Professional Documents

Culture Documents

Instructions Carb Type 7L

Uploaded by

Edgar Alexander Grisales VallejoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Instructions Carb Type 7L

Uploaded by

Edgar Alexander Grisales VallejoCopyright:

Available Formats

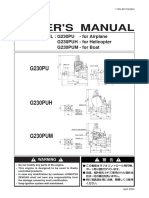

OPERATING INSTRUCTIONS FOR THE O.S.

TYPE 7L CARBURETTOR

The O.S. Type 7L carburettor has been designed to provide a correctly balanced mixture of fuel and air at all

throttle settings. It ensures steady revolutions and a smooth response even to abrupt operation of the

throttle.

Three adjustable controls are provided on the Type 7L

carburettor. (See photo below.)

• The Needle-Valve: For adjusting the mixture strength

when the throttle is fully open.

• The Mixture Control Screw: For adjusting the mixture

strength at part-throttle and idling speeds, to obtain

steady idling and smooth acceleration to medium speeds.

• The Throttle Stop Screw: For establishing the minimum

idling speed.

PROVISIONAL SETTING

The use of a muffler-pressurized fuel system is recom-

mended. Open the Needle-Valve three turns from the fully

closed position before starting the engine.

ADJUSTING THE CARBURETTOR

1) Set the throttle very slightly open from the idle position

(See Fig. 1) and start the engine in the usual way. It is

1.5~2.0mm preferable to have the throttle only slightly open, to avoid

unnecessarily high revolutions when the engine starts.

2) Now open the throttle fully and gradually close the

Needle-Valve until the engine is running at its maximum

speed.*

•Warnings:

Fig1

(a) Do not close the Needle-Valve to too "lean" a setting,

as this will cause overheating which may result in

internal damage and reduced engine life. Set the

Needle-Valve approximately 1/4 to 1/2 turn open (i.e.

"rich") from the peak r.p.m. setting, even though this

will slightly reduce r.p.m. on the ground.

(b)Make sure that the engine is fully "run-in" before

operating it continuously at full power.

(See engine instruction leaflet.)

3) Having set the Needle-Valve as described above, close the

throttle. The engine should idle steadily and continuous-

ly. (If it stops immediately, first try turning the Throttle

Stop Screw clockwise a few degrees to raise the idling

speed a little.)

(a) If, however, the engine idles unevenly and smokes a

good deal when the throttle is re-opened, before pick-

ing up speed, it is probable that the idling mixture is

too rich. In this case it will be necessary to turn the

Mixture Control Screw clockwise about 10 to 15

degrees.

(b)Alternatively, if the Mixture Control Screw is set too

lean, the engine may stop when the throttle is closed,

or it may idle for a few moments, then speed up very

slightly before coming to a stop. Re-opening the

throttle under these conditions will usually result in

the engine cutting out abruptly, without smoking.

Idle Mixture Throttle Lever Corrective action is to turn the Mixture Control

Control Screw Screw about 10 to 15 degrees counter-clockwise.

Mixture Control Screw adjustment is not unduly critical,

Mixture Control Valve but do not turn it more than 10—15 degrees at a time.

Throttle Stop Screw Carry out readjustments progressively and patiently,

remembering the symptoms of rich and lean running,

quoted above, until the engine responds quickly and

Mixture Control Valve

Stopper Plug Screw positively to the throttle.

4) The Throttle Stop Screw is fixing the minimum idling

speed. If, after carrying out mixture adjustments, the

Needle Valve Fuel Inlet

idling speed is found to be too high, the Throttle Stop

Screw should be turned counter-clockwise until the

desired idling speed is obtained.

Note: Once the correct carburettor settings have been esta-

blished, it should be unnecessary to alter them. Such

slight needle-valve readjustments as may be required

to compensate for variations in atmospheric condi-

tions will not normally affect the other two controls.

Slight readjustments may be necessary for optimum

performance if different types of fuel, glowplugs or

propellers are used.

CARBURETTOR CLEANLINESS

The correct functioning of the carburettor depends on its

small fuel orifices remaining clear. The minute particles of

foreign matter that are present in any fuel can easily partial-

ly obstruct these orifices and upset mixture strength so that

engine performance becomes erratic and unreliable.

It is recommended that fuel is passed through a filter when

the tank is filled and that a good in-line filter is installed

between the fuel tank and carburettor and, furthermore,

that this filter is frequently cleaned to remove dirt and lint

that accumulates on the filter screen. Finally, occasionally

remove the needle-valve holder from the carburettor and

extract any remaining foreign matter that may have lodged

inside the carburettor.

PARTS LIST

Code No. Description

27781400 Throttle Lever Assembly (with screw & lock washer)

27781200 Carburettor Rotor

27181600 Throttle Stop Screw Assembly

27181620 Throttle Stop Screw

27181610 Throttle Stop Screw Holder Ass'y

27481220 Rotor Guide Screw (with washer)

27781100 Carburettor Body

29015019 Carburettor Rubber Gasket

27781300 Mixture Control Valve Assembly

21281800 "0"Ring(L)

24881824 "0"Ring(S)

22081304 Plug Screw (with washer)

22681953 Fuel Inlet (with washer)

27381330 Mixture Control Screw (with spring)

27681340 Mixture Control Valve Stopper

27481900 Needle Valve Assembly

27381940 Needle Valve Holder Assembly

26711305 Ratchet Spring

45581970 Needle (with "0" ring & set-screw)

24981837 "0" Ring

26381501 Set-screw

The specifications are subject to alteration for improvement without notice

6-15 3-chome Imagawa Higashisumiyoshiku

Osaka 546. Japan. TEL. Osaka (06) 702-0225

Copyright 1987 by O.S. Engines Mfg. Co., Ltd. All rights reserved Printed in Japan

You might also like

- 7B5B4BK4D4E26781008manual 2077287029Document2 pages7B5B4BK4D4E26781008manual 2077287029FedePereiroBeyerNo ratings yet

- Edelbrock Jetting Tunning QuiksilverDocument8 pagesEdelbrock Jetting Tunning QuiksilverivanchoNo ratings yet

- Adjust carburetor settings and check float levelDocument4 pagesAdjust carburetor settings and check float levelelnyniosNo ratings yet

- 91sr S PDFDocument2 pages91sr S PDFricardoNo ratings yet

- Owner's Manual for G230PU Engine ModelsDocument4 pagesOwner's Manual for G230PU Engine Models6KILLER100% (1)

- 2BK Carb-ManualDocument2 pages2BK Carb-Manualfildan211No ratings yet

- Pratt & Whitney R-1340 Engine Operating SupplementDocument7 pagesPratt & Whitney R-1340 Engine Operating Supplementarizonaflyer1_732976100% (1)

- RP 43827Document2 pagesRP 43827Edgar Alexander Grisales VallejoNo ratings yet

- ZENO2012 AAaa G620PU, G620PU-1Document8 pagesZENO2012 AAaa G620PU, G620PU-1Martin Leonardo Arias PazNo ratings yet

- IDA Low Speed CalibrationDocument3 pagesIDA Low Speed Calibrationirony2No ratings yet

- Zenoah 3366 G620PUDocument8 pagesZenoah 3366 G620PUMuhammad Indra RespatiNo ratings yet

- Carburetor Setup and Best Idle (Ajustar Carburador)Document2 pagesCarburetor Setup and Best Idle (Ajustar Carburador)Lex RadilloNo ratings yet

- SUN Dwell / TachDocument8 pagesSUN Dwell / TachWongstorn DamrongmaneeNo ratings yet

- Wolseley Merry Tiller ManualDocument10 pagesWolseley Merry Tiller ManualcancuniaNo ratings yet

- 510-0245 Carb TuningDocument2 pages510-0245 Carb TuningChris KronzNo ratings yet

- PTO Engagement and Disengagement GuideDocument6 pagesPTO Engagement and Disengagement GuideRodolfo AlmeidaNo ratings yet

- WheelHorse WORKHORSE "700" TRACTOR Manual1-3745-3741Document12 pagesWheelHorse WORKHORSE "700" TRACTOR Manual1-3745-3741Kevins Small Engine and Tractor ServiceNo ratings yet

- Engine Break-In Procedure SummaryDocument3 pagesEngine Break-In Procedure SummarySimon CooperNo ratings yet

- How To Shift The Spicer PRO-SHIFT 18 Speed Transmission: Starting Vehicle From A StopDocument2 pagesHow To Shift The Spicer PRO-SHIFT 18 Speed Transmission: Starting Vehicle From A StopMA RIONo ratings yet

- Volvo 2002 Diesel Volvo 2002 DieselDocument7 pagesVolvo 2002 Diesel Volvo 2002 DieselМаксимNo ratings yet

- Operator'S Manual: (Helicopter Engine)Document2 pagesOperator'S Manual: (Helicopter Engine)seilfredNo ratings yet

- Chotia-460 NewManualDocument8 pagesChotia-460 NewManualErin LassleyNo ratings yet

- 8woodward GoverningDocument58 pages8woodward Governinglilya mohNo ratings yet

- XTNG GEN II CARB User's ManualDocument4 pagesXTNG GEN II CARB User's Manuali Randy100% (1)

- Evolution Engines ManualDocument6 pagesEvolution Engines Manualamalraj1005100% (1)

- 1.MANAGE THE OPERATION OF PROPULSION PLANT MACHINERY (Ok) PDFDocument133 pages1.MANAGE THE OPERATION OF PROPULSION PLANT MACHINERY (Ok) PDFjurusan teknika100% (1)

- Group 2 operational checks and troubleshootingDocument8 pagesGroup 2 operational checks and troubleshootingMarco OlivettoNo ratings yet

- Metro 3 Operating Tips PDFDocument18 pagesMetro 3 Operating Tips PDFFatih Iscan100% (1)

- A Guide To Small Engine Carburetor Service and TroubleshootingDocument30 pagesA Guide To Small Engine Carburetor Service and TroubleshootingThomasMortbergNo ratings yet

- Carburetor Idle Speed AdjustmentDocument2 pagesCarburetor Idle Speed AdjustmentPabloNo ratings yet

- Mikuni Tuningmanual - 021003Document20 pagesMikuni Tuningmanual - 021003Faqih GoetiaNo ratings yet

- KitchenAid Manual SEODocument30 pagesKitchenAid Manual SEOhartfordmove9328100% (1)

- Weber ManualDocument18 pagesWeber Manualjme.91No ratings yet

- Convertible 76 Own Man 1973-2Document22 pagesConvertible 76 Own Man 1973-2da008co100% (2)

- Mengelola Pengoperasian Peralatan MesinDocument96 pagesMengelola Pengoperasian Peralatan Mesinarfan rijalNo ratings yet

- KIA Carens II - Part 2Document99 pagesKIA Carens II - Part 2altaeozdwiNo ratings yet

- Operation of Engine: Section 01Document14 pagesOperation of Engine: Section 01Mahmut YILMAZNo ratings yet

- Running with cylinders out of operationDocument6 pagesRunning with cylinders out of operationLagon AinNo ratings yet

- Detector Service ManualDocument4 pagesDetector Service Manualkhanh khanhNo ratings yet

- 02 - Compression - InspectionDocument1 page02 - Compression - InspectionjordantNo ratings yet

- Important maintenance tips for out-of-season engine storageDocument6 pagesImportant maintenance tips for out-of-season engine storageCassandra HuttoNo ratings yet

- Riding Your Tvs Metro Plus: Applicable For Electric Start Model OnlyDocument5 pagesRiding Your Tvs Metro Plus: Applicable For Electric Start Model OnlyMahi Un NobiNo ratings yet

- TIM Fungsi 1 EditDocument41 pagesTIM Fungsi 1 EditWignar DheaNo ratings yet

- HSR Tuning Manual 050102Document16 pagesHSR Tuning Manual 050102tomektomek6347No ratings yet

- Adjustment and Tuning of A Chainsaw CarburetorDocument4 pagesAdjustment and Tuning of A Chainsaw CarburetorE8200100% (1)

- Table 1.: InstallationDocument12 pagesTable 1.: InstallationRicardo MonteroNo ratings yet

- Hphd40 Post Hole DiggerDocument20 pagesHphd40 Post Hole DiggerGlenn FarrellNo ratings yet

- Operators Manuel International Cub Cadet 72, 104, 105, 124, ZND 125 TractorsDocument44 pagesOperators Manuel International Cub Cadet 72, 104, 105, 124, ZND 125 Tractorsfundreamer1No ratings yet

- Watingen 6Document3 pagesWatingen 6WillNo ratings yet

- DZ 200 CdiDocument2 pagesDZ 200 CdipowerveeNo ratings yet

- Excessive Fuel Consumption: Downloaded From Manuals Search EngineDocument10 pagesExcessive Fuel Consumption: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- PR 3816Document60 pagesPR 3816Robert BNo ratings yet

- Bidang Keahlian Teknika (Att-Ii) Tingkat ManajemenDocument7 pagesBidang Keahlian Teknika (Att-Ii) Tingkat ManajemenGopi SivasamyNo ratings yet

- Trick Flow Camshaft Degreeing Kit: Instructions ForDocument4 pagesTrick Flow Camshaft Degreeing Kit: Instructions ForROYALNo ratings yet

- Power Man GeneratorDocument1 pagePower Man GeneratorDmxaudio DmxaudioNo ratings yet

- Turbine shaft hogging and turning gearDocument3 pagesTurbine shaft hogging and turning gearOleg ShkolnikNo ratings yet

- .46NX Evolution Engine: User GuideDocument7 pages.46NX Evolution Engine: User GuideJuan Camilo GarciaNo ratings yet

- Learn to Drive: Everything New Drivers Need to KnowFrom EverandLearn to Drive: Everything New Drivers Need to KnowRating: 4 out of 5 stars4/5 (1)

- Diesel Engine Care and Repair: A Captain's Quick GuideFrom EverandDiesel Engine Care and Repair: A Captain's Quick GuideRating: 5 out of 5 stars5/5 (1)

- Spring Manual19 1Document15 pagesSpring Manual19 1Edgar Alexander Grisales VallejoNo ratings yet

- Bosch Guide To Flow WrappingDocument30 pagesBosch Guide To Flow WrappingHanis Ainurokhmi100% (1)

- Dleg0085 ManualDocument24 pagesDleg0085 ManualEdgar Alexander Grisales VallejoNo ratings yet

- Flying With Flaps - Understanding Their Use. - Model Airplane NewsDocument6 pagesFlying With Flaps - Understanding Their Use. - Model Airplane NewsEdgar Alexander Grisales VallejoNo ratings yet

- Dleg0020 Manual v1 1Document24 pagesDleg0020 Manual v1 1Edgar Alexander Grisales VallejoNo ratings yet

- ADXL345Document40 pagesADXL345aashlinnNo ratings yet

- Haste LoyDocument16 pagesHaste LoybitanjungNo ratings yet

- AGWA Guide GlazingDocument96 pagesAGWA Guide GlazingMoren AlfonsoNo ratings yet

- BERGSTROM, Karl Jones. Playing For Togetherness (Tese)Document127 pagesBERGSTROM, Karl Jones. Playing For Togetherness (Tese)Goshai DaianNo ratings yet

- RCC Chimneys - CICIND Code PDFDocument23 pagesRCC Chimneys - CICIND Code PDFVasanth KumarNo ratings yet

- SRFP 2015 Web List PDFDocument1 pageSRFP 2015 Web List PDFabhishekNo ratings yet

- BG BG 202102080912862 User Manual - File (Long) BG BG-8Document1 pageBG BG 202102080912862 User Manual - File (Long) BG BG-8hofolo39No ratings yet

- Unit 3 Digital Documentation: Multiple Choice QuestionsDocument7 pagesUnit 3 Digital Documentation: Multiple Choice Questions07tp27652% (21)

- Pore and Formation PressureDocument4 pagesPore and Formation PressureramadhanipdNo ratings yet

- John Constantine Rouge Loner Primordial Orphan Paranormal DetectiveDocument4 pagesJohn Constantine Rouge Loner Primordial Orphan Paranormal DetectiveMirko PrćićNo ratings yet

- Engine Cpta Czca Czea Ea211 EngDocument360 pagesEngine Cpta Czca Czea Ea211 EngleuchiNo ratings yet

- Adobe Scan 25 Dec 202Document1 pageAdobe Scan 25 Dec 202Jimit ShahNo ratings yet

- Cause and Effect Diagram for Iron in ProductDocument2 pagesCause and Effect Diagram for Iron in ProductHungNo ratings yet

- General Appraiser Market Analysis and Highest & Best Use-Schedule PDFDocument7 pagesGeneral Appraiser Market Analysis and Highest & Best Use-Schedule PDFadonisghlNo ratings yet

- Simplified Coil DesignDocument6 pagesSimplified Coil DesignNestor Alberto EscalaNo ratings yet

- Lesson Plan Sir MarcosDocument7 pagesLesson Plan Sir MarcosJhon AgustinNo ratings yet

- Towards Innovative Community Building: DLSU Holds Henry Sy, Sr. Hall GroundbreakingDocument2 pagesTowards Innovative Community Building: DLSU Holds Henry Sy, Sr. Hall GroundbreakingCarl ChiangNo ratings yet

- ZFDC 20 1HDocument1 pageZFDC 20 1Hkentier21No ratings yet

- Python Quals PytestDocument4 pagesPython Quals PytestAnkit RathoreNo ratings yet

- ENG302 Part 2Document7 pagesENG302 Part 2Oğuzhan DalkılıçNo ratings yet

- PHENOL Coloremetric Tests CHEMetsDocument2 pagesPHENOL Coloremetric Tests CHEMetsmma1976No ratings yet

- Sims4 App InfoDocument5 pagesSims4 App InfooltisorNo ratings yet

- Water Supply PDFDocument18 pagesWater Supply PDFtechnicalvijayNo ratings yet

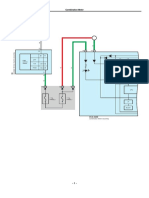

- Combination Meter: D1 (A), D2 (B)Document10 pagesCombination Meter: D1 (A), D2 (B)PeterNo ratings yet

- Eugene A. Nida - Theories of TranslationDocument15 pagesEugene A. Nida - Theories of TranslationYohanes Eko Portable100% (2)

- Tecnair Close Control Catalog 0213Document36 pagesTecnair Close Control Catalog 0213Uzman HassanNo ratings yet

- StuffIt Deluxe Users GuideDocument100 pagesStuffIt Deluxe Users Guidesergio vieiraNo ratings yet

- Costallocationvideolectureslides 000XADocument12 pagesCostallocationvideolectureslides 000XAWOw Wong100% (1)

- Sample Interview Questions – Promoting Diversity and InclusionDocument3 pagesSample Interview Questions – Promoting Diversity and InclusionLiah Piano-Beast UchihaNo ratings yet

- Module 5 Greek ArchDocument22 pagesModule 5 Greek ArchKyla A. EstoestaNo ratings yet

- A Phenomenological Research Design IllustratedDocument15 pagesA Phenomenological Research Design IllustratedMATEI100% (1)

- Catalan NumbersDocument17 pagesCatalan NumbersVishal GuptaNo ratings yet