

Thursday, November 16, 2017 19:57:07 Page 34

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

instrument cluster during ignition key ON. From the OFF position, turn the key to ON and check the TPM

indicator lamp to observe one of the following:

If after 10 seconds the indicator lamp is illuminating continuously (not flashing), refer to LOW

PRESSURE .

If after 10 seconds the indicator lamp flashes on/off for 75 seconds, then remains on solid, there is a

system fault detected. Refer to SYSTEM FAULT .

LOW PRESSURE

NOTE: Tire pressure may increase from 2 to 6 psi (14 to 41 kPa) during normal driving

conditions. Do NOT reduce this normal pressure build up.

NOTE: Tire pressure will vary with temperature by about 1 psi (6.9 kPa) for every 12°F

(6.5°C). This means that when the outside temperature decreases, the tire

pressure will also decrease. Tire pressure should always be set based on cold

inflation tire pressure. For details, refer to TIRES, DESCRIPTION.

Check air pressure as necessary in all tires using a known accurate air gauge and adjust to the specification

listed on the Tire Inflation Pressure Label (Placard) provided with the vehicle (usually applied to the driver side

B-pillar). After adjusting air pressure in a tire on the vehicle, allow approximately two minutes for the message

or indicator lamp to go out.

If air pressure in any tire is low, inspect all the tires for leaks. A water "dunk tank" or other water test may be

used to check for a leak around the sensor as long as any water at the valve core is removed once the procedure

is completed. The water can be easily expelled from the core area by pushing in on the core for several seconds,

allowing escaping air to drive out any moisture. Reinflate the tire as necessary. Always make sure the original

(special) valve stem cap is securely installed to keep moisture out of the sensor.

If the indicator lamp is still ON continuously, refer to the appropriate diagnostic information.

SYSTEM FAULT

After an ignition key ON, if a system fault is detected, a chime will sound, and the TPM indicator (telltale) lamp

will flash for 75 seconds, then remain on solid. A system fault can occur by many scenarios, including the

following:

Signal interference due to electronic devices or driving next to facilities emitting the same Radio

Frequencies as the TPM sensors.

Installing some form of aftermarket window tinting that affects radio wave signals.

Accumulation of snow or ice around the wheels or wheel housings.

Using tire chains on the vehicle.

Using wheels not equipped with TPM sensors.

If a system fault is detected, refer to DIAGNOSIS AND TESTING .

Thursday, November 16, 2017 19:57:08 Page 35

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

SPECIFICATIONS

SPECIFICATIONS

DESCRIPTION N.m Ft. Lbs. In. Lbs.

Tire Pressure Sensor to Valve 1.4 - 12

Stem Mounting Screw

SENSOR, TIRE PRESSURE MONITORING (TPM)

CAUTION

CAUTION

CAUTION: The Tire Pressure Monitoring (TPM) system has been optimized for the

original equipment tires and wheels. TPM system pressures have been

established for the tire size equipped on the vehicle. Undesirable system

operation or sensor damage may result when using replacement

equipment that is not of the same size, type, or style. Aftermarket wheels

can cause sensor damage. Do not use aftermarket tire sealants or balance

beads if your vehicle is equipped with TPM, as damage to the sensors may

result.

CAUTION: Do not attempt to install a tire pressure sensor in an aftermarket wheel.

Use tire pressure sensors in original style factory wheels only. If

aftermarket wheels are installed, and therefore do not contain tire pressure

sensors, the system will not function properly and the driver will be

continuously notified of a system malfunction.

CAUTION: After inspecting or adjusting the tire pressure always reinstall the valve

stem cap. This will prevent moisture and dirt from entering the valve stem,

which could damage the Tire Pressure Sensor.

CAUTION: Tire pressure sensor valve stem caps and cores are specially designed for

the sensors. Due to risk of corrosion, do not use a standard valve stem

cap or core in a tire pressure sensor in place of the original equipment

style sensor cap and core.

CAUTION: Any time a sensor is to be installed in a wheel, it is necessary to install a

new sensor-to-wheel seal, metal washer and valve stem nut, to ensure air

tight sealing.

CAUTION: When installing the valve core, be sure to tighten the core to

specifications. Overtightening by a little as three or four inch pounds can

damage the sensor.

Thursday, November 16, 2017 19:57:08 Page 36

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

DESCRIPTION

DESCRIPTION

Fig. 32: Tire Pressure Sensor & Components

Courtesy of CHRYSLER GROUP, LLC

NOTE: Replace the valve stem assembly and tire pressure sensor mounting screw with

each tire change.

NOTE: The tire pressure sensor (1), the valve stem (3), and all valve stem components

including the cap (4) and the valve core can be serviced and replaced

individually.

NOTE: Install a NEW valve stem (3) and valve stem core if they are removed from the

wheel or valve stem.

One tire pressure sensor (1) is mounted to a valve stem (3) specifically designed for mounting the pressure

sensor in each wheel in place of the traditional tire valve stem. Each sensor has an internal battery that lasts up

to 10 years. The battery is not serviceable. At the time of battery failure, the sensor must be replaced. The TPM

system operates on a 433 MHz radio frequency. The tire pressure sensor valve stem looks similar to a standard

valve stem with the tire mounted on the wheel.

NOTE: This vehicle uses the 433 MHz TPM sensor. Although 315 MHz and 433 MHz

sensors are identical in size and shape, they are not interchangeable. Always

make sure the correct sensor is being used. A RKE-TPM Analyzer can be used

to determine the sensor's frequency without having to dismount the tire.

The TPM sensors are designed for original style factory wheels. It is not recommended to install a tire pressure

Thursday, November 16, 2017 19:57:08 Page 37

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

sensor in an aftermarket wheel. (This could cause sealing and system performance issues.)

The valve stem caps and cores used are specifically designed for the tire pressure monitoring sensors. Although

similar to standard valve stem caps and cores, they are different. The valve stem cap has a special seal inside to

keep moisture and corrosion out. The valve stem core has a special nickel coating to protect from corrosion.

Two different types of sensor valve stem are used :

1. Standard rubber snap-in valve stem (3).

Fig. 33: Standard Rubber Snap-In Valve Stem

Courtesy of CHRYSLER GROUP, LLC

2. Screw in valve stem (3) and retaining nut (on aluminum outboard mounted wheels only).

Thursday, November 16, 2017 19:57:08 Page 38

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

Fig. 34: Tire Pressure Sensor & Components

Courtesy of CHRYSLER GROUP, LLC

Fig. 35: Tire Pressure Sensor ID

Courtesy of CHRYSLER GROUP, LLC

The inner dually wheels contain a unique senor that is identified by "ID" (1) marked on the sensor housing. It is

not compatible in other locations and must always be mounted as an inboard wheel. It has a standard rubber

snap-in valve stem.

OPERATION

OPERATION

Thursday, November 16, 2017 19:57:08 Page 39

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

CAUTION: The TPMS has been optimized for the original equipment tires and wheels.

TPMS pressures have been established for the tire size equipped on your

vehicle. Undesirable system operation or sensor damage may result when

using replacement equipment that is not of the same size, type, and/or

style. After-market wheels can cause sensor damage. Do not use

aftermarket tire sealants or balance beads if your vehicle is equipped with

a TPMS, as damage to the sensors may result.

CAUTION: After inspecting or adjusting the tire pressure always reinstall the valve

stem cap. This will prevent moisture and dirt from entering the valve stem,

which could damage the Tire Pressure Monitoring Sensor.

CAUTION: Tire pressure sensor valve stem caps and cores are specially designed for

the sensors. Due to risk of corrosion, do not use a standard valve stem

cap or core in a tire pressure sensor in place of the original equipment

style sensor cap and core.

CAUTION: Any time a sensor is to be reinstalled in a wheel, a new valve stem

assembly must be installed to ensure air tight sealing.

NOTE: TPM thresholds have been established for the original tire size equipped on the

vehicle. Use original size tires only to maintain system accuracy.

The battery operated tire pressure sensor is both a transmitter and a receiver. The TPM sensor can be forced to

transmit if using a special tool such as a TPM-RKE Analyzer. The TPM-RKE Analyzer has the ability to

change the sensor mode and to diagnose a faulty TPM sensor. Using a TPM-RKE Analyzer can take up to a

minute to force a transmission from a sensor.

Each sensor's (transmitter) broadcast is uniquely coded so that the module can monitor the state of each of the

sensors on the four rotating road wheels. The module can automatically learn and store the sensor's ID while

driving "within 20 minutes continuously above 20 m.p.h. (32 Km/h)" after a sensor has been replaced. The

vehicle must be stationary for more then 20 minutes in order to initiate the learning sequence.

The sensor IDs can also be programmed using the TPM-RKE Analyzer Tool. Scan each TPM sensor at each

road wheel, and store each Sensor ID in the correct location. (LEFT FRONT, LEFT REAR, RIGHT FRONT,

and RIGHT REAR) Connect the TPM-RKE Analyzer Tool to the Scan Tool. Then follow the programming

steps outlined in the diagnostic Scan Tool for "Program Tire Pressure Sensor ID w/ TPM Tool".

REMOVAL

STANDARD RUBBER SNAP-IN VALVE STEM

1. Raise and support vehicle. Refer to HOISTING, STANDARD PROCEDURE .

2. Remove tire and wheel assembly.

Thursday, November 16, 2017 19:57:08 Page 40

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

CAUTION: The cap used on this valve stem contains an O-ring seal to prevent

contamination and moisture from entering the valve stem. Do not

substitute a regular valve stem cap in its place.

Fig. 36: Start Mount/Dismount Tool Within 10 Degrees Of Valve Stem

Courtesy of CHRYSLER GROUP, LLC

3. Dismount tire from wheel following tire changer manufacturers instructions while paying special

attention to the following to avoid damaging the pressure sensor:

a. When breaking the tire bead loose from the wheel rim, avoid using the Bead Breaker in the area of

the sensor (1). That includes both outer and inner beads of the tire.

b. When preparing to dismount the tire from the wheel, carefully insert the mounting/dismounting tool

280° from the valve stem ± 10°, then proceed to dismount the tire from the wheel. Use this process

on both outer and inner tire beads.

Thursday, November 16, 2017 19:57:08 Page 41

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

Fig. 37: Tire Pressure Sensor & Components

Courtesy of CHRYSLER GROUP, LLC

4. Remove the sensor to valve stem retainer screw (2) and remove the sensor (1) from the valve stem (3).

NOTE: Replace the valve stem (2) assembly with each tire change.

NOTE: Install a NEW valve stem (2) and valve stem core if they are removed from

the wheel or valve stem.

5. Remove the valve stem (3) from the wheel.

SCREW IN VALVE STEM

1. Raise and support vehicle. Refer to HOISTING, STANDARD PROCEDURE .

2. Remove tire and wheel assembly.

CAUTION: The cap used on this valve stem contains an O-ring seal to prevent

contamination and moisture from entering the valve stem. Do not

substitute a regular valve stem cap in its place.

Thursday, November 16, 2017 19:57:08 Page 42

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

Fig. 38: Start Mount/Dismount Tool Within 10 Degrees Of Valve Stem

Courtesy of CHRYSLER GROUP, LLC

3. Dismount tire from wheel following tire changer manufacturers instructions while paying special

attention to the following to avoid damaging the pressure sensor:

a. When breaking the tire bead loose from the wheel rim, avoid using the Bead Breaker in the area of

the sensor (1). That includes both outer and inner beads of the tire.

b. When preparing to dismount the tire from the wheel, carefully insert the mounting/dismounting tool

280° from the valve stem ± 10°, then proceed to dismount the tire from the wheel. Use this process

on both outer and inner tire beads.

Fig. 39: Standard Rubber Snap-In Valve Stem

Courtesy of CHRYSLER GROUP, LLC

Thursday, November 16, 2017 19:57:08 Page 43

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

4. Remove the sensor to valve stem retainer screw (4) and remove the sensor (5) from the valve stem (2).

NOTE: Replace the valve stem (2) assembly with each tire change.

NOTE: Install a NEW valve stem (2) and valve stem core if they are removed from

the wheel or valve stem.

5. Remove the valve stem (2) from the wheel by removing the retaining nut.

INSTALLATION

STANDARD RUBBER SNAP-IN VALVE STEM

NOTE: If replacing tire pressure sensor, a new valve stem will be pre-mounted to the

sensor as an assembly. Verify that the sensor is positioned properly before

seating the valve stem. If replacing a valve stem only (using the existing tire

pressure sensor), the new valve stem will include a new tire pressure sensor

mounting screw. Always use a new mounting screw when attaching a sensor to

a valve stem.

Fig. 40: Tire Pressure Sensor & Components

Courtesy of CHRYSLER GROUP, LLC

CAUTION: Any time a sensor is to be reinstalled in a wheel, a new valve stem

assembly must be installed to ensure air tight sealing.

1. Wipe area clean around sensor/valve stem mounting hole in wheel. Make sure surface of wheel is not

damaged.

Thursday, November 16, 2017 19:57:08 Page 44

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

NOTE: When installing a new valve stem, tire bead lubricant should be used for

proper installation.

NOTE: If replacing tire pressure sensor, a new valve stem will be pre-mounted to

the sensor as an assembly. Verify that the sensor is positioned properly

before seating the valve stem.

2. Insert valve stem (3) through wheel and pull through to seat with standard valve stem installation tool.

3. If replacing the valve stem (3) only (using the existing tire pressure sensor), verify that the flat sides of

the brass extension on the bottom of the valve stem (5) are at a 90 degree angle with the wheel. Position

the pressure sensor (1) over the brass extension (5), install a New retainer screw (2) and tighten to 1.4

N.m (12 in. lbs.).

4. Mount tire on wheel following tire changer manufacturers instructions, paying special attention to the

following to avoid damaging tire pressure sensor:

Fig. 41: Mounting Tire Using Rotating Wheel Machine

Courtesy of CHRYSLER GROUP, LLC

a. Rotating Wheel Tire Changers - Once the wheel is mounted to the changer, position the sensor

valve stem (2) approximately 280° from the head of the changer (located at 1) in a clockwise

direction before rotating the wheel (also in a clockwise direction) to mount the tire. Use this

procedure on both the outer and inner tire beads.

Thursday, November 16, 2017 19:57:08 Page 45

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

Fig. 42: Mounting Tire Using Rotating Tool Machine

Courtesy of CHRYSLER GROUP, LLC

b. Rotating Tool Tire Changers - Position the wheel on the changer so that the sensor valve stem (1) is

located approximately 210° clockwise from the installation end of the mounting/dismounting tool

(2) once the tool is mounted for tire installation. Make sure the sensor is clear of the lower bead

breaker area (3) to avoid damaging the sensor when the breaker rises. Rotate the tool (2) in a

counterclockwise direction to mount the tire. Use this procedure on both the outer and inner tire

beads.

c. Adjust air pressure to that listed on Tire Inflation Pressure Label (Placard) provided with vehicle

(usually applied to driver's side B-pillar). Make sure original style valve stem cap is securely

installed to keep moisture out of sensor.

d. Install tire and wheel assembly on the vehicle.

e. Remove the support and lower the vehicle.

f. Perform one of the following to make the system learn the new sensor ID.

g. Use the TPM-RKE Analyzer, 9936, with the Scan Tool to program the RF Hub module with the

tire pressure sensor ID. This is part of the TPM Diagnostic Verification Test. Refer to

STANDARD PROCEDURE .

h. Once the vehicle has remained stationary for more than 20 minutes, drive vehicle for a minimum of

20 minutes while maintaining a continuous speed above 20 mph (32 km/h). During this time, the

system will learn the new sensor ID. This is part of the TPM Diagnostic Verification Test. Refer to

STANDARD PROCEDURE .

NOTE: If a sensor cannot be trained, refer to appropriate diagnostic information.

SCREW IN VALVE STEM

Thursday, November 16, 2017 19:57:08 Page 46

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

NOTE: If replacing tire pressure sensor, a new valve stem will be pre-mounted to the

sensor as an assembly. Verify that the sensor is positioned properly before

seating the valve stem. If replacing a valve stem only (using the existing tire

pressure sensor), the new valve stem will include a new tire pressure sensor

mounting screw. Always use a new mounting screw when attaching a sensor to

a valve stem.

Fig. 43: Standard Rubber Snap-In Valve Stem

Courtesy of CHRYSLER GROUP, LLC

CAUTION: Any time a sensor is to be reinstalled in a wheel, a new valve stem

assembly must be installed to ensure air tight sealing.

1. Wipe area clean around sensor/valve stem mounting hole in wheel. Make sure surface of wheel is not

damaged.

2. Insert valve stem (2) through wheel and tighten retaining nut.

3. If replacing the valve stem only (using the existing tire pressure sensor), verify that the flat sides of the

brass extension on the bottom of the valve stem are at a 90 degree angle with the wheel. Position the

pressure sensor over the brass extension, install a New retainer screw (4) and tighten to 1.4 N.m (12 in.

lbs.).

4. Mount tire on wheel following tire changer manufacturers instructions, paying special attention to the

following to avoid damaging tire pressure sensor:

Thursday, November 16, 2017 19:57:08 Page 47

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

Fig. 44: Mounting Tire Using Rotating Wheel Machine

Courtesy of CHRYSLER GROUP, LLC

a. Rotating Wheel Tire Changers - Once the wheel is mounted to the changer, position the sensor

valve stem (2) approximately 280° from the head of the changer (located at 1) in a clockwise

direction before rotating the wheel (also in a clockwise direction) to mount the tire. Use this

procedure on both the outer and inner tire beads.

Fig. 45: Mounting Tire Using Rotating Tool Machine

Courtesy of CHRYSLER GROUP, LLC

b. Rotating Tool Tire Changers - Position the wheel on the changer so that the sensor valve stem (1) is

Thursday, November 16, 2017 19:57:08 Page 48

2014 RAM 3500 HD Laramie

2014 SUSPENSION Tires & Wheels - Service Information - Ram Pickup

located approximately 210° clockwise from the installation end of the mounting/dismounting tool

(2) once the tool is mounted for tire installation. Make sure the sensor is clear of the lower bead

breaker area (3) to avoid damaging the sensor when the breaker rises. Rotate the tool (2) in a

counterclockwise direction to mount the tire. Use this procedure on both the outer and inner tire

beads.

c. Adjust air pressure to that listed on Tire Inflation Pressure Label (Placard) provided with vehicle

(usually applied to driver's side B-pillar). Make sure original style valve stem cap is securely

installed to keep moisture out of sensor.

d. Install tire and wheel assembly on the vehicle.

e. Remove the support and lower the vehicle.

f. Perform one of the following to make the system learn the new sensor ID.

g. Use the TPM-RKE Analyzer, 9936, with the Scan Tool to program the RF Hub module with the

tire pressure sensor ID. This is part of the TPM Diagnostic Verification Test. Refer to

STANDARD PROCEDURE .

h. Once the vehicle has remained stationary for more than 20 minutes, drive vehicle for a minimum of

20 minutes while maintaining a continuous speed above 20 mph (32 km/h). During this time, the

system will learn the new sensor ID. This is part of the TPM Diagnostic Verification Test. Refer to

STANDARD PROCEDURE .

NOTE: If a sensor cannot be trained, refer to appropriate diagnostic information.

Thursday, November 16, 2017 19:57:08 Page 49

You might also like

- REMINDER INDICATOR RESET PROCEDURES Chrysler Dodge Plymouth RAM - 1978-14 PDFDocument22 pagesREMINDER INDICATOR RESET PROCEDURES Chrysler Dodge Plymouth RAM - 1978-14 PDFcharlesNo ratings yet

- TRANSFER CASE BW44-47 - Service Information - Ram Pickup PDFDocument60 pagesTRANSFER CASE BW44-47 - Service Information - Ram Pickup PDFcharles100% (1)

- System Wiring Diagrams Ram - 3500 HD 1 of 2Document167 pagesSystem Wiring Diagrams Ram - 3500 HD 1 of 2charlesNo ratings yet

- HVAC Heating & Air Conditioning - Electrical Diagnostics - Ram Pickup PDFDocument213 pagesHVAC Heating & Air Conditioning - Electrical Diagnostics - Ram Pickup PDFcharlesNo ratings yet

- ENGINE 6.7L Diesel - Service Information - Ram Pickup PDFDocument317 pagesENGINE 6.7L Diesel - Service Information - Ram Pickup PDFcharles100% (2)

- Land Rover LR3 Shop Manual Maintenance SchedulesDocument13 pagesLand Rover LR3 Shop Manual Maintenance Schedulesbmgeisler0% (1)

- SYSTEM WIRING DIAGRAMS RAM - 3500 HD 2 of 2 PDFDocument97 pagesSYSTEM WIRING DIAGRAMS RAM - 3500 HD 2 of 2 PDFcharlesNo ratings yet

- TRANSFER CASE BW44-46 - Service Information - Ram Pickup PDFDocument42 pagesTRANSFER CASE BW44-46 - Service Information - Ram Pickup PDFcharles100% (1)

- GENERAL INFORMATION Circuit Testing Procedures - Non-DTC-Based Diagnostics - Ram Pickup PDFDocument51 pagesGENERAL INFORMATION Circuit Testing Procedures - Non-DTC-Based Diagnostics - Ram Pickup PDFcharlesNo ratings yet

- Popular Electricity - 1909 - 07Document132 pagesPopular Electricity - 1909 - 07sezaroNo ratings yet

- ENGINE 6.4L - Service Information - Ram Pickup PDFDocument294 pagesENGINE 6.4L - Service Information - Ram Pickup PDFcharlesNo ratings yet

- MANUAL TRANSMISSION G56 - Service Information - Ram Pickup PDFDocument101 pagesMANUAL TRANSMISSION G56 - Service Information - Ram Pickup PDFcharlesNo ratings yet

- ENGINE Starting - Service Information - Ram Pickup PDFDocument27 pagesENGINE Starting - Service Information - Ram Pickup PDFcharlesNo ratings yet

- Frenos de Tambor Sierra GMC 2010Document53 pagesFrenos de Tambor Sierra GMC 2010josecuellar69No ratings yet

- Accuride Wheels Rim Wheel Safety and Service Manual ACC7 0002 Rev 4-06-22 12Document68 pagesAccuride Wheels Rim Wheel Safety and Service Manual ACC7 0002 Rev 4-06-22 12Hugo RodriguezNo ratings yet

- The Unofficial DSA Learner Driver, Practical Driving Lesson and Driving Test Syllabus: You WILL Pass!From EverandThe Unofficial DSA Learner Driver, Practical Driving Lesson and Driving Test Syllabus: You WILL Pass!Rating: 4.5 out of 5 stars4.5/5 (2)

- Tire Maintenance, Safety and Warranty Manual: Associated BrandsDocument48 pagesTire Maintenance, Safety and Warranty Manual: Associated BrandsjorgegachaNo ratings yet

- Electronic Circuit Laboratory MANUAL PDFDocument94 pagesElectronic Circuit Laboratory MANUAL PDFAbel KalavadakkenNo ratings yet

- Brake System DesignDocument10 pagesBrake System DesignAsif KhanNo ratings yet

- ENGINE Fuel System - Ram Pickup PDFDocument391 pagesENGINE Fuel System - Ram Pickup PDFcharlesNo ratings yet

- GENERAL INFORMATION Vehicle Data - Ram Pickup PDFDocument14 pagesGENERAL INFORMATION Vehicle Data - Ram Pickup PDFcharlesNo ratings yet

- Azure Transit Vnet Deployment GuideDocument178 pagesAzure Transit Vnet Deployment GuidecharlesNo ratings yet

- Vehicle Dynamics and Damping: First Revised EditionFrom EverandVehicle Dynamics and Damping: First Revised EditionRating: 4 out of 5 stars4/5 (2)

- Breakdowns and Incidents: DVSA Safe Driving for Life SeriesFrom EverandBreakdowns and Incidents: DVSA Safe Driving for Life SeriesNo ratings yet

- Guide To Tyre Management On Heavy VehiclesDocument16 pagesGuide To Tyre Management On Heavy VehicleskabarridakuNo ratings yet

- Ralliart Japan's Suspension Tuning GuideDocument3 pagesRalliart Japan's Suspension Tuning GuidePedro CarvalhoNo ratings yet

- PDF Operators, With Code Specific For Level 3Document21 pagesPDF Operators, With Code Specific For Level 3toyota952No ratings yet

- SUSPENSION Front Air Suspension Control Module (ASCM) - Electrical Diagnostics - Ram Pickup PDFDocument236 pagesSUSPENSION Front Air Suspension Control Module (ASCM) - Electrical Diagnostics - Ram Pickup PDFcharles100% (1)

- Goodyear Ackerman Steering Effect On Tyre WearDocument7 pagesGoodyear Ackerman Steering Effect On Tyre WearpvekzNo ratings yet

- Samsung UE49NU7172U Chassis UWX80Document104 pagesSamsung UE49NU7172U Chassis UWX80Pravin MevadaNo ratings yet

- BFGoodrich Truck Tires Data BookDocument20 pagesBFGoodrich Truck Tires Data Bookluis eduardo corzo enriquezNo ratings yet

- Brake System Design PDFDocument10 pagesBrake System Design PDFaciddropsNo ratings yet

- TRANSFER CASE Final Drive Control Module (FDCM) - Electrical Diagnostics - Ram Pickup PDFDocument139 pagesTRANSFER CASE Final Drive Control Module (FDCM) - Electrical Diagnostics - Ram Pickup PDFcharlesNo ratings yet

- Steering Diagnostics Service Manual: TRW AutomotiveDocument52 pagesSteering Diagnostics Service Manual: TRW Automotivecristian picadoNo ratings yet

- 2012 RAM - Tires & WheelsDocument51 pages2012 RAM - Tires & WheelsHenry SilvaNo ratings yet

- 204-04A Wheels and Tires - General Procedures - Wheel To Tire Runout MinimizationDocument4 pages204-04A Wheels and Tires - General Procedures - Wheel To Tire Runout MinimizationCARLOS LIMADANo ratings yet

- Brake Noise, Judder and Dragging Diagnosis and ServicingDocument4 pagesBrake Noise, Judder and Dragging Diagnosis and ServicingbeyondteckNo ratings yet

- Frenos de TamborDocument46 pagesFrenos de Tamborjosecuellar69No ratings yet

- Tire Management GuidelinesDocument23 pagesTire Management Guidelinesjosuedelios88No ratings yet

- Description & Operation: WarningDocument44 pagesDescription & Operation: WarningIngenieria MultifuncionalNo ratings yet

- 204-04A - Wheels and TiresDocument21 pages204-04A - Wheels and TiresSofia AltuzarraNo ratings yet

- 206-00 Brake System General - General Procedures - Brake Disc MachiningDocument4 pages206-00 Brake System General - General Procedures - Brake Disc MachiningCARLOS LIMADANo ratings yet

- Subject: Wheel Alignment Specifications, Requirements and Recommendations For GM VehiclesDocument10 pagesSubject: Wheel Alignment Specifications, Requirements and Recommendations For GM VehiclesAnonymous 3aPuAai0% (1)